Insimbi engagqwali isifinyezo sensimbi engagqwali nensimbi engamelana ne-asidi.Insimbi ekwazi ukumelana nemithombo ebuthakathaka yokugqwala efana nomoya, isitimu namanzi noma enempahla engagqwali ibizwa ngensimbi engagqwali;Insimbi imelana ne-chemical corrosion medium (acid, alkali, salt and other chemical etching) ibizwa ngensimbi engamelana ne-asidi.

Insimbi engagqwali isho insimbi ekwazi ukumelana nokugqwala okubuthakathaka njengomoya, isitimu namanzi kanye nemidiya yokufaka amakhemikhali njenge-asidi, i-alkali nosawoti, eyaziwa nangokuthi insimbi engagqwali engamelana ne-asidi.Ekusetshenzisweni okungokoqobo, insimbi imelana nendawo engaqinile yokugqwala ngokuvamile ibizwa ngokuthi insimbi engagqwali, kuyilapho insimbi imelana namakhemikhali ibizwa ngokuthi insimbi engamelana ne-asidi.Ngenxa yomehluko ekwakhekeni kwamakhemikhali phakathi kwalokhu okubili, eyokuqala ayimelani ngempela nokugqwala okuphakathi kwamakhemikhali, kuyilapho yakamuva ngokuvamile ayinabala.Ukumelana nokugqwala kwensimbi engagqwali kuncike ezintweni ze-alloy eziqukethwe ensimbi.

Ngokuvamile, ngokwesakhiwo se-metallographic, izinsimbi ezingenasici ezijwayelekile zihlukaniswa zibe izinhlobo ezintathu: izinsimbi ezingenasici ze-austenitic, izinsimbi ezingenasici ze-ferritic nezinsimbi ezingenasici ze-martensitic.Ngokwesisekelo salezi zakhiwo ezintathu eziyisisekelo ze-metallographic, insimbi yesigaba esikabili, insimbi eyenza imvula ibe lukhuni nensimbi ye-alloy ephezulu enensimbi engaphansi kuka-50% itholelwe izidingo nezinjongo ezithile.

Ihlukaniswe yaba:

Insimbi engagqwali ye-Austenitic

I-matrix ngokuyinhloko iyisakhiwo se-austenitic (isigaba se-CY) esinesakhiwo sekristalu eyi-cubic egxile ebusweni, esingenazibuthe, futhi siqiniswa kakhulu (futhi singaholela kumagnetism athile) ngokusebenza okubandayo.I-American Iron and Steel Institute ikhonjiswa ngezinombolo zochungechunge ezingama-200 nezingu-300, njenge-304.

Insimbi engagqwali ye-Ferritic

I-matrix ngokuyinhloko iyisakhiwo se-ferrite (isigaba a) esinesakhiwo sekristalu eyi-cubic egxile emzimbeni, esingakazibuthe, futhi ngokuvamile asikwazi ukwenziwa lukhuni ngokwelashwa kokushisa, kodwa singaqiniswa kancane ukusebenza okubandayo.I-American Iron and Steel Institute imakwe ku-430 no-446.

