Shin kun san hanyoyin da yawa don daidaitaccen saitin kayan aiki akan lathes CNC?

Hanyar Binciken Taɓa: - Wannan hanyar tana amfani da binciken da ya taɓa kayan aiki don auna matsayinsa dangane da wurin nunin injin.Yana ba da cikakkun bayanai game da diamita da tsayin kayan aiki.

Kayan aiki Pre-Seter:Ana amfani da kayan aiki da aka riga aka saita don auna ma'auni na kayan aiki a wajen na'ura.Wannan hanyar tana ba da damar saita kayan aiki cikin sauri da daidai.

Hanyar Kashe Kayan aiki:- A cikin wannan hanyar, mai aiki yana auna tsayi da diamita na kayan aiki ta amfani da kayan aiki irin su calipers da micrometers.Sannan ana shigar da ƙimar cikin tsarin sarrafa injin.

Ma'aunin Laser Tool:Ana amfani da tsarin Laser don saitawa da auna girman kayan aiki.Ta hanyar ƙaddamar da hasken wuta na Laser a kan yankan kayan aiki, suna ba da cikakkun bayanai na kayan aiki masu sauri.

Hanyar Gane Hoto:Babban tsarin kwamfuta na iya amfani da fasahar gano hoto don ƙididdige girman kayan aiki ta atomatik.Suna yin hakan ne ta hanyar ɗaukar hotunan kayan aikin, nazarin abubuwan da ke cikin sa sannan kuma ƙididdige ma'auni.

Wannan labari ne mai matukar amfani.Labarin ya fara gabatar da ka'idoji da ra'ayoyin da ke bayan "hanyar saitin kayan aiki na gwaji" wanda aka saba amfani da shi tare da lathes CNC.Sannan ya gabatar da hanyoyin hannu guda huɗu na saitunan kayan aikin gwaji don tsarin juya CNC.Don inganta daidaiton saitunan kayan aikin sa, an haɓaka shirin sarrafa hanyar yanke gwaji ta atomatik bisa "yanke ta atomatik - aunawa - ramuwa na kuskure".Hakanan an taƙaita hanyoyin saitin kayan aiki huɗu daidai.

1. Ka'ida da ra'ayoyin da ke bayan hanyar saitin kayan aiki don lathes CNC

Fahimtar ka'idodin saitin kayan aiki na CNC na lathe yana da mahimmanci ga masu aiki waɗanda ke son kiyaye ra'ayoyi masu haske game da saitin kayan aiki, sarrafa kayan aikin saitin kayan aiki, da ba da shawarar sabbin hanyoyin.Saitin kayan aiki shine ƙayyadadden matsayi na tsarin daidaitawa na workpiece, wanda ke canzawa lokacin tsara tsarin daidaita kayan aikin injin.Saitin kayan aiki ya haɗa da samun daidaitawar injin don farkon shirin kayan aiki, da kuma ƙayyade kayan aiki na kayan aiki dangane da wannan kayan aikin.

Ana amfani da ƙa'idodi masu zuwa don nuna ra'ayoyi da ra'ayoyin da ke bayan saitin kayan aiki ta amfani da hanyar yanke gwaji.Yi amfani da Tsarin Juya Koyarwar Tauraro na Hua Medieval (lambar sigar 5.30 na software na aikace-aikacen);Yi amfani da tsakiyar ƙarshen fuskar dama akan aikin aikin don asalin shirin kuma saita shi tare da umarnin G92.Shirye-shiryen diamita, daidaitawar aikin aikin na shirin farawa H sune (100,50);shigar da kayan aiki guda huɗu akan mariƙin kayan aiki.Kayan aiki No.1 kayan aiki ne mai jujjuyawa na 90deg kuma kayan aikin No. Reference 2 shine 90deg a waje da'irar mai jujjuyawa mai kyau.wuka, A'a. Wuka ta 4 wuka ce mai zaren triangular tare da kusurwa 60deg (misalan labarin duk iri ɗaya ne).

