Shin kun san waɗanne filaye ne ke buƙatar ƙarin daidaito don sassan injina?

Jirgin sama:

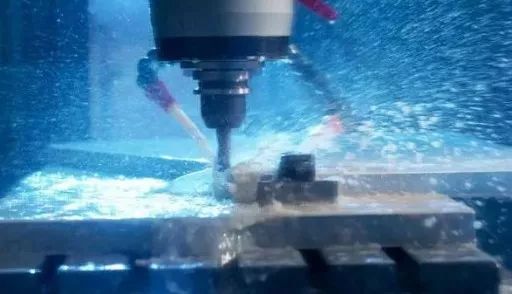

Sassan masana'antar sararin samaniya kamar injin turbine ko kayan aikin jirgin sama suna buƙatar injina da madaidaicin madaidaicin, kuma cikin tsananin haƙuri.Anyi wannan don tabbatar da aiki da aminci.Ruwan injin jet, alal misali, na iya buƙatar daidaito tsakanin microns don kiyaye ingantaccen ƙarfin kuzari da kwararar iska.

Na'urorin likitanci:

Don tabbatar da aminci da daidaitawa, duk sassan da aka kera don na'urorin likita kamar kayan aikin tiyata ko na'urorin da aka dasa dole ne su kasance daidai.Gyaran kasusuwa na al'ada, alal misali, na iya buƙatar madaidaicin girma da ƙarewa a saman don tabbatar da dacewa da haɗin kai a cikin jiki.

Mota:

A cikin masana'antar kera, ana buƙatar daidaito don sassa kamar watsawa da sassan injin.Madaidaicin kayan aikin watsawa ko allurar mai na iya buƙatar juriya mai ƙarfi don tabbatar da ingantaccen aiki da dorewa.

Kayan lantarki:

Ana buƙatar sassan injina a cikin masana'antar lantarki su kasance daidai sosai don takamaiman buƙatun ƙira.Madaidaicin mashin ɗin microprocessor na iya buƙatar juriya mai ƙarfi don daidaitawa daidai da rarraba zafi.

Makamashi mai sabuntawa:

Don haɓaka samar da makamashi, da kuma tabbatar da dogaro, ɓangarorin da aka ƙera a cikin fasahohin da za a iya sabunta su kamar filayen hasken rana ko abubuwan injin turbin iska suna buƙatar daidaito.Tsarin injin injin injin injin injin injin injin injin injin na iya buƙatar ainihin bayanan bayanan haƙori da jeri don haɓaka ƙarfin samar da wutar lantarki.

Me game da wuraren da daidaiton kayan aikin injin ba su da wahala?

Gina:

Wasu sassa, kamar masu ɗaure da kayan aikin gini, waɗanda aka yi amfani da su wajen ayyukan gini, ƙila ba za su buƙaci daidaici ɗaya da mahimman abubuwan injina ko abubuwan haɗin sararin samaniya ba.Bakin ƙarfe a cikin ayyukan ginin ƙila ba ya buƙatar juriya iri ɗaya kamar ingantattun abubuwan da ke cikin injunan madaidaicin.

Masana'antar Kayan Aiki:

Wasu sassa a cikin masana'antar kayan daki, kamar datsa na ado, braket ko kayan masarufi, basa buƙatar zama daidaici.Wasu sassa, kamar ingantattun kayan aikin injina a cikin ingantattun kayan daki waɗanda ke buƙatar daidaito, suna da ƙarin juriya.

Kayan aiki don amfanin gona:

Wasu ɓangarorin injunan aikin gona kamar maɓalli, tallafi ko murfin kariya maiyuwa baya buƙatar riƙe su cikin tsananin juriya.Bakin da aka yi amfani da shi don hawa wani ɓangaren kayan aikin da ba daidai ba na iya buƙatar daidaito daidai da sassan injunan aikin gona.

Daidaiton aiki shine matakin daidaita girman saman, siffa da matsayi zuwa ma'aunin lissafi da aka kayyade a cikin zane.

Matsakaicin girman shine madaidaicin ma'auni na geometric don girman.

Geometry na saman da'irar ce, silinda ko jirgin sama.;

Yana yiwuwa a sami saman da ke layi ɗaya, perpendicular ko coaxial.Kuskuren injina shine bambanci tsakanin ma'auni na geometric na wani sashi da ingantattun sigogin joometric su.

