1

Umthelela ekusikeni izinga lokushisa: ijubane lokusika, izinga lokudla, inani lokusika emuva.

Umthelela kumandla okusika: inani lokusika emuva, izinga lokudla, isivinini sokusika.

Umthelela wokuqina kwamathuluzi: isivinini sokusika, isilinganiso sokuphakelayo, inani lokusika emuva.

2

Lapho inani lokuzibandakanya emuva liphindwe kabili, amandla okusika aphindwe kabili;

Uma izinga lokudla liphindwe kabili, amandla okusika akhuphuka cishe ngo-70%;

Lapho ijubane lokusika liphindwe kabili, amandla okusika ayancipha kancane kancane;

Ngamanye amazwi, uma i-G99 isetshenziswa, isivinini sokusika sizokhula, kodwa amandla okusika ngeke ashintshe kakhulu.

3

Ngokusho kokukhishwa kwezinsimbi zensimbi, kungahlulelwa ukuthi amandla okusika kanye nokushisa okusika kungaphakathi kwebanga elijwayelekile.

Uma inani langempela elingu-X likalwa kanye nobubanzi Y bomdwebo bukhulu kuno-0.8, ithuluzi elijikayo eline-engeli yesibili yokuchezuka engu-52 degrees (okungukuthi, ithuluzi elivame ukusetshenziswa elijikayo eline-blade engu-35 degrees kanye ne-engeli yokuchezuka ehamba phambili 93 degrees) I-R ephuma emotweni ingase isule ummese lapho iqala khona.

5

Izinga lokushisa elimelelwa umbala we-iron filings: umhlophe ungaphansi kwama-degrees angu-200

Okuphuzi 220-240 degrees

Okuluhlaza okwesibhakabhaka okumnyama okungu-290 degrees

Okuluhlaza okwesibhakabhaka 320-350 degrees

Okunsomi okumnyama okukhulu kuno-500 degrees

Okubomvu kungaphezu kuka-800 degrees

6

I-FUNAC OI mtc ngokuvamile izenzakalela kumyalo we-G:

G69: Angiqiniseki

G21: Okokufaka kosayizi wemethrikhi

I-G25: Ukutholwa kokuguquguquka kwesivinini se-spindle kunqanyuliwe

I-G80: Ukukhansela umjikelezo wamathini

I-G54: uhlelo lokuxhumanisa oluzenzakalelayo

I-G18: Ukukhetha indiza ye-ZX

I-G96 (G97): isilawuli sesivinini somugqa njalo

I-G99: Okuphakelayo ngenguquko ngayinye

I-G40: Ukukhanselwa kwesinxephezelo sekhala lethuluzi (G41 G42)

I-G22: ukutholwa kokushaywa kwesitoreji VULIWE

I-G67: Ukukhanselwa kocingo lwemodi yohlelo lweMacro

G64: Angiqiniseki

I-G13.1: Ukukhanselwa kwemodi ye-polar coordinate interpolation

7

Intambo yangaphandle ngokuvamile i-1.3P, futhi intambo yangaphakathi ingu-1.08P.

8

Isivinini sochungechunge S1200/pitch*safety factor (ngokuvamile ngu-0.8).

9

Ifomula yesinxephezelo sekhala engu-R: ukusuka phansi kuye phezulu, i-chamfering: Z=R*(1-tan(a/2)) X=R(1-tan(a/2))*tan(a) ukusuka phezulu ukuya phezulu Yehla ku-chamfer bese ushintsha ukususa kube ukuhlanganisa.

10

Ngaso sonke isikhathi lapho okuphakelayo kukhuphuka ngo-0.05, ijubane liyancipha ngo-50-80 revolutions.Lokhu kungenxa yokuthi ukunciphisa ijubane kusho ukuthi ukugqoka kwethuluzi kuncipha, futhicnc ukusikaamandla akhuphuka kancane, ukuze enze ukwanda kokuphakelayo okwenza amandla okusika akhule kanye nezinga lokushisa likhuphuke.Umthelela.

11

Umthelela wokusika isivinini kanye namandla okusika ethuluzini kubaluleke kakhulu, futhi isizathu esiyinhloko sokuthi ithuluzi liwe ngenxa yamandla okusika ngokweqile.Ubuhlobo phakathi kwejubane lokusika namandla okusika: lapho isivinini sokusika sishesha, okuphakelayo kuhlala kungashintshiwe, futhi amandla okusika ayancipha kancane kancane.Okuphakeme kakhulu, lapho amandla okusika nokucindezeleka kwangaphakathi kukhulu kakhulu ukuthi ukufakwa kungathwala, kuzokhipha (Yebo, kunezizathu ezifana nokucindezeleka nokwehla kokuqina okubangelwa ukushintsha kwezinga lokushisa).