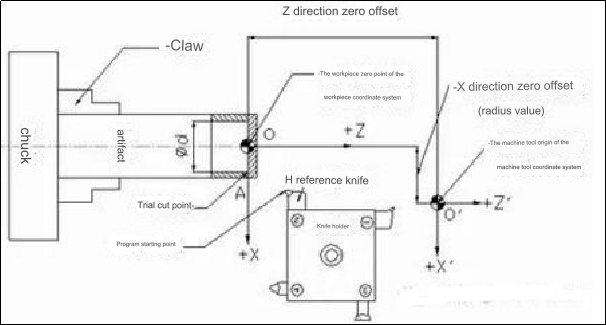

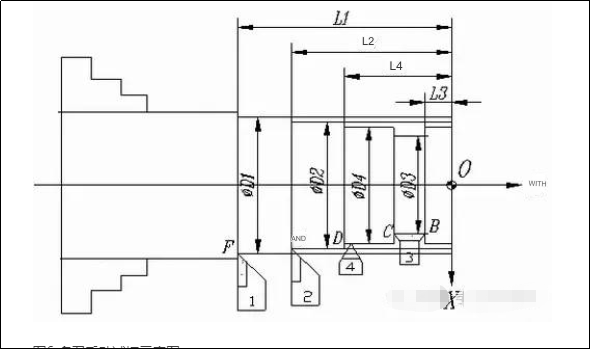

Ana amfani da daidaitawar "kayan injin" don saitin kayan aiki.Kamar yadda aka nuna a cikin adadi 1, kayan aikin tunani "gwaji da hannu yana yanke da'irar waje da ƙarshen fuskar aikin kuma yana yin rikodin daidaitawar kayan aikin injin XZ akan nunin.Daidaita kayan aikin injin don asalin shirin O an samo su ne daga alaƙar haɗin gwiwar kayan aikin injin a batu A da O: XO = XA - Phd, ZO=ZA.Yin amfani da daidaitawar kayan aiki don H dangane da maki O (100,50), a ƙarshe zamu iya samun daidaitawar kayan aikin injin don maki H: XH = 100 - Phd, ZH = ZA + 50.Wannan tsarin daidaita kayan aikin ya dogara ne akan matsayin tip ɗin kayan aiki akan kayan aikin tunani.

Hoto 1 Tsarin tsari don yanke gwaji na hannu da saitunan kayan aiki

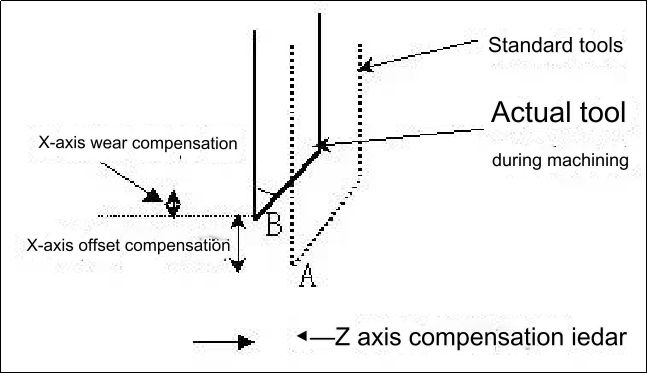

A cikin Hoto 2, ƙaddamarwa tsakanin ma'ana A da tip na kayan aiki na B yana faruwa saboda bambance-bambance a cikin kari da matsayi a cikin X- da Z-direction na kayan aikin da aka ƙulla a cikin mai riƙe kayan aiki.Tsarin daidaitawa na asali na kayan aikin ba ya aiki.Kowace kayan aiki kuma za ta sa a wani nau'i daban-daban yayin amfani.Don haka, dole ne a biya diyya na kayan aiki da ƙimar lalacewa ga kowane kayan aiki.

Don ƙayyade ƙimar kayan aiki, kowane kayan aiki dole ne a daidaita shi zuwa takamaiman wurin tunani (maki A ko B a cikin Hoto 1) akan kayan aikin.CRT tana nuna daidaitawar kayan aikin injin wanda ya bambanta da na kayan aikin kayan aikin da ba na magana ba.Saboda haka, an sanya su a wuri ɗaya.Ta amfani da lissafin hannu ko lissafin software, ana cire haɗin haɗin kayan aikin injin daga na kayan aikin tunani.Ana ƙididdige kashe kayan aikin don kowace na'urar da ba ta dace ba.

