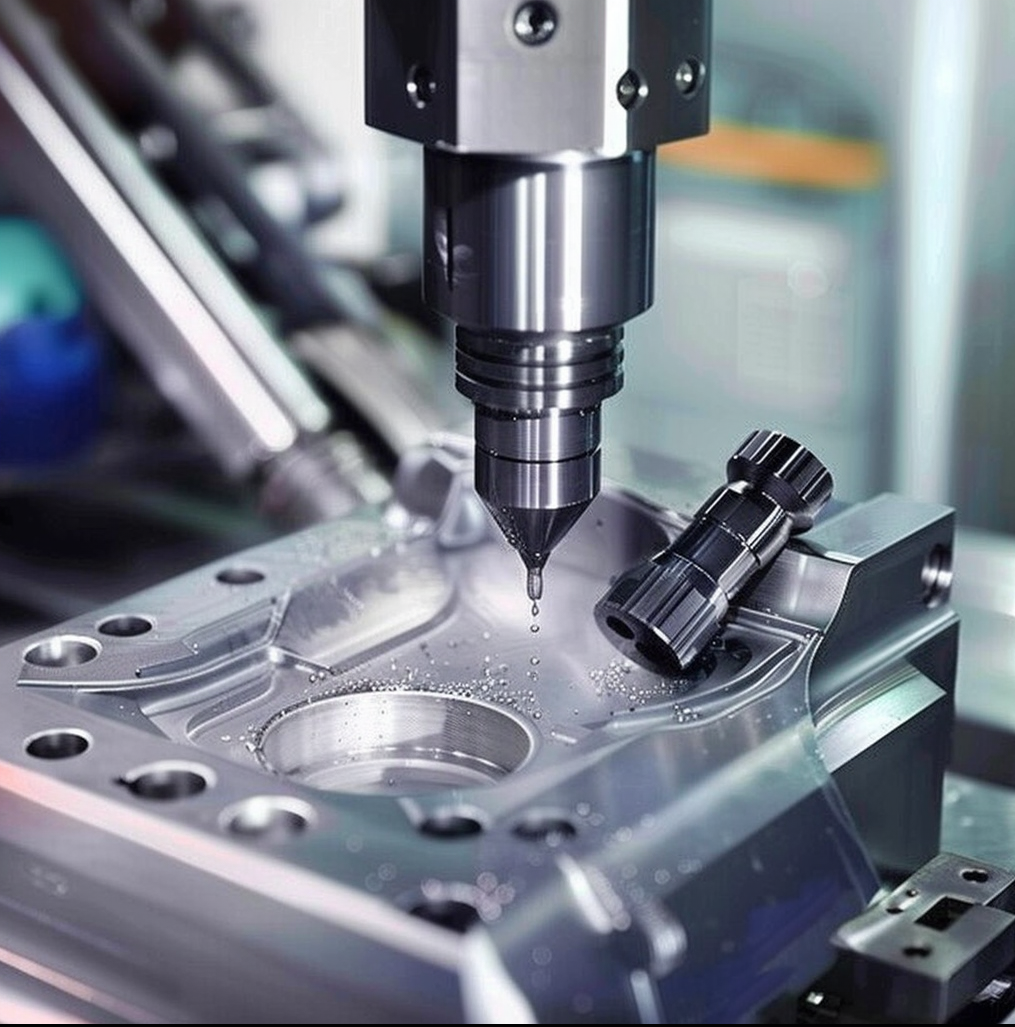

Kulondola kwa kukonza ndi mlingo womwe kukula kwenikweni, mawonekedwe, ndi malo a magawo atatu a geometric a gawo lokonzedwa amafanana ndi magawo abwino a geometric omwe amafunidwa ndi zojambulazo.Magawo abwino a geometric amatanthawuza kukula kwa gawoli, mawonekedwe amtundu wa geometry ngati mabwalo, masilindala, ndege, ma cones, mizere yowongoka, ndi zina zotero, ndi malo ogwirizana pakati pa malo monga kufanana, verticality, coaxiality, symmetry, ndi zina zotero.Kusiyana pakati pa magawo enieni a geometric a gawolo ndi magawo abwino a geometric amadziwika ngati cholakwika cha makina.

