Yintoni usetyenziso lokubala amatyathanga edimension yendibano?

Ukuchaneka nokuchaneka:

Ukubala amatsheyini obungakanani bendibano kuya kuqinisekisa ukuba unemilinganiselo echanekileyo kunye nemilinganiselo yamacandelo.Oku kuya kunceda nokuqinisekisa ulungelelwaniso olufanelekileyo kunye nokufaneleka.

Ukutshintshelana:

Amakhonkco emilinganiselo yeNdibano asetyenziselwa ukumisela imida yokunyamezela yamacandelo kunye nokuqinisekisa ukuguquguquka.Oku kubaluleke ngakumbi kwimveliso yobuninzi apho amacandelo kufuneka adityaniswe okanye atshintshwe ngokulula.

Ukunqanda ukuphazamiseka:

Ukubala amatyathanga obungakanani bendibano kunokunceda ukuthintela ukungqubana okanye ukuphazamiseka phakathi kwamacandelo.Unokuqinisekisa ukuba amacandelo aya kudibana ngokutyibilikayo ngokumisela imilinganiselo yawo ngqo.

Uhlalutyo loxinzelelo:

Ngokubala amakhonkco edimension yendibano, iinjineli zinokuqonda ukuhanjiswa koxinzelelo ngaphakathi kwindibano.Olu lwazi lubalulekile kuyilo lwamalungu olwakhiwo ukuqinisekisa ukuba ayakwazi ukumelana nomthwalo olindelekileyo okanye amandla.

Ulawulo lwemeko:

Ngokubala ngokuchanekileyo amakhonkco edimension yendibano unokuseka imigangatho yokulawula umgangatho, okuya kukuvumela ukuba uchonge naziphi na iimpazamo okanye ukuphambuka kwinkqubo yokuvelisa.Oku kuya kunceda ukugcina imigangatho ephezulu kunye nokunciphisa iziphene.

Ukuphucula iindleko:

Ngokunciphisa inkunkuma, ukunciphisa iimpazamo zemveliso kunye nokuqinisekisa ukusebenza kakuhle kwezibonelelo, ukubalwa kwamakhonkco edimension yendibano kuya kukhokelela ekuphuculweni kweendleko.Oku kubaluleke ngakumbi kumashishini afuna ukuchaneka okuphezulu, njenge-aerospace okanye ukuveliswa kweemoto.

Dimension chain definition:

Ikhonkco yedimension yendibano yityathanga lobungakanani obuquka imilinganiselo kunye nezikhundla ezihambelanayo zamacandelo amaninzi kwinkqubo yokuhlanganisa.

Ikhonkco le-dimensional liqinisekisa ukuchaneka kwendibano kunye nengqiqo ngexesha lenkqubo yendibano.

Ukuqonda okulula kuya kubakho ikhonkco lemilinganiselo yamacandelo kunye nobudlelwane bendibano.

Yintoni iSize Chain?

Ikhonkco lokulinganisa liqela lemilinganiselo edibeneyo eyenziwe ngexesha lokuhlanganisa umatshini okanye ukusetyenzwa kwenxalenye.

Ikhonkco lokulinganisa lenziwe ngamakhonkco kunye namakhonkco avaliweyo.Umsesane ovaliweyo unokubunjwa ngokwemvelo emva kwendibano okanye ukusebenza komatshini.

Ikhonkco le-dimensional lingasetyenziselwa ukuhlalutya kunye nokuyila imilinganiselo yenkqubo yobugcisa.Kubalulekile ekuqulunqeni iinkqubo zomatshini kunye nokuqinisekisa ukuchaneka kwendibano.

Kutheni kukho ikhonkco ledimension?

Ikhonkco le-dimensional likhona ukuqinisekisa ukuba icandelo ngalinye lenziwa ngokuchaneka okufunekayo.

Ukuqinisekisa umgangatho ekuqhubeni, ukudibanisa, kunye nokusetyenziswa kuyimfuneko ukubala kwaye uhlalutye imilinganiselo ethile, ukunyamezela, kunye neemfuno zobugcisa.

Ikhonkco le-dimensional yingcamango elula eqinisekisa ukuveliswa kobuninzi beemveliso.Lunxulumano phakathi kwamalungu kwinkqubo yokudityaniswa eyenza amatyathanga anomlinganiselo.