Hoto na 2 Ramuwa don kashe kayan aiki da lalacewa

Madaidaicin saitunan kayan aikin yanke gwajin hannu yana iyakance.Ana kiran wannan da rough tooling.Kamar yadda aka nuna a cikin Hoto na 3, don samun ingantattun sakamako a cikin alawus ɗin injin ɗincnc auto part, Za a iya tsara shirin yanke gwaji mai sauƙi mai sarrafa kansa.Ana ci gaba da gyaggyara wuka na tunani ta amfani da manufar "diyya ta atomatik yankan-aunawa-kuskure".Ana amfani da madaidaicin kayan aiki da wurin farawa na kayan aikin da ba na tunani ba don tabbatar da cewa bambanci tsakanin ƙimar koyarwar sarrafawa da ainihin ƙimar ƙimar ta cika daidaitattun buƙatun.Daidaitaccen saitin kayan aiki shine saitin kayan aiki wanda ke faruwa a wannan matakin.

Ya zama gama gari don gyara abubuwan da ba daidai ba bayan gyaran farko.Wannan shi ne saboda tabbatar da matsayin wurin farawa na kayan aiki daidai ne wani abin da ake buƙata don daidaitattun kayan aiki.

Ana samun wannan tsarin saitin kayan aiki na asali ta hanyar haɗa waɗannan matakai guda biyu: gwada yanke wuka da hannu tare da tunani don samun daidaitawar kayan aikin injin don tuntuɓar saitin kayan aiki.- Yi ƙididdigewa ko ƙididdige kayan aikin ta atomatik na kowane kayan aikin da ba na tunani ba.– Wukar magana tana nan a kusan farkon shirin.– The tunani wuka akai-akai kira sama da gwajin yankan shirin.Za a motsa mai riƙe da kayan aiki a cikin MDI ko yanayin mataki don rama kurakurai da gyara matsayi na farawa.Bayan auna girman wukar da ba ta tushe za ta yi ta kiran shirin yankan gwaji akai-akai.Ana gyara gyaran kayan aikin bisa ga wannan diyya.Wannan yana nufin cewa kayan aikin tunani zai kasance a tsaye a daidai farkon shirin.