Insimbi engagqwali ye-Martensitic

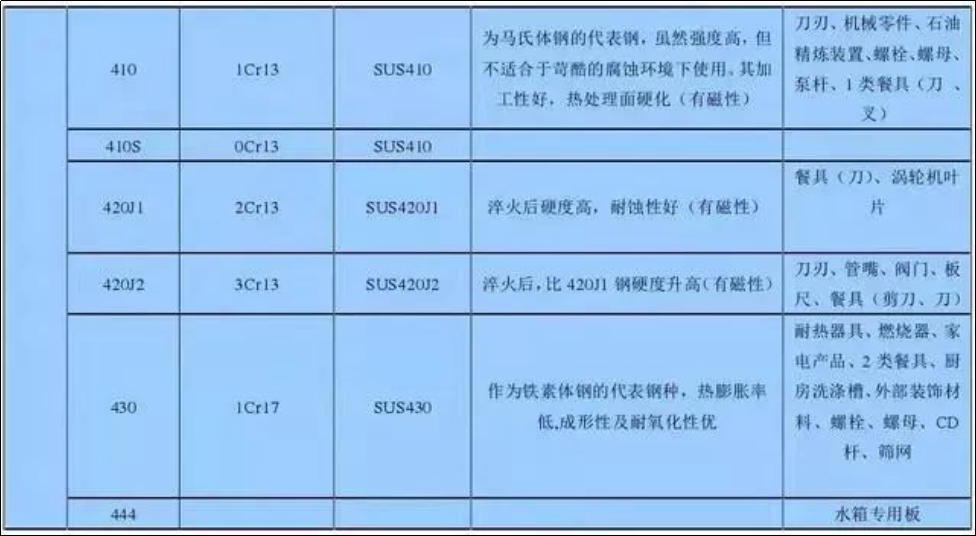

I-matrix iyisakhiwo se-martensitic (i-cubic egxile emzimbeni noma i-cubic), kazibuthe, futhi izakhiwo zayo zemishini zingalungiswa ngokwelashwa kokushisa.I-American Iron and Steel Institute iboniswa izinombolo 410, 420, kanye ne-440. I-Martensite inesakhiwo se-austenitic ekushiseni okuphezulu.Uma ipholile ekamelweni lokushisa ngesilinganiso esifanele, isakhiwo se-austenitic singaguqulwa sibe i-martensite (okungukuthi, iqiniswe).

I-Austenitic ferritic (duplex) insimbi engagqwali

I-matrix inazo zombili izakhiwo zezigaba ezimbili ze-austenite ne-ferrite, futhi okuqukethwe kwe-matrix yesigaba esincane ngokuvamile kungaphezu kuka-15%, okuwuzibuthe futhi okungaqiniswa ukusebenza okubandayo.I-329 iyinsimbi engagqwali eyiduplex ejwayelekile.Uma kuqhathaniswa nensimbi engagqwali ye-austenitic, insimbi yesigaba esikabili inamandla aphezulu, futhi ukumelana kwayo nokugqwala kwe-intergranular, ukugqwala kokucindezeleka kwe-chloride kanye nokugqwala kwe-pitting kuye kwathuthukiswa kakhulu.

Imvula iqinisa insimbi engagqwali

Insimbi engagqwali i-matrix yayo iyi-austenitic noma i-martensitic futhi ingaba lukhuni ngokwelashwa kokuqina kwemvula.I-American Iron and Steel Institute imakwe ngezinombolo zochungechunge ezingama-600, njenge-630, okungukuthi 17-4PH.

Ngokuvamile, ngaphandle kwe-alloy, insimbi engagqwali ye-austenitic inokumelana nokugqwala okuhle kakhulu.Insimbi engagqwali yeFerritic ingasetshenziswa emvelweni ngokugqwala okuphansi.Emvelweni enokugqwala okuncane, insimbi engagqwali ye-martensitic kanye nemvula eqinisa insimbi engagqwali ingasetshenziswa uma impahla idingeka ukuze ibe namandla aphezulu noma ubulukhuni.

