Precision Turning Parts

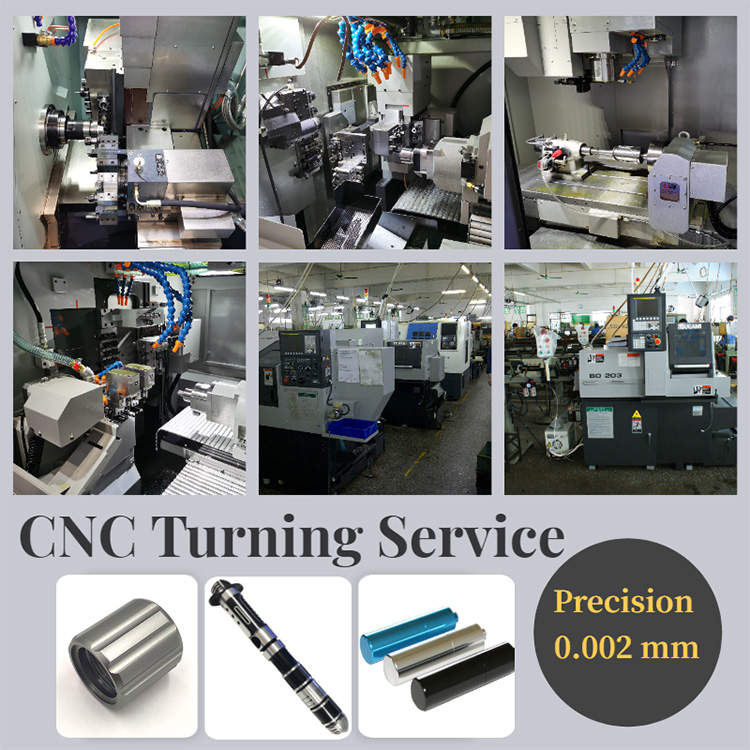

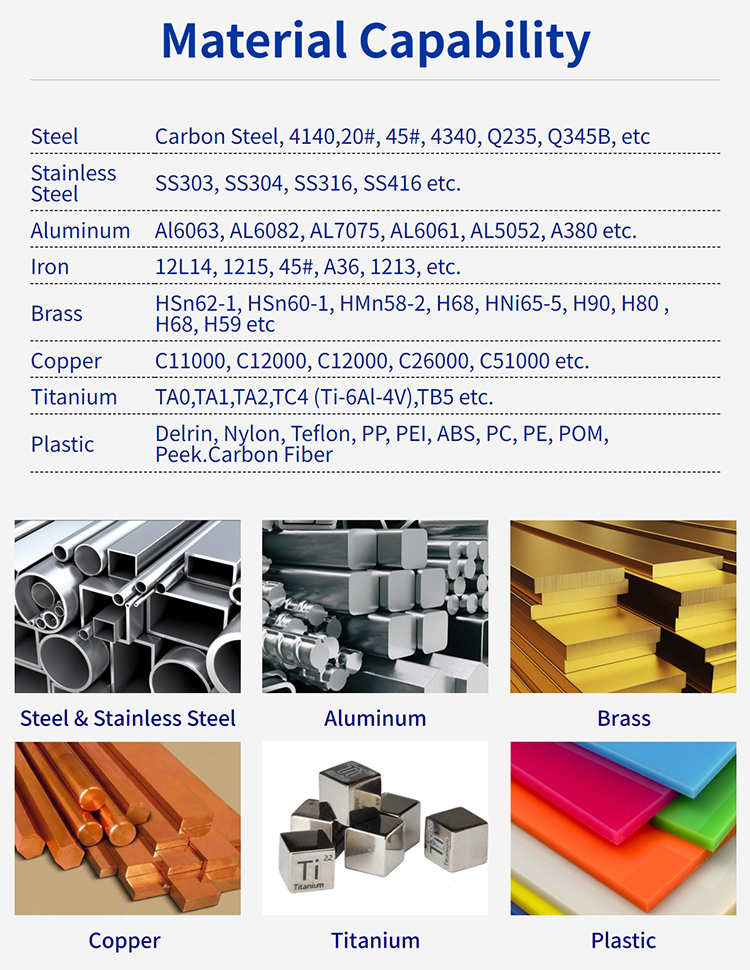

Processing equipments: cnc machining center, cnc lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM, wire-cutting machine, CNC bending machine etc.

Service project: To provide production design, production and technical service, mould development and processing, etc.

Surface treatment: Heat treatment, polishing, PVD/CVD coating, galvanized, electroplating, spraying, and painting etc.