Hoto na 3 Tsarin Tsari na Saitin Kayan aiki don Yanke Gwajin Wuka da yawa

Bayanin dabarun saitin wuka mai ƙazanta

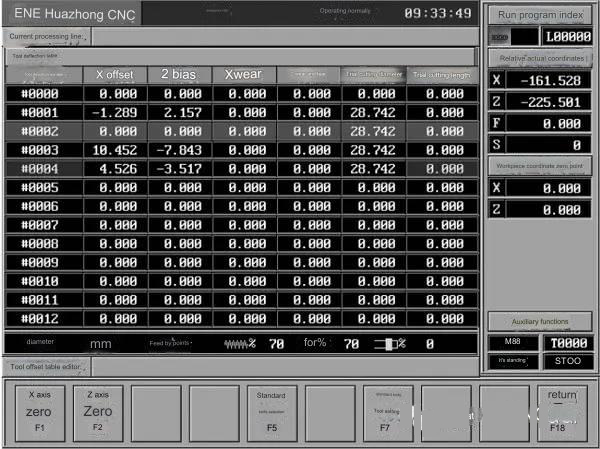

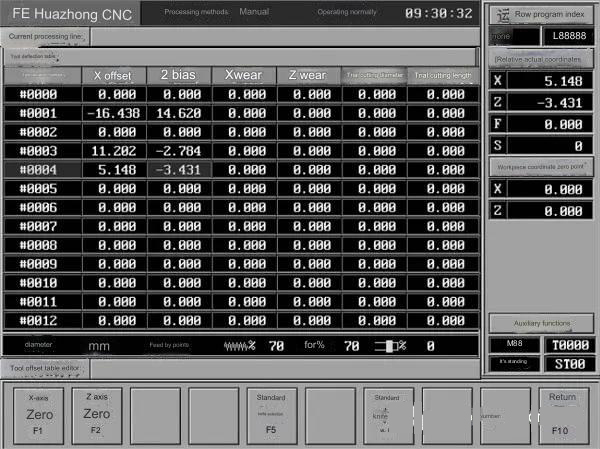

Don shirya saitin kayan aiki, zaku iya amfani da kowane ɗayan hanyoyin masu zuwa: danna maɓallin F2 a cikin menu na ƙasa na tsarin MDI don samun damar teburin kayan aiki.Yi amfani da maɓallan don matsar da mashaya mai haske zuwa wurin lambar kayan aiki wanda ya dace da kowane kayan aiki kuma danna maɓallin F5.Canza darajar X da Z na lambobin kashe kayan aiki #0000 da #0001, sannan danna maɓallin F5.

1) saita hanyar kashe kayan aiki ta atomatik ta zaɓar kayan aikin tunani.

Ana nuna matakan saita kayan aikin a cikin Figures 1 da 4.

Za a iya matsar da mashaya shuɗi mai haske tare da maɓallan don daidaita kayan aikin # 0002 don kayan aiki na lamba 2.Kayan aikin tunani 2. Don saita lamba 2, danna maɓallin F5.Za a saita kayan aikin 2 azaman kayan aiki na asali.

2) Yanke da'irar waje tare da kayan aikin tunani kuma lura da daidaitawar injin-kayan aikin X.Bayan janye kayan aiki, dakatar da injin kuma auna diamita na waje na sashin shaft.

3) Wurin magana yana komawa wurin A da aka rubuta ta hanyar "jog+step".Shigar da PhD da sifili a cikin ginshiƙan don yanke diamita na gwajin da tsayin yanke gwajin bi da bi.

4) Janye daidaitaccen kayan aiki kuma zaɓi lambar kayan aiki mara inganci.Sa'an nan, da hannu canza kayan aiki.Tushen kayan aiki don kowane kayan aikin da ba daidai ba ya kamata a daidaita shi ta gani tare da maki A ta amfani da hanyar "jog + mataki".Daidaita daidaitaccen madaidaicin bayan kayan aikin yana daidaitawa na gani.Idan ka shigar da sifili da PhD a cikin ginshiƙan don tsayin yanke gwaji da diamita, za a nuna ɓangarorin wuka na duk wuƙaƙen da ba na magana ba kai tsaye a cikin ginshiƙin kashewa na X da Z.

5) Da zarar kayan aikin tunani ya koma maki A, MDI za ta gudanar da “G91 G00/ko” G01 X[100 PhD] Z50 don isa wurin farawa na shirin.

Hoto 4 Tsarin tsari na kayan aikin tunani yana saita kayan aiki ta atomatik don daidaitaccen kayan aiki

2. Saita daidaitawar kayan aikin tunani zuwa sifili a wurin saitin kayan aiki kuma ta atomatik nuna hanyar kashe kayan aikin.

Kamar yadda aka nuna a Figure 1 da Figure 5, matakan saitin kayan aiki sune kamar haka:

1) Daidai da mataki (2) a sama.

2) Wuka mai magana yana komawa zuwa wurin yanke gwaji A ta hanyar "jog + mataki" bisa ga ƙimar da aka rubuta.

3) A cikin mahallin da aka nuna a Hoto na 4, danna maɓallin F1 don "saitin X-axis zuwa sifili" kuma danna maɓallin F2 don " saita Z-axis zuwa sifili ".Sannan “haƙiƙan haɗin kai na gaske” da CRT ke nunawa sune (0, 0).