Izimpawu nenjongo

Ukwelashwa kwendawo

Ukuhlukaniswa kokuqina

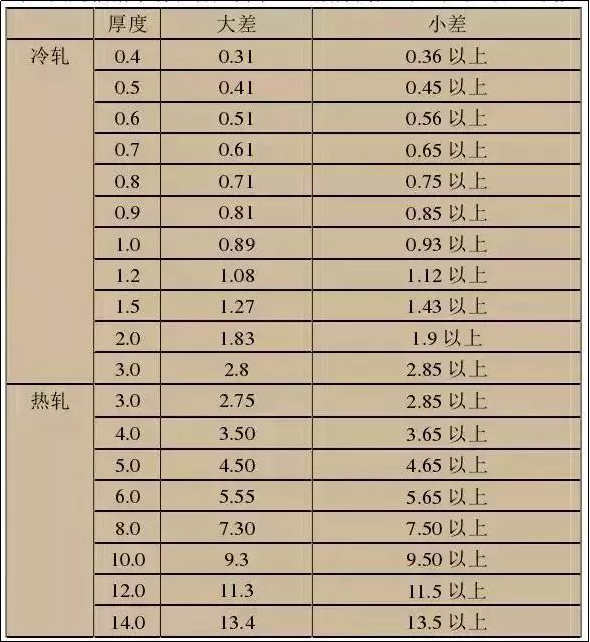

1. Ngoba ohlelweni lokugingqika lwemishini yezitshalo zensimbi, umqulu ukhubazekile kancane ngenxa yokushisisa, okuholela ekuphambukeni kogqinsi lwepuleti eligoqiwe.Ngokuvamile, ubukhulu obuphakathi buncane ezinhlangothini zombili.Lapho ukala ubukhulu bepuleti, ingxenye ephakathi yekhanda lepuleti izolinganiswa ngokuvumelana nemithetho kazwelonke.

2. Ukubekezelelana ngokuvamile kuhlukaniswe ukubekezelelana okukhulu kanye nokubekezelelana okuncane ngokuya ngesidingo semakethe kanye nekhasimende: isibonelo.

Hlobo luni lwensimbi engagqwali okungelula ukugqwala?

Kunezici ezintathu eziyinhloko ezithinta ukugqwala kwensimbi engagqwali:

1. Okuqukethwe kwezakhi ze-alloying.

Ngokuvamile, insimbi enokuqukethwe kwe-chromium engu-10.5% akulula ukugqwala.Ukuphakama kokuqukethwe kwe-chromium ne-nickel, kuba ngcono ukumelana nokugqwala.Isibonelo, okuqukethwe kwe-nickel kokubalulekile kwe-304 kufanele kube ngu-8-10%, futhi okuqukethwe kwe-chromium kufanele kube ngu-18-20%.Ngokuvamile, insimbi enjalo engenasici ngeke igqwale.

2. Inqubo yokuncibilikisa yomkhiqizi izophinde ithinte ukumelana nokugqwala kwensimbi engagqwali.

Izitshalo ezinkulu zensimbi engagqwali ezinobuchwepheshe obuhle bokuncibilika, imishini ethuthukisiwe kanye nenqubo ethuthukisiwe ingaqinisekisa ukulawulwa kwezakhi ze-alloy, ukususwa kokungcola nokulawula izinga lokushisa lokupholisa i-billet, ngakho ikhwalithi yomkhiqizo izinzile futhi inokwethenjelwa, ikhwalithi yangaphakathi yinhle, futhi ilungile. akulula ukugqwala.Ngokuphambene nalokho, ezinye izitshalo zensimbi ezincane zisemuva ngemishini nobuchwepheshe.Ngesikhathi sokuncibilika, ukungcola akukwazi ukususwa, futhi imikhiqizo ekhiqizwayo izogqwala nakanjani.

3. Indawo yangaphandle, indawo eyomile futhi engenawo umoya akulula ukugqwala.

Kodwa-ke, izindawo ezinomswakama ophezulu womoya, isimo sezulu esinemvula eqhubekayo, noma i-pH ephezulu emoyeni zijwayele ukugqwala.304 insimbi engagqwali izogqwala uma indawo ezungezile impofu kakhulu.

Indlela yokubhekana namabala okugqwala ensimbi engagqwali?

1. Izindlela zamakhemikhali

Sebenzisa unamathisele wokuhlanza i-asidi noma fafaza ukuze usize izingxenye ezigqwalile ukuthi zidlule futhi zenze ifilimu ye-chromium oxide ukubuyisela ukumelana nokugqwala.Ngemuva kokuhlanza i-asidi, ukuze ususe zonke izinto ezingcolile nezinsalela ze-asidi, kubaluleke kakhulu ukugeza kahle ngamanzi ahlanzekile.Ngemuva kwakho konke ukwelashwa, phinda upholishe ngezinto zokupholisha futhi uvale nge-wax yokupholisha.Kulabo abanokugqwala okuncane endaweni, ingxube kawoyela yenjini engu-1:1 ingasetshenziswa futhi ukususa izindawo zokugqwala ngeragi ehlanzekile.