Amanyathelo enkcazo yetsheyini yobungakanani:

1. Ibenchmark yendibano kufuneka itshixiwe.

2. Lungisa isithuba sendibano.

3. Ukunyamezela iinxalenye zendibano kufuneka kuchazwe.

4. Ikhonkco ledimensional lidala ikhonkco ledimension yeloop evaliweyo njengendibanocnc amacandelo omatshini.

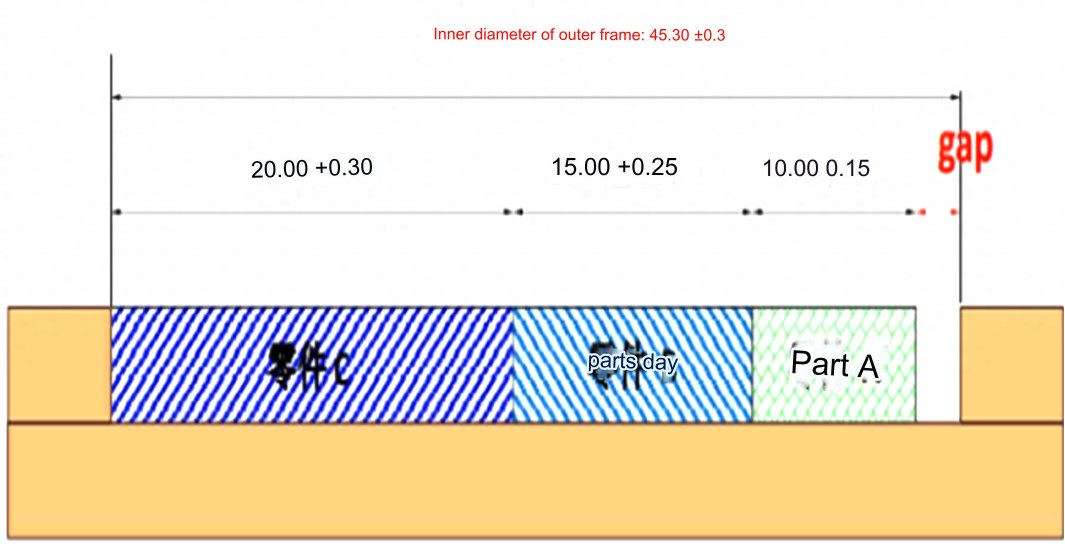

I-Assembly dimension chain case 1

Njengoko kubonisiwe kulo mfanekiso, uqikelelo lophawu lonyamezelo luvavanywa ngokubala:

Qala ngokubala ngokotenxa ophezulu:

Ubungakanani obukhulu besakhelo sangaphandle ubukhulu bangaphakathi: 45.6

Ubungakanani bomda ongaphezulu wenxalenye A: 10.15

Ubungakanani bomda kwinxalenye B: 15.25

Ubungakanani bomda kwinxalenye C: 20.3

bala:

45.6-10.15-15.25-20.3=-0.1

Ukuphazamiseka kuya kuba yi-0.1mm ukuba iindawo zifikelela kumda ophezulu.Oku kuya kubangela ukuba amalungu angadityaniswanga kakuhle.Kucacile ukuba ukunyamezela komzobo kufuneka kuphuculwe.

Emva koko ubale ukutenxa ngokucinezela:

Ubungakanani bomda osezantsi wesakhelo sangaphandle sedayamitha yangaphakathi: 45.0

Ubungakanani bomda osezantsi wenxalenye A: 9.85

Ubungakanani bomda osezantsi wecandelo B: 14.75

Ubungakanani bomda osezantsi wecandelo C: 19.7

bala:

45.0-9.85-14.75-19.7=0.7

Ukuba iinxalenye zicutshungulwa ngokutenxeka okuphantsi ngoko i-gap yendibano iya kuba yi-0.7mm.Akuqinisekwanga ukuba iindawo ziya kuba nokutenxa okusezantsi xa zisetyenzwa ngokwenene.

Uze ubale ngokusekwe ku-zero ukutenxa:

Isiseko sedayamitha yangaphakathi yesakhelo sangaphandle: 45.3

Icandelo A ubukhulu obusisiseko: 10

Icandelo B ubukhulu obusisiseko: 15

Icandelo C ubungakanani obusisiseko: 20

bala:

45.3-10-15-20=0.3

Phawula:Ukucinga ukuba iindawo zinobungakanani obusisiseko, kuya kubakho i-0.3mm yendibano ye-gap.Kwakhona akukho siqinisekiso sokuba akuyi kubakho nakuphi na ukutenxa kubungakanani bamacandelo ngexesha lokuqhubekeka.

Izikhewu ezinokuvela emva kokucubungula imizobo ngokwemigangatho yokunyamezelana kwemilinganiselo.

Ubuninzi besithuba: 45.6-9.85-14.75-19.7= 1.3

Ubuncinci umsantsa: 45-10.15-15.25-20.3= -0.7

Umzobo ubonisa ukuba nangona iinxalenye zingaphakathi kokunyamezela, kunokubakho i-gap okanye ukuphazamiseka ukuya kwi-0.7 mm.Iimfuno zendibano azikwazanga ukufezekiswa kwezi meko zinzima.

