Wonke umntu uqhelene nomsonto.Njengabalingane kushishino lokuvelisa, sihlala sifuna ukongeza imisonto ngokweemfuno zabathengi xa kusetyenzwa izincedisi zehardware ezifanaCNC Machining iindawo, CNC ukuguqula iindawokwayeCNC milling iinxalenye.

1. Yintoni umsonto?

Umsonto yiheliksi esikwe kwisixhobo sokusebenza nokuba sivela ngaphandle okanye ngaphakathi.Imisebenzi ephambili yemisonto yile:

1. Yenza uxhulumaniso lomatshini ngokudibanisa iimveliso zentambo yangaphakathi kunye neemveliso zentambo zangaphandle.

2. Dlulisela isindululo ngokuguqula intshukumo ejikelezayo ukuya kwintshukumo yomgca kwaye ngokuphambeneyo.

3. Fumana inzuzo yoomatshini.

2. Iprofayili yomsonto kunye nesigama

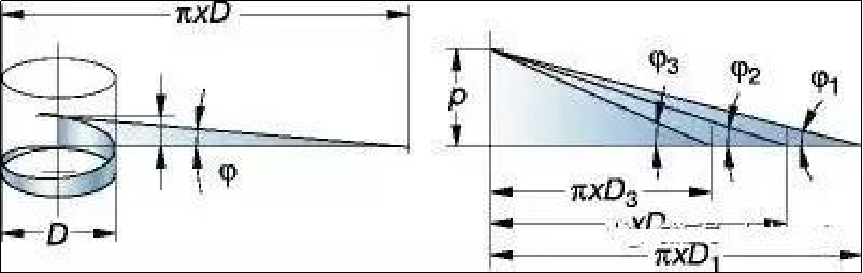

Iprofayili yomsonto imisela ijometri yomsonto, kuquka i-diameter ye-workpiece (enkulu, i-pitch, kunye ne-diameter encinci);i-engile yeprofayili yomsonto;i-pitch kunye ne-helix angle.

1. Amagama omsonto

① Ezantsi: Umphezulu ongezantsi odibanisa imisonto emibini esecaleni emeleneyo.

② iflenki: umphezulu wecala lomsonto odibanisa i-crest kunye nomzantsi wezinyo.

③Crest: Umphezulu odibanisa amaflanki amabini.

P = inowuthi, mm okanye imisonto nge-intshi nganye (tpi)

ß = i-engile yeprofayili

ϕ = i-engile ye-helix yomsonto

d = ubukhulu obukhulu bomsonto wangaphandle

D = ubukhulu obukhulu bomsonto wangaphakathi

d1 = i-diameter encinci yomsonto wangaphandle

D1 = Idayamitha encinci yentambo yangaphakathi

d2 = i-pitch diameter yomsonto wangaphandle

I-D2 = i-diameter ye-thread pitch yangaphakathi

I-pitch diameter, d2/D2

Idayamitha esebenzayo yomsonto.Malunga nesiqingatha phakathi kwedayamitha ezinkulu nezincinci.

Ijometri yomsonto isekelwe kwidayamitha yepitch yentambo (d, D) kunye nepitch (P): umgama we-axial ecaleni komsonto kwi-workpiece ukusuka kwindawo enye kwiprofayili ukuya kwinqanaba elilandelayo elihambelanayo.Oku kunokubonwa njengonxantathu odlula i-workpiece.

vc = isantya sokusika (m/min)

ap = ubunzulu bomsonto bubonke (mm)

nap = ubunzulu bomsonto bubonke (mm)