2. Indlela yemishini

Ukuhlanza ukuqhuma, ukudubula ngengilazi noma izinhlayiya zobumba, ukucwiliswa, ukuxubha nokupholisha.Kungenzeka ukususa ukungcola okubangelwa izinto ezikhishwe ngaphambilini, izinto zokupholisha noma izinto zokuqothula ngezindlela zemishini.Zonke izinhlobo zokungcola, ikakhulukazi izinhlayiya zensimbi zangaphandle, zingase zibe umthombo wokugqwala, ikakhulukazi endaweni enomswakama.Ngakho-ke, indawo ehlanzwe ngomshini kufanele ihlanzwe ngokusemthethweni ngaphansi kwezimo ezomile.Indlela yemishini ingasetshenziswa kuphela ukuhlanza ubuso, futhi ayikwazi ukushintsha ukumelana nokugqwala kwezinto ngokwazo.Ngakho-ke, kunconywa ukuphinda upholishe ngemishini yokupholisha ngemva kokuhlanza ngomshini futhi uvale nge-wax yokupholisha.

Okuvame ukusetshenziswa ensimbi engagqwali amamaki kanye izakhiwo

1. 304 insimbi engagqwali.Ingenye yezinsimbi ezingenasici ze-austenitic ezisetshenziswa kakhulu ezinenani elikhulu lezicelo.Ilungele ukukhiqiza izingxenye ezakhiwe ngomdwebo ojulile, amapayipi okuhambisa i-asidi, imikhumbi,izingxenye ze-cnc zesakhiwo sokuphenduka, imizimba yezinsimbi ehlukahlukene, njll., kanye nezinto zokusebenza nezingxenye ezingezona uzibuthe nezinezinga lokushisa eliphansi.

