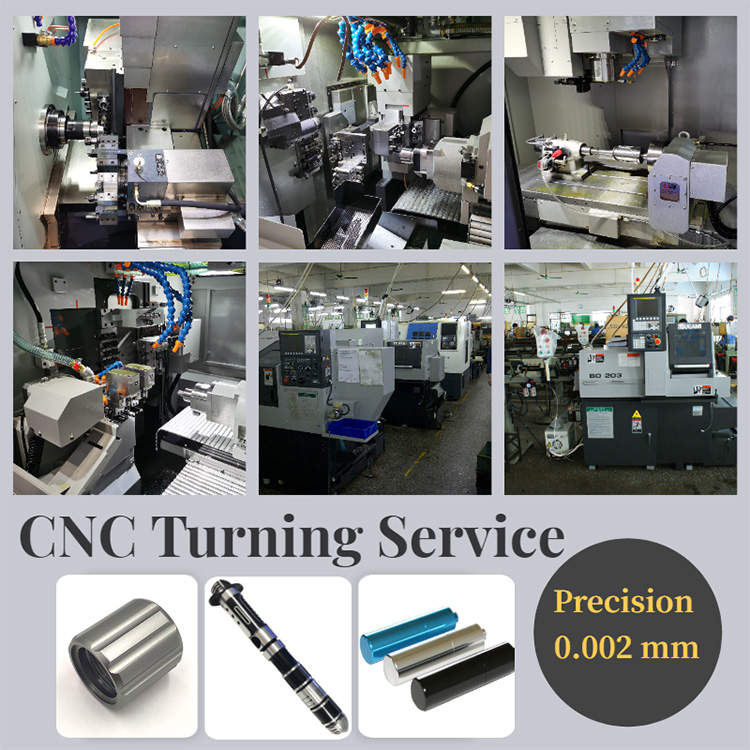

Cnc Turned Components

The traditional machining is done by hand-operating ordinary machine tools. When machining, the mechanical tool is used to cut the metal by hand, and the tool is used to measure the accuracy of the product by means of a caliper. Modern industry has already been operating with computer-controlled digital machine tools. CNC machine tools can automatically process any product and component directly according to the program programmed by the technician. This is what we call CNC machining. CNC machining is widely used in any field of machining, and it is the development trend of mold processing and an important and necessary technical means.

Tag:cnc lathe process/ cnc lathe services/ cnc precision turning/ cnc turned components/ cnc turning/ turn services/ turned partslathe services