Ukudibanisa uhlalutyo olungentla, izikhewu zendibano zeendlela ezintathu ezigqithisileyo zezi: -0.1, +0.7, kunye ne-0.3.Bala ireyithi yesiphene:

Bala inani lamalungu aneziphene ukubala ireyithi yesiphene.

Umlinganiselo onesiphene ngulo:

(x+y+z) / nx 100%

Ngokwemiqathango enikiweyo kulo mbuzo, le nkqubo ilandelayo yeequations ingadweliswa:

x + y + z = n

x = n * ( – 0.1 / ( – 0.1 + 0.3 + 0.7) )

y = n * ( 0.7 / ( – 0.1 + 0.3 + 0.7) )

z = n * ( 0.3 / ( – 0.1 + 0.3 + 0.7) )

Beka ezi nxaki zingentla kule fomula ilandelayo ukubala ireyithi enesiphene:

( – 0.1 * n / ( – 0.1 + 0.3 + 0.7) ) + ( 0.7 * n / ( – 0.1 + 0.3 + 0.7) ) + ( 0.3 * n / ( – 0.1 + 0.3 + 0.7) / nx 100%

Izinga lesisombululo esibi li-15.24%.

Ukudibanisa ukubalwa kokunyamezela kunye nomngcipheko we-15,24% yesiphene, imveliso kufuneka ilungiswe ukunyamezela kwendibano.

1. Akukho tyathanga lobungakanani obuvaliweyo, kwaye uhlalutyo kunye nothelekiso alusekelwanga kwikhonkco elipheleleyo le-dimension.

2. Zininzi iimpazamo zengqiqo ezikhoyo.Umhleli utshintshe "ukunyamezela okuphezulu", "ukunyamezela okuphantsi", kunye "nokunyamezela okusemgangathweni".

3. Kubalulekile ukuqinisekisa i-algorithm yokubala amazinga esivuno.

Ireyithi yesivuno sokusetyenzwa kwenxalenye iqhelekile kusasazwa.Oko kukuthi, amathuba okubaiindawo zeplastiki ezenziwe ngoomatshinibakwixabiso labo eliphakathi yeyona inkulu.Kule meko, ubukhulu obunokwenzeka benxalenye yimilinganiselo yayo esisiseko.

Bala ireyithi eneziphene.Lo ngumlinganiselo phakathi kwenani lamalungu anesiphene avelisiweyo kunye nenani lilonke elivelisiweyo.Singawabala njani amanani amanani sisebenzisa ixabiso lesikhewu?Ayinanto yakwenza nexabiso lokugqibela lesithuba esifunekayo?Ukuba imilinganiselo iyisiseko, ngoko inokwahlulwa kwaye isetyenziswe ekubaleni izinga eliphosakeleyo.

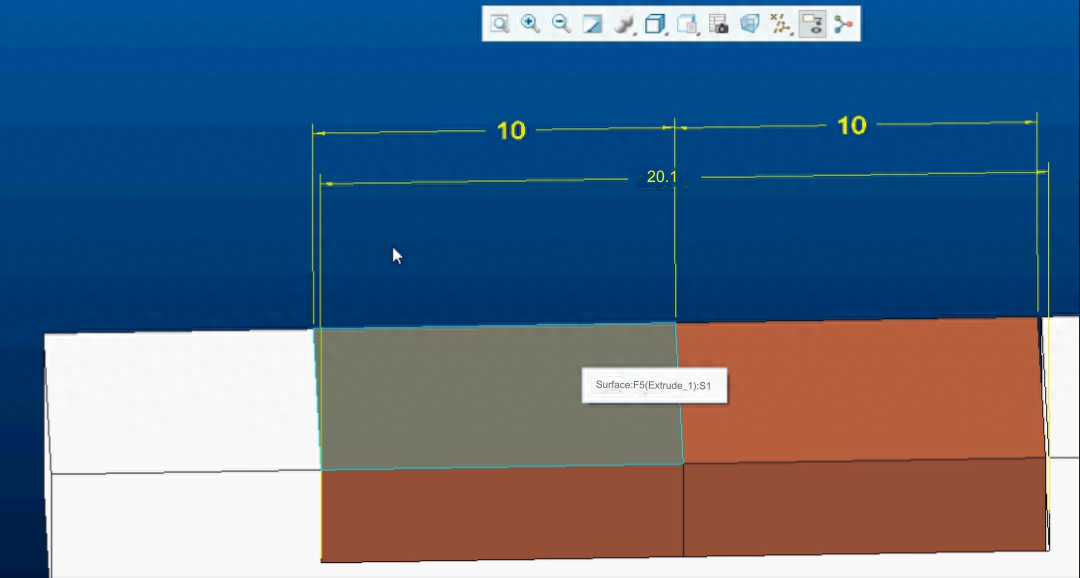

I-Assembly dimension chain case 2

Qinisekisa ukuba umsantsa phakathi kwamalungu mkhulu kuno-0.1mm

Ukunyamezela inxalenye ye-1 yi-10.00 + 0.00/-0.10

Ukunyamezela inxalenye ye-2 yi-10.00 + 0.00/-0.10

Ukunyamezela kwindibano yi-20.1 + 0.10 / 0.00.

