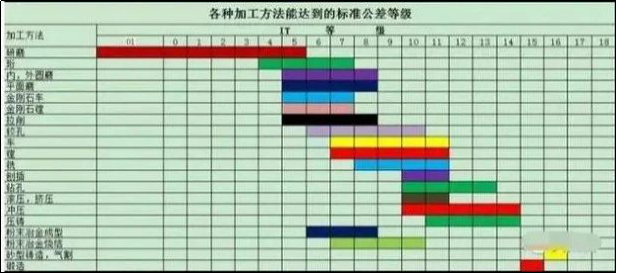

Juyawa, niƙa, shiryawa, niƙa, hakowa, gundura, mafi girman daidaiton waɗannan kayan aikin injin da matakan haƙuri waɗanda hanyoyin sarrafawa daban-daban zasu iya cimma duk suna nan.

Juyawa

Tsarin yankan wanda kayan aikin ke juyawa da kayan aikin juyawa yana motsawa a cikin madaidaiciyar layi ko lankwasa a cikin jirgin. Ana yin jujjuya gabaɗaya akan lathe, wanda ake amfani da shi don aiwatar da saman cylindrical na ciki da na waje, fuskokin ƙarewa, filaye masu tsini, kafa saman da zaren kayan aiki.

Daidaiton juyowa gabaɗaya IT8-IT7 ne, kuma ƙarancin ƙasa shine 1.6 ~ 0.8 μm.

1) Juyawa mai jujjuyawar za ta ɗauki babban zurfin yankan da babban ƙimar abinci don haɓaka haɓakar juyi ba tare da rage saurin yanke ba, amma daidaiton mashin ɗin zai iya isa IT11 kawai kuma ƙarancin ƙasa shine R α 20 ~ 10 μ m.

2) Babban saurin gudu da ƙananan ƙimar abinci da zurfin yankan za a karbe su gwargwadon yuwuwar juyi juyi da ƙare juyi. Daidaitaccen mashin ɗin zai iya kaiwa IT10 ~ IT7, kuma ƙarancin ƙasa shine R 10 ~ 0.16 μm.

3) Babban gudundaidaitaccen jujjuyawar sassan ƙarfe mara ƙarfetare da kayan aikin jujjuya lu'u-lu'u da aka goge a kan madaidaicin lathe na iya sa daidaiton mashin ɗin ya kai IT7 ~ IT5, kuma ƙarancin saman shine R α 0.04 ~ 0.01 μ m. Ana kiran irin wannan juyi "juyawan madubi".

Milling

Milling yana nufin amfani da kayan aikin gefuna da yawa masu juyawa don yanke kayan aiki, wanda shine ingantacciyar hanyar sarrafawa. Ya dace da machining jirgin sama, tsagi, daban-daban kafa saman (kamar spline, gear da zaren) da kuma musamman surface na mutu. Dangane da wannan ko gaba da shugabanci na babban motsi gudun da workpiece ciyar shugabanci a lokacin milling, shi za a iya raba gaba milling da kuma baya milling.

Daidaiton machining na niƙa na iya kaiwa ga IT8 ~ IT7 gabaɗaya, kuma ƙarancin ƙasa shine 6.3 ~ 1.6 μm.

1) Daidaitaccen machining yayin milling shine IT11 ~ IT13, kuma ƙarancin ƙasa shine 5 ~ 20 μm.

2) Machining daidaito IT8 ~ IT11 da surface roughness 2.5 ~ 10 a cikin rabin daidaici milling μ m.

3) Daidaitaccen machining yayin madaidaicin niƙa shine IT16 ~ IT8, kuma ƙarancin ƙasa shine 0.63 ~ 5 μm.

Tsara

Planing hanya ce mai yankewa wacce ke amfani da mai tsarawa don yin motsi mai jujjuyawar dangi a kwance akan kayan aikin, wanda galibi ana amfani da shi don sarrafa sassan sassa.

Daidaiton machining na planing na iya kaiwa ga IT9 ~ IT7 gabaɗaya, kuma ƙarancin ƙasa shine Ra6.3 ~ 1.6 μm.

1) Roughing machining daidaito iya isa IT12 ~ IT11, da kuma surface roughness ne 25 ~ 12.5 μm.

2) A Semi kammala machining daidaito iya isa IT10 ~ IT9, da kuma surface roughness ne 6.2 ~ 3.2 μm.

