Tlhaloso ea Tsebo ea Mechini ka Anebon

Tsebo ea mochini ke bokhoni ba ho utloisisa le ho sebelisa mehopolo, melao-motheo le litloaelo tse fapaneng tsa mochini.Tsebo ea mechine e kenyelletsa kutloisiso ea mechine, mekhoa le lisebelisoa hammoho le lisebelisoa le mekhoa.Sena se kenyelletsa tsebo ea melao-motheo ea mochini, joalo ka matla le motsamao, matla le litsamaiso tsa likere le li-pulleys.Tsebo ea boenjiniere ba mechini e kenyelletsa moralo, tlhokomelo le mekhoa ea ho rarolla mathata, hammoho le melao-motheo ea boenjiniere ba mechini.Tsebo ea mechine e bohlokoa bakeng sa litsebi tse ngata le liindasteri tse sebetsang ka mekhoa ea mechine.Tsena li kenyelletsa boenjiniere, tlhahiso le kaho.

1. Mekhoa ea ho hlōleha ha likarolo tsa mechine ke efe?

(1) Ho senyeha ho feletseng

(2) Ho khopama ho feteletseng ho sa feleng

(3) Ho senyeha ha karolo ea bokaholimo

(4) Ho se sebetse ka lebaka la ho sitisoa ha maemo a tloaelehileng a ho sebetsa

Ke mabaka afe a bakang tlhoko ea khafetsa ea anti-unscrew bakeng sa likhokahano tsa likhoele?

Mohopolo oa mantlha oa anti-unscrew ke ofe?

Ke mekhoa efe e fapaneng e teng ea ho thibela ho lokoloha?

Karabo:

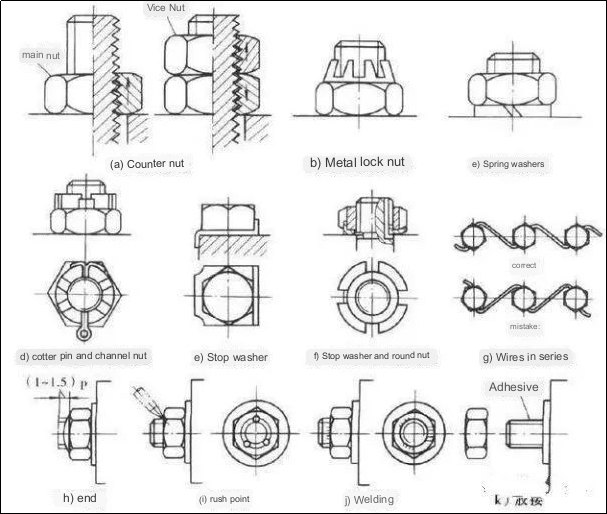

Ka kakaretso, khokahanyo e entsoeng ka khoele e ka phethahatsa mekhoa ea ho itšeha 'me e ke ke ea itokolla ka boomo.Leha ho le joalo, maemong a amang ho thothomela, ho thothomela, kapa ho fetoha ha mocheso ho matla, ho na le monyetla oa hore nate e kopanyang e theohe butle-butle.Lebaka le ka sehloohong la ho hlepha ha khoele ke ho potoloha ho lekanyelitsoeng pakeng tsa lipara tsa khoele.Ka lebaka leo, hoa hlokahala ho kenyelletsa mehato e thibelang ho lokoloha moahong oa sebele.

Mekhoa e sebelisoang hangata e kenyelletsa:

1. friction-based anti-loosening - ho boloka khohlano pakeng tsa lipara tsa khoele ho thibela ho lokoloha, joalo ka ho sebelisa li-washer tsa selemo le linate tse habeli lehlakoreng le ka holimo;

2. Mechanical anti-loosening - utilizing obstructivelikarolo tse entsoeng ka mochineho netefatsa ho thibela ho lokoloha, hangata ho sebelisa linate tse slotted le likhoele tsa cotter, har'a tse ling;

3. Tšitiso e thehiloeng khahlanong le ho lokoloha ha li-thread pairs - ho fetola le ho fetola kamano pakeng tsa lipara tsa khoele, joalo ka ho sebelisa mokhoa o thehiloeng ho tšusumetso.

