A matsayinka na memba na masana'antar, shin da gaske kuna fahimtar bambanci tsakanin jiyya daban-daban na kayan aiki daban-daban?

Akwai dabaru daban-daban na jiyya na sama, gami da amma ba'a iyakance ga:

Rufe:Aiwatar da ɗan ƙaramin abu (kamar fenti, enamel, ko ƙarfe) don kare ƙasa, haɓaka kayan kwalliya, hana lalata, ko haɓaka takamaiman ayyuka.

Sanya:Electroplating ya haɗa da ajiye wani ɗan ƙaramin ƙarfe na bakin ciki akan saman wani abu don inganta juriya na lalata, haɓakawa, ko bayyanar.

Maganin zafi:Aiwatar da sarrafawar zafin jiki da tsarin sanyaya don canza tsarin microstructure da kaddarorin karafa, kamar inganta taurin, ƙarfi, ko ductility.

Tsaftacewa da shiri:Cire ƙazanta, gurɓatawa, ko yadudduka oxidation daga saman don tabbatar da dacewa da mannewa da haɗin kai na sutura ko wasu jiyya na saman.

Gyaran saman:Ana amfani da dabaru kamar ion implantation, surface alloying, ko Laser jiyya don canza abun da ke ciki ko tsarin da surface don inganta kaddarorin kamar taurin, sa juriya, ko sinadarai inertness.

Rubutun saman:Ƙirƙirar ƙayyadaddun alamu, tsagi, ko sassauƙa a saman don inganta riko, rage juzu'i, ko haɓaka kyan gani.

Ma'anar:

Maganin saman shine tsari na ƙirƙirar Layer na kayan saman akan tushe tare da nau'ikan inji, jiki, da sinadarai daban-daban.

Manufar:

Sau da yawa ana yin maganin saman don haɓaka aikin samfur, kamar juriya na lalata, dorewa, ko ado.Ana yin maganin saman ƙasa ta hanyar niƙa na inji, jiyya na zafi na saman, feshin ƙasa, da maganin sinadarai.Maganin saman ya haɗa da tsaftacewa, sharewa, ɓarnawa, ɓata lokaci, da ɓata saman kayan aikin.

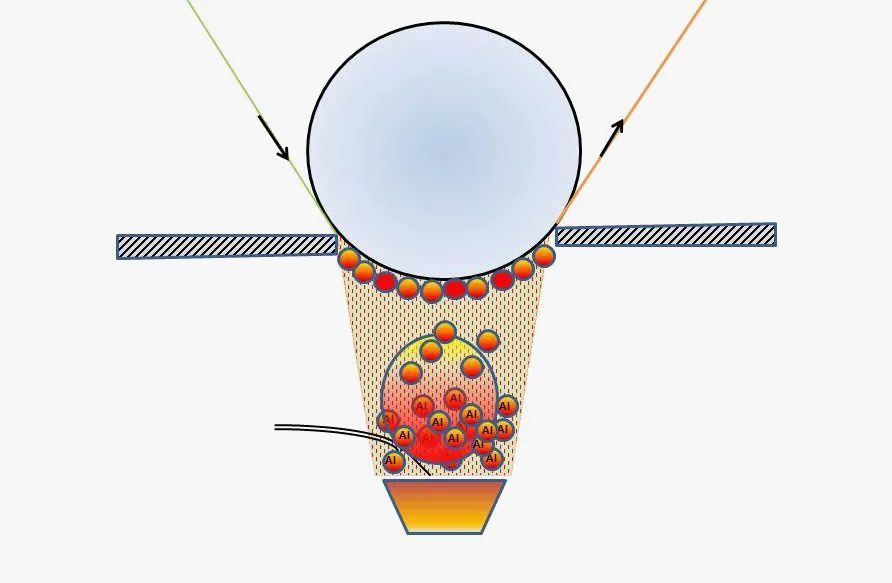

01. Vacuum plating

——Vacuum Metalizing ——

Vacuum plating yana faruwa ne sakamakon wani tsari na jiki.A cikin injin daskarewa, ana allurar argon sannan kuma ya kai ga manufa.Daga nan sai a raba abin da aka sa a gaba zuwa cikin kwayoyin halitta waɗanda ke daɗaɗa su ta hanyar kayan aiki, suna ƙirƙirar yunifom, ƙirar ƙarfe mai santsi.

Abubuwan da ake buƙata:

1. Vacuum plating yana yiwuwa a kan nau'o'in kayan aiki masu yawa ciki har da karafa, kayan aiki, yumbu, gilashi, da robobi masu laushi da wuya.Aluminum shine maganin da aka fi sani da electroplating saman, sannan kuma jan karfe da azurfa.