Lo gama nje ibandla lisanyamezelene, aliyi kuba nasiphako.

1. Akucaci ukuba yintoni i-gap yokugqibela yendibano, kwaye ngoko ke kunzima ukugweba ukuba ifanelekile.

2. Bala awona maxabiso aphezulu kunye nawona mancinci amaxabiso emvume ngokusekwe kwimilinganiselo yeprojekthi.

Elona xabiso likhulu lesikhewu : 20.2-9.9-9.9=0.4

Ubuncinci bexabiso lomsantsa ngu-20-10-10=0

Akunakwenzeka ukugqiba ukuba ngaba kufanelekile ngokusekelwe kwisithuba phakathi kwe-0-0.4.Isigqibo sokuba "akukho nto yendibano embi" ayinyani..

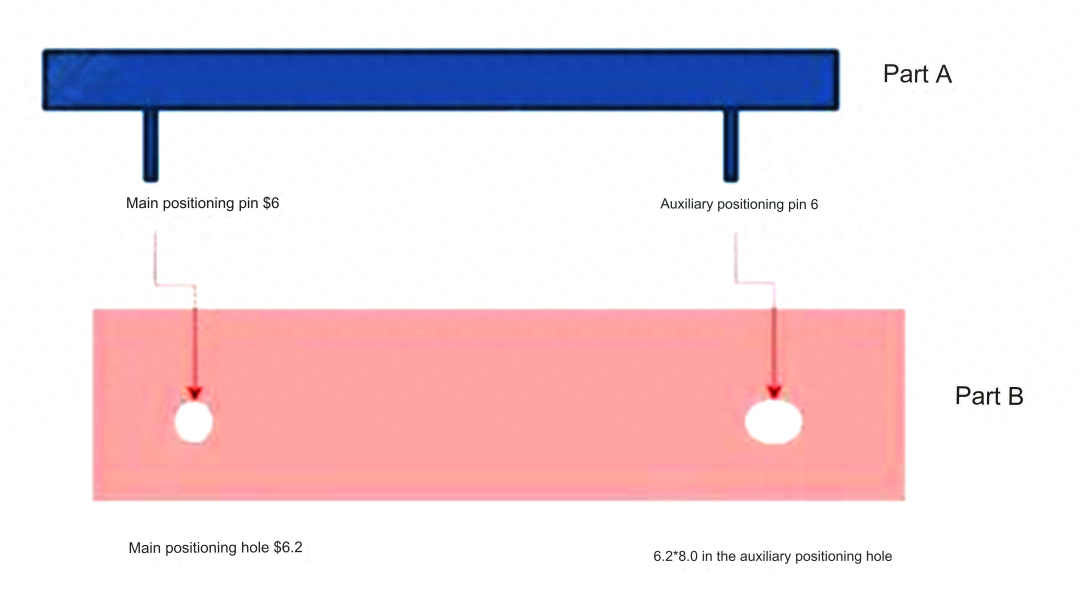

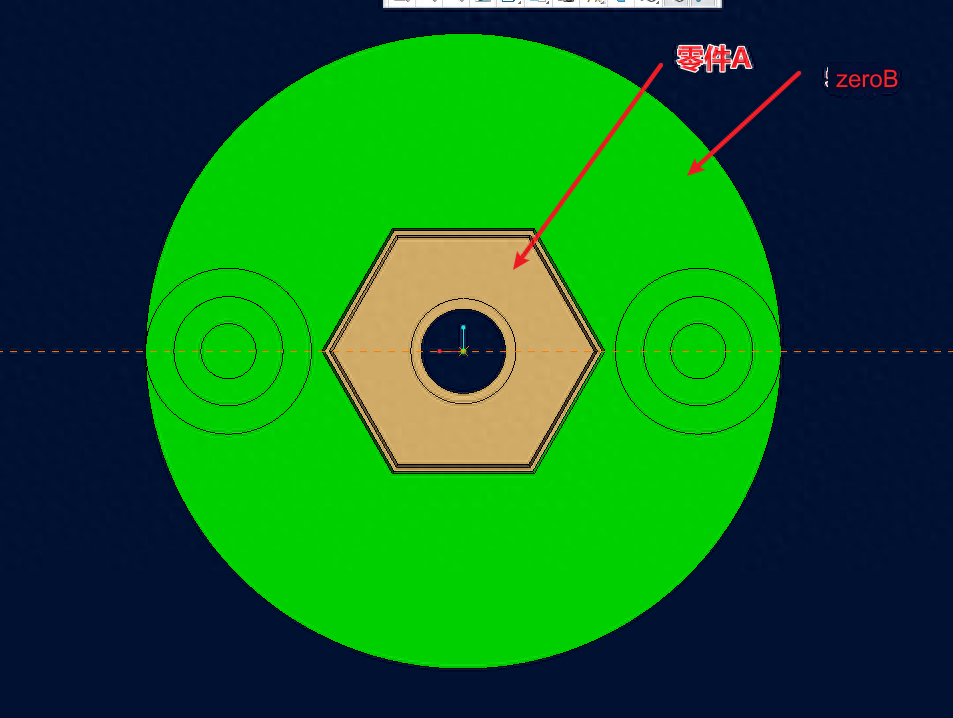

I-Assembly dimension chain case 3

Phakathi kwemingxunya yeqokobhe kunye nezithuba, kukho ubungakanani obuthathu bekhonkco.

Ukunyamezelana komgama ophakathi phakathi kwezithuba ezimbini kufuneka kube ngaphantsi kokunyamezela kwendibano yamadoda kwikhonkco lokuqala lomlinganiselo.