Sepheo sa ho tiisa maqhama a likhoele ke sefe?

Pfana ka mekhoa e mengata ea ho laola matla a sebelisoang.

Karabo:

Sepheo sa ho tiisa likhokahano tse khoeleng ke ho lumella liboutu ho hlahisa matla a pele a tiisang.Ts'ebetso ena ea ho tiisa pele e leka ho matlafatsa ts'episo le ho tiea ha khokahanyo ho thibela likheo leha e le life kapa motsamao o amanang pakeng tsa likarolo tse hokahaneng tlas'a maemo a ho laela.Mekhoa e 'meli e sebetsang ea ho laola matla a tiisang ke ho sebelisa sekontiri sa torque kapa sekontiri se sa khaotseng sa torque.Hang ha torque e hlokahalang e fihlile, e ka notleloa sebakeng.Ntle le moo, bolelele ba bolt bo ka lekanyetsoa ho laola matla a pele a tiisang.

Ho thella ho fapana joang le ho thellisa ka mabanta?

Moqapi oa koloi ea V-belt, ke hobane'ng ha ho na le moeli ho bonyane ba bophara ba pulley e nyenyane?

Karabo:

Elastic sliding e emela tšobotsi ea tlhaho ea ho khanna mabanta e ke keng ea qojoa.E etsahala ha ho e-na le phapang pakeng tsa tsitsipano 'me thepa ea lebanta ka boeona ke elastomer.Ka lehlakoreng le leng, ho thellisa ke mofuta oa ho hloleha ho hlahang ka lebaka la ho jara haholo 'me ho lokela ho thibeloa ka litšenyehelo tsohle.

Ka ho khetheha, skidding e etsahala ka pulley e nyenyane.Ho eketseha ha meroalo e ka ntle ho lebisa phapanong e kholo ea tsitsipano lipakeng tsa mahlakore a mabeli, e leng se fellang ka ho atolosoa ha sebaka seo ho thellang hoa elastic ho etsahalang.Elastic sliding e emela phetoho ea bongata, athe ho thella ho bolela phetoho ea boleng.Ka lebaka leo, ho thibela ho thellisa, ho na le moeli holim'a bophara bo fokolang ba pulley e nyenyane, kaha li-diameter tse nyenyane tsa pulley li etsa hore ho be le li-angles tse nyenyane tsa ho phuthela le ho fokotsa libaka tsa ho kopana, ho etsa hore ho thella ho ka etsahala.

Lebelo le thellang la bokaholimo ba leino le amana joang le khatello ea maikutlo e lumelletsoeng ea tšepe e putsoa le li turbine tsa boronse tsa aluminium-aluminium?

Karabo:

Khatello ea maikutlo e lumelletsoeng ea tšepe e bohlooho le li-turbine tsa boronse tsa aluminium-aluminium li susumetsoa ke lebelo le thellang la bokaholimo ba leino ka lebaka la mokhoa o moholo oa ho hloleha o tsejoang e le ho khomarela holim'a leino.Ho khomarela ka ho toba ho ameha ka lebelo la ho thella, kahoo ho ama khatello ea maikutlo e amohelehang.Ka lehlakoreng le leng, mokhoa o ka sehloohong oa ho hloleha ha li-turbine tsa tin bronze ke likoti tse holim'a leino, tse bakoang ke khatello ea maikutlo.Ka hona, khatello ea maikutlo e lumelletsoeng ha e amane le lebelo la ho thella.

Enumtheha melao e tloaelehileng ea motsamao, litšoaneleho tsa tšusumetso, le maemo a loketseng bakeng sa molateli oa mochini oa cam.

Karabo:

Melao ea motsamao bakeng sa molateli oa mochini oa cam e kenyelletsa ho sisinyeha ha lebelo le sa feleng, melao e fapaneng ea ho theola lebelo, le motsamao o bonolo oa harmonic (cosine acceleration motion law).Molao oa kamehla oa lebelo o bonts'a tšusumetso e thata mme o fumana ts'ebeliso maemong a lebelo le tlase le a boima bo bobebe.

