Aliyense amadziwa ulusi.Monga ogwira nawo ntchito pamakampani opanga zinthu, nthawi zambiri timafunikira kuwonjezera ulusi molingana ndi zosowa zamakasitomala pokonza Chalk hardware mongaCNC Machining magawo, CNC kutembenuza magawondiCNC mphero zigawo.

1. Ulusi ndi chiyani?

Ulusi ndi helix yomwe imadulidwa kukhala chogwirira ntchito kuchokera kunja kapena mkati.Ntchito zazikulu za ulusi ndi:

1. Pangani mgwirizano wamakina pophatikiza ulusi wamkati ndi ulusi wakunja.

2. Kusamutsa zoyenda ndi kutembenuza rotary zoyenda liniya zoyenda ndi mosemphanitsa.

3. Pezani zabwino zamakina.

2. Mbiri ya ulusi ndi mawu

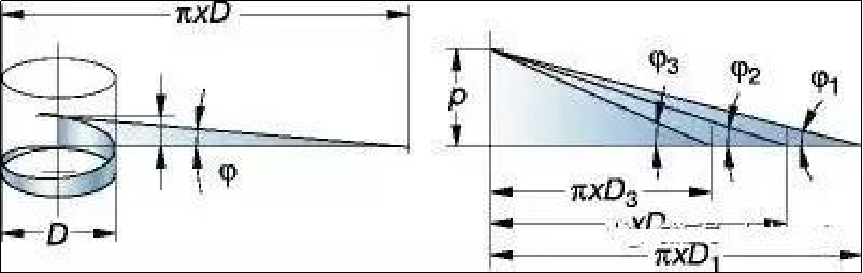

Mbiri ya ulusi imatsimikizira ma geometry a ulusi, kuphatikizapo kutalika kwa workpiece (yaikulu, phula, ndi ma diameter ang'onoang'ono);ngodya ya mbiri ya ulusi;phula ndi helix angle.

1. Mawu a ulusi

① Pansi: Pansi pansi polumikiza maulusi awiri oyandikana nawo.

② mbali: mbali ya ulusi yomwe imalumikiza pachimake ndi pansi pa dzino.

③Crest: Pamwamba polumikiza mbali ziwiri.

P = phula, mm kapena ulusi pa inchi (tpi)

ß = mbiri ya mbiri

ϕ = ulusi wa helix angle

d = kukula kwakukulu kwa ulusi wakunja

D = kukula kwakukulu kwa ulusi wamkati

d1 = mainchesi ochepa a ulusi wakunja

D1 = Chidutswa chaching'ono cha ulusi wamkati

d2 = phula lalikulu la ulusi wakunja

D2 = ulusi wamkati mkati mwake

M'mimba mwake, d2/D2

Kuchita bwino kwa ulusi.Pafupifupi theka pakati pa mainchesi akuluakulu ndi ang'onoang'ono.

Geometry ya ulusi imachokera ku ulusi phula m'mimba mwake (d, D) ndi phula (P): mtunda wa axial pamodzi ndi ulusi pa workpiece kuchokera pa mfundo imodzi pa mbiri kupita ku mfundo yotsatira.Izi zitha kuwonedwanso ngati makona atatu akulambalala workpiece.

vc = kuthamanga (m/min)

ap = kuya kwa ulusi wonse (mm)

nap = kuya kwa ulusi wonse (mm)

tpi = ulusi pa inchi

Feed = phula

2. Mbiri ya ulusi wamba

1. Kuwerengera ndi kulolerana kwa ulusi wakunja wa phula la 60 ° mtundu wa dzino (mtundu wa GB197/196)

a.Kuwerengera kukula koyambira kwa phula lalikulu

Kukula koyambira kwa phula lalikulu la ulusi = kukula kwakukulu kwa ulusi - pitch × coefficient value.

