Machining kukanganisa kunoreva dhigirii rekutsauka pakati peiyo chaiyo geometric paramita (geometric saizi, geometric chimiro uye mutual chinzvimbo) chechikamu mushure mekugadzira uye yakakodzera geometric paramita.

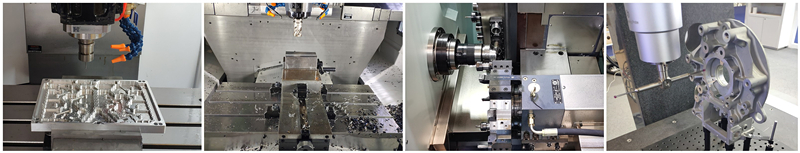

Chiyero chekubvumirana pakati peiyo chaiyo geometric parameters uye yakanakira geometric parameters mushure mechikamu chakagadzirwa ndiko machining akarurama.Iyo idiki yekukanganisa kwekugadzira, iyo yakakwirira dhigirii yekuenderana uye inokwidza iyo machining kururama.7075 aluminium machining

Machining kunyatsoita uye kukanganisa kwekugadzira magadzirirwo maviri edambudziko.Naizvozvo, ukuru hwekukanganisa kwekugadzira hunoratidza mwero weiyo machining kurongeka.Zvikonzero zvikuru zvekukanganisa kwemuchina ndezvizvi:

1. Kugadzira kukanganisa kwemuchina chishandiso

Iko kukanganisa kwekugadzira kwechishandiso chemuchina kunyanya kunosanganisira kukanganisa kwekutenderera kwespindle, chikanganiso chenjanji uye kukanganisa kwecheni yekufambisa.

Spindle kutenderera kukanganisa kunoreva kuchinjika kweiyo chaiyo kutenderera axis ye spindle inoenderana neavhareji kutenderera axis panguva yega yega, iyo inozokanganisa zvakananga kurongeka kweworkpiece kuti igadziriswe.Zvikonzero zvikuru zvekukanganisa kutenderera kwespindle iko coaxiality kukanganisa kweiyo spindle, kukanganisa kwekubereka kwayo, iko coaxiality kukanganisa pakati pemabhengi, uye kutenderera kweiyo spindle.Iyo njanji njanji ndiyo bhenji yekuona hukama hwehukama hwechimwe nechimwe chinhu chemuchina wemuchina pachishandiso chemuchina, uye zvakare ndiyo bhenji yekufamba kwechishandiso chemuchina.aluminium cnc machining

Iko kukanganisa kwekugadzira kweiyo gwara renjanji pachayo, kusaenzana kupfeka kwegwara renjanji uye mhando yekumisikidza ndizvo zvakakosha zvinokonzeresa kukanganisa kwenjanji.Transmission chain error inoreva chikanganiso chekufamba pakati pezvinhu zvekutapurirana pakutanga nekupera kwecheni yekufambisa.Izvo zvinokonzerwa nekugadzira uye zvikanganiso zvegungano zvechikamu chimwe nechimwe muketani yekutumira, pamwe nekupfeka panguva yekushandiswa.

2. Iko kukanganisa kwejometri yemudziyo

Chero chishandiso chinozopfeka panguva yekucheka, izvo zvinokonzeresa shanduko muhukuru uye chimiro cheiyo workpiece.Kupesvedzera kwechishandiso che geometric kukanganisa pane machining kukanganisa kunosiyana nerudzi rwechishandiso: kana yakagadziriswa-saizi chishandiso chinoshandiswa pakugadzira, kukanganisa kwekugadzira kwechishandiso kuchakanganisa zvakananga kurongeka kweiyo workpiece;zvezvishandiso zvakajairika (zvakadai sekushandura maturusi, nezvimwewo), kukanganisa kwayo kwekugadzira Iyo haina mhedzisiro yakananga pakukanganisa machining.

3. Iko kukanganisa kwejometri kwekugadzirisa

Basa rekugadzirisa nderekuita kuti workpiece yakaenzana nemudziyo uye chigadziro chemuchina kuti chive nechinzvimbo chakarurama, saka kukanganisa kwejometri kwekugadzirisa kune simba guru pane kukanganisa kwekugadzira (kunyanya kukanganisa kwechinzvimbo).

4. Position kukanganisa

Iko kukanganisa kwekumisikidza kunonyanya kusanganisira kukanganisa kwereferensi yekumisikidza uye kukanganisa kusiri iko kwekugadzira kwevaviri vanomira.Paunenge uchigadzira iyo workpiece pamushini wemuchina, akati wandei geometric zvinhu pane workpiece zvinofanirwa kusarudzwa senzvimbo yekumisikidza datum panguva yekugadzirisa.datum) hazvienderane, iyo datum misalignment kukanganisa ichaitika.