1. Gabatarwa

Babban manufar machining daidaito shine don samar da samfurori.Dukkanin daidaiton injina da kurakuran injina sharuɗɗan ne da ake amfani da su don kimanta ma'auni na geometric na saman da aka kera.Ana amfani da darajar haƙuri don auna daidaiton injina.Mafi girman daidaito, ƙarami da daraja.Ana iya bayyana kuskuren mashin ɗin azaman ƙimar lambobi.Mafi girman ƙimar lambobi shine mafi girman kuskuren.Sabanin haka, babban madaidaicin aiki yana da alaƙa da ƙananan kurakuran sarrafawa.Akwai matakan haƙuri 20, kama daga IT01 zuwa IT18.IT01 shine matakin madaidaicin mashin ɗin wanda shine mafi girma, IT18 mafi ƙanƙanta, kuma IT7 da IT8 gabaɗaya sune matakan da matsakaicin daidaito.matakin.

Ba zai yiwu a sami ainihin sigogi ta amfani da kowace hanya ba.Muddin kuskuren sarrafawa ya faɗi cikin kewayon haƙuri da aka ƙayyade ta ɓangaren zanen kuma bai fi aikin sashin ba, ana iya ɗaukar daidaiton aiki.

2. Abubuwan da ke da alaƙa

Daidaiton girman girman:

Yankin juriya shine yanki inda ainihin girman sashi da tsakiyar yankin haƙuri daidai suke.

Daidaiton siffa:

Matsayin da siffar geometric na farfajiyar kayan aikin da aka yi amfani da shi ya dace da madaidaicin nau'i na geometric.

Daidaiton matsayi:

Bambancin daidaiton matsayi tsakanin saman sassan da ake sarrafa su.

Dangantaka:

Lokacin zayyana sassan na'ura da ƙayyade daidaiton mashin ɗin su, yana da mahimmanci don sarrafa kuskuren sifa tare da haƙurin matsayi.Kuskuren matsayi kuma yakamata ya zama ƙarami fiye da juriyar girman girma.Don madaidaicin sassa da sassa masu mahimmanci, abubuwan da ake buƙata don daidaiton siffar ya kamata su kasance mafi girma.

3. Hanyar Daidaitawa

1. Daidaita tsarin tsari

Daidaita hanyar don yanke gwaji: Auna girman, daidaita adadin yankan kayan aiki sannan a yanke.Maimaita har sai kun isa girman da ake so.Ana amfani da wannan hanyar musamman don ƙananan tsari da kuma samar da yanki ɗaya.

Hanyar d'ajustement: Don samun girman da ake so, daidaita matsayi na dangi na kayan aikin inji, kayan aiki da kayan aiki.Wannan hanyar tana da haɓaka mai girma kuma galibi ana amfani da ita wajen samarwa da yawa.

2. Rage kurakuran kayan aikin injin

1) Haɓaka daidaiton masana'anta na sandal

Yakamata a inganta daidaiton jujjuyawa.

1 Zaɓi madaidaicin mirgina bearings;

2 Yi amfani da igiyoyin matsa lamba masu ƙarfi tare da madaidaicin madaidaicin ƙuƙuman mai da yawa.

3 Yin amfani da madaidaicin madaidaicin magudanar ruwa

Yana da mahimmanci don inganta daidaiton na'urorin haɗi.

1 Haɓaka daidaiton jaridar spindle da ramukan goyan bayan akwatin;

2 Haɓaka daidaiton daidaitawar saman tare da ɗaukar nauyi.

3 Auna da daidaita kewayon radial na sassa don daidaitawa ko rama kurakurai.

2) Preloading bearings yadda ya kamata

1 Zai iya kawar da gibba;

2 Ƙara taurin kai

3 Kuskuren abin juyi Uniform.

3) Kauce wa tunani na spindle daidaito a kan workpiece.

3. Kuskuren sarkar watsawa: Rage su

1) Daidaitaccen watsawa da adadin sassa suna da yawa.

2) Matsayin watsawa ya fi ƙanƙanta lokacin da nau'in watsawa yana kusa da ƙarshe.

3) Daidaitaccen yanki ya kamata ya fi sauran sassan watsawa girma.

4. Rage sawar kayan aiki

Sabunta kayan aikin yana da mahimmanci kafin su kai matakin lalacewa mai tsanani.

5. Rage nakasar damuwa a cikin tsarin tsari

Musamman daga:

1) Ƙara ƙarfi da ƙarfin tsarin.Wannan ya haɗa da mafi raunin hanyoyin haɗin gwiwar tsarin tsari.

2) Rage kaya da bambancinsa

Ƙara ƙin tsarin

1 Tsarin tsari mai ma'ana

1) Kamar yadda zai yiwu, rage adadin saman da ke haɗuwa.

