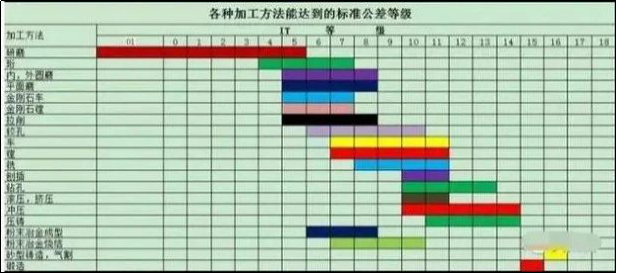

Kutendeuka, kugaya, kuronga, kukuya, kuchera, kufinha, iko kurongeka kwepamusoro kweaya maturusi emuchina uye mazinga ekushivirira ayo akasiyana nzira dzekugadzirisa anogona kuwana zvese zviri pano.

Kutendeuka

Iyo nzira yekucheka iyo iyo workpiece inotenderera uye chishandiso chekushandura chinofamba mumutsara wakatwasuka kana curve mundege.Kutendeuka kunowanzoitwa pane lathe, iyo inoshandiswa kugadzirisa mukati uye kunze cylindrical nzvimbo, magumo zviso, conical nzvimbo, kuumba nzvimbo uye shinda dzebasa rekushanda.

Iko kutendeuka chaiko kunowanzo kuve IT8-IT7, uye kushata kwepamusoro ndeye 1.6 ~ 0.8 μ m.

1) Iko kutendeuka kwakashata kunotora kudzika kukuru kwekucheka uye chiyero chikuru chekudya kuvandudza kushanda kwekushandura pasina kuderedza kukurumidza kucheka, asi machining akarurama anogona kungosvika IT11 uye kushata kwepamusoro iR α 20 ~ 10 μ m.

2) Kumhanya kwepamusoro uye diki rekudya uye kudzika kwekucheka kunogamuchirwa kusvika pazvinogoneka kune semi kupedzisa kutendeuka uye kupedzisa kutendeuka.Kurongeka kwekugadzira kunogona kusvika IT10~IT7, uye kushata kwepamusoro kuri R α 10 ~ 0.16 μ m.

3) High speedkunyatsotendeuka kwenhengo dzesimbi dzisina ferrousnedhaimondi rinotenderedza chishandiso chakakwenenzverwa pakakwirira-chaiyo lathe inogona kuita kuti machining anyatsosvika IT7~IT5, uye kushata kwepamusoro iR α 0.04 ~ 0.01 μ m.Kutendeuka kwemhando iyi kunonzi "mirror turning".

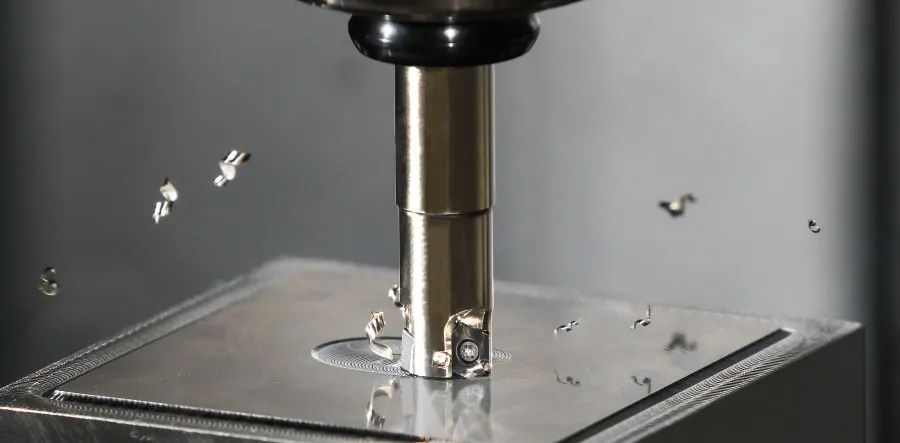

Kugaya

Kugaya kunoreva kushandiswa kwekutenderedza akawanda edge maturusi ekucheka maworkpiece, inova inonyatso shanda nzira yekugadzirisa.Inokodzera machining ndege, groove, akasiyana ekugadzira nzvimbo (senge spline, giya uye shinda) uye yakakosha nzvimbo yekufa.Zvinoenderana neyakafanana kana yakatarisana negwara rekumhanya kukuru uye workpiece feed direction panguva yekugaya, inogona kukamurwa kuita milling yekumberi uye reverse milling.

Kurongeka kwekugadzira kwekugaya kunogona kusvika IT8~IT7, uye kushata kwepamusoro i6.3 ~ 1.6 μ m.

1) Kurongeka kwekugadzira panguva yekugaya kwakashata ndeye IT11 ~ IT13, uye kushata kwepamusoro ndeye 5 ~ 20 μ m.

2) Machining kunyatsoita IT8~IT11 uye kushata kwepamusoro 2.5 ~ 10 mune semi precision milling μ m.

3) Kurongeka kwekugadzira panguva yekunyatsogaya ndeye IT16~IT8, uye kushata kwepamusoro ndeye 0.63 ~ 5 μ m.

