Ngokuvamile sinezinketho ezintathu zokukhetha umjikelezo wokumba:

1. G73 (Chip breaking cycle)

Ivamise ukusetshenziselwa umshini izimbobo izikhathi ezingaphezu kuka-3 ububanzi bebhithi, kodwa hhayi ngaphezu kobude obusebenzayo bonqenqema bebhithi

2. G81 (imbobo engashoni)

Ivamise ukusetshenziselwa izimbobo zasesikhungweni sokumba, i-chamfering kanye nezimbobo zomshini ezifika izikhathi ezi-3 ububanzi be-drill bit.

Ngokufika kwamathuluzi okupholisa angaphakathi, lo mjikelezo uphinde usetshenziselwe ukubhoboza izimbobo ukuze kuthuthukiswe ukusebenza kahle kokucubungula.

3. G83 (Ukujikeleza kwembobo ejulile)

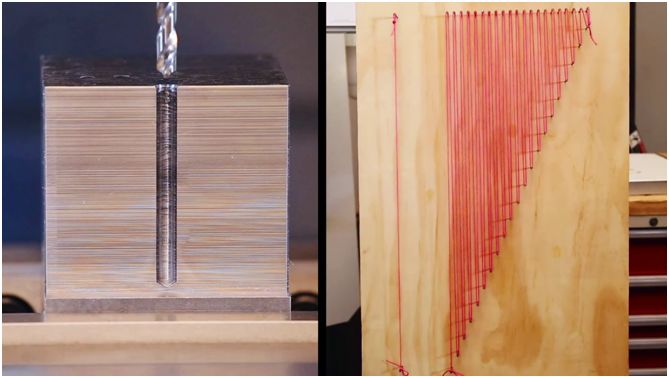

Ivamise ukusetshenziselwa ukukhanda izimbobo ezijulilecnc omshini

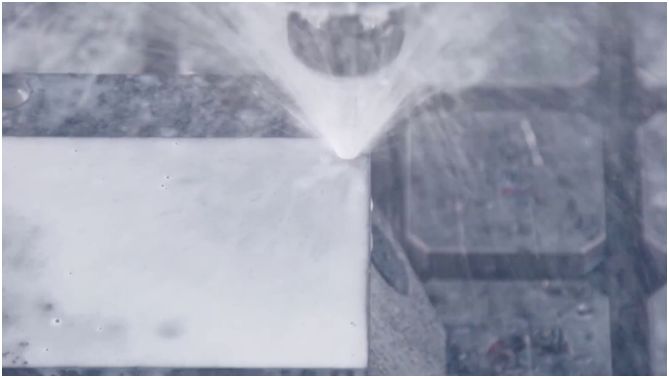

Ukupholisa (amanzi okukhipha) emshinini ofakwe isikhungo sokuphotha

Umsiki futhi usekela amakesi okupholisa aphakathi nendawo (amanzi okukhipha amanzi).

Ukukhetha i-G81 ukucubungula izimbobo kuyisinqumo esingcono kakhulu

I-high pressure coolant ngeke nje isuse ukushisa okukhiqizwa ekubholeni, izoba yi-lubrication efika ngesikhathi, ukucindezela okuphezulu kuzothinta ngokuqondile ukuphulwa kwe-chip yenduku, ngakho-ke i-chip encane izophinde ibe nembobo yokukhishwa kwamanzi okucindezela okukhulu ngesikhathi, gwema ukugqoka kwethuluzi lesibili lokusika kanye nekhwalithi yokucubungula yembobo, ngoba akukho ukupholisa, ukuthambisa, inkinga yokukhishwa kwe-chip, Ngakho-ke yisixazululo esiphephile nesisebenza kahle kakhulu semijikelezo emithathu yokumba.i-aluminium extrusion

Izinto zokucubungula zinzima ukuphula ama-chips kodwa ezinye izimo zokusebenza zinhle

I-G73 iyisinqumo esihle uma kungekho ukupholisa kwesikhungo sokupholisa (amanzi).

