Aluminum Cnc Services

ALUMINUM CNC SERVICES

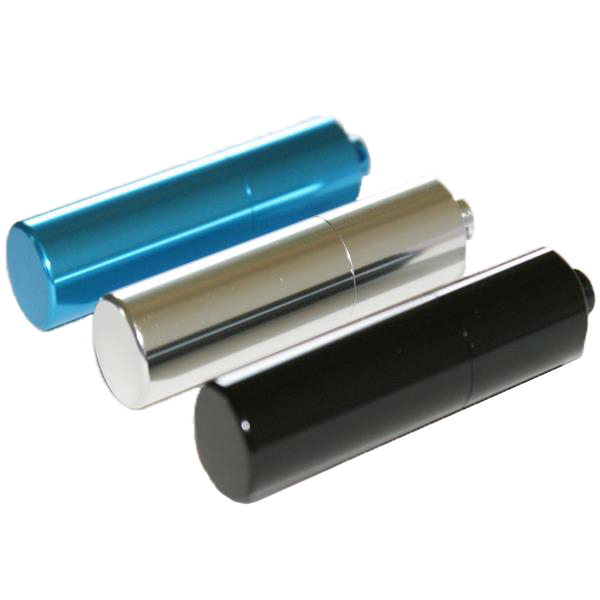

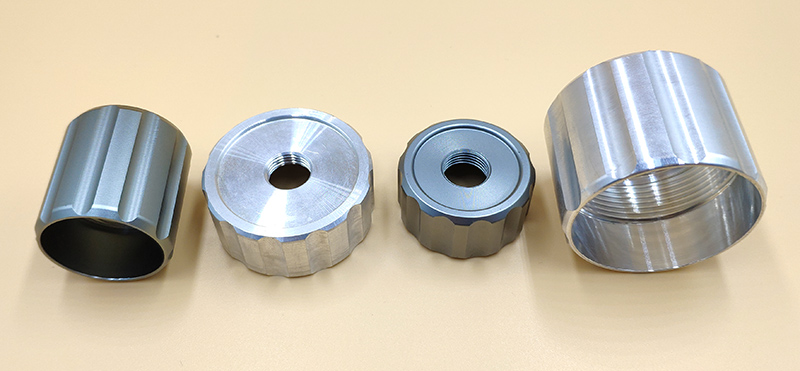

1.Part name: OEM ODM CNC Precision Turning Machining Aluminium Alloy Parts of Anodized