Chiwonetsero cha formula: d/DP×0.6495

2. Kuwerengera ndi kulolerana kwa phula la 60 ° ulusi wamkati (GB197/196)

a.6H mlingo ulusi phula m'mimba mwake kulolerana (kutengera phula phula)

Malire apamwamba:

P0.8+0.125P1.00+0.150P1.25+0.16P1.5+0.180

P1.25+0.00P2.0+0.212P2.5+0.224

Mtengo wotsika ndi "0",

Njira yapamwamba yowerengera 2+TD2 ndiye kukula koyambira + kulolerana.

Mwachitsanzo, phula lapakati la M8-6H ulusi wamkati ndi: 7.188 + 0.160 = 7.348 Pamwamba: 7.188 ndi malire otsika.

b.Mawerengedwe a kuchuluka kwa phula la ulusi wamkati ndi wofanana ndi ulusi wakunja

Ndiko kuti, D2 = DP × 0.6495, ndiko kuti, pakati pa ulusi wamkati ndi wofanana ndi mainchesi akuluakulu a ulusi-pitch × coefficient value.

c.6G kalasi ulusi phula m'mimba mwake zoyambira zopatuka E1 (kutengera ulusi phula)

P0.8+0.024P1.00+0.026P1.25+0.028P1.5+0.032

P1.75+0.034P1.00+0.026P2.5+0.042

3. Kuwerengera ndi kulolerana kwa mainchesi akuluakulu a ulusi wakunja (GB197/196)

a.Malire apamwamba a 6h awiri awiri a ulusi wakunja

Ndiye kuti, chitsanzo cha ulusi wamtengo wapatali M8 ndi φ8.00 ndipo kulolerana kwapamwamba ndi "0".

b.Kulekerera kwa mtengo wotsika wa malire a mainchesi akuluakulu a kalasi ya 6h ya ulusi wakunja (kutengera phula la ulusi)

P0.8-0.15P1.00-0.18P1.25-0.212P1.5-0.236P1.75-0.265

P2.0-0.28P2.5-0.335

Kuwerengera kwa malire otsika a mainchesi akulu: d-Td ndiye gawo loyambira la mainchesi akulu a ulusi - kulolerana.

4. Kuwerengera ndi kulolerana kwazing'onozing'ono za ulusi wamkati

a.Kuwerengera kukula koyambira kwa kagawo kakang'ono ka ulusi wamkati (D1)

Kukula koyambira kwa mainchesi ang'onoang'ono a ulusi = kukula kwa ulusi wamkati - phula × factor

5. Kuwerengera njira yogawa mutu umodzi wogawa

Njira yowerengera ya njira yogawa magawo amodzi: n=40/Z

n: chiwerengero cha zosintha zomwe mutu wogawa uyenera kutembenuka

Z: Gawo lofanana la workpiece

40: chiwerengero chokhazikika cha mutu wogawa

6. Chiwerengero cha hexagon cholembedwa mozungulira

① Pezani mbali ya hexagonal (S pamwamba) ya bwalo D

S=0.866D ndi diameter×0.866 (koyeyefiyenti)

② Werengetsani kukula kwa bwalo (D) kuchokera mbali zina za hexagon (S pamwamba)

D=1.1547S ndi mbali yotsutsana×1.1547 (koyefiyenti)

7. Njira yowerengera ya mbali zopingasa za hexagonal ndi ma diagonal munjira yozizira

① Pezani mbali ina ya e kuchokera mbali ina (S) ya hexagon yakunja

e=1.13s ndi mbali yotsutsana×1.13

②Pezani ngodya ina (e) kuchokera mbali ina (ma) yamkati mwa hexagon

e=1.14s ndi mbali yotsutsana×1.14 (koyefiyenti)

③ Pezani kukula kwa mutu wa ngodya ina (D) mbali ina (s) ya hexagon yakunja

Kuzungulira kwa bwalo (D) kuyenera kuwerengedwa molingana ndi (chilinganizo chachiwiri mu 6) mbali ya hexagonal (s pamwamba), ndipo mtengo wapakati wa offset uyenera kuwonjezeka moyenerera, ndiko kuti, D≥1.1547s.Kuchuluka kwa offset center kungayerekezedwe.