2) Hana hanyoyin haɗin gida na ƙananan taurin kai;

3) Abubuwan asali na asali da abubuwa masu goyan baya yakamata su kasance da tsari mai ma'ana da ketare.

2 Inganta taurin lamba akan saman haɗin gwiwa

1) Haɓaka inganci da daidaiton abubuwan da ke haɗa sassan tare a cikin kayan aikin injin.

2) Preloading kayan aikin injin

3) Ƙara daidaiton matsayi na workpiece da kuma rage girman yanayin.

3 Ɗauki madaidaicin matsi da hanyoyin matsayi

Rage nauyi da tasirinsa

1 Zaɓi sigogin lissafi na kayan aiki da yankan yawa don rage ƙarfin yanke.

2 Sai a hada tarkacen guraren wuri guda tare da izinin sarrafa su ya zama daidai da daidaitawa.

6. Za a iya rage nakasar thermal na tsarin tsari

1 Ware hanyoyin zafi kuma rage samar da zafi

1) Yi amfani da ƙananan yankan adadin;

2) Rarrabe roughing da gamawa lokacinabubuwan niƙabukatar high daidaito.

3) Ya zuwa yanzu, raba tushen zafi da injin don rage nakasar thermal.

4) Idan ba za a iya raba tushen zafi ba (kamar sandal bearings ko dunƙule goro nau'i-nau'i), inganta gogayya kaddarorin daga tsarin, lubrication da sauran al'amurran, rage zafi samar, ko amfani da zafi-insulating kayan.

5) Yi amfani da sanyaya iska mai tilastawa ko sanyaya ruwa da sauran hanyoyin watsar da zafi.

2 Ma'aunin zafin jiki

3 Ɗauki ma'auni masu ma'ana don haɗuwa da tsarin kayan aikin injin

1) Yarda da tsarin thermally-symmetrical a cikin akwati na gearbox - daidaitaccen tsari na shinge, bearings da gear watsawa na iya rage lalacewar akwatin ta hanyar tabbatar da cewa zafin jiki na bangon akwatin daidai ne.

2) Zaɓi ƙa'idar taro na kayan aikin injin tare da kulawa.

4 Haɓaka ma'aunin canja wurin zafi

5 Sarrafa zafin yanayi

7. Rage ragowar damuwa

1. Ƙara tsarin zafi don kawar da damuwa a cikin jiki;

2. Shirya tsarin ku ta hanyar da ta dace.

4. Tasirin dalilai

1 Kuskuren ƙa'idar inji

Kalmar “kuskuren ƙa’idar inji” tana nufin kuskuren da ke faruwa lokacin da ake yin mashin ɗin ta amfani da madaidaicin bayanin martaba, ko alaƙar watsawa.Ƙirƙirar rikitattun filaye, zaren da gears na iya haifar da kuskuren inji.

Don sauƙaƙe amfani da shi, maimakon amfani da tsutsa na asali don involute, ana amfani da ainihin tsutsa ta Archimedean ko daidaitaccen bayanin martaba na yau da kullun.Wannan yana haifar da kurakurai a siffar hakori.

Lokacin zabar kayan aiki, ƙimar p ɗin kawai za a iya kusantar (p = 3.1415) saboda akwai iyakataccen adadin hakora akan lathe.Kayan aikin da aka yi amfani da shi don samar da aikin aiki (motsin karkace), ba zai zama daidai ba.Wannan yana haifar da kuskuren fira.

Ana aiwatar da sau da yawa tare da kusan aiki a ƙarƙashin zaton cewa za a iya rage kurakuran ka'idoji don saduwa da buƙatun aiki (10% -15% haƙuri akan girma) don ƙara yawan aiki da rage farashi.

2 kuskuren daidaitawa

Lokacin da muka ce kayan aikin injin yana da gyare-gyaren da ba daidai ba, muna nufin kuskuren.

3 Kuskuren inji

Ana amfani da kalmar kuskuren kayan aikin inji don bayyana kuskuren masana'anta, kuskuren shigarwa, da lalacewa na kayan aiki.Wannan ya haɗa da galibi kurakuran jagora da jujjuyawa na layin jagorar injin-kayan aiki da kuma kuskuren watsawa a cikin sarkar watsa injin-kayan aiki.

Kuskuren jagorar inji

1. Yana da daidaito na jagorar dogo na jagora - bambanci tsakanin jagorancin motsi na sassa masu motsi da manufa mai kyau.Ya hada da:

Ana auna jagorar ta madaidaiciyar Dy (jirgin sama) da Dz (jirgin sama na tsaye).