Ukunyamezelana phakathi kwezithuba kunye nemingxuma kufuneka ibe yincinci kwikhonkco lesibini le-dimension kunomgama ophakathi wezithuba ezimbini.

Ikhonkco leSithathu soMdaniso: Unyamezelo lwesithuba sesithuba kufuneka lube ngaphantsi kwelo lomngxuma.

Ukunyamezela inxalenye A yi-100 + -0.15

Ukunyamezela inxalenye B: 99.8 + 0.15

Umgama phakathi kwezikhonkwane zeziko lecandelo A kunye necandelo B yi-70 + -0.2

Umgama phakathi kwemingxuma esembindini yecandelo B yi-70 + -0.2

Idayamitha yendawo yephini ye-A yi-6+0.00/0.1

Idayamitha yenxalenye B yomngxuma wokumisa yi-6.4+0.1/0.0

Njengoko kuboniswe kulo mfanekiso, uphawu lokunyamezela aluyi kuchaphazela indibano ukuba idibana nokunyamezela.

Ukunyamezelana kwezikhundla kusetyenziselwa ukuqinisekisa ukuba iimfuno zendibano yokugqibela zinokufikelelwa.Imingxuma yezikhonkwane kunye nezikhonkwane kwicandelo A kunye no-B kunye neendawo zazo ziphawulwe kusetyenziswa izidanga.