8. Chiwerengero cha mawerengedwe a square olembedwa mozungulira

① kuzungulira (D) kuti mupeze mbali ina ya sikweya (S pamwamba)

S=0.7071D ndi m'mimba mwake×0.7071

② Pezani bwalo (D) kuchokera mbali zina za lalikulu (S pamwamba)

D=1.414S ndi mbali yotsutsana×1.414

9. Mawerengedwe a masikweya mbali zopingasa ndi ngodya zoyang'ana m'njira yozizira

① Pezani ngodya ina (e) mbali ina (S) ya bwalo lakunja

e=1.4s ndi mbali ina (s)×1.4 parameter

② Pezani ngodya ina (e) kuchokera mbali ina (ma) yapakati

e=1.45s ndi mbali ina (s)×1.45 coefficient

10. Njira yowerengera kuchuluka kwa hexagon

s20.866×H/m/k amatanthauza mbali yopingasa×mbali yotsutsana×0.866×utali kapena makulidwe.

11. Kuwerengera kuchuluka kwa frustum (cone) thupi

0.262H(D2+d2+D×d) ndi 0.262×utali×(mutu waukulu m'mimba mwake×mutu waukulu m'mimba mwake+mutu wawung'ono wang'ono×mutu wawung'ono+m'mimba mwake wamutu wawung'ono×mutu wawung'ono).

12. Fomula yowerengera kuchuluka kwa thupi lozungulira (monga mutu wozungulira)

3.1416h2(Rh/3) ndi 3.1416×utali×utali×(radius-utali÷3).

13. Fomula yowerengera ya makulidwe a matepi a ulusi wamkati

1. Kuwerengera kwa tap main diameter D0

D0=D+(0.866025P/8)×(0.5~1.3) ndiye kukula kwake kwa ulusi waukulu wa tap + 0.866025 phula ÷ 8×0.5 mpaka 1.3.

Zindikirani: Kusankhidwa kwa 0.5 mpaka 1.3 kuyenera kutsimikiziridwa molingana ndi kukula kwa phula.Kukula kwa phula, kocheperako iyenera kugwiritsidwa ntchito.M'malo mwake, mtengo wocheperako wa phula, wofananawo uyenera kugwiritsidwa ntchito.

2. Kuwerengera kuchuluka kwa phula (D2)

D2=(3×0.866025P)/8, ndiye kuti, tap diameter=3×0.866025×pitch÷8

3. Kuwerengera kuchuluka kwa mpopi (D1)

D1=(5×0.866025P)/8 ndi m'mimba mwake = 5×0.866025×pitch÷8

14. Fomula yowerengera kutalika kwa zinthu zomwe zimagwiritsidwa ntchito pamutu wozizira kupanga mawonekedwe osiyanasiyana

Amadziwika kuti voliyumu chilinganizo cha bwalo ndi awiri×m'mimba mwake×0.7854×utali kapena utali wozungulira×3.1416×utali.Ndiko kuti, d2×0.7854×L kapena R2×3.1416×L

Powerengera, voliyumu ya X÷diameter÷diameter÷0.7854 kapena X÷radius÷radius÷3.1416 yazinthu zofunika pakukonzamagawo a cnc Machiningndicnc kutembenuza magawondi kutalika kwa zinthu.

Mzerewu = X/(3.1416R2) kapena X/0.7854d2

X mu fomula imayimira kuchuluka kwazinthu zofunikira;

L amaimira kutalika kwa mtengo wa chakudya chenicheni;

R/d imayimira utali wozungulira kapena m'mimba mwake wa chakudya chenichenicho.

Nthawi yotumiza: Jan-11-2023