tpi = imisonto nge-intshi nganye

Ukutya = inowuthi

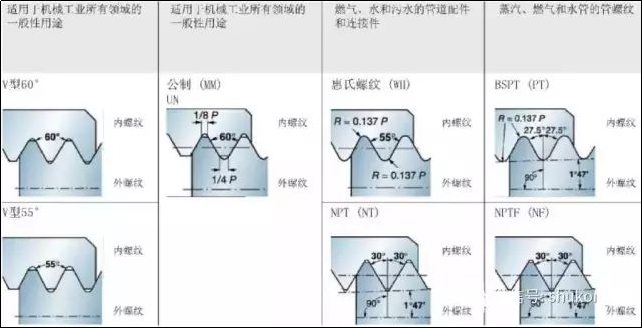

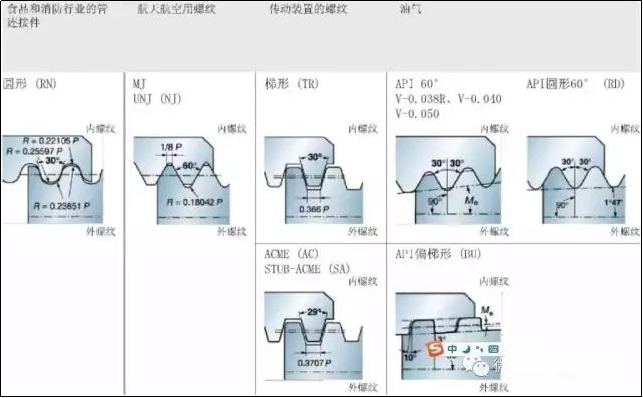

2. Iprofayili yomsonto eqhelekileyo

1. Ukubalwa kunye nokunyamezelana kwe-thread pitch diameter yangaphandle ye-60 ° uhlobo lwezinyo (umgangatho wesizwe we-GB197/196)

a.Ukubalwa kobungakanani obusisiseko bedayamitha yepitshi

Ubungakanani obusisiseko bobubanzi be-pitch yentambo = ubukhulu obukhulu bentambo - i-pitch × ixabiso le-coefficient.

Ukumelwa kwefomula: d/DP×0.6495

2. Ukubalwa kunye nokunyamezela kwe-pitch diameter ye-60 ° intambo yangaphakathi (GB197/196)

inqanaba le-a.6H lemisonto yepitch yokunyamezelana kwedayamitha (ngokusekwe kwipitch yentambo)

Umda ophezulu:

P0.8+0.125P1.00+0.150P1.25+0.16P1.5+0.180

P1.25+0.00P2.0+0.212P2.5+0.224

Ixabiso elisezantsi lomda ngu “0”,

Umlinganiselo ophezulu wokubala ifomula 2+TD2 ubungakanani obusisiseko + ukunyamezela.

Ngokomzekelo, i-pitch diameter ye-M8-6H intambo yangaphakathi: 7.188 + 0.160 = 7.348 Umda ophezulu: 7.188 ngumda ophantsi.

b.Ifomula yokubala ye-pitch ye-diameter yentambo yangaphakathi iyafana naleyo yomsonto wangaphandle

Oko kukuthi, i-D2 = DP × 0.6495, oko kukuthi, i-diameter ephakathi kwentambo yangaphakathi ilingana nobukhulu obukhulu be-thread-pitch × ixabiso le-coefficient.

c.6G iklasi ye-pitch pitch yeklasi ukutenxa isiseko se-E1 (esekelwe kwi-pitch pitch)

P0.8+0.024P1.00+0.026P1.25+0.028P1.5+0.032

P1.75+0.034P1.00+0.026P2.5+0.042

3. Ukubalwa kunye nokunyamezela kwedayimitha enkulu yomsonto wangaphandle (GB197/196)

a.Umda ophezulu we-6h ubukhulu obukhulu bomsonto wangaphandle

Oko kukuthi, umzekelo wexabiso lomsonto wedayamitha ye-M8 yi-φ8.00 kwaye ukunyamezela umda ophezulu ngu "0".

b.Ukunyamezela kwexabiso eliphantsi lomda we-diameter enkulu yeklasi ye-6h yentambo yangaphandle (esekelwe kwi-pitch pitch)

P0.8-0.15P1.00-0.18P1.25-0.212P1.5-0.236P1.75-0.265

P2.0-0.28P2.5-0.335

Ifomula yokubala yomda osezantsi wedayamitha enkulu: i-d-Td ngumlinganiselo osisiseko wedayamitha enkulu yomsonto - ukunyamezela.

4. Ukubala kunye nokunyamezela kwe-diameter encinci yentambo yangaphakathi

a.Ukubalwa kobungakanani obusisiseko bobubanzi obuncinci bomsonto wangaphakathi (D1)

Ubungakanani obusisiseko bobubanzi obuncinci bentambo = ubungakanani obusisiseko bentambo yangaphakathi - i-pitch × factor

5. Ifomula yokubala yendlela yokwahlula intloko enye

Ifomula yokubala yendlela yolwahlulo olunye: n=40/Z

n: inani leenguqu ekufuneka intloko eyahlulayo ijike

Z: Iqhezu elilinganayo lomsebenzi

40: inani eliqingqiweyo lentloko eyahlulayo

6. Ifomula yokubala yehexagon ebhalwe kwisangqa

① Fumana icala elinehexagonal elijongeneyo (S umphezulu) wesangqa D

S=0.866D ubukhulu×0.866 (i-coefficient)

② Bala ubukhulu besangqa (D) ukusuka kumacala ahlukeneyo wehexagon (S surface)

D=1.1547S licala elichaseneyo×1.1547 (i-coefficient)