I-Assembly dimension chain case 4

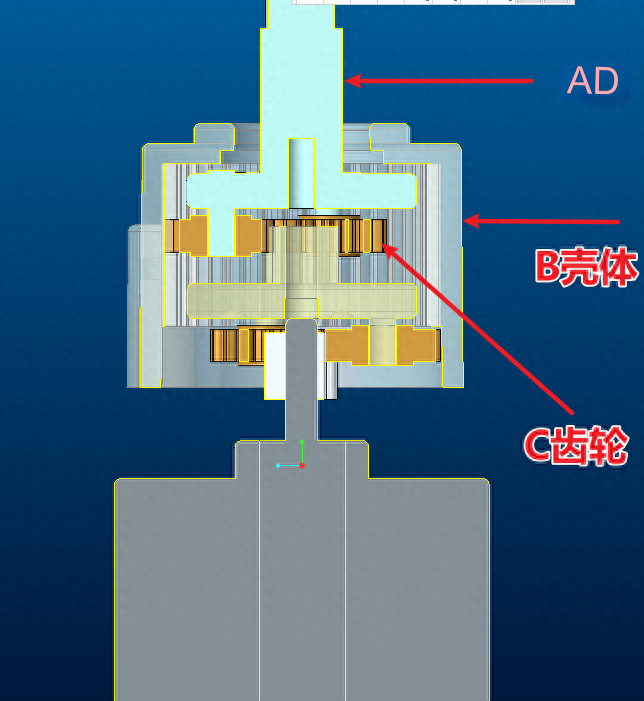

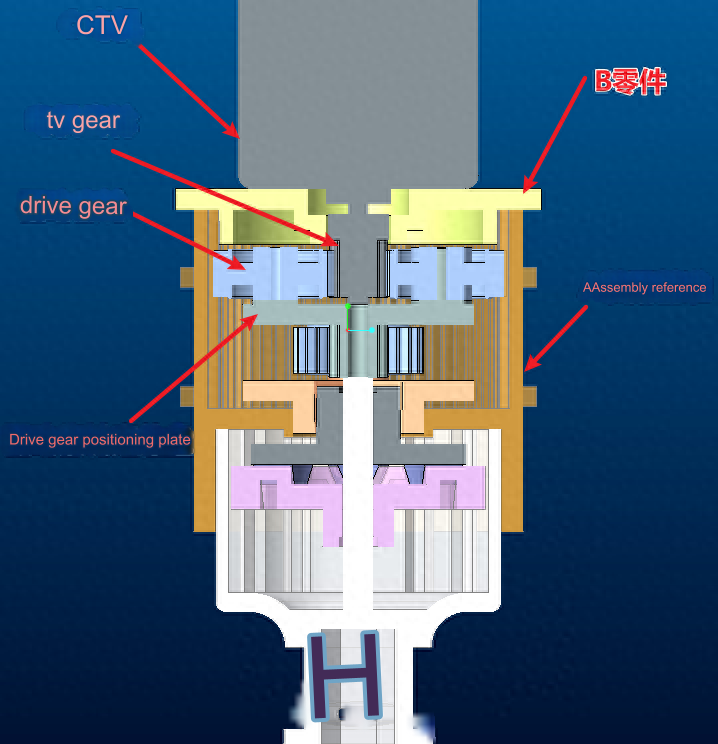

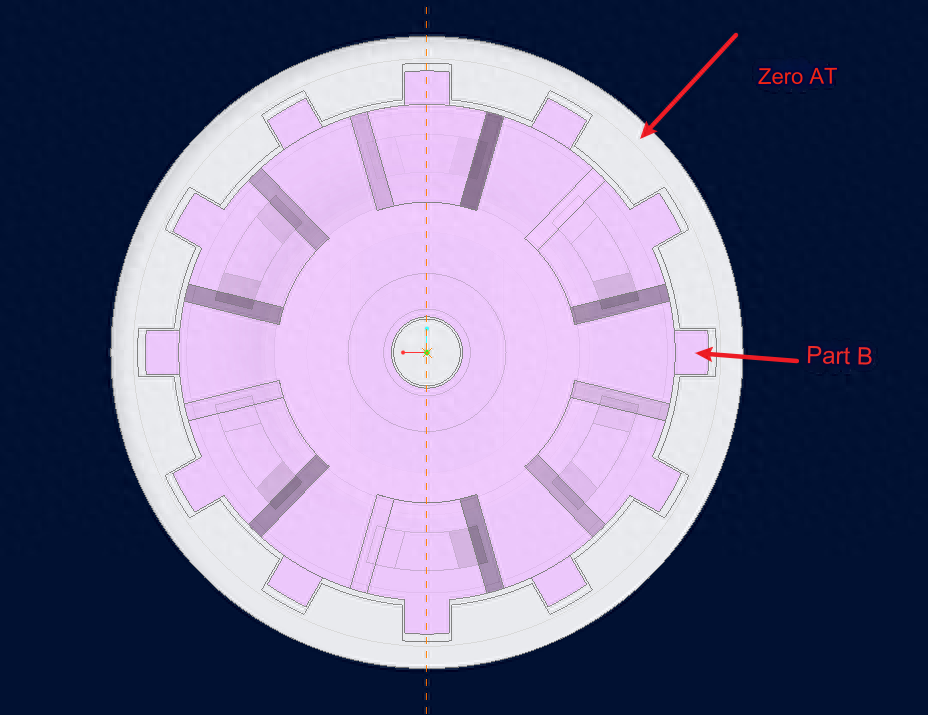

Njengoko kubonisiwe kumfanekiso, okokuqala qinisekisa ukunyamezela kwezindlu ze-B.Ukunyamezela kwindibano ye-axis kufuneka ibe ngaphantsi kwe-B yezindlu kunye ne-C gear.Ukutshintshwa kwezindlu ze-B akuyi kuchaphazeleka ukuba kusetyenziswa izixhobo ze-C.

