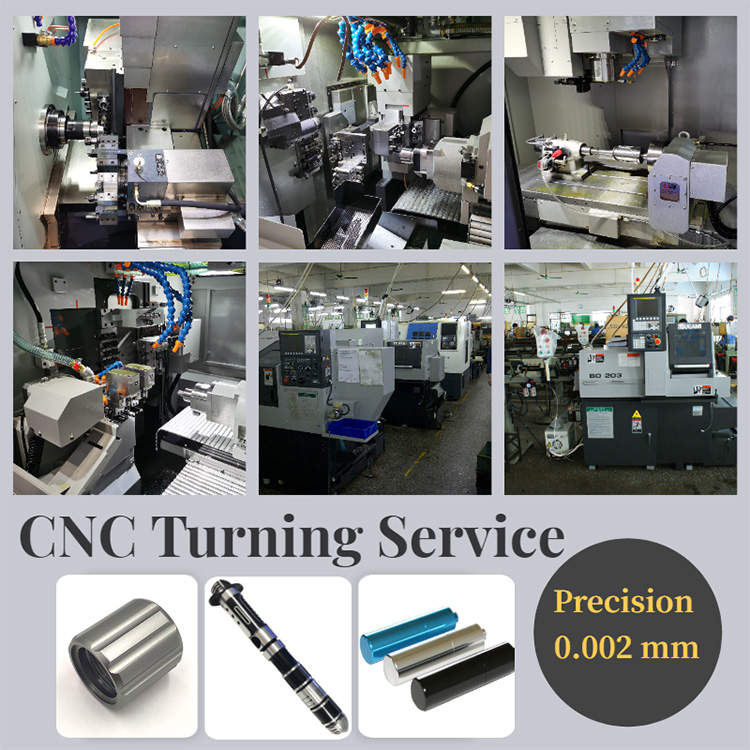

CNC Turning Part

Efficient cutting is a systematic project. By selecting machine tools and processing equipment with good technical conditions, sufficient power and stiffness, the rigidity of the entire cutting system can be improved, the cutting conditions can be improved, and the deformation of the parts can be avoided or reduced.

Our advantage:

1. Fast processing speed: automatic tool change, reducing unnecessary tool change time and improving efficiency.

2. Large processing stroke: 600*800*400.

3. High precision of parts: the tolerance of parts is controlled between 0.05-0.1mm

Top Label:

cnc lathe process/ cnc lathe services/ cnc precision turning/ cnc turned components/ cnc turning/ turn services/ turned partslathe services

Write your message here and send it to us