2 Daidaitawar layin gaba da na baya (hargitsi);

(3) Kurakurai a tsaye ko daidaici tsakanin jujjuyawar igiya da titin dogo a duka jiragen sama na kwance da na tsaye.

2. Daidaitaccen jagorar layin dogo yana da babban tasiri akan yankan mashin ɗin.

Wannan saboda yana la'akari da ƙaurawar dangi tsakanin kayan aiki da kayan aiki wanda kuskuren layin dogo ya haifar.Juyawa aiki ne na jujjuya inda jagorar kwance take da kuskure.Ana iya yin watsi da kurakuran shugabanci a tsaye.Hanyar juyawa yana canza hanyar da kayan aiki ke kula da kuskure.Hanyar tsaye ita ce jagorar da ta fi dacewa da kurakurai yayin shiryawa.Madaidaicin jagororin gado a cikin jirgin sama na tsaye yana ƙayyade daidaiton shimfidar wuri da madaidaiciyar saman injina.

Kuskuren jujjuya kayan aiki na inji

Kuskuren jujjuya sandar sanda shine bambanci tsakanin madaidaicin axis juyi.Wannan ya haɗa da madauwari ta fuskar sandal, madauwari mai madauwari da radial mai madauwari da karkatar sandar kusurwa.

1, Tasirin madauwari runout madauwari akan daidaiton aiki.

① Babu tasiri akan jiyya na cylindrical

② Zai haifar da kuskure ko rashin daidaituwa tsakanin axis na cylindrical da ƙarshen lokacin juyawa da ban sha'awa.

③ Kuskuren zagayowar farar yana haifar da lokacin da ake sarrafa zaren.

2. Tasirin radial spindle yana gudana akan daidaito:

① Kuskuren kewayawa na da'irar radial ana auna ta ta hanyar amplitude runout na rami.

② Za a iya ƙididdige radius na da'irar daga ƙarshen kayan aiki zuwa matsakaicin madaidaicin, ba tare da la'akari da ko ana juyawa ko gundura ba.

3. Tasirin kusurwar karkatarwa na babban shaft geometric axis akan daidaiton machining

① An shirya ma'auni na geometric a cikin hanyar conical tare da kusurwar mazugi, wanda ya dace da motsi na eccentric a kusa da ma'anar ma'anar ma'auni na geometrical lokacin da aka duba shi daga kowane sashe.Wannan darajar eccentric ya bambanta da na hangen nesa axial.

② Axis wani nau'in geometric ne wanda ke jujjuyawa a cikin jirgin.Wannan daidai yake da ainihin axis, amma yana tafiya a cikin jirgin a madaidaiciyar layi mai jituwa.

③ A zahiri, kusurwar babban shaft's axis geometric yana wakiltar haɗin waɗannan nau'ikan lilo guda biyu.

Kuskuren watsawa sarkar watsa kayan aikin inji

Kuskuren watsawa shine bambancin motsi na dangi tsakanin sashin watsawa na farko da sashin watsawa na ƙarshe na sarkar watsawa.

④ Kuskuren masana'anta da sawa akan kayan aiki

Babban kuskure a cikin kayan aiki shine: 1) kuskuren masana'anta na abubuwan sanyawa da abubuwan da ke jagorantar kayan aiki, da tsarin ƙididdigewa da clamping kankare.2) Bayan taro na daidaitawa, kuskuren girman dangi tsakanin waɗannan sassa daban-daban.3) Sawa a saman kayan aikin da abin ya shafa.Abubuwan da ke cikin Wechat Processing Metal yana da kyau, kuma ya cancanci kulawar ku.

⑤ kurakurai masana'antu da lalacewa na kayan aiki

Nau'o'in kayan aiki daban-daban suna da tasiri daban-daban akan daidaiton mashin ɗin.

1) Daidaiton kayan aiki tare da ƙayyadaddun ma'auni (irin su drills, reamers, keyway milling cuts, round broaches, da dai sauransu).Matsakaicin ma'auni yana shafar kai tsaye ta wurin aikin aikin.

2) Daidaitaccen kayan aiki (kamar kayan aikin juyawa, kayan aikin niƙa, ƙafafun niƙa, da dai sauransu), zai shafi daidaitattun siffar kai tsaye.Daidaitaccen siffar aikin aikin yana shafar daidaitattun siffar kai tsaye.