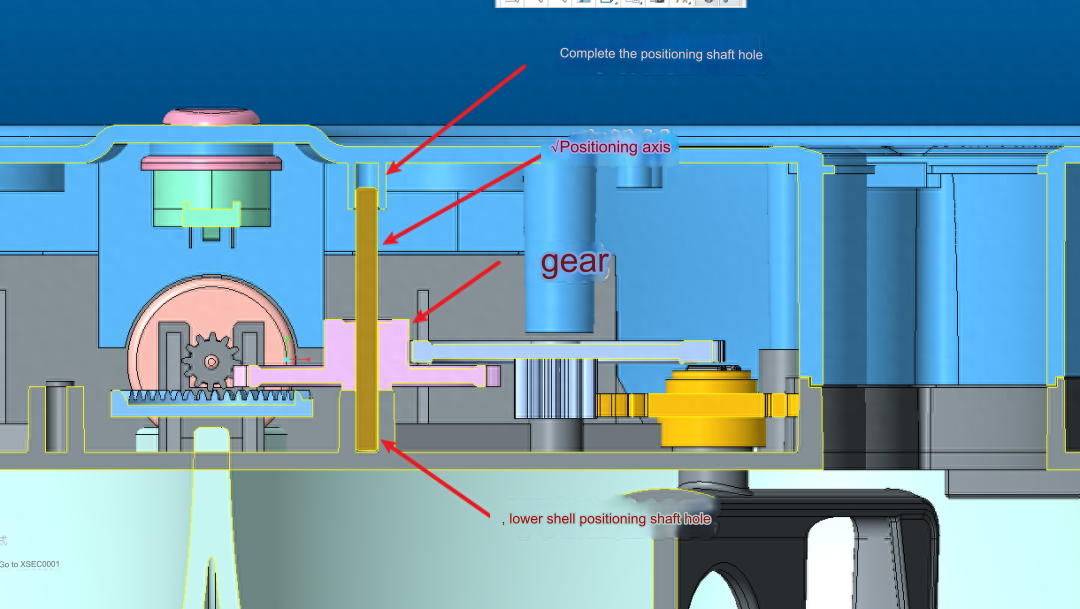

I-Assembly dimension chain case 5

I-perpendicularity ye-axis yendawo kwiqokobhe elisezantsi itshixiwe.

Ukuqinisekisa ukuma, igobolondo elisezantsi kunye ne-shaft yokumisa kufuneka zidityaniswe ngonyamezelo olukhulu kunolo lweqokobhe eliphezulu.

Ukuthintela i-shaft ukuba ikhutshwe kwindawo yayo emva kokuba igobolondo eliphezulu lihlanganiswe, ukunyamezela phakathi kweegobolondo eziphezulu kunye nezisezantsi kufuneka kube kukhulu kunokunyamezela ukuhlanganisana kwe-shaft yokumisa.

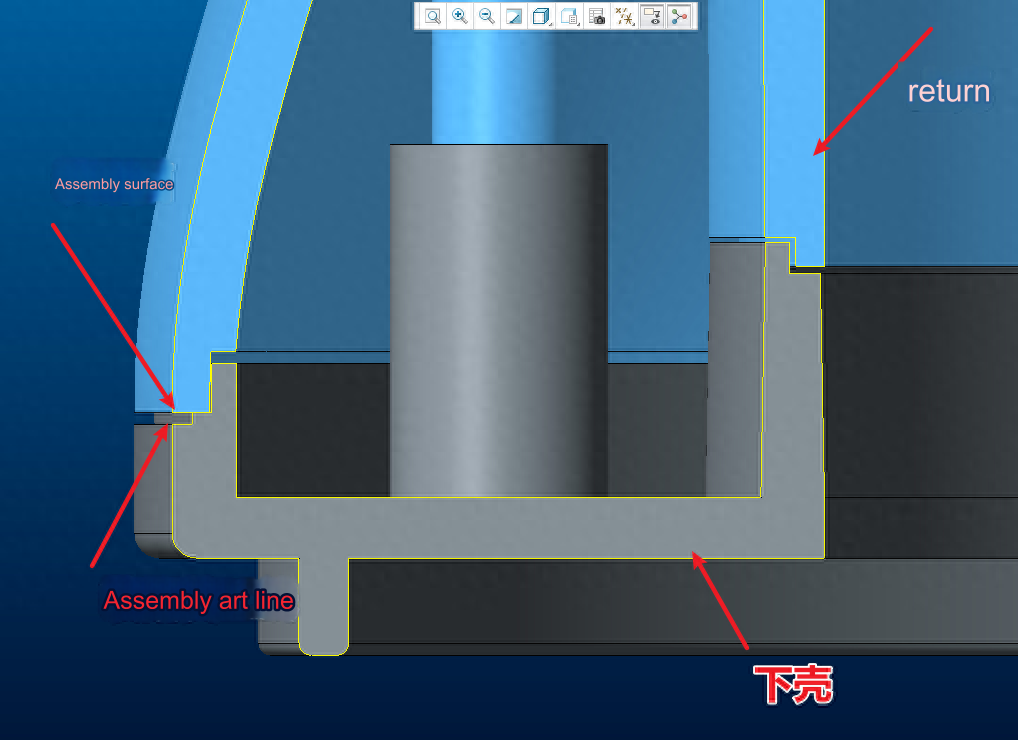

I-Assembly dimension chain case 6

Ukuqinisekisa ukuhambelana kokuphakama komgca wobugcisa ngaphandle kwendibano, ukunyamezela kwi-concave joint yezindlu ezisezantsi kufuneka kube kuncinci kunoko kudibeneyo kwi-convex yendlu ephezulu.