2. Abubuwan halitta ba za a iya ɗora su ba saboda danshin su zai tsoma baki tare da yanayi mara kyau.

Farashin tsari:

Kudin aiki yana da yawa a cikin ɗigon ruwa saboda aikin aikin dole ne a fesa sa'an nan a loda, sauke, a sake fesa.Har ila yau, ya dogara da yadda hadaddun da girman aikin aikin yake.

Tasirin muhalli:

Vacuum Electroplating yayi kama da feshi dangane da tasirin muhallinsa.

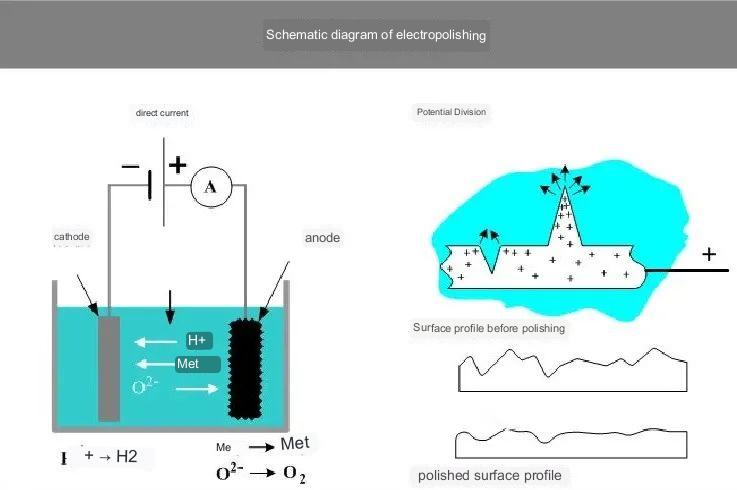

02. Electropolishing

—— Electropolishing ——

Electropolishing wani tsari ne na electrochemical wanda atoms na workpiece da aka nutsar a cikin wani electrolyte ana canza su zuwa ions kuma ana cire su daga saman saboda wucewar wutar lantarki, ta haka ne ke samun tasirin cire burrs masu kyau da kuma kara haske daga saman workpiece.

Abubuwan da ake buƙata:

1. Yawancin karafa za a iya goge su ta hanyar electrolytically, daga cikinsu akwai polishing na bakin karfe da aka fi amfani da su (musamman ma austenitic nukiliya sa bakin karfe).

2. Daban-daban kayan ba za a iya electropolished a lokaci guda, ko ma sanya a cikin guda electrolytic sauran ƙarfi.

Farashin tsari:

Dukkanin aikin polishing electrolytic ana kammala shi ta atomatik, don haka farashin aiki ya ragu sosai.Tasirin muhalli: Electrolytic polishing yana amfani da ƙananan sinadarai masu cutarwa.Duk tsarin yana buƙatar ƙaramin adadin ruwa kuma yana da sauƙin aiki.Bugu da kari, zai iya tsawaita kaddarorin bakin karfe da jinkirta lalata na bakin karfe.

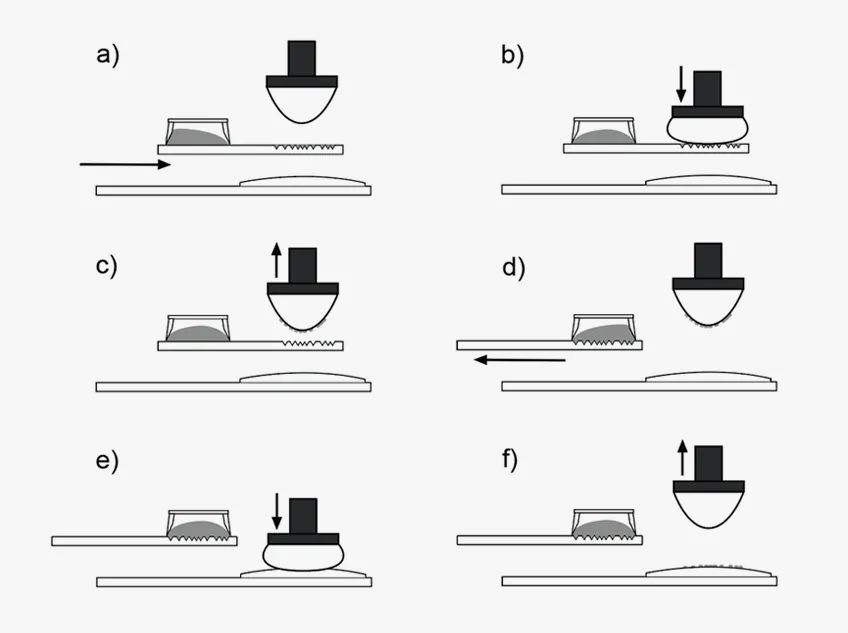

03. Tsarin buga kushin

——Pad Printing——

Samun damar buga rubutu, zane-zane da hotuna akan saman abubuwa marasa tsari yanzu ya zama muhimmin bugu na musamman.

