CNC Machined Component cnc machining part

10 years more experienced engineers team and well trained sales team to support every project

Long term cooperation is our target, quality and price are our basic to achieve it.

Provide different shipping way quotes to customer, accordingly customer accepted delivery time to find cheapest shipping way.

Why choose us? Because you don't need concern too much, we will think for you, after you place order, you only need pay, we will do all things for you.

Capacity:

| CNC Turning | φ0.5 - φ300 * 750 mm | +/-0.002 mm |

| CNC Milling | 510 * 1020 * 500 mm(max) | +/-0.002 mm |

| CNC Stamping | 1000 * 1000 mm(max) | +/-0.05 mm |

| Drawing Format | IGS,STP,X_T ,DXF,DWG , Pro/E, PDF | |

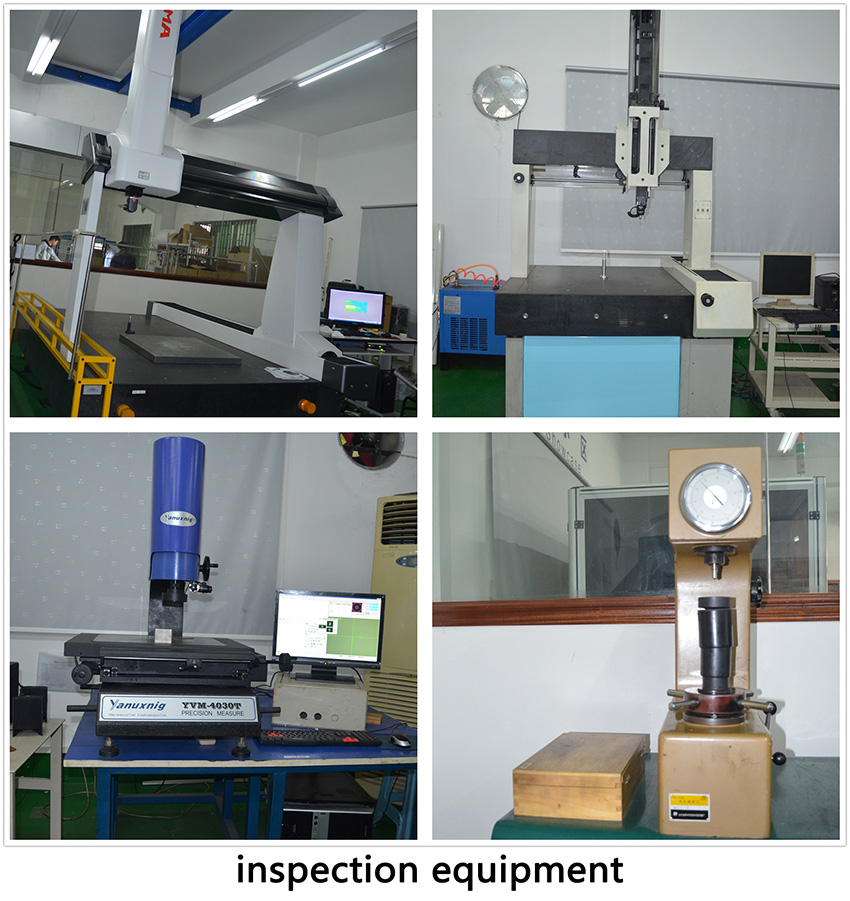

| Test Equipment | measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. | |

Material Available:

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

| Copper | C11000,C12000,C12000 C36000 etc. |

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

| Iron | A36, 45#, 1213, 12L14, 1215 etc. |

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, Teflon, PP,PEI, Peek etc. |

Finishing:

| Zinc plating, Chrome plating, Nickel plating, Tin plating, Polishing, Anodizing, Power-coating, Oxide black, Sandblast Anodizing, Electroless nickel, Fe/Zn8/C PER ISO 2081, etc. |

Write your message here and send it to us