DIY CNC Milling Aluminum

We will do our utmost to work hard to accelerate our position in the world's leading and high-tech companies, and accelerate the rapid delivery of customized 3/4/5 Aixs Cnc processing machinery spare parts. Cnc milling anodized aluminum parts rapid prototyping.

Auto parts processing steps:

1. CNC computer Milling, through the CNC processing equipment according to the path set by the program, on the basis of the raw materials of the product, to obtain the prototype of the part.

2. It is hand-processed, after the prototype of the part comes out, the appearance of the sample will have some burrs and extra parts of the corners, the staff should use sandpaper to smooth, so that the appearance becomes smooth and refined.

3. Laser engraving, that is using laser technology to remove the paint of the sample's appearance, so that a part of the sample is transparent.

4. Oxidation, that is, anodizing, It is the function of electrolysis. Because of the poor corrosion resistance of the oxidation formed after the treatment and the low cost of the website, it is rarely used in the process.

5. Drawing, It is to pull out a strip of fine marks on the parts' appearance, such a treatment will make the sample feel better.

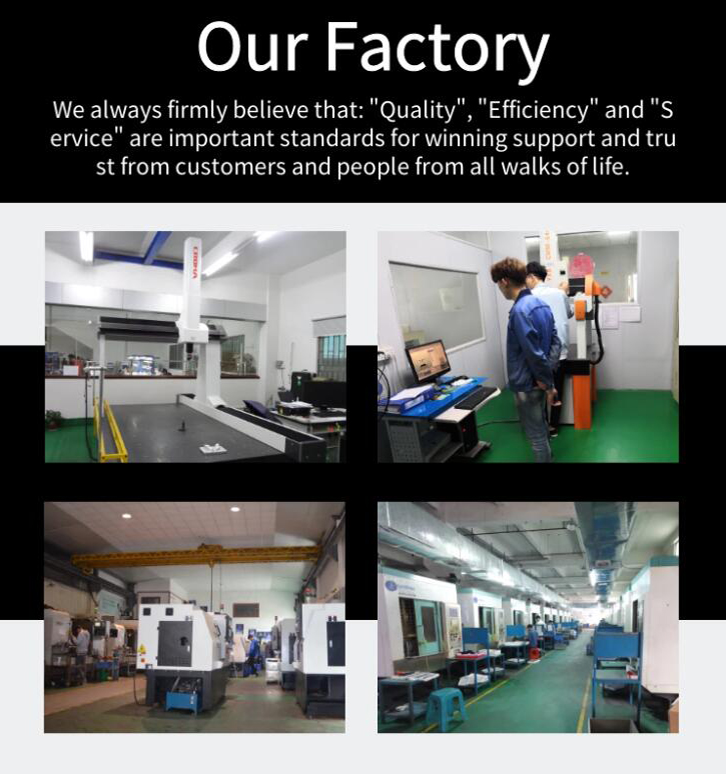

Anebon has a wide range of imported CNC Milling machines from Vertical Mills to Hi-Speed Fanuc Robodrill machines and 5-Axis Machining Centers. Anebon utilize the latest in CAD/CAM technology. Our Master CAM Software enables us to design and simulate 2D/3D models & components.