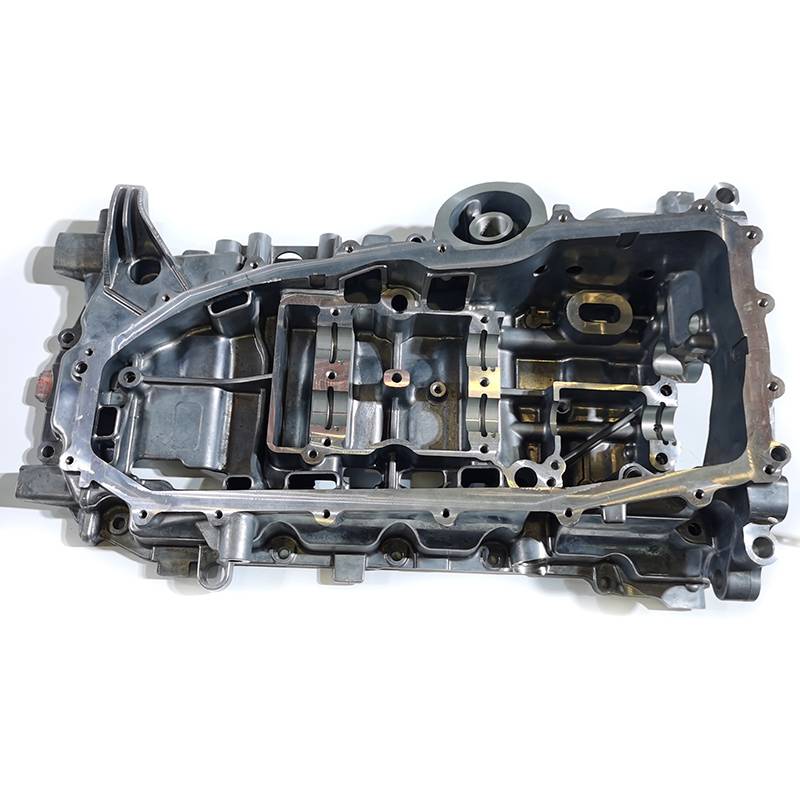

Precision Machining in the Automotive Industry

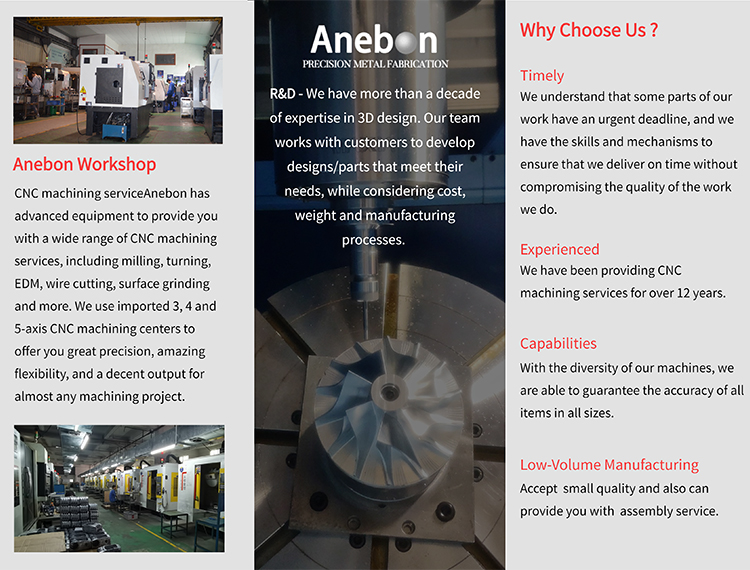

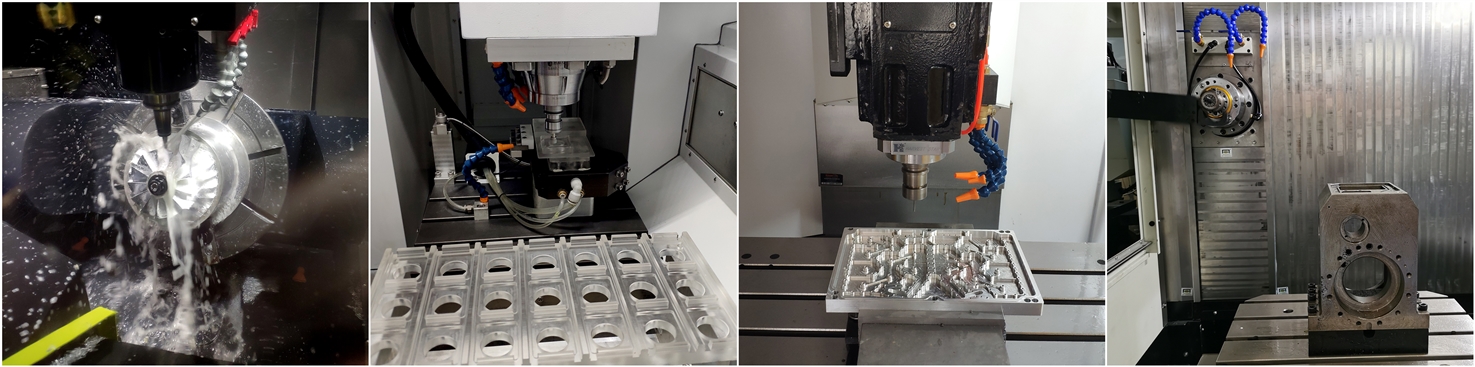

Anebon Metal provides the most advanced cnc processing services and has more than 10 years of experience in serving the automotive industry. Our experts are confident that they have the technology to produce complete and reliable high-volume parts, and have obtained the support of the quality and long-term reliability that customers expect.

Frequently produced auto parts:Titanium valve,Brake system components,Pin,Spline shaft,bushing,Timing cover,Valve retainer