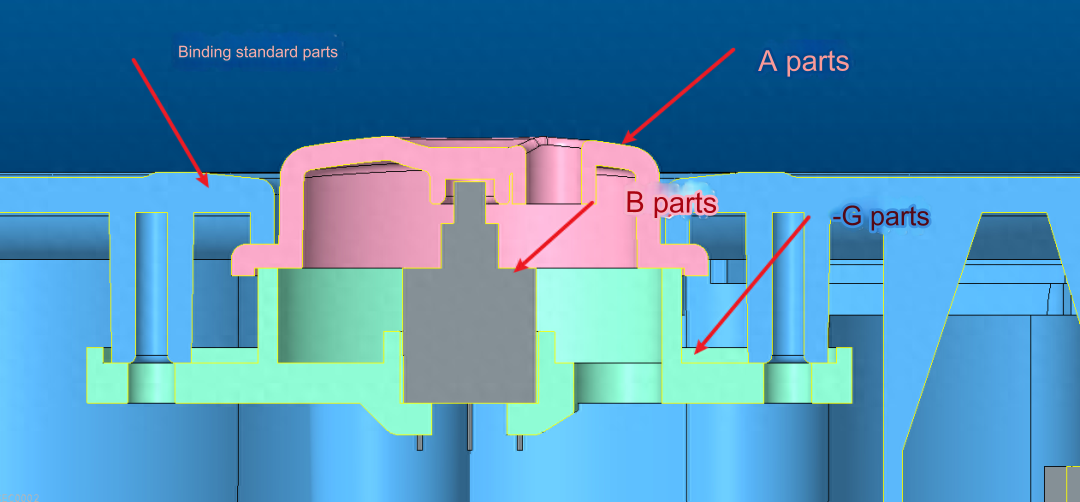

I-Assembly dimension chain case 7

Ukuqinisekisa ukuba akukho msantsa phakathi kwamacandelo A kunye no-B, ukunyamezela kwecandelo A kunye nenxalenye yendibano yesiseko kufuneka ibe nkulu kunecandelo B kunye necandelo C lidibene.

I-Assembly dimension chain case 8

Okokuqala, njengoko kubonisiwe kumzobo: jonga kuqala ukunyamezela kwendibano A.

Ukunyamezelana phakathi kwedatha edityanisiweyo A kunye nemoto C kufuneka ibencinci kunoko phakathi kwemoto B kunye necandelo B.

Ukuqinisekisa ukujikeleza okugudileyo, i-drive gear kufuneka ijikeleze kakuhle.Uluhlu lwedatha yendibano kunye nokunyamezela izixhobo zokuqhuba kufuneka kube ngaphantsi kwenye.

I-Assembly dimension chain case 9

Ukumakisha ukunyamezela kwimeko yendibano ye-multipoint, i-shaft encinci kunye nomgaqo wemingxuma emikhulu isetyenziswa.Oku kuya kuqinisekisa ukuba akukho kuphazamiseka kwendibano.

I-Assembly dimension chain case 10

Ukuphazamiseka kweNdibano akuyi kwenzeka ngenxa yokuba ukunyamezela komngxuma kulungile kwaye i-axis ayibi.

Ngobuchwephesha obuphambili be-Anebon ngokufanayo nomoya wethu wokuvelisa izinto ezintsha, intsebenziswano efanayo, izibonelelo kunye nophuhliso, siza kwakha ikamva eliqaqambileyo kunye neshishini lakho elibekekileyo le-OEM Manufacturer Custom High.Amalungu e-aluminiyam achanekileyo, iindawo zentsimbi ezijikayo,iindawo zokugaya ze-cnc, Kwaye kukho nabahlobo abaninzi abasondele phesheya abeze ukuze babonwe, okanye basiphathise ukuba sibathengele ezinye izinto.Uya kwamkeleka kakhulu ukuba uze eTshayina, kwisixeko sase-Anebon nakwindawo yokuvelisa yase-Anebon!

I-China i-Wholesale yase-China eyenziwe ngoomatshini, iimveliso ze-cnc, iintsimbi ezijike iintsimbi kunye nesitampu sobhedu.I-Anebon inetekhnoloji yemveliso ephucukileyo, kwaye ifuna ukwenza izinto ezintsha kwiimveliso.Kwangaxeshanye, inkonzo entle iye yaphucula igama elihle.I-Anebon ikholelwa ukuba nje ukuba uyayiqonda imveliso yethu, kufuneka uzimisele ukuba ngamahlakani nathi.Ndijonge phambili kumbuzo wakho.

Ixesha lokuposa: Oct-12-2023