1. Lingaliro la kukonza kulondola

Kulondola kwa makina ndikofunika kwambiri popanga zopangirats.Kulondola kwa Machining ndi zolakwika zamakina ndi mawu awiri omwe amagwiritsidwa ntchito poyesa magawo a geometric pamtunda wopangidwa ndi makina.The kulolerana kalasi ntchito kuyeza Machining kulondola.Kulondola kumakhala kokwera pamene mtengo wa giredi uli wocheperako.Kulakwitsa kwa Machining kumawonetsedwa mu manambala.Cholakwikacho chimakhala chofunikira kwambiri ngati chiwerengero cha manambala ndi chachikulu.Kulondola kwapamwamba kumatanthawuza zolakwika zochepa zokonza, ndipo mosiyana, kutsika kumatanthauza zolakwika zambiri pokonza.

Pali magawo 20 olekerera kuyambira IT01, IT0, IT1, IT2, IT3 mpaka IT18.Pakati pawo, IT01 imayimira kulondola kwapamwamba kwambiri kwa gawolo, IT18 imayimira kulondola kwa makina otsika kwambiri, ndipo nthawi zambiri, IT7 ndi IT8 ali ndi makina olondola apakati.Mlingo.

"Zigawo zenizeni zomwe zimapezedwa ndi njira iliyonse yopangira zizikhala zolondola.Komabe, malinga ngati cholakwika chokonzekera chili mkati mwazololera zomwe zafotokozedwa ndi gawo lojambula, kulondola kwadongosolo kumaonedwa kuti ndikotsimikizika.Izi zikutanthauza kuti kulondola kwa ntchitoyo kumadalira ntchito ya gawo lomwe likupangidwa komanso zofunikira zake monga momwe zafotokozedwera pachithunzichi.

Ubwino wa makinawo umadalira pazifukwa ziwiri zazikulu: momwe makina amagwirira ntchito komanso momwe makina amagwirira ntchito.Kukonzekera kwa magawo kumatsimikiziridwa ndi mbali ziwiri: kulondola kwa processing ndi khalidwe lapamwamba.

Kuwongolera kulondola, kumbali imodzi, kumatanthawuza momwe magawo enieni a geometric (kukula, mawonekedwe, ndi malo) a gawolo pambuyo pokonza amafanana ndi magawo abwino a geometric.Kusiyana pakati pa magawo enieni ndi abwino a geometric kumatchedwa Machining error.Kukula kwa cholakwika cha makina kumawonetsa kuchuluka kwa makina olondola.Kulakwitsa kwakukulu kumatanthawuza kutsika kolondola kwa kukonza, pamene zolakwika zazing'ono zimasonyeza kulondola kwapamwamba.

2. Zokhudzana ndi kulondola kwa makina

(1) Kulondola kwa dimensional

Zimatanthawuza ku mlingo womwe kukula kwenikweni kwa gawo lokonzedwa likufanana ndi pakati pa malo olekerera a gawolo.

(2) Kulondola kwa mawonekedwe

Zimatanthawuza momwe mawonekedwe enieni a geometric a gawo lopangidwa ndi makina amafanana ndi mawonekedwe abwino a geometric.

(3) Kulondola kwa malo

Zimatanthawuza kusiyana kwenikweni kwa malo olondola pakati pa malo oyenerera a zomwe zakonzedwamwatsatanetsatane makina makina.

(4) Kugwirizana

Popanga magawo a makina ndikuwonetsetsa kulondola kwa makina, kuyang'ana pakuwongolera zolakwika za mawonekedwe mkati mwa kulolerana kwamalo ndikofunikira.Kuonjezera apo, ndikofunika kuonetsetsa kuti cholakwika cha malo ndi chaching'ono kusiyana ndi kulolerana kwa dimensional.Magawo olondola kapena malo ofunikira amafunikira mawonekedwe apamwamba kuposa kulondola kwamalo ndi malo apamwamba kuposa kulondola kwa dimensional.Kutsatira malangizowa kumatsimikizira kuti mbali zamakina zidapangidwa ndikupangidwa mwaluso kwambiri.