Iyo workpiece yekumisikidza nzvimbo uye iyo yekumisikidza chinhu pamwe chete inoumba iyo yekumisikidza peya.Kusiyana kwepamusoro kwechinzvimbo chekushanda kunokonzerwa nekugadzirwa kusina kururama kwepairi yekumisikidza uye mukaha unofananidzwa pakati pemapeya ekumisikidza kunonzi kukanganisa kwekugadzira kusarurama kwepairi yekumisikidza.Iko kukanganisa kwekugadzira kusina kunaka kwepairi yekumisikidza kuchaitika chete apo nzira yekugadzirisa inoshandiswa pakugadzirisa, uye haizoitiki mukuedza kwekucheka nzira.

5. Kukanganisa kunokonzerwa neforce deformation ye process system

Kuomarara kweworkpiece: Kana iyo workpiece kuomarara muhurongwa hwekuita kwakadzikira zvichienzaniswa nematurusi emuchina, maturusi, uye zvigadziriso, pasi pechiito chekucheka simba, deformation yebasa rekushanda nekuda kwekusakwana kuomarara kuchave nekukanganisa kukuru pakukanganisa machining.

Tool rigidity: Kuomarara kwecylindrical turning tool mune yakajairwa (y) kutungamira kweiyo machined surface yakakura kwazvo, uye deformation yayo inogona kufuratirwa.Kana kufinha gomba remukati rine dhayamita diki, kuomarara kwebhari rekushandisa kwakashata, uye simba deformation yebhari rekushandisa rine pesvedzero huru pakuita machining kwegomba.

Kuomarara kwemidziyo yemuchina: Zvishandiso zvemuchina zvinoumbwa nezvikamu zvakawanda.Iko hakuna yakakodzera nzira yekuverenga yakapusa yekuomarara kwemidziyo yemuchina.Parizvino, kuoma kwezvikamu zvemakina emidziyo kunonyanya kutariswa nenzira dzekuyedza.Zvinhu zvinokanganisa kuomarara kwemidziyo yemuchina zvinosanganisira pesvedzero yekubata deformation yejoint surface, pesvedzero yekukweshana, pesvedzero yezvikamu zvakaderera-kuoma, uye pesvedzero yemvumo.aluminium cnc machining zvikamu

6. Zvikanganiso zvinokonzerwa nekupisa kwekupisa kwemaitiro ekugadzirisa

Kupisa kwekupisa kwegadziriro yegadziriro kune simba guru pakukanganisa kwekugadzira, kunyanya mukugadzirisa machining uye hukuru-hukuru machining, kukanganisa kwekugadzira kunokonzerwa nekupisa kwekupisa kunogona kuverengera 50% yehuwandu hwekukanganisa kwekushanda.

7. Kugadzirisa kukanganisa

Muchigadziro chega chega chekugadzira, pane nguva dzose nzira imwe kana imwe yekugadzirisa kune maitiro ekugadzirisa.Sezvo kugadziridza hakugoni kunyatsojeka, kukanganisa kwekugadzirisa kunoitika.Mune iyo process system, iyo mutual positional kurongeka kweiyo workpiece uye chishandiso pamushini chishandiso chinovimbiswa nekugadzirisa muchina chishandiso, chishandiso, gadziriso kana workpiece.Kana iyo chaiyo yepakutanga yematurusi emuchina, maturusi, zvigadziriso uye workpiece blanks zvese zvinosangana nezvinodiwa tekinoroji pasina kufunga zvine simba zvinhu, iko kukanganisa kwekugadzirisa kunoita basa rekuita mukukanganisa kwekugadzira.

8. Kuyera kukanganisa

Kana chikamu chikayerwa panguva kana mushure mekugadzirisa, kuyerwa kwechiyero kunokanganiswa zvakananga nenzira yekuyera, kurongeka kwechiyereso chekushandisa, uye workpiece uye subjective uye chinangwa zvinhu.

9. Kushushikana kwemukati

Kushushikana kuripo mukati mechikamu pasina simba rekunze kunonzi kushushikana kwemukati.Kamwe kushushikana kwemukati kunogadzirwa pane workpiece, iyo workpiece simbi ichave isina kugadzikana mamiriro epamusoro simba.Ichaita semusikirwo kushandura kune yakagadzikana mamiriro yakaderera simba pamwero, achiperekedzwa deformation, kuitira kuti workpiece anorasikirwa kwayo yepakutanga machining kururama.

Anebon Metal Products Limited inogona kupa CNC Machining, Die Casting, Sheet Metal Fabrication service, ndapota inzwa wakasununguka kutibata nesu.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Nguva yekutumira: Jan-11-2022