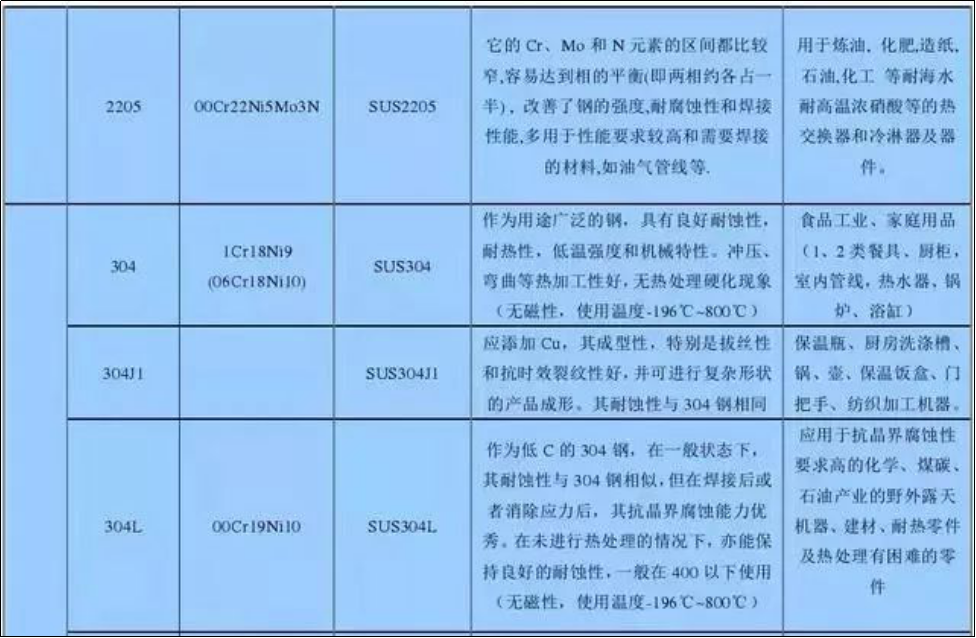

2. 304L insimbi engagqwali.I-ultra-low carbon austenitic insimbi engagqwali ethuthukisiwe ukuxazulula ukuthambekela okukhulu kwe-intergranular corrosion ye-304 insimbi engagqwali okubangelwa imvula ye-Cr23C6 ngaphansi kwezinye izimo, ukumelana kwayo nokugqwala okuthuthukisiwe kwe-intergranular kungcono kakhulu kunensimbi engagqwali engama-304.Ngaphandle kwamandla aphansi, ezinye izakhiwo ziyafana nensimbi engagqwali engu-321.Isetshenziselwa ikakhulukazi okokusebenza okumelana nokugqwala kanye nezingxenye ezidinga ukushiselwa kodwa ezingeke zelashwe ngesisombululo, futhi ingasetshenziswa ukwenza imizimba yezinsimbi ehlukahlukene.

3. 304H insimbi engagqwali.Egatsheni langaphakathi lensimbi engagqwali engu-304, ingxenyenamba ye-carbon mass ingu-0.04% - 0.10%, futhi ukusebenza kwezinga lokushisa eliphezulu kungaphezu kwensimbi engagqwali engu-304.

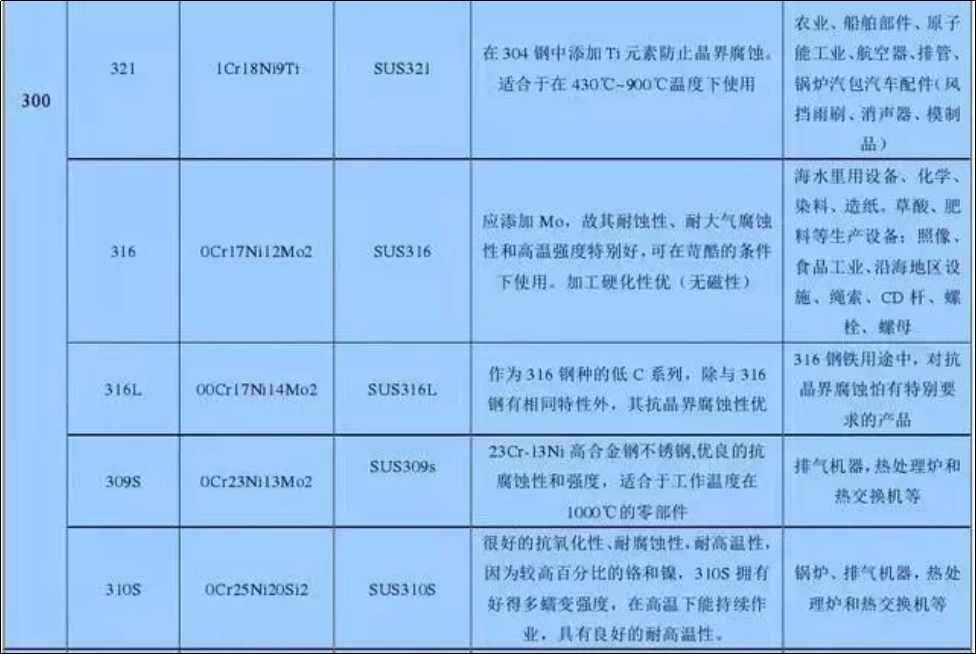

4. 316 insimbi engagqwali.Ukwengezwa kwe-molybdenum ngesisekelo sensimbi engu-10Cr18Ni12 kwenza insimbi ibe nokumelana okuhle nokunciphisa ukugqwala okuphakathi nendawo.Emanzini olwandle nakweminye imidiya, ukumelana nokugqwala kuphakeme kunensimbi engagqwali engu-304, esetshenziselwa kakhulu ukufaka izinto ezivimbela ukugqwala.