12

Niniukunemba imishiniI-CNC lathes, amaphuzu alandelayo kufanele anakwe ngokukhethekile:

(1) Kulathesi wamanje we-CNC wezomnotho ezweni lami, amamotho ajwayelekile ezigaba ezintathu asynchronous ngokuvamile asetshenziswa ukubona ukuguqulwa kwesivinini esingenasinyathelo ngokusebenzisa iziguquli zefrikhwensi.Uma kungekho ukwehla kwemishini, i-torque yokuphumayo ye-spindle ngokuvamile ayanele ngesivinini esiphansi.Uma umthwalo wokusika umkhulu kakhulu, kulula ukuthukuthela Izimoto, kodwa amanye amathuluzi omshini anezikhundla zamagiya ukuxazulula le nkinga kahle kakhulu.

(2) Ngokusemandleni, ithuluzi lingaqedela ukucutshungulwa kwengxenye eyodwa noma ishifu eyodwa yomsebenzi.Ekuqedeni izingxenye ezinkulu, ukunakwa okukhethekile kufanele kukhokhwe ukuze kugwenywe ukushintsha ithuluzi phakathi ukuze kuqinisekiswe ukuthi ithuluzi lingacutshungulwa ngesikhathi esisodwa.

(3) Niniukuphendukaintambo ene-CNC lathe, sebenzisa isivinini esiphezulu ngangokunokwenzeka ukuze uzuze ukukhiqizwa kwekhwalithi ephezulu nokusebenza kahle.

(4) Sebenzisa i-G96 ngangokunokwenzeka.

(5) Umqondo oyisisekelo we-high-speed machining ukwenza okuphakelayo kudlule isivinini sokushisa ukushisa, ukuze ukushisa okusika kukhishwe ngamafayili ensimbi ukuhlukanisa ukushisa okusika ku-workpiece, ukuze kuqinisekiswe ukuthi i-workpiece iyakwenza. ungashisi noma ushise kancane.Ngakho-ke, ukukhanda ngesivinini esikhulu kuyisinqumo esiphakeme kakhulu.Ijubane lokusika lifaniswa nezinga eliphezulu lokuphakela ngenkathi kukhethwa inani elincane lokuhlanganyela emuva.

(6) Naka isinxephezelo sekhala lethuluzi R.

13

Ithebula Lokugreda I-Workpiece Material Machinability Grading (Minor P79)

Izikhathi zokusika intambo ezivame ukusetshenziswa kanye nesilinganiso sokuzibandakanya emuva (i-P587 enkulu)

Amafomula wokubala wezibalo zejiyomethri ezivame ukusetshenziswa (i-P42 enkulu)

Ishadi Lokuguqulwa Amayintshi ukuya kumamilimitha (P27 enkulu)

14

Ukudlidliza kanye nokuphuka kwamathuluzi kuvame ukwenzeka ngesikhathi sokugwaza.Imbangela yakho konke lokhu ukuthi amandla okusika abe mkhulu futhi ukuqina kwethuluzi akwanele.Ubude besandiso sethuluzi bufushane, i-engeli yokukhulula iba yincane, futhi indawo yeblade inkulu, kuba ngcono ukuqina.Ngamandla amakhulu okusika, kodwa ububanzi obukhulu be-groove cutter, amandla okusika angakwazi ukumelana nawo azokwanda ngokufanele, kodwa amandla ayo okusika nawo azokhula.Ngokuphambene nalokho, i-groove cutter encane, amandla amancane engakwazi ukumelana nayo, kodwa amandla ayo okusika nawo mancane.

15

Izizathu zokudlidliza ngesikhathi se-slot:

(1) Ubude besandiso bethuluzi bude kakhulu, okuholela ekwehleni kokuqina.

(2) Izinga lokuphakelayo lihamba kancane kakhulu, okuzobangela amandla okusika iyunithi futhi kubangele ukudlidliza okukhulu.Ifomula ithi: P=F/back cut amount*f P iyunithi yokusika amandla F amandla okusika, futhi isivinini siyashesha kakhulu Izophinde idlidlize ummese.

(3) Ukuqina kwethuluzi lomshini akwanele, okusho ukuthi, ithuluzi lingathwala amandla okusika, kodwa ithuluzi lomshini alikwazi ukukuthwala.Ukulibeka ngembaba, ithuluzi lomshini alinyakazi.Ngokuvamile, imibhede emisha ayinalo lolu hlobo lwenkinga.Umbhede onalolu hlobo lwenkinga umdala noma umdala.Kuphakathi kokuthi uvame ukuhlangana nababulali bamathuluzi omshini.

