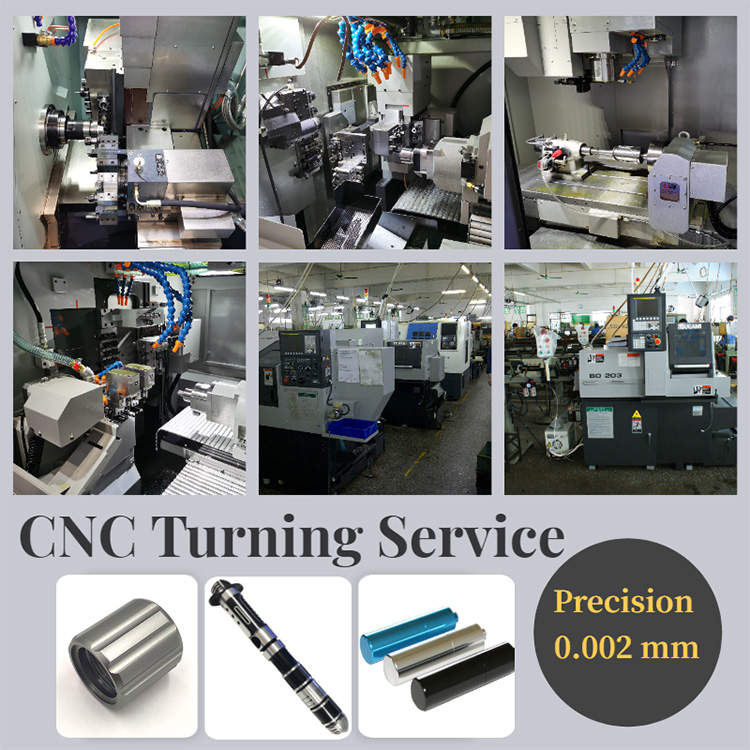

Cnc Turning And Milling

Since the advent of the CNC lathe in the 1950s, it has been used in single-piece production and small-volume production. The use of CNC lathes to machine complex-shaped parts has not only improved labor productivity and processing quality, but also shortened the production preparation cycle and reduced the Workers' technical proficiency requirements. Therefore, it has become an important development direction for achieving technological innovation and technological revolution in single-piece and small-batch production. Countries around the world are also vigorously developing this new technology.

Tag:cnc lathe process/ cnc lathe services/ cnc precision turning/ cnc turned components/ cnc turning/ turn services/ turned partslathe services