5. 316L insimbi engagqwali.I-Ultra low carbon steel, ekwazi ukumelana kahle nokugqwala kwe-intergranular, ifaneleka ukukhiqiza izingxenye zokushisela usayizi wesigaba esiwugqinsi, njengezinto ezilwa nokugqwala emishinini ye-petrochemical.

6. 316H insimbi engagqwali.Egatsheni langaphakathi le-316 yensimbi engagqwali, ingxenyenamba ye-carbon mass ingu-0.04% - 0.10%, futhi ukusebenza okuphezulu kwezinga lokushisa kungaphezu kwalokho kwe-316 stainless steel.

7. 317 insimbi engagqwali.Ukumelana ne-pitting corrosion and creep iphakeme kune-316L yensimbi engagqwali.Isetshenziselwa ukukhiqiza imishini ye-petrochemical kanye ne-organic acid ukumelana.

8. 321 insimbi engagqwali.I-Titanium stabilized austenitic stainless steel ingathathelwa indawo yi-ultra-low carbon austenitic stainless steel ngenxa yokumelana nokugqwala okuthuthukisiwe kwe-intergranular kanye nezakhiwo ezinhle zomshini wokushisa okuphezulu.Ngaphandle kwezikhathi ezikhethekile ezifana nezinga lokushisa eliphezulu noma ukumelana nokugqwala kwe-hydrogen, ngokuvamile akunconywa ukuthi kusetshenziswe.

9. 347 insimbi engagqwali.I-Niobium izinzile i-austenitic insimbi engagqwali.Ukwengezwa kwe-niobium kuthuthukisa ukumelana nokugqwala kwe-intergranular.Ukumelana nokugqwala kwayo ku-asidi, i-alkali, usawoti kanye neminye imithombo yezindaba egqwalayo kuyafana nensimbi engagqwali engu-321.Ngokusebenza kahle kwe-welding, ingasetshenziswa njengezinto zombili ezimelana nokugqwala kanye nensimbi ekwazi ukumelana nokushisa.Isetshenziswa kakhulu emandleni ashisayo nasezindaweni ze-petrochemical, njengokwenza imikhumbi, amapayipi, izishintshi zokushisa, ama-shafts, amashubhu omlilo ezithandweni zezimboni, nama-thermometers eshubhu lomlilo.

10. 904L insimbi engagqwali.I-Super complete austenitic stainless steel iyinsimbi engagqwali eyi-austenitic eyaqanjwa yi-OUTOKUMPU Company yase-Finland.Ingxenye yayo ye-nickel mass ingama-24% - 26%, kanti ingxenyena ye-carbon mass ingaphansi kuka-0.02%.Inokumelana nokugqwala okuhle kakhulu.Inokumelana nokugqwala okuhle kuma-asidi angenayo i-oxidizing njenge-sulfuric acid, i-acetic acid, i-formic acid ne-phosphoric acid, kanye nokumelana kahle nokugqwala kokugqwala kanye nokugqwala kwengcindezi.Isebenza ekugxilisweni okuhlukahlukene kwe-sulfuric acid engaphansi kuka-70 ℃, futhi inokumelana okuhle nokugqwala kwe-acetic yanoma yikuphi ukugxila kanye nezinga lokushisa ngaphansi kwengcindezi evamile kanye ne-asidi exubile ye-formic acid ne-acetic acid.Izinga langempela le-ASMESB-625 liyihlukanise njenge-nickel base alloy, futhi izinga elisha layihlukanisa njengensimbi engagqwali.E-China, kukhona kuphela uhlobo olufanayo lwensimbi engu-015Cr19Ni26Mo5Cu2.Abakhiqizi bezinsimbi abambalwa baseYurophu basebenzisa insimbi engagqwali engu-904L njengento ebalulekile.Isibonelo, ishubhu yokulinganisa ye-E+H mass flowmeter isebenzisa insimbi engagqwali engu-904L, futhi ikesi lamawashi e-Rolex lisebenzisa insimbi engagqwali engu-904L.