4) Da hannu canza kayan aikin da ba na magana ba don haka tip ɗin kayan aikin sa ya kasance daidai da gani tare da aya A. A wannan lokacin, ƙimar "ƙwararrun ainihin haɗin gwiwar" da aka nuna akan CRT shine kayan aiki na kayan aiki na kayan aiki dangane da kayan aiki.Yi amfani da ▲ da maɓallai don matsar da shuɗi Haskaka lambar kashe kayan aiki na kayan aikin da ba na magana ba, yi rikodin sa kuma shigar da shi cikin matsayi daidai.

5) Daidai da matakin da ya gabata (5).

Hoto 5 Zane na Tsare-tsare na Kayan aiki yana nunawa ta atomatik lokacin da aka saita na'urar Magana zuwa sifili a cikin daidaitawar saitin kayan aiki.

3. Ana ƙididdige hanyar ƙaddamar da wuka ta hanyar ƙididdige yanke gwajin da hannu tare da wukake masu yawa na ɓangaren madauwari na waje.

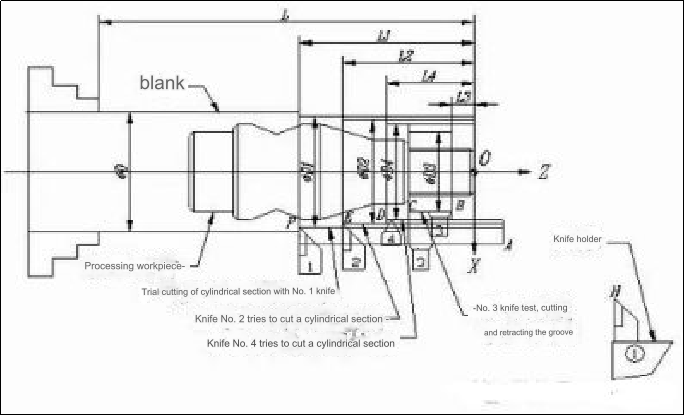

Kamar yadda aka nuna a adadi na 6, tsarin yana daidaita wukake 1, 2 da 4 da hannu kuma yana yanke axis.Sannan yana yin rikodin haɗin gwiwar injin don yanke ƙarshen kowane wuka.(Maki F, D, da E a adadi na 6).Auna diamita da tsawon kowane bangare.Sauya wukar yankan lamba 1.Kamar yadda aka nuna a hoton, yanke hutun kayan aiki.Daidaita igiyar yankan tare da titin dama, yi rikodin daidaitawa don maki B kuma auna L3 da PhD3 kamar yadda yake a cikin adadi.Ƙarfafa haɗin kai tsakanin maki F, E da D ga kowane kayan aiki, da asalin O za a iya ƙaddara ta hanyar kwatanta bayanan da ke sama.

Ana iya ganin cewa haɗin gwiwar kayan aikin injin sune (X2-PhD2 + 100 da Z2-L2 + 50) da kuma haɗin gwiwar kayan aikin injin don farawa shirin daidai da kayan aikin tunani.Ana nuna hanyar lissafin a cikin tebur 1. A cikin ɓangarorin, shigar da ƙididdiga da ƙididdiga masu ƙididdiga.Lura: Nisa yanke gwaji shine tazara tsakanin madaidaicin ma'aunin sifili na workpiece da ƙarshen ƙarshen yanke gwajin a cikin jagorar Z.Hanyoyi masu kyau da mara kyau ana ƙaddara su ta hanyar haɗin kai.

Hoto 6 Tsarin tsari na yankan gwaji na wuka da yawa

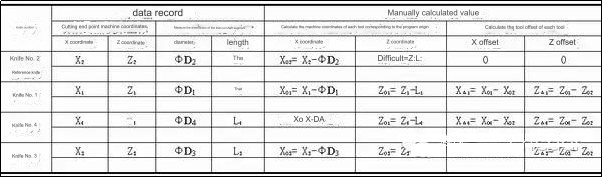

Tebur 1 Lissafi na kayan aiki na kayan aiki don kayan aikin da ba daidai ba

Wannan hanya ta ba da damar yin gwajin gwaji mai sauƙi, kamar yadda ya kawar da buƙatar yin daidaitattun wuraren yanke gwajin.Koyaya, dole ne a lissafta kashe wuka da hannu.Kuna iya ƙididdige madaidaicin kayan aiki da sauri idan kun buga takardar tare da dabara sannan ku cika guraben.