3. Njira Yosinthira:

1. Sinthani ndondomeko ya ndondomeko kuti muwonetsetse kuti ntchito yabwino.

2. Chepetsani zolakwika za zida zamakina kuti muwongolere zolondola.

3. Chepetsani zolakwika zopatsirana ndi unyolo kuti muwonjezere mphamvu zamakina.

4. Chepetsani kuvala kwa zida kuti mukhalebe olondola komanso abwino.

5. Kuchepetsa kupsinjika kwa dongosolo la ndondomeko kuti mupewe kuwonongeka kulikonse.

6. Kuchepetsa kutentha kwa dongosolo la ndondomeko kuti mukhalebe okhazikika.

7. Chepetsani kupanikizika kotsalira kuti muwonetsetse kuti ntchito yokhazikika komanso yodalirika.

4. Zomwe zimayambitsa kukhudzidwa

(1) Kulakwitsa kwa mfundo yokonza

Zolakwa za Machining nthawi zambiri zimayamba chifukwa chogwiritsa ntchito mbiri ya tsamba kapena ubale wopatsirana pokonza.Zolakwa izi zimakonda kuchitika panthawi ya ulusi, zida, komanso kukonza zovuta.Pofuna kupititsa patsogolo zokolola ndi kuchepetsa mtengo, pafupifupi processing nthawi zambiri amagwiritsidwa ntchito bola ngati cholakwika cha chiphunzitso chikugwirizana ndi zofunikira zoyendetsera ntchito.

(2) Kulakwitsa kosintha

Kulakwitsa kosintha kwa zida zamakina kumatanthawuza kulakwitsa komwe kumachitika chifukwa chakusintha kolakwika.

(3) Kulakwitsa kwa chida cha makina

Zolakwika za zida zamakina zimatanthawuza zolakwika pakupanga, kukhazikitsa, ndi kuvala.Zimaphatikizapo zolakwika zowongolera pa njanji yowongolera zida zamakina, zolakwika zozungulira pazida zamakina, ndi zolakwika zopatsira unyolo pamakina.

5. Njira yoyezera

Kulondola kwa kukonza kumatengera njira zosiyanasiyana zoyezera molingana ndi zomwe zili mumayendedwe olondola komanso zofunikira zolondola.Kawirikawiri, pali njira zotsatirazi:

(1) Kutengera ngati gawo loyezera limayesedwa mwachindunji, likhoza kugawidwa m'mitundu iwiri: yolunjika ndi yosadziwika.

Kuyeza kwachindunji,gawo loyezedwa limayesedwa mwachindunji kuti lipeze miyeso yoyezedwa.Mwachitsanzo, ma calipers ndi ofananira angagwiritsidwe ntchito kuyeza parameter mwachindunji.

Muyezo wosalunjika:Kuti tipeze kukula kwake kwa chinthu, titha kuyeza mwachindunji kapena kugwiritsa ntchito muyeso wosalunjika.Kuyeza kwachindunji kumakhala kowoneka bwino, koma kuyeza kosalunjika ndikofunikira pamene zofunikira zolondola sizingakwaniritsidwe mwa kuyeza kwachindunji.Muyezo wosalunjika umaphatikizapo kuyeza magawo a geometric okhudzana ndi kukula kwa chinthu ndi kuwerengera kukula kwake potengera magawowo.

(2) Pali mitundu iwiri ya zida zoyezera malinga ndi kuchuluka kwa kuwerenga kwawo.Muyezo wathunthu umayimira mtengo weniweni wa kukula kwake, pomwe miyeso yofananira siyimatero.

Muyezo wathunthu:Kuwerengera kumayimira mwachindunji kukula kwa kukula kwake, monga kuyeza ndi vernier caliper.