Abubuwan da ake buƙata:

Ana iya amfani da bugu na kushin don kusan duk kayan, sai dai kayan da suka fi laushi fiye da siliki, kamar PTFE.

Farashin tsari:

low m kudin da kuma low aiki kudin.

Tasirin muhalli: Tun da yake wannan tsari yana iyakance ga tawada masu narkewa (waɗanda ke ɗauke da sinadarai masu cutarwa), yana da babban tasirin muhalli.

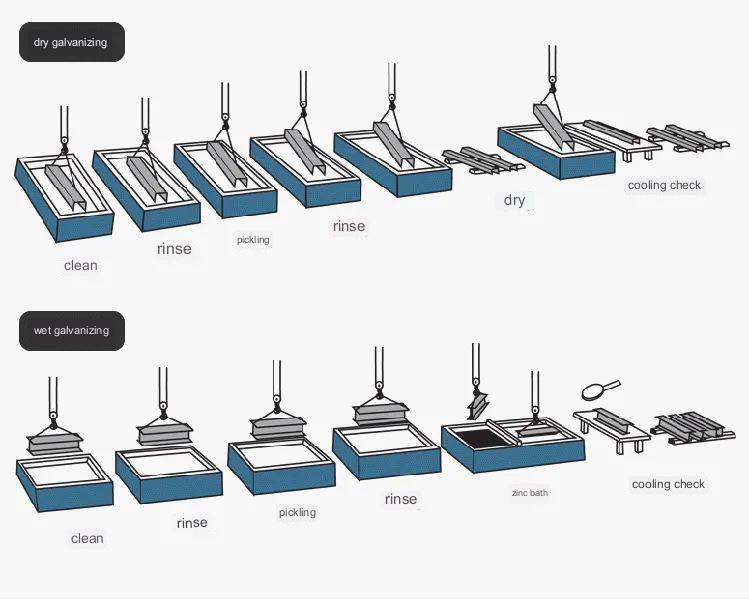

04. Tsarin Galvanizing

-- Galvanizing --

Maganin saman da ke shafa bakin bakin ciki na zinc zuwa saman kayan ƙarfe na gami.Ana yin wannan don kayan ado, kuma yana da kaddarorin anti-tsatsa.Tushen zinc akan saman yana aiki azaman kariyar kariyar lantarki don hana lalata ƙarfe.Hot- tsoma galvanizing shine babbar hanyar da ake amfani da ita.

Abubuwan da ake buƙata:

Galvanizing magani ne na saman ƙarfe da ƙarfe kawai.

Farashin tsari:

Babu kudin ƙira.Gajeren zagaye/matsakaicin farashin aiki.Ingancin saman yanki ya dogara ne akan shirye-shiryen saman da hannu kafin galvanizing.

Tsarin galvanizing yana da tasiri mai kyau akan yanayin.Yana ƙara tsawon rai nacnc niƙa sassadaga shekaru 40 zuwa 100, kuma yana hana tsatsa da lalata.Hakanan za'a iya mayar da yanki na galvanized zuwa tankinsa na galvanized lokacin da ya kai ƙarshen rayuwarsa mai amfani.Wannan ba zai haifar da sinadarai ko sharar jiki ba.

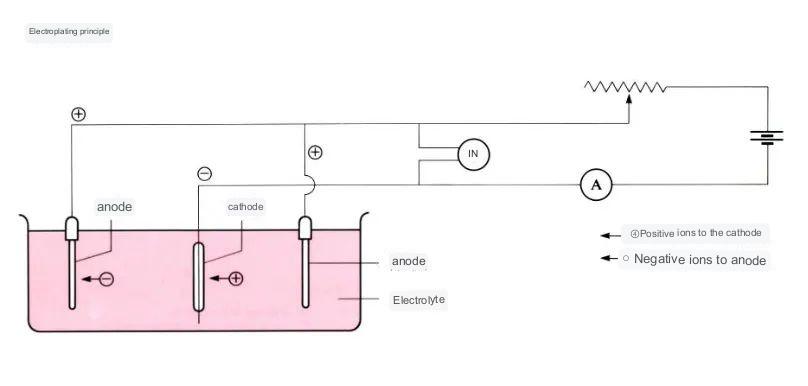

05. Tsarin Electrolating

-- Electrolating --

Electroplating shine tsarin yin amfani da siriri na karfe zuwa sassa ta amfani da electrolysis.Wannan yana taimakawa wajen haɓaka juriya na lalata, juriya, juriya da ƙayatarwa.Yawancin tsabar kudi suna da nau'ikan lantarki na