Melao ea metsamao ea deceleration, ho kenyeletsoa ho potlakisa khafetsa, e na le tšusumetso e feto-fetohang 'me e loketse maemo a mahareng ho isa ho a tlase.Motsamao o bonolo oa harmonic (cosine 4-chord acceleration motion law) o fana ka tšusumetso e bonolo ha ho na le nako ea khefutso, e etsa hore ho be molemo bakeng sa maemo a mahareng ho isa ho a tlase.Maemong a lebelo le phahameng ntle le linako tsa phomolo, ha ho na tšusumetso e feto-fetohang, e etsang hore e tšoanele maemo ao.

Akaretsa melao-motheo e laolang menoana ea meno.

Karabo:

Ho sa tsotellehe hore na li-profiles tsa meno li kopana hokae, mohala o tloaelehileng o tloaelehileng o fetang moo ho kopanang teng o tlameha ho kopana le ntlha e itseng moleng o bohareng.Boemo bona bo tiisa hore karolelano ea phetisetso e tsitsitseng e bolokiloe.

Mekhoa e fapaneng ea ho lokisa likarolo tsa shaft ka circumferentially ke efe?(Fana ka mekhoa e fetang 4)

Karabo:

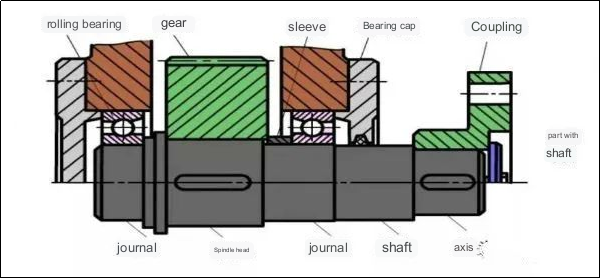

Menyetla ea ho lokisa selikalikoe e kenyelletsa tšebeliso ea khokahanyo ea linotlolo, khokahanyo e arohaneng, khokahanyo ea ho kena-kenana le tšitiso, sekoti se sete, khokahanyo ea phini, le motsoako oa ho atolosa.

Ke mefuta efe ea mantlha ea mekhoa ea ho lokisa li-axial bakeng sa ho hokela likarolo ho shaft?

Ke litšobotsi life tse khethollang e 'ngoe le e' ngoe?(bolela ho feta bane)

Karabo:

Mekhoa ea ho lokisa ea axial ea ho hokela likarolo ho shaft e kenyelletsa mefuta e mengata ea bohlokoa, e 'ngoe le e' ngoe e na le litšobotsi tse ikhethang.Tsena li kenyelletsa ho lokisa melala, ho lokisa likhoele, ho lokisa metsi, le ho lokisa flange.Ho lokisa molala ho kenyelletsa tšebeliso ea molala kapa clamp e tiisitsoeng ho pota-potile molamu ho tiisa karolo ea axially.Ho lokisa likhoele ho kenyelletsa tšebeliso ea likhoele holim'a shaft kapa karolo ho li kopanya ka thata.Hydraulic fixation e sebelisa khatello ea hydraulic ho theha khokahano e tiileng lipakeng tsa karolo le shaft.Ho lokisa flange ho kenyelletsa tšebeliso ea flange e bolted kapa e cheselitsoeng holikarolo tsa mochini oa cncle shaft, ho netefatsa hore ho na le sehokelo se sireletsehileng sa axial.

Ke hobane'ng ha ho hlokahala ho etsa lipalo tsa ho leka-lekana mocheso bakeng sa likoloi tse koetsoeng tsa liboko?

Araba:

Lits'oants'o tse kentsoeng li bonts'a ho thella le maemo a holimo a khohlano.Ka lebaka la matla a bona a fokolang a ho qhala mocheso le tšekamelo ea litaba tsa ho khomarela, ho etsa lipalo tsa tekanyo ea mocheso hoa hlokahala.

Ke likhopolo life tse peli tsa lipalo tsa matla tse sebelisoang lipalong tsa matla a gear?

Ke liphoso life tseo ba li shebileng?

Haeba phetisetso ea gear e sebelisa leino le bonolo le koetsoeng, mokhoa oa eona oa moralo ke ofe?

