Cnc Machined Aluminum

China cnc machining milling part factories

Custom made factory High precision hot forging and cnc machining part;

High Precision CNC Machining Part;

Gas-type Fitting Rigid Standard CNC Machining Part

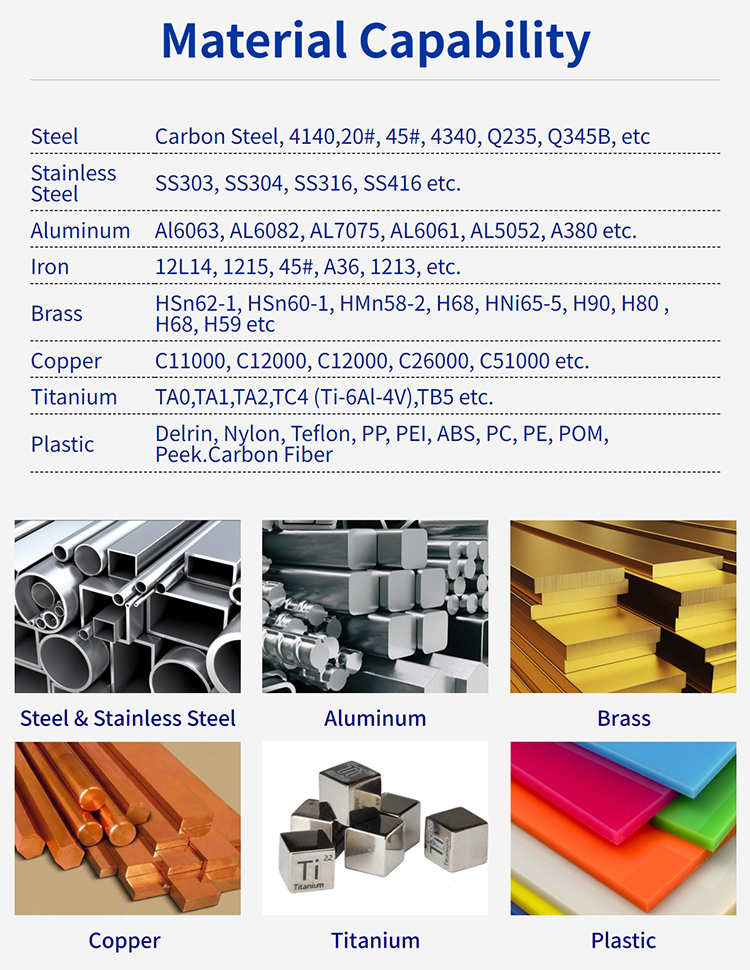

| Material | Aluminum; Brass; Bronze; Copper; Stainless Steel; Plastic; Acrylic; |

| Precision | 0.01-0.02mm |

| Packing | Cartons or customized |

| Color | Painting/anodizing/ Polish/silk screen/chrome plate/rubber/coating |

| Transportation | International express by DHL, UPS, etc & FOB Shanghai |

| Delivery | Within 15-25 workdays after deposit or payment received |

| Payment terms | L/C, Paypal, Western Union, or 50% pre T/T 50% balance before shipment |

| Software | Solid work, Pro/E, AutoCAD CAM, Catia, etc |

Has been a high quality CNC part supplier for many years Dongguan Anebon Metal Products Co.,Ltd. is a comprehensive enterprise integrating development, design, production, sales and service, mainly engaged in machinery parts manufacturing business. The company is registered in the Dongguan Administration for Industry and Commerce and has the right to operate import and export.

Our Advantage

(1) The company provides after sales service and technical assistance as per the customers requirement and needs.

(2) We have the ability to use English, Japanese, Chinese, and other languages to communicate with customers.

(3) Product.and a stable supply at reasonable prices.

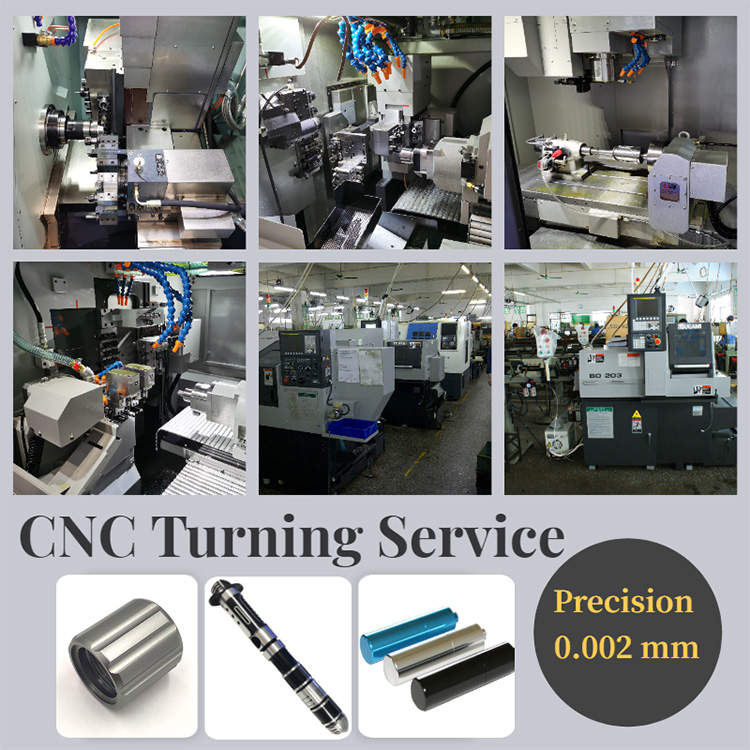

(4) We are equipped with more than 60 sets of machines and equipment, such as: CNC lathes, CNC milling machines,Jig grinders, punching machines, drilling machines, EDM machines, jig grinders, ID/OD grinders,,surface grinders, and various other grinders, saws and inspection equipment etc.

(5) Reasonable price and higher quality because we have rich experiece production workers and professional engineers and strong.material purchasing team.

Contact Us Now!

If you have any question or requirements, please don't hesitate to email us, thanks.

Please contact us for more detailed informations. Welcome to visit our factory directly.