Hoto na 7 Tsarin tsari don saitin kayan aiki na atomatik akan tsarin CNC na Star Century

Multi-kayan aiki atomatik saitin kayan aiki na 4th Century Star CNC tsarin

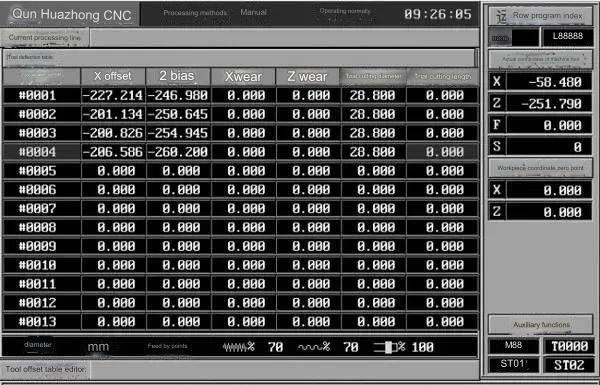

Duk hanyoyin da aka ambata a sama don kashe kayan aiki hanyoyin dangi ne.Bayan ƙwararrun ma'aikatan sun yi saitin sigina da gwajin tsarin, HNC-21T yana ba masu amfani damar zaɓar "cikakkiyar hanyar kashewa" lokacin saita kayan aiki.A cikin shirye-shiryen mashin ɗin, cikakkiyar madaidaicin kayan aiki ya ɗan bambanta da hanyar kashe kayan aikin dangi.Ba lallai ba ne a yi amfani da G92 ko G54 don tsarin haɗin gwiwar workpiece, kuma ba lallai ba ne a soke ramuwar kayan aiki.Dubi shirin O1005 ga misali.Kamar yadda aka nuna a hoto na 6, bayan tsarin ya koma sifili, bari kowace wuka ta gwada da hannu don yanke sashin Silinda.

Cika lambobin kashe kayan aiki don kowane wuka bayan auna tsayi da diamita.An jera tsawon yankan gwaji a cikin ginshiƙi don diamita yankan gwaji.Software na tsarin, ta amfani da hanyar da aka bayyana a cikin "Multiknife Cutting of External Shaft Segment - Manual Calculation for Knife Offset", na iya lissafin atomatik kayan aikin injin na kowane wuka bisa ga asalin shirin.Wannan hanyar saitin kayan aiki shine mafi sauri, kuma ya dace musamman don samar da masana'antu.

Takaitacciyar dabarun saitin kayan aiki guda biyar daidai

Ka'idar daidaitaccen saitin kayan aiki shine "aunawa ta atomatik, yanke gwaji ta atomatik da ramuwar kuskure".Ana iya raba ramuwar kuskure zuwa nau'i biyu: Don aikin MDI na kayan aiki, ko matakan motsi na kayan aiki don rama matsayinsa na farawa;kuma ga kayan aikin da ba daidai ba don rama kayan aikin sa na kayan aiki ko ƙimar sawa.Don guje wa rudani, an tsara Tebu 2 don ƙididdigewa da rikodin ƙima.

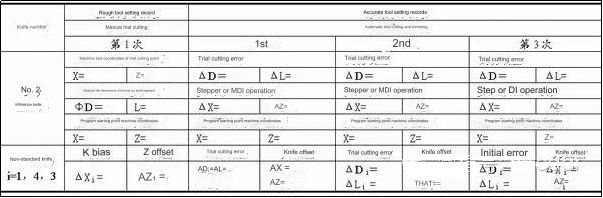

Tebura 2 Tsarin Rikodi na Kayan aiki don Hanyar Yanke Gwaji (Naúrar: mm

1. Gyara hanyar kashewa don kowane kayan aiki marasa daidaituwa bayan kayan aikin tunani ya gyara wurin farawa.

Ana nuna matakan saita kayan aiki a hoto na 3.