3) Kuskuren sifa a cikin ruwan yankan ya ɓullo (kamar hobs, spline hobos, gear shaper cutters, da dai sauransu).Kuskuren ruwa zai shafi daidaiton siffar saman.

4) Daidaitaccen masana'anta na kayan aiki ba ya shafar daidaiton sarrafa shi kai tsaye.Duk da haka, yana da dadi don amfani.

⑥ Tsari tsarin damuwa nakasawa

Ƙarƙashin rinjayar ƙarfi da nauyi, tsarin zai lalace.Wannan zai haifar da kurakurai na sarrafawa kuma zai shafi kwanciyar hankali.Babban abin la'akari shine nakasar kayan aikin injin, nakasar kayan aiki da nakasar duka tsarin sarrafawa.

Yanke ƙarfi da daidaiton injina

An ƙirƙiri kuskuren cylindricity lokacin da ɓangaren injin ɗin ya kasance mai kauri a tsakiya kuma sirara a ƙarshensa, dangane da nakasar da injin ya haifar.Don sarrafa abubuwan shaft, kawai nakasawa da damuwa na aikin aikin ana la'akari da su.The workpiece bayyana lokacin farin ciki a tsakiya da kuma bakin ciki a iyakar.Idan kawai nakasawa da aka yi la'akari da aiki nacnc shaft machining sassashi ne nakasawa ko kayan aikin injin, to, siffar aikin aikin bayan aiki zai kasance kishiyar sassan shaft ɗin da aka sarrafa.

Tasirin matsawa ƙarfi a cikin daidaiton injina

Aikin aikin zai lalace lokacin da aka matse shi saboda ƙarancin taurinsa ko rashin matsewar da bai dace ba.Wannan yana haifar da kuskuren sarrafawa.

⑦ Thermal nakasawa a cikin tsarin tsari

Tsarin tsari ya zama mai zafi da lalacewa a lokacin sarrafawa saboda zafi da aka samar ta hanyar zafi na waje ko tushen zafi na ciki.Nakasar thermal yana da alhakin 40-70% na kurakurai na injina a cikin manyan kayan aiki da ingantattun injina.

Akwai nau'ikan daman Thermal guda biyu na aikin da zai iya shafar sarrafa gwal: suturar rigar da ba a daidaita dumama ba.

⑧ Rage Damuwa a cikin Kayan Aiki

Ƙarfafa damuwa a cikin saura yanayi:

1) Ragowar damuwa da aka haifar a lokacin maganin zafi da aikin kera amfrayo;

2) Sanyin gyaran gashi na iya haifar da damuwa.

3) Yanke na iya haifar da damuwa saura.

⑨ Gudanar da tasirin muhalli

Yawancin ƙananan ƙwayoyin ƙarfe da yawa akan wurin sarrafawa.Wadannan kwakwalwan ƙarfe na ƙarfe za su yi tasiri a kan daidaiton machining ɓangaren idan an samo su kusa da matsayi na ramin ko saman sararin samaniya.juya sassa.Kwakwalwar ƙarfe da ƙanƙanta don gani za su yi tasiri kan daidaito a ingantaccen aiki mai inganci.Sanannen abu ne cewa wannan tasirin tasirin zai iya zama matsala, amma yana da wuya a kawar da shi.Dabarar ma'aikacin ita ma babbar al'amari ce.

Manufar farko ta Anebon ita ce ba ku abokan cinikinmu kyakkyawar dangantaka ta kasuwanci, ba da kulawa ta musamman ga dukkansu don Sabuwar Zane-zane na OEM Shenzhen Madaidaicin Hardware Factory Custom Fabrication CNC niƙa tsari, madaidaicin simintin gyare-gyare, sabis na samfur.Kuna iya buɗe mafi ƙarancin farashi anan.Hakanan zaku sami samfuran inganci da mafita da sabis mai ban mamaki anan!Kada ku yi jinkirin kama Anebon!

Sabuwar Zane-zanen Kaya don Sabis ɗin Injin CNC na China da CustomCNC Machining Service, Anebon yana da lambobi na dandamali na kasuwancin waje, wanda shine Alibaba, Globalsources, Kasuwar Duniya, Made-in-china."XinGuangYang" HID samfurori da mafita suna sayar da su sosai a Turai, Amurka, Gabas ta Tsakiya da sauran yankuna fiye da kasashe 30.

Idan kuna son faɗi sassan da aka kera, da fatan za a ji daɗin aika hotuna zuwa Imel na hukuma na Anebon: info@anebon.com

Lokacin aikawa: Dec-20-2023