Karabo:

Lipalo tsa matla a Gear li kenyelletsa ho tseba hore na matla a ho kopana le mokhathala oa bokaholimo ba leino le matla a mokhathala a kobehang a motso oa leino.Matla a ho khathala a ikemiseditse ho thibela ho hloleha ha mokhathala ho thibela leino ka holim'a leino, ha matla a mokhathala a kobehang a sebetsana le ho robeha ha mokhathala motso oa leino.Phetiso ea gear e sebelisang sebaka se koetsoeng sa leino le bonolo se latela mokhoa oa moralo oa ho nahana ka matla a ho khathala ha leino le ho netefatsa matla a mokhathala a kobehang a motso oa leino.

Mesebetsi e fapaneng ea li-couplings le li-clutches ke efe?

Li fapane joang ho tse ling?

Karabo:

Ka bobeli li-couplings le li-clutch li sebeletsa morero oa ho hokahanya li-shaft tse peli ho nolofalletsa phetiso ea torque le ho potoloha ho hokahaneng.Leha ho le joalo, li fapane ho ea ka bokhoni ba bona ba ho itokolla nakong ea ts'ebetso.Cli-ouplings li kopanya li-shafts tse ke keng tsa aroloa ha li ntse li sebelisoa;khaoha ea bona ke khoneha feela ka disassembling ealikarolo tse phethohangka mor'a ho koala.Ka lehlakoreng le leng, li-clutches li fana ka bokhoni ba ho kenya letsoho kapa ho theola li-shaft tse peli ka nako efe kapa efe nakong ea ts'ebetso ea mochini.

Hlalosa litlhokahalo tsa bohlokoa tsa hore libere tsa lifilimi tsa oli li sebetse hantle.

Karabo:

Libaka tse peli tse tsamaeang ka mokhoa o lekanyelitsoeng li tlameha ho theha lekhalo le bōpehileng joaloka chedge;lebelo la ho thella pakeng tsa bokaholimo le tlameha ho netefatsa ho kena ha oli e tlotsang ho tsoa koung e kholo le ho tsoa koung e nyane;oli e tlotsang e tlameha ho ba le viscosity e itseng, mme phepelo e lekaneng ea oli ea hlokahala.

Fana ka tlhaloso e khuts'oane mabapi le litlamorao, likarolo tse khethollang, le ts'ebeliso e tloaelehileng ea mofuta oa 7310.

Karabo:

Tlhaloso ea khoutu: Khoutu "7" e emela bolo ea khokahanyo ea angular.Lebitso "(0)" le bolela bophara bo tloaelehileng, 'me "0" e le khetho.Nomoro "3" e bolela letoto le mahareng ho latela bophara.Qetellong, "10" e lumellana le bophara bo ka hare ba 50mm.

Likarolo le lits'ebetso:

Mohlala ona oa ho jara o ka mamella ka nako e le 'ngoe meroalo ea radial le axial ka tsela e le' ngoe.E fana ka lebelo le phahameng la moeli 'me hangata e sebelisoa ka bobeli.

Ka har'a sistimi ea phetisetso e kenyelletsang phetisetso ea lisebelisoa, phetisetso ea mabanta, le phetiso ea ketane, ke mofuta ofe oa phetisetso eo hangata e behoang ka lebelo le holimo ka ho fetesisa?

Ka lehlakoreng le leng, ke karolo efe ea phetisetso e hlophisitsoeng sebakeng se tlase sa gear?

Hlalosa lebaka le utloahalang la tokisetso ena.

Karabo:

Ka kakaretso, lebanta la koloi le behiloe boemong bo phahameng ka ho fetisisa ba lebelo, ha ketane ea likoloi e behoa sebakeng se tlaase ka ho fetisisa sa gear.The belt drive e na le litšobotsi tse kang phetisetso e tsitsitseng, cushioning, le ho monya ho ts'oenyeha, ho etsa hore e be molemo bakeng sa enjene ka lebelo le holimo.Ka lehlakoreng le leng, li-drive tsa ketane li atisa ho hlahisa lerata nakong ea ts'ebetso 'me li loketse hamolemo maemo a lebelo le tlaase, kahoo hangata li abeloa sethaleng sa gear se tlaase.