16

Lapho ngishayela impahla, ngathola ukuthi usayizi wawulungile ekuqaleni, kodwa ngemva kwamahora ambalwa okusebenza, ngathola ukuthi usayizi wawushintshile futhi nosayizi wawungazinzile.Isizathu kungenzeka ukuthi amandla okusika ayengenamandla kakhulu ngoba imimese yonke yayimisha ekuqaleni.Inkulu, kodwa ngemva kwesikhathi esithile, ithuluzi liyaguga futhi amandla okusika abe mkhulu, okwenza ucezu lomsebenzi lugudluke ku-chuck, ngakho usayizi mdala futhi awuzinzile.

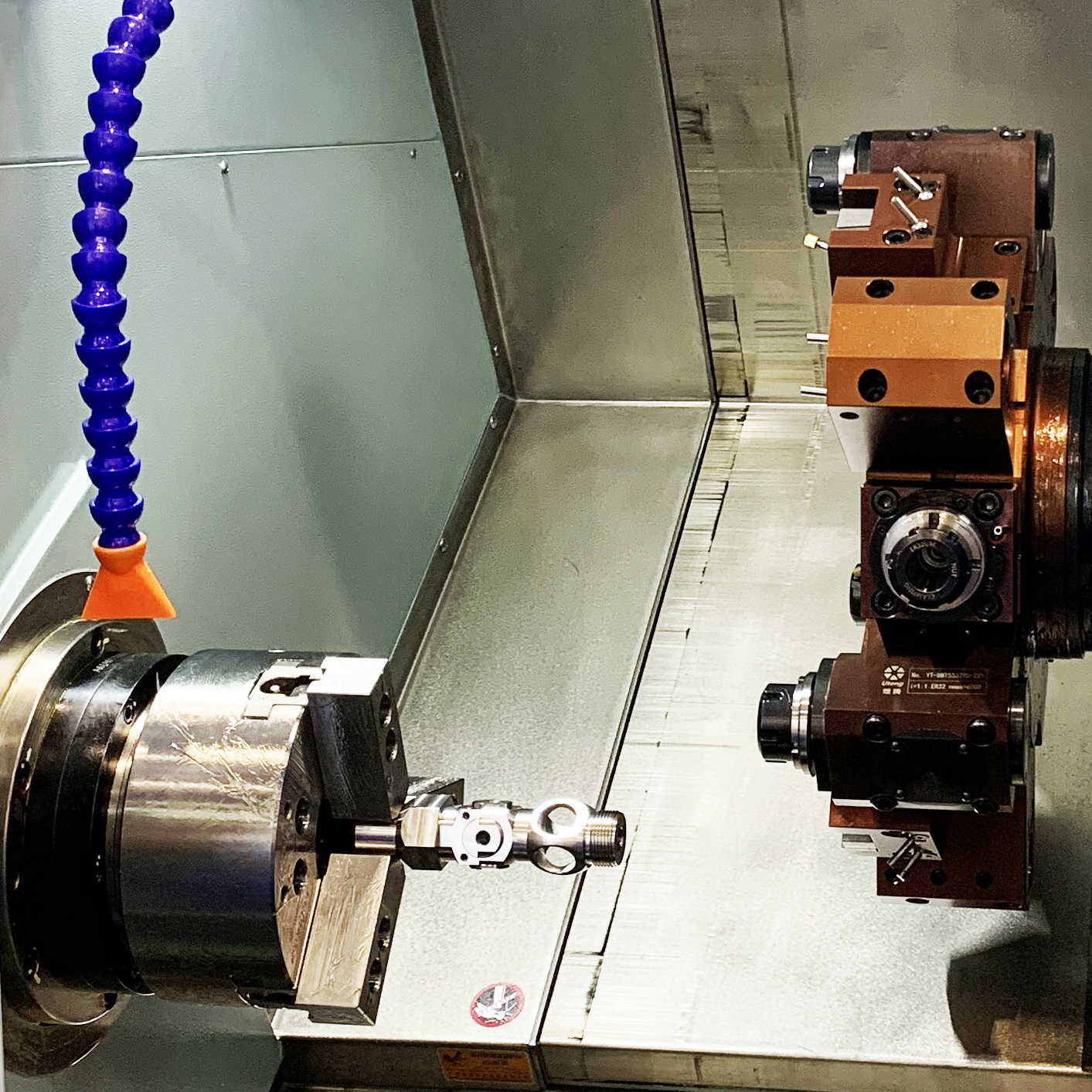

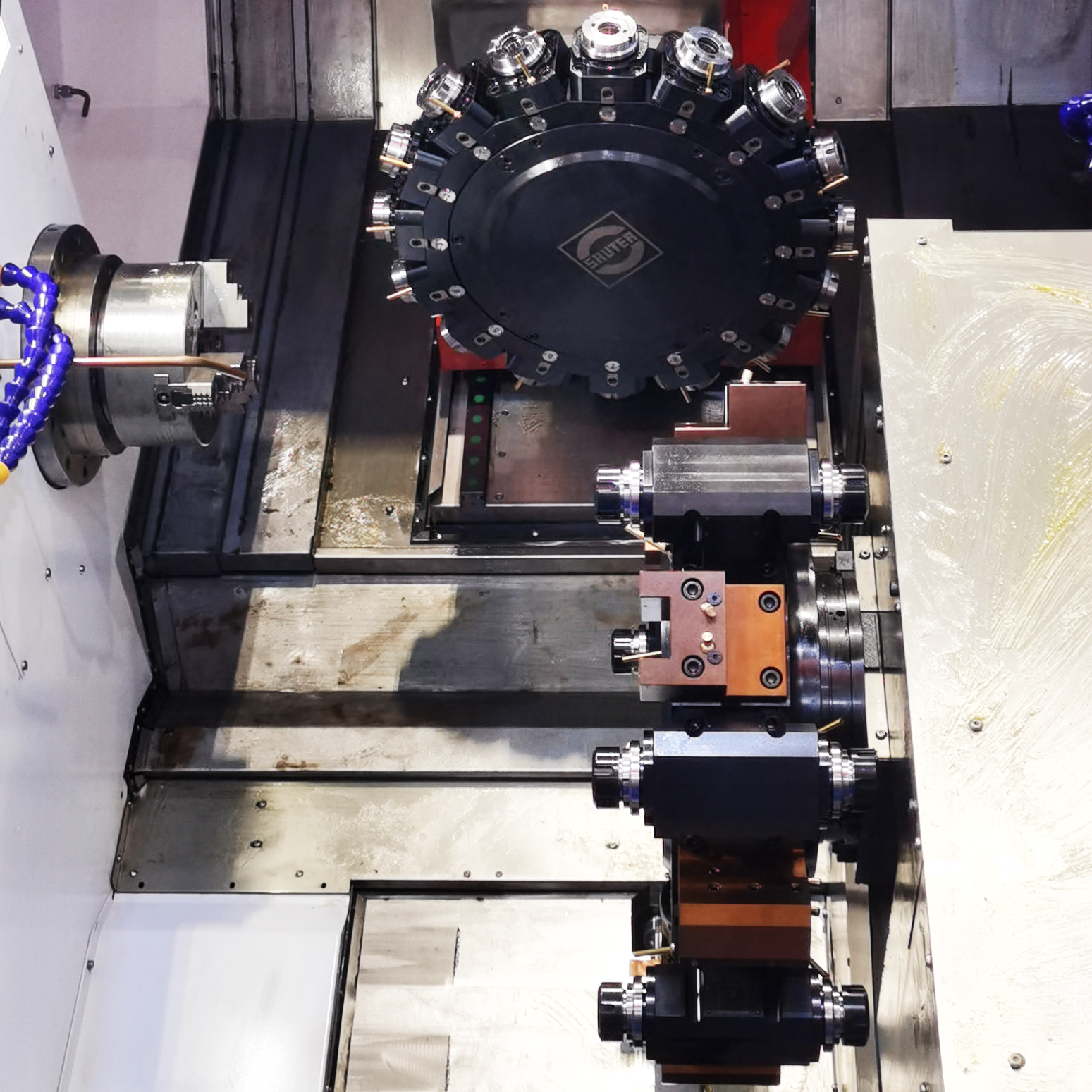

I-Anebon inemishini yokukhiqiza ethuthuke kakhulu, onjiniyela abanolwazi nabaqeqeshiwe nabasebenzi, amasistimu aziwayo okulawula ikhwalithi kanye neqembu elinobungane lokuthengisa elinobungcweti elisekela ngaphambi/ngemuva kokuthengisa le-China wholesale OEM Plastic ABS/PA/POM CNC Lathe CNC Milling 4 Axis/5 Axis CNC machining izingxenye, CNC turning izingxenye.Njengamanje, i-Anebon ibheke phambili ekusebenzisaneni okukhulu nakakhulu namakhasimende aphesheya ngokuya ngezinzuzo ezifanayo.Sicela uzizwele mahhala ukuze uxhumane nathi ukuze uthole imininingwane eyengeziwe.

2022 Ikhwalithi ephezulu yaseChina CNC kanye Nemishini, Nethimba labasebenzi abanolwazi nabanolwazi, imakethe ye-Anebon ihlanganisa iNingizimu Melika, i-USA, Mid East, kanye neNyakatho Afrika.Amakhasimende amaningi abe ngabangane be-Anebon ngemuva kokubambisana okuhle ne-Anebon.Uma unesidingo sanoma yimiphi imikhiqizo yethu, khumbula ukusithinta manje.I-Anebon izolangazelela ukuzwa kuwe maduzane.

Isikhathi sokuthumela: Feb-09-2023