Quality-Anebon has passed ISO 9001:2015 certification. In addition, our quality management program includes various sophisticated testing technologies and proprietary measurement procedures in the industry.

|

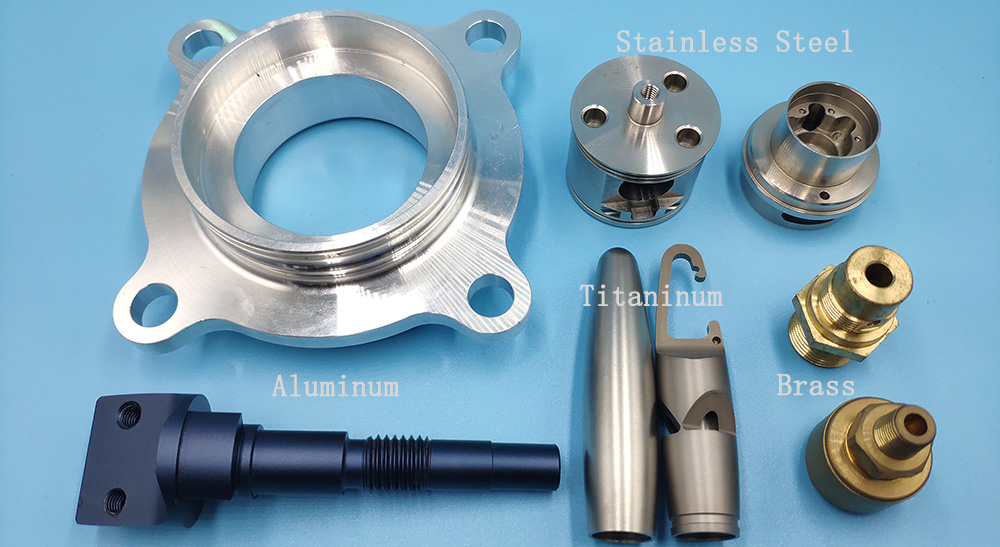

PRECISION MACHINING MATERIALS |

|

|

METALS |

PLASTICS |

|

Alloys |

PVC |

|

Aluminum |

Acetal |

|

Brass |

Nylon |

|

Copper |

Delrin |

|

Stainless Steel |

PTFE |

|

Special Alloys |

UHMW |

|

Precision Steel |

Ultem |

|

Titanium |

PEEK |

| Aluminum Cnc Machining Parts | Aluminum Machining Parts | small part machining |

| Aluminum Machining | Aluminum Cnc Parts | machined metal parts |

| parts machining service | Mechanical Components | metal machining services |