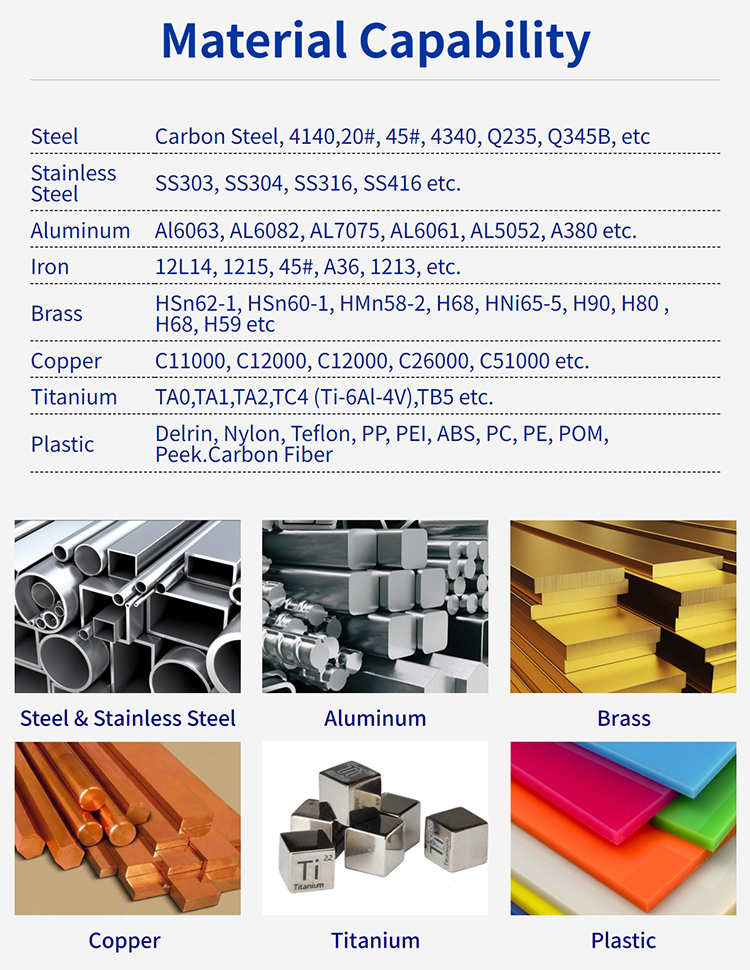

2.Material to process: aluminum, stainless steel, carbon steel, brass

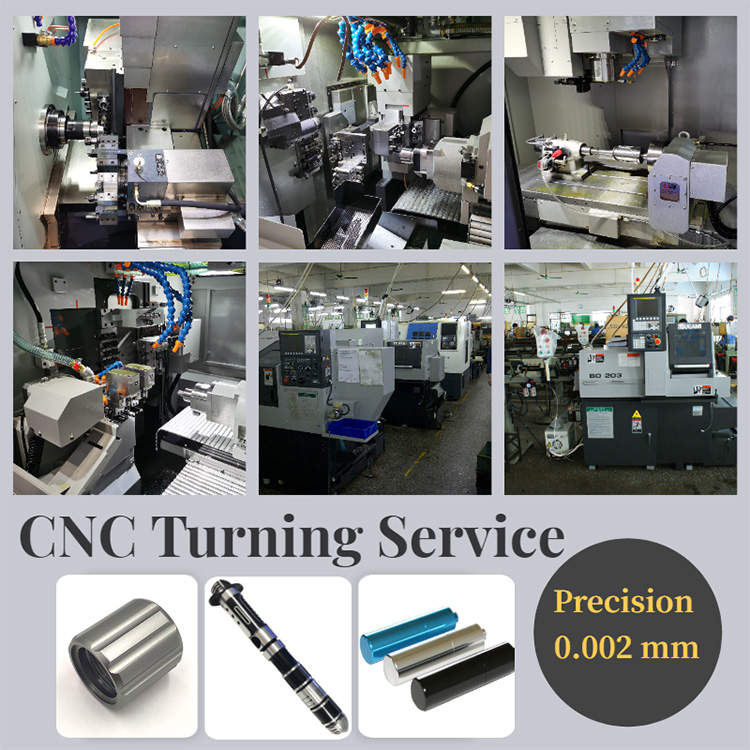

3.Precision: 0.010-0.002mm

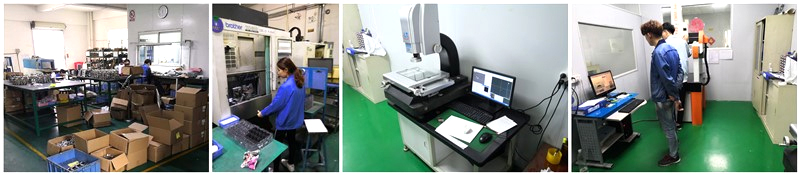

4.Equipments: CNC lathe, processing center, miller, cylindrical bore grinder, surface form grinder, punching machine, etc.

5.Surface treatment: zinc, nickel, anodized, polishing

6.Parts are used on vehicles, printing machines, food processing machines, textile machines, electronic machines, etc.

7.We are able to supply sheet metal, Precision metal machined components, surface treatment such as anodize and plating according to our customers’ requirement.

8.FOB Price: USD0.05-10/Piece

9.Packaging details: inner plastic bag, outer standard carton box

10.Delivery time: 25-35 days

Our company specializes in the production of auto parts, motorcycle accessories, mechanical parts and power tool accessories, aluminum processing parts, manufacturing various types of valve bodies, zinc

Alloy die castings, aluminum alloy die castings, aluminum gravity castings, CNC machining parts, machined parts, fasteners and other mechanical parts and all kinds of plastic products.

Is a set of mold design and development, aluminum, zinc alloy casting production, machining-based production-oriented enterprises. Enterprises rely on science and technology as the backing, depending on the quality of life,

Employed some senior technical personnel and management personnel, plus first-class mold manufacturing equipment, hot and cold chamber die casting machine, gravity casting heat treatment equipment.

Into a number of fully imported processing centers, CNC milling machines and various types of mechanical processing equipment, combined with complete testing tools and equipment, with a new image,

Excellent quality has won the trust of domestic and foreign customers, products are exported to the United States, Japan, South Korea and European countries.