11. 440C insimbi engagqwali.Ukuqina kwensimbi engagqwali ye-martensitic, insimbi engagqwali eqinile nensimbi engagqwali kuphakeme kakhulu, futhi ukuqina yi-HRC57.Isetshenziswa kakhulu ukwenza ama-nozzles, ama-bearings, ama-valve cores, izihlalo ze-valve, imikhono, iziqu ze-valve,izingxenye zemishini ye-cncnjll.

12. 17-4PH insimbi engagqwali.Imvula ye-Martensitic eyenza lukhuni insimbi engagqwali, enobulukhuni be-HRC44, inamandla aphezulu, ubulukhuni nokumelana nokugqwala, futhi ayikwazi ukusetshenziswa emazingeni okushisa angaphezu kuka-300 ℃.Inokumelana nokugqwala okuhle emkhathini kanye ne-asidi ehlanjululwe noma usawoti.Ukumelana nokugqwala kwayo kuyafana nensimbi engagqwali engama-304 kanye nensimbi engagqwali engama-430.Isetshenziselwa ukwenza amapulatifomu angaphesheya kwezilwandle, ama-turbine blades, ama-valve cores, izihlalo zamavalvu, imikhono, iziqu ze-valve, njll.

13. 300 Series – Chromium Nickel Austenitic Stainless Steel

301 - I-ductility enhle, esetshenziselwa imikhiqizo yokubumba.Ingase futhi iqiniswe ngokushesha ngokucubungula ngomshini, ngokushisela okuhle.Ukumelana nokugqoka namandla okukhathala kuphakeme kunensimbi engagqwali engu-304.Insimbi engagqwali engu-301 ikhombisa ukuqina komsebenzi osobala ngesikhathi sokuguqulwa, futhi isetshenziswa ezikhathini ezahlukahlukene ezidinga amandla aphezulu.

302 - Empeleni, iwuhlobo lwensimbi engagqwali engama-304 enokuqukethwe kwekhabhoni ephezulu, engathola amandla aphezulu ngokugoqeka okubandayo.

I-302B - insimbi engagqwali enokuqukethwe okuphezulu kwe-silicon, ekwazi ukumelana nokushisa okuphezulu kwe-oxidation.

I-303 kanye ne-303Se yizinsimbi ezingenasici ezisikwa mahhala eziqukethe isulfure ne-selenium ngokulandelanayo, ezisetshenziswa ezikhathini lapho ukusika kwamahhala nokucwebezela okuphezulu kudingwa kakhulu.I-303Se insimbi engagqwali iphinde isetshenziselwe ukwenza izingxenye zomshini ezidinga ukucasuka okushisayo, ngoba ngaphansi kwezimo ezinjalo, le nsimbi engagqwali inokusebenza okuhle kokushisayo.

I-304N – iyinsimbi engagqwali equkethe i-nitrogen.I-nitrogen yengezwa ukuthuthukisa amandla ensimbi.

I-305 ne-384 - Insimbi engagqwali iqukethe i-nickel ephezulu, futhi izinga layo lokuqina lomsebenzi liphansi, elifanele izikhathi ezihlukahlukene ezinezidingo eziphezulu zokubumba okubandayo.

308 - Ukwenza induku yokushisela.

Okuqukethwe kwe-nickel ne-chromium kwezinsimbi ezingenasici ezingama-309, 310, 314 nezingu-330 kuphakeme uma kuqhathaniswa ukuze kuthuthukiswe ukumelana ne-oxidation namandla okukhasa ezinsimbi emazingeni okushisa aphezulu.Nakuba i-30S5 kanye ne-310S kuyizinhlobonhlobo zama-stainless steels angu-309 kanye nama-310, umehluko ukuthi okuqukethwe kwekhabhoni kuphansi, ukuze kuncishiswe i-carbide etholakala eduze nendawo yokushisela.I-330 insimbi engagqwali inokumelana okuphezulu kakhulu kwe-carburizing kanye nokumelana nokushaqeka okushisayo.

Isikhathi sokuthumela: Dec-05-2022