Kuronga

Kuronga inzira yekucheka inoshandisa planer kugadzira yakatwasuka mutsara mutsara unodzosera mafambiro pane workpiece, iyo inonyanya kushandiswa pakugadzirisa contour yezvikamu.

Iko kurongeka kwekugadzira kwekugadzira kunogona kusvika IT9 ~ IT7, uye kushata kwepamusoro kuri Ra6.3 ~ 1.6 μ m.

1) Kurongeka kwemachina kurongeka kunogona kusvika IT12 ~ IT11, uye kushata kwepamusoro i25 ~ 12.5 μ m.

2) Iyo semi yekupedzisa machining kurongeka inogona kusvika IT10 ~ IT9, uye kushata kwepamusoro ndeye 6.2 ~ 3.2 μ m.

3) Iyo chaiyo yekupedzisa kuronga inogona kusvika IT8 ~ IT7, uye kushata kwepamusoro ndeye 3.2 ~ 1.6 μ m.

Kukuya

Kukuya kunoreva nzira yekugadzirisa yekubvisa zvinhu zvakawandisa kubva kune workpiece ine abrasive uye abrasive maturusi.Iyo ndeyekupedzisa uye inoshandiswa zvakanyanya muindasitiri yekugadzira michina.

Kukuya kunowanzo shandiswa semi kupedzisa nekupedzisa, nekurongeka kweIT8~IT5 kana kutokwira, uye kushata kwepamusoro kunowanzo 1.25 ~ 0.16 μ m.

1) Hushasha hwepamusoro hwekugaya chaiko ndeye 0.16 ~ 0.04 μ m.

2) Ultra precision kukuya roughness ndeye 0.04-0.01 μ m.

3) Kushata kwepamusoro kwegirazi kugaya kunogona kusvika 0.01 μ M pazasi.

Kuchera

Kuchera inzira yakakosha yekugadziriswa kwegomba.Kuchera kunowanzoitwa pamichina yekuchera uye lathes, kana pamichina inofinha kana muchina wekugaya.

Kunyatsoita machining ekuchera kwakadzikira, kazhinji kunosvika IT10, uye kushata kwepamusoro kunowanzo 12.5 ~ 6.3 μ m.Mushure mekuchera, kudzoreredza uye kugadzirisa zvakare kunowanzo shandiswa semi kupedzisa uye kupedzisa.

Boring

Boring imhando yemukati dhayamita yekucheka maitiro anoshandisa chishandiso kukudza gomba kana imwe denderedzwa contour.Rudzi rwekushandisa rwayo runowanzo kubva pahafu yakaoma machining kusvika pakupedza.Chishandiso chinoshandiswa chinowanzova chinhu chimwe chete chinofinha (chinonzi boring bar).

1) Iko kufinha kwechokwadi kwezvinhu zvesimbi zvinogona kusvika IT9 ~ IT7, uye kushata kwepamusoro ndeye 2.5 ~ 0.16 μ m.

2) Kurongeka kwekugadzira kweiyo chaiyo kufinha kunogona kusvika IT7 ~ IT6, uye kushata kwepamusoro kuri 0.63 ~ 0.08 μ m.

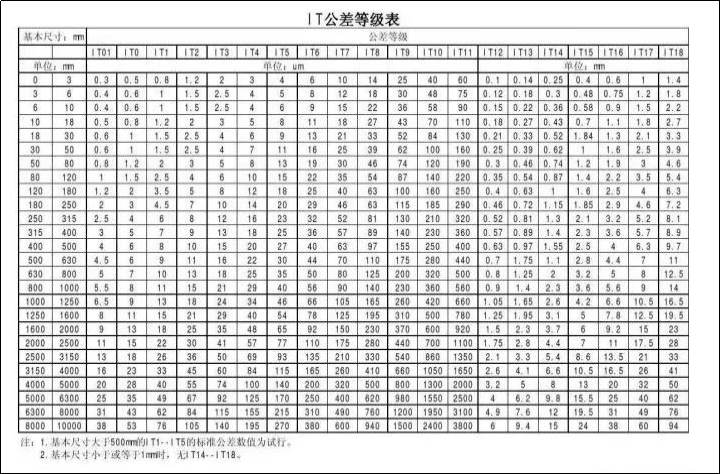

Cherechedza:High precision Machiningrinonyanya kushandiswa kuratidza kunaka kwezvigadzirwa, uye ishoko rinoshandiswa kuongorora geometric paramita yenzvimbo dzakagadzirwa nemichina.Chiyero chekuyera machining kurongeka ndeyekushivirira giredhi.Kune makumi maviri zviyero kubva kuIT01, IT0, IT1, IT2, IT3 kusvika IT18, pakati payo IT01 inomiririra iyo yepamusoro machining kurongeka kwechikamu, IT18 inomiririra yakaderera machining kurongeka kwechikamu.Michina yekuchera migodhi ndeye IT7, uye michina yekurima ndeye IT8.Zvinoenderana nemabasa akasiyana ezvikamu zvechigadzirwa, iyo machining chaiyo inodiwa kuti iwanikwe yakasiyana, uye fomu rekugadzirisa uye maitiro akasarudzwa zvakare akasiyana.

Nguva yekutumira: Nov-07-2022