Ke eng e bakang lebelo le sa ts'oanang la phetiso ea ketane?

Lintho tse ka sehloohong tse e susumetsang ke life?

Ke tlas'a maemo afe moo karolelano ea phetisetso ea hang-hang e ka lulang e le teng?

Karabo:

1) Lebelo le sa tloaelehang la phetisetso ea ketane le bakoa haholo ke phello ea polygonal e hlahang mochineng oa ketane;2) Lintlha tsa bohlokoa tse e susumetsang li kenyelletsa lebelo la ketane, molumo oa ketane, le palo ea meno ea sprocket;3) Ha palo ea meno a li-sprockets tse kholo le tse nyane li lekana (e leng, z1=z2) 'me sebaka se bohareng pakeng tsa tsona ke palo e lekaneng ea molumo (p), karolelano ea phetisetso ea hang-hang e lula e le 1.

Ke hobane'ng ha bophara ba leino (b1) ba pinion bo le boholo hanyenyane ho feta bophara ba leino (b2) la lisebelisoa tse kholo ho fokotsa lisebelisoa tsa cylindrical?

Ha u bala matla, na coefficient ea bophara ba leino (ψd) e lokela ho thehoa ho b1 kapa b2?Hobaneng?

Karabo:

1) Ho thibela axial misalignment ea likere ka lebaka la liphoso tsa kopano, bophara ba leino la meshing bo fokotsehile, bo lebisang ho eketseha ha mosebetsi.Kahoo, bophara ba leino (b1) la lisebelisoa tse nyane e lokela ho ba kholo hanyane ho feta b2 ea lisebelisoa tse kholoanyane.Palo ea matla e lokela ho ipapisa le bophara ba leino (b2) la gear e kholo hobane e emela bophara ba 'nete ba ho kopana ha li-cylindrical gears li kenella.

Ke hobane'ng ha bophara ba pulley e nyenyane (d1) e lokela ho lekana kapa e kholo ho feta bophara ba bonyane (dmin) le angle ea ho phuthela ea lebili la koloi (α1) e lekana kapa e kholo ho feta 120 ° ka ho khanna lebanta la deceleration?

Ka kakaretso, lebelo la lebanta le khothalletsoang le pakeng tsa 5 ho isa ho 25 m / s.

Ke eng cho qala haeba lebelo la lebanta le feta lebelo lee?

Karabo:

1) Bophara bo nyane ba pulley e nyane bo lebisa khatellong e phahameng ea ho khumama lebanta.Ho thibela khatello ea maikutlo e feteletseng, bophara bo fokolang ba pulley e nyane bo lokela ho bolokoa.

2) Leqhubu la ho phuthela (α1) la lebili la koloi le ama tsitsipano e kholo ea lebanta.E nyane α1 e fella ka matla a tlase a matla a ho hula.Ho matlafatsa matla a ho hula a sebetsang hantle le ho thibela ho thella, ho khothaletsoa angle ea α1≥120° ka kakaretso.

3) Haeba lebelo la lebanta le oela ka ntle ho sebaka sa 5 ho isa ho 25 m / s, ho ka ba le liphello.Lebelo le ka tlaase ho moeli le ka 'na la hloka matla a maholoanyane a atlehang a ho hula (Fe), a lebisang ho eketseha ha palo ea mabanta (z) le mohaho o moholoanyane oa lebanta.Ka lehlakoreng le leng, lebelo le feteletseng la lebanta le ka fella ka matla a phahameng a centrifugal (Fc), a hlokang tlhokomelo.

Melemo le likotsi tsa ho roala ha helical.

Karabo:

Melemo

1) E bonts'a ho apara ho fokolang, 'me mokhoa oa ho lokisa o ka sebelisoa ho felisa tumello le ho etsa hore ho be le boemo bo itseng ba pre-deformation, kahoo e matlafatsa ho tiea le ho finyella ho nepahala ha phetisetso e phahameng.

2) Ho fapana le lits'ebetso tsa ho notlela, e khona ho fetola motsamao oa mola hore e be motsamao oa rotary.