7. Ifomula yokubala yamacala anehexagonal achaseneyo kunye nediagonal kwinkqubo yesihloko esibandayo

① Fumana i-engile echaseneyo e ukusuka kwelinye icala (S) lehexagon yangaphandle

e=1.13s licala elichaseneyo×1.13

②Fumana i-engile echaseneyo (e) ukusuka kwelinye icala (s) le-hexagon yangaphakathi

e=1.14s licala elichaseneyo×1.14 (i-coefficient)

③ Fumana idiamitha yemathiriyeli yentloko yekona echaseneyo (D) ukusuka kwelinye icala (s) lehexagon yangaphandle

Ububanzi besangqa (D) kufuneka kubalwe ngokwe (ifomula yesibini kwi-6) i-hexagonal echaseneyo (s surface), kunye nexabiso le-offset center kufuneka linyuswe ngokufanelekileyo, oko kukuthi, D≥1.1547s.Isixa seziko lokulinganisa sinokuqikelelwa kuphela.

8. Ifomula yokubala yesikwere ebhalwe kwisangqa

① Yenza isangqa (D) ukufumana icala elichasene nesikwere (S umphezulu)

S=0.7071D ubukhulu×0.7071

② Fumana isangqa (D) ukusuka kumacala ahlukeneyo kwisikwere (S umphezulu)

D=1.414S licala elichaseneyo×1.414

9. Ifomula yokubala yesikwere kumacala achaseneyo kunye nee-engile ezichaseneyo kwinkqubo yesihloko esibandayo

① Fumana i-engile echaseneyo (e) ukusuka kwelinye icala (S) lesikwere esingaphandle

e=1.4s licala elichaseneyo (ama)×1.4 iparamitha

② Fumana i-engile echaseneyo (e) ukusuka kwelinye icala (s) lesikwere esingaphakathi

e=1.45s licala elichaseneyo (s)×1.45 i-coefficient

10. Ifomula yokubala umthamo wehexagon

s20.866×H/m/k lithetha icala elichaseneyo×elichaseneyo×0.866×ubude okanye ubukhulu.

11. Ifomula yokubala umthamo we-frustum (cone) umzimba

I-0.262H(D2+d2+D×d) yi-0.262×ubude×(idayamitha yentloko enkulu×idayamitha yentloko enkulu+idayamitha yentloko encinci×intloko encinci+idayamitha yentloko enkulu×idayamitha yentloko encinci).

12. Ifomula yokubala yomthamo womzimba ongqukuva (njengentloko eyisisetyhula)

3.1416h2(Rh/3) yi 3.1416×ubude×ubude×(radius-height÷3).

13. Ifomula yokubala yemilinganiselo yomatshini yeetephu zemisonto yangaphakathi

1. Ukubalwa kwetaphu enkulu yedayamitha D0

D0=D+(0.866025P/8)×(0.5~1.3) yisayizi esisiseko yempompo yedayamitha yentambo enkulu + 0.866025 pitch ÷ 8×0.5 ukuya ku-1.3.

Qaphela: Ukukhethwa kwe-0.5 kwi-1.3 kufuneka kuqinisekiswe ngokobukhulu bebala.Ixabiso le-pitch likhulu, i-coefficient encinci kufuneka isetyenziswe.Ngokuchasene noko, i-pitch value encinci, i-coefficient enkulu ehambelanayo kufuneka isetyenziswe.

2. Ukubalwa komthamo wempompo yepitshi (D2)

D2=(3×0.866025P)/8, oko kukuthi, tap diameter=3×0.866025×pitch÷8

3. Ukubalwa komthamo wempompo (D1)

D1=(5×0.866025P)/8 yimpompo yediameter=5×0.866025×pitch÷8

14. Ifomula yokubala yobude bemathiriyeli esetyenziselwa ukubumba isihloko esibandayo kwiimilo ezahlukeneyo

Kuyaziwa ukuba umthamo wefomula yesangqa × ububanzi × 0.7854 × ubude okanye iradiyasi × 3.1416 × ubude.Oko kukuthi, d2×0.7854×L okanye R2×3.1416×L

Xa ubala, umthamo X÷diameter÷diameter÷0.7854 okanye X÷radius÷radius÷3.1416 wemathiriyeli efunekayo ukuze kuqhutywecnc iindawo zomatshinikwayecnc ukuguqula iindawobubude besixhobo.

Ifomyula yeKholam = X/(3.1416R2) okanye X/0.7854d2

X kwifomula imele ixabiso lomthamo wezinto ezifunekayo;

L imele ubude bexabiso lokondliwa kwangempela;

I-R/d imele i-radius okanye i-diameter yokondla okuyiyo.

Ixesha lokuposa: Jan-11-2023