3) Madaidaicin ƙaddamarwa na gamawa zai iya isa IT8 ~ IT7, kuma ƙarancin ƙasa shine 3.2 ~ 1.6 μm.

Nika

Nika yana nufin hanyar sarrafawa na cire wuce haddi kayan aiki daga kayan aiki tare da kayan aikin abrasive da abrasive. Nasa ne na gamawa kuma ana amfani da shi sosai a cikin masana'antar kera injina.

Yawancin lokaci ana amfani da niƙa don kammalawa da ƙarewa, tare da daidaiton IT8 ~ IT5 ko ma mafi girma, kuma ƙarancin ƙasa gabaɗaya 1.25 ~ 0.16 μm.

1) Matsakaicin madaidaicin niƙa shine 0.16 ~ 0.04 μm.

2) matsananci daidaici nika surface roughness ne 0.04-0.01 μm.

3) Ƙaƙƙarfan ƙarancin madubi na niƙa zai iya kaiwa 0.01 μ M a ƙasa.

Yin hakowa

Hakowa hanya ce ta asali ta sarrafa rami. Sau da yawa ana yin hakowa akan injunan hakowa da lathes, ko kan injunan ban gajiya ko injin niƙa.

Machining daidaito na hakowa ne in mun gwada da low, kullum kai IT10, da kuma surface roughness ne kullum 12.5 ~ 6.3 μm. Bayan hakowa, ana amfani da reaming da reaming sau da yawa don kammalawa da ƙarewa.

M

Boring wani nau'i ne na yanke diamita na ciki wanda ke amfani da kayan aiki don faɗaɗa rami ko sauran madauwari. Kewayon aikace-aikacen sa gabaɗaya daga injina mai ƙayatarwa zuwa ƙarewa. Kayan aikin da aka yi amfani da shi yawanci kayan aiki ne mai ban sha'awa na gefe guda (wanda ake kira mashaya mai ban sha'awa).

1) A m daidaito na karfe kayan iya kullum isa IT9 ~ IT7, da kuma surface roughness ne 2.5 ~ 0.16 μm.

2) Machining daidaito na madaidaicin m iya isa IT7 ~ IT6, da kuma surface roughness ne 0.63 ~ 0.08 μ m.

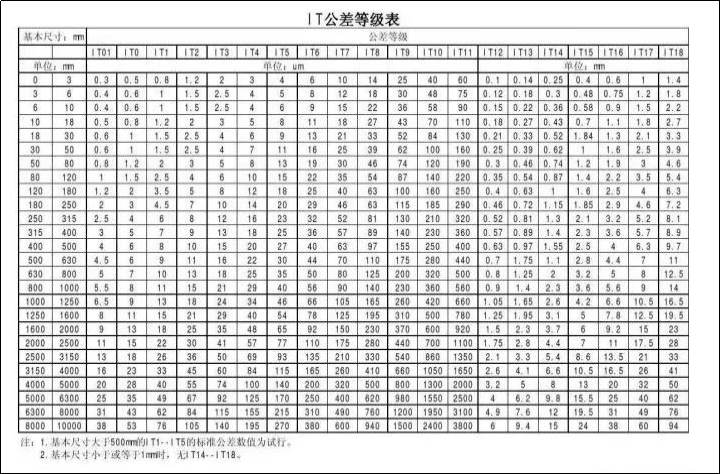

Lura:Machining mai ingancigalibi ana amfani da shi don nuna kyawun samfuran, kuma kalma ce da ake amfani da ita don kimanta ma'auni na geometric na saman injina. Ma'auni don auna daidaiton mashin ɗin shine ƙimar haƙuri. Akwai ma'auni 20 daga IT01, IT0, IT1, IT2, IT3 zuwa IT18, daga cikinsu IT01 yana wakiltar mafi girman daidaiton mashin ɗin ɓangaren, IT18 yana wakiltar mafi ƙarancin daidaiton injin ɗin ɓangaren. Injin hakar ma'adinai na IT7 na gabaɗaya ne, kuma injinan noma na gabaɗaya na IT8 ne. Dangane da ayyuka daban-daban na sassan samfura, daidaitattun mashin ɗin da ake buƙata don cimma ya bambanta, kuma nau'in sarrafawa da tsarin da aka zaɓa suma sun bambanta.

Lokacin aikawa: Nuwamba-07-2022