Mefokolo

1) Sebopeho se rarahane ebile se na le liphephetso tlhahisong.

2) Mekhoa e meng e ka 'na ea hloka mokhoa o eketsehileng oa ho koala ho thibela ho fetoha.

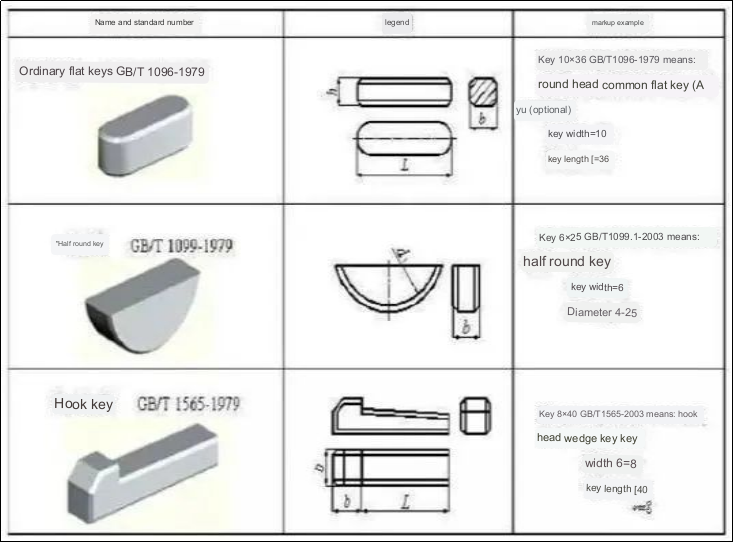

Molao-motheo oa bohlokoa oa ho khetha linotlolo ke ofe?

Karabo:

Ha u khetha linotlolo, ho na le lintlha tse peli tsa bohlokoa: mofuta le boholo.Khetho ea mofuta o itšetlehile ka lintlha tse kang litšobotsi tsa sebopeho sa khokahano ea bohlokoa, litlhoko tsa tšebeliso, le maemo a ho sebetsa.

Ka lehlakoreng le leng, khetho ea boholo e lokela ho khomarela litekanyetso tse tloaelehileng le litlhoko tsa matla.Boholo ba senotlolo bo na le litekanyo tsa li-cross-sectional (bophara ba senotlolo b * bophahamo ba senotlolo h) le bolelele L. Khetho ea litekanyo tse fapaneng b * h e khethoa ke bophara ba shaft d, ha bolelele ba senotlolo L bo ka khona. ka kakaretso ho khethoa ho ipapisitsoe le bolelele ba hub, ho bolelang hore bolelele ba senotlolo L ha boa lokela ho feta bolelele ba sebaka.Ho feta moo, bakeng sa linotlolo tse bataletseng tsa tataiso, bolelele ba L' hangata bo pota-pota (1.5-2) makhetlo a bophara ba shaft d, ho nahanoa ka bolelele ba sebaka le sebaka sa ho thella.

Anebon e itšetleha ka bokhoni ba eona bo matla ba tekheniki mme e tsoela pele ho nts'etsapele mahlale a tsoetseng pele ho fihlela litlhoko tsa ts'ebetso ea tšepe ea CNC,5 axis cnc milling, le ho bapala koloi.Re ananela haholo litlhahiso tsohle le maikutlo.Ka tšebelisano-'moho e ntle, re ka fihlela nts'etsopele le ntlafatso.

Joalo ka moetsi oa ODM naheng ea China, Anebon e sebetsa ka ho khetheha ho etsa likarolo tsa setempe sa aluminium le likarolo tsa mochini oa ho etsa.Hajoale, lihlahisoa tsa rona li rometsoe linaheng tse fetang mashome a tšeletseng le libakeng tse fapaneng ho pota lefatše, ho kenyeletsoa Asia Boroa-bochabela, Amerika, Afrika, Europe Bochabela, Russia le Canada.Anebon e ikemiselitse ho theha likhokahano tse pharalletseng le bareki ba ka bang teng Chaena le libakeng tse ling tsa lefats'e.

Nako ea poso: Aug-16-2023