Packing: PE bag, carton, wooden box

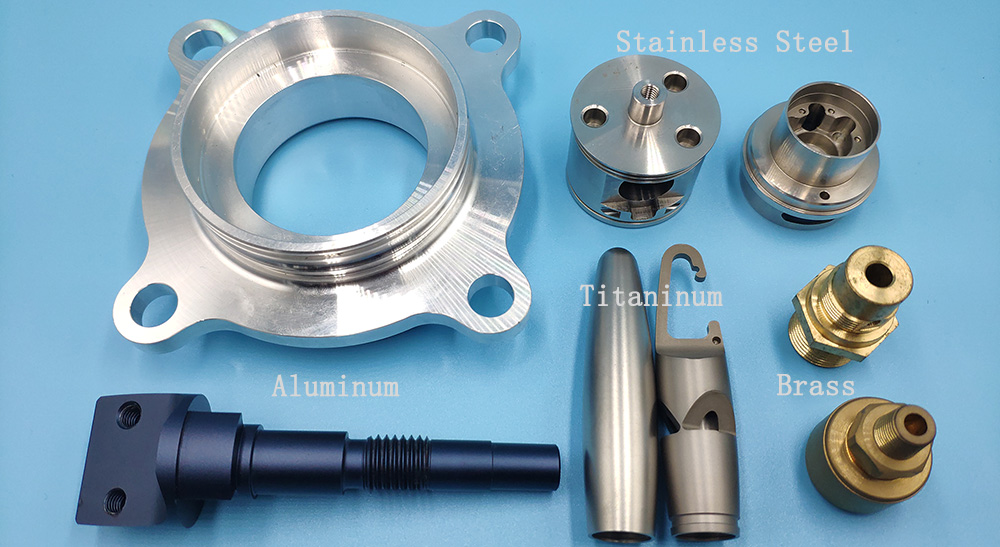

Business scope: CNC center machining, drilling, turning, grinding, tapping, mould design and processing, casting, sheet mental working etc.

Application: Automation machine, medical device, industrial machine, automobile, electric appliance, and other industries.

Machining scope: Building and lifting industry, Engineering and engineering design industry, Aerospace industry, Machinery and tools industry, Electronic instrumentation equipment industry, automotive industry

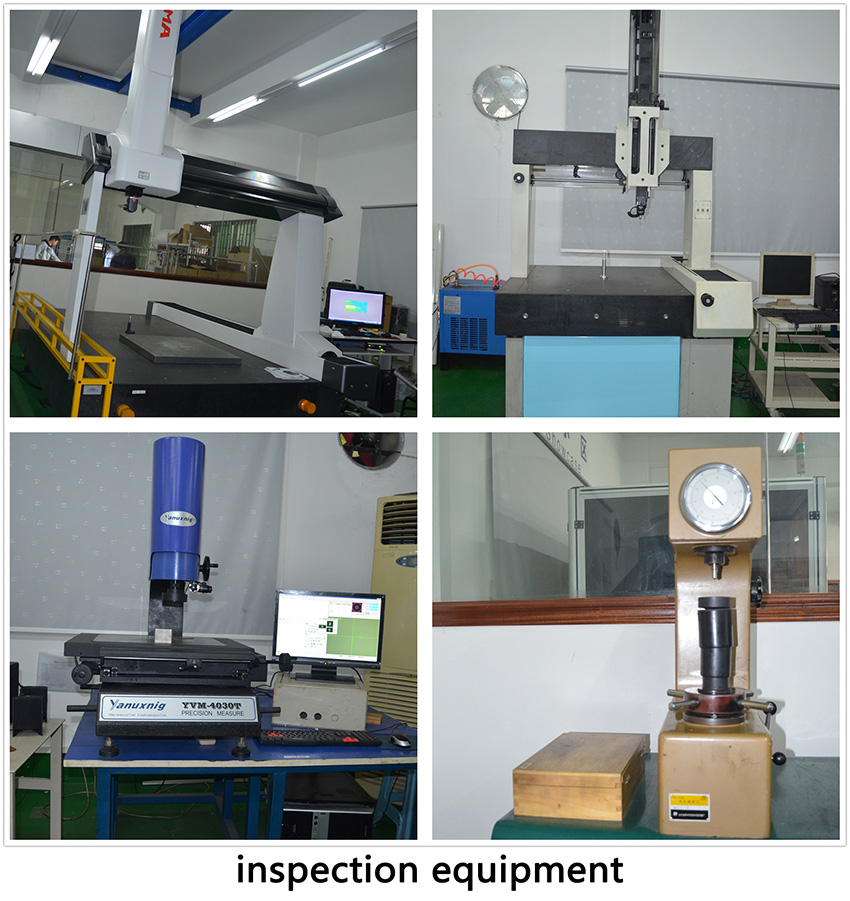

Testing machine: Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on.

Minimum order quantity: 1000pcs

Delivery: 10-30 days

|

Machining |

Milling |

Turning |

|

Cnc Machining Factory

|

Cnc Milling Machine Spare Parts

|

Cnc Turning Centre

|

|

Cnc Machining Facility

|

Cnc Milling Machine Small

|

Cnc Turning Centers

|

|

Cnc Machining Examples

|

Cnc Milling Machine Simulator |

Cnc Turning Center With Live Tooling |