Lokhu kuzozungeza isikhathi esifushane sokumisa isikhashana noma ibanga lensingo ukuze ubone i-chip breaker, kodwa udinga ikhono elihle lokususa i-chip, ithangi elibushelelezi lokususwa kwe-chip lizokwenza ukuthi izilahli ziphume ngokushesha, ukugwema umugqa olandelayo wokubhoboza imvuthuluka ephothiwe. , ukubukela phansi ikhwalithi yembobo, ukusebenzisa umoya ocindezelwe njengokususwa kwe-chip eyisizayo nakho kuyisinqumo esihle.

Uma izimo zingazinzile, i-G83 iyindlela ephephe kunazo zonke.

I-deep hole machining izoba ngenxa yomkhawulo wokusika we-drill awukwazi ukupholisa okufika ngesikhathi, ukugcoba nokugqoka ngokushesha, ukujula kwembobo ye-chip kuyophinde ngoba ubuhlobo bunzima ukukhipha ngesikhathi, uma i-chip groove ivimbela ukupholisa. uketshezi, akugcini nje ukunciphisa kakhulu impilo yesevisi yomsiki, kodwa ngenxa yokuthi i-chip yesibili yokusika ingenza udonga lwembobo yomshini olukhuni, ngaleyo ndlela ibangele umjikelezo ononya.

Uma ithuluzi liphakanyiselwe kubude bereferensi -R njalo ngebanga elifushane lika -q, lingase lilungele ukwenziwa imishini eduze naphansi kwembobo, kodwa kuzothatha isikhathi esiningi ukucubungula ingxenye yokuqala yembobo, okuholela ekutheni ukumosha okungadingekile.

Ingabe ikhona indlela engcono?cnc metal machining

Nazi izindlela ezimbili ze-G83 deep hole circulation

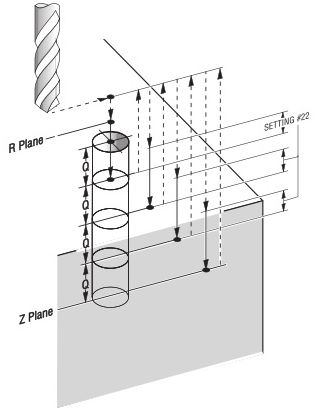

1: G83 X_ Y_ Z_ R_ Q_ F_

2: G83 X_ Y_ Z_ I_ J_ K_ R_ F_

Ngendlela yokuqala, inani le-Q liyinani elingaguquki, okusho ukuthi ukujula okufanayo kusetshenziswa kusukela phezulu kuya phansi kwembobo isikhathi ngasinye.Ngenxa yesidingo sokuphepha kokucubungula, inani elincane livame ukukhethwa, okusho futhi izinga eliphansi kakhulu lokususwa kwensimbi, elichitha isikhathi esiningi sokucubungula cishe.

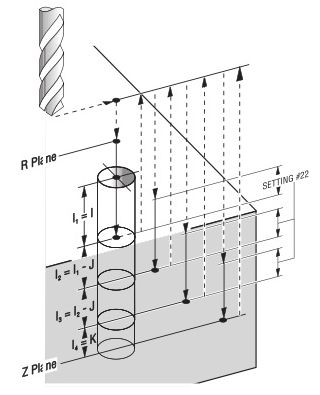

Endleleni yesibili, ukujula kokusikwa ngakunye kuchazwa ngu-I,J, no-K:

Uma phezulu kwembobo kusesimweni esihle sokusebenza, singasetha inani elikhulu le-I ukuze sithuthukise ukusebenza kahle kokucubungula;Uma isimo esimaphakathi sokusebenza sembobo yomshini sivamile, sisebenzisa indlela yokunciphisa inani le-J kancane kancane ukuze siqinisekise ukuphepha nokusebenza kahle;Uma isimo sokusebenza sisibi phansi kwembobo yomshini, sibeka inani lika-K ukuze siqinisekise ukuphepha kokucubungula.

Indlela yesibili, uma isetshenziswa ekusebenzeni, ingenza ukubhola kwakho kusebenze kahle ngo-50% futhi kungabizi lutho!

I-Anebon Metal Products Limited inganikeza i-CNC Machining, i-Die Casting, isevisi yokwenziwa kwe-Sheet Metal, sicela ukhululeke ukuxhumana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Isikhathi sokuthumela: Mar-25-2022