Bayan ƙayyadaddun ƙayyadaddun kayan aiki, kayan aikin tunani yakamata su kasance a farkon shirin.Shigar da diyya na kowane kayan aiki marasa daidaituwa a cikin matsayi mai dacewa na tebur.

Yi amfani da shirin O1000 don aiwatar da PhD2xL2 don yin yanke gwaji.

Sa'an nan, auna diamita da tsayin shingen yankan yanki, kwatanta su da darajar a cikin shirin umarni, kuma ƙayyade kuskuren.

Gyara wurin farawa na shirin idan ƙimar kuskuren MDI ko motsi mataki ya fi ƙimar kuskuren MDI.

5) Gyara darajar umarnin O1000 a hankali bisa ma'aunin da aka auna kuma ajiye shirin.Maimaita matakai (2) har sai wurin farawa na kayan aikin tunani ya kasance cikin kewayon daidaito.Yi la'akari da daidaitawar injin-kayan aiki don farkon shirin da aka gyara.Saita haɗin kai a sifili.

6) Kira O1001 (wuka no. 1, No. O1002 (wuka no. 3) ga kowane gwaji yanke, da kuma auna tsawon Li (i=1, 2, 3) da diamita PhDi na kowane sashe.

7) Rarraba kurakurai ta amfani da hanyar tebur 3.

Maimaita matakai na 6 zuwa 7 har sai kurakuran mashin ɗin sun kasance cikin kewayon daidaito kuma an dakatar da kayan aiki a farkon shirin kuma baya motsawa.

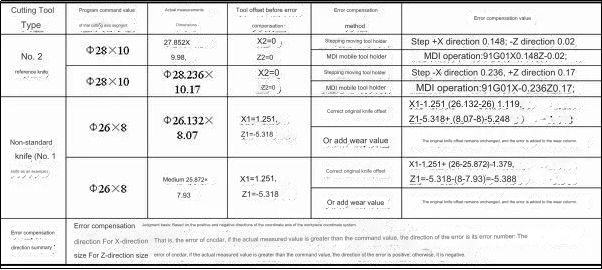

Tebura 3 Misalin ramuwa na kuskure don yanke gwaji ta atomatik na sassan shinge na silinda (raka'a: mm).

2. Gyara wurin farawa na kowane kayan aiki daban-daban

Ka'idar saitin kayan aiki na wannan hanyar ita ce kowane kayan aiki yana daidaita wurin shirinsa na farawa, don haka a kaikaice daidai da matsayi iri ɗaya.

Ana nuna matakan saita kayan aiki a hoto na 3.

Bayan m kayan aiki calibration, da A'a.

Matakai na 2) zuwa (5) na farkon ingantacciyar hanyar saitin kayan aiki iri ɗaya ne.

Yi amfani da shirin O1000 don aiwatar da yanke gwaji.Auna tsawon Li da diamita PhDi na kowane sashe.

Kayan aikin motsi na mataki ko mai riƙe kayan aikin MDI yana rama kurakurai kuma yana daidaita kowane shirin farawa na kayan aiki.

Maimaita matakai (6) har sai wurin farawa na kowane kayan aikin da ba daidai ba ya kasance cikin kewayon daidaiton da aka yarda.

Za'a iya samun dama ga teburin daidaita kayan aiki ta hanyar shigar da haɗin gwiwar dangi da aka nuna akan CRT cikin ginshiƙi na X da Z da ke daidai da adadin kayan aikin.Wannan hanya ta dace kuma mai sauƙi.Wannan hanya tana da sauƙi kuma mai dacewa.

3. Gyara duk hanyoyin kashe kuɗi don kayan aikin da ba daidai ba a lokaci guda bayan gyaggyara matsayi na farawa na shirin tuntuɓar kayan aiki.

Hanyar iri ɗaya ce da ta farkon ingantaccen tsarin saitin kayan aiki.Bambancin da ke tsakanin su biyun shi ne, a mataki na 7, ana kiran shirin O1003, wanda ke kiran wukake guda uku a lokaci guda (O1004 yana cire No. Shirin O1003 ya maye gurbin sashe na 2 na sarrafa kayan aiki. Sauran matakai iri ɗaya ne.