Muyezo wachibale:Mtengo wowerengera umangowonetsa kupatuka kwa kukula kwake koyerekeza ndi kuchuluka kwanthawi zonse.Ngati mumagwiritsa ntchito chofananira kuti muyese kukula kwa shaft, muyenera kusintha kaye zero malo a chidacho ndi chipika choyezera ndikuyesa.Mtengo woyerekeza ndi kusiyana pakati pa m'mimba mwake wa shaft wakumbali ndi kukula kwa block block.Ichi ndi muyeso wachibale.Nthawi zambiri, kulondola kwa muyeso wachibale ndi wokwera, koma kuyeza kumakhala kovuta kwambiri.

(3) Malingana ndi ngati malo oyezerawo akukhudzana ndi mutu woyezera wa chida choyezera, amagawidwa muyeso yokhudzana ndi kusagwirizana.

Muyezo wa anzanu:Mutu woyezera umagwiritsa ntchito mphamvu yamakina pamtunda womwe ukuyesedwa, monga kugwiritsa ntchito micrometer kuyeza zigawo.

Muyezo wosalumikizana nawo:Mutu woyezera wosalumikizana umapewa kutengera mphamvu yoyezera pazotsatira.Njira zimaphatikizapo kusokoneza mafunde ndi kuwala kwa mafunde.

(4) Malinga ndi kuchuluka kwa magawo omwe amayezedwa nthawi imodzi, amagawidwa kukhala muyeso umodzi komanso muyeso wokwanira.

Muyeso umodzi:Gawo lililonse la gawo loyesedwa limayesedwa mosiyana.

Muyezo wathunthu:Ndikofunikira kuyeza zizindikiro zomveka bwino zomwe zikuwonetsa magawo ofunikira acnc zigawo.Mwachitsanzo, poyeza ulusi ndi makina oonera zinthu zing'onozing'ono, tingayezetse kukula kwa phula kwenikweni, cholakwika cha theka la angle, ndi kulakwitsa kochulukira kochulukirako kungayesedwe.

(5) Udindo wa muyeso mu ndondomeko yokonza umagawidwa muyeso yogwira ntchito ndi yoyezera chabe.

Muyezo wokhazikika:The workpiece imayesedwa panthawi yokonza, ndipo zotsatira zake zimagwiritsidwa ntchito mwachindunji kuti zithetsedwe kwa gawolo, potero zimalepheretsa kubadwa kwa zinyalala panthawi yake.

Muyeso wapang'onopang'ono:Pambuyo Machining, workpiece amayezedwa kudziwa ngati ali oyenerera.Kuyeza uku kumangozindikiritsa zing'onozing'ono.

(6) Malingana ndi momwe gawo lopimidwa limakhalira panthawi yoyezera, limagawidwa muyeso lokhazikika komanso lamphamvu.

Muyezo wosasunthika:Muyeso wake ndi wongoima.Yesani m'mimba mwake ngati micrometer.

Muyeso wamphamvu:Panthawi yoyezera, mutu woyezera ndi malo oyezerawo amasuntha poyerekezera ndi momwe zinthu zimagwirira ntchito.Njira zoyezera zamphamvu zimawonetsa momwe zigawo zomwe zili pafupi kugwiritsidwira ntchito ndipo ndizomwe zimapangidwira muukadaulo woyezera.

Anebon amatsatira mfundo yofunika yakuti: “Ubwino ndiwo moyo wa bizinezi, ndipo udindo ukhoza kukhala moyo wake.”Pakuchotsera kwakukulu pamayendedwe olondola a 5 Axis CNC LatheZigawo Zopangidwa ndi CNC, Anebon ali ndi chidaliro kuti titha kupereka zinthu zamtengo wapatali ndi mayankho pamtengo wokwanira komanso chithandizo chapamwamba pambuyo pogulitsa kwa ogula.Ndipo Anebon adzamanga ulendo wautali.

Chinese Professional ChinaGawo la CNCndi Zida Zopangira Zitsulo, Anebon imadalira zida zapamwamba, kapangidwe kabwino, ntchito yabwino kwambiri yamakasitomala, komanso mitengo yampikisano kuti makasitomala ambiri azikhulupirira kunyumba ndi kunja.Kufikira 95% yazinthu zimatumizidwa kumisika yakunja.

Nthawi yotumiza: Apr-08-2024