6. Ana iya gyara wukake guda hudu a lokaci guda ta amfani da wannan hanyar

Don gano kuskuren inji, auna diamita na kowane sashe, PhDi, da tsawon kowane sashe, Li (i=2, 1, 4), ta amfani da hanyar daidaita kayan aikin dangi.Yi amfani da MDI ko motsi mataki-mataki zuwa mariƙin kayan aiki don kayan aikin tunani.Gyara wurin farawa shirin.Don kayan aikin da ba na yau da kullun ba, fara gyara gyara ta amfani da na asali.Sa'an nan, shigar da sabon biya diyya.Hakanan dole ne a shigar da kuskuren machining don kayan aikin tunani a cikin ginshiƙin lalacewa.Kira shirin yankan gwaji na O1005 idan an yi amfani da cikakken kayan aikin diyya don daidaita kayan aikin.Sa'an nan, rama kurakuran injiniyoyi na kayan aikin a cikin ginshiƙan lalacewa na lambobin kashe kayan aikin su daban-daban.

Menene tasirin zabar madaidaicin hanyar saitin kayan aiki don lathes na CNC akan ingancinCNC machining sassa?

Daidaito da daidaito:

Za a daidaita kayan aikin yankan da kyau idan an saita kayan aiki daidai.Wannan yana tasiri kai tsaye da daidaito da daidaito a ayyukan injina.Saitin kayan aikin da ba daidai ba na iya haifar da kurakuran ƙira, ƙarancin fage, har ma da guntuwa.

Daidaituwa:

Saitunan kayan aiki masu dacewa suna tabbatar da daidaituwar ayyukan injina da daidaiton inganci a cikin sassa da yawa.Yana rage bambance-bambance a cikin gamawar saman da girma, kuma yana taimakawa wajen kula da juriya.

Rayuwar Kayan aiki da Tufafin Kayan aiki:

Ta hanyar tabbatar da cewa kayan aiki yana aiki da kyau tare da kayan aiki, daidaitaccen saitin kayan aiki zai iya haɓaka rayuwar kayan aiki.Saitunan kayan aikin da ba daidai ba na iya haifar da lalacewa mai yawa da raguwa na kayan aiki, wanda zai rage rayuwar kayan aiki.

Yawan aiki da inganci

Dabarun saitin kayan aiki masu inganci na iya rage lokacin saitin na'ura da haɓaka lokacin aiki.Yana ƙara yawan aiki ta hanyar rage lokutan aiki da haɓaka lokacin yankewa.Wannan yana ba da damar sauye-sauyen kayan aiki da sauri kuma yana rage lokutan mashin ɗin gabaɗaya.

Tsaron Mai aiki

Ana iya shafar amincin mai aiki ta hanyar zabar madaidaicin hanyar saitin kayan aiki.Wasu hanyoyin kamar gano hoto ko ma'aunin kayan aikin laser suna kawar da buƙatar sarrafa kayan aikin da hannu, rage damar rauni.

Manufar Anebon ita ce fahimtar ingantacciyar ɓarna daga masana'anta da samar da babban tallafi ga abokan cinikin gida da na waje da zuciya ɗaya don 2022 High Quality Bakin Karfe Aluminum High Precision Custom MadeCanjin CNC, Milling,cnc kayayyakin gyaradomin Aerospace, Domin fadada mu kasa da kasa kasuwar, Anebon yafi samar da mu kasashen waje abokan ciniki Top quality yi inji sassa, milled sassa da cnc juya sabis.

Sin wholesale China Machinery Parts da kuma CNC machining Service, Anebon goyon bayan da ruhun "bidi'a, jituwa, tawagar aiki da kuma rabawa, sawu, pragmatic ci gaba".Ka ba mu dama kuma za mu tabbatar da iyawarmu.Tare da irin taimakon ku, Anebon ya yi imanin cewa za mu iya ƙirƙirar makoma mai haske tare da ku tare.

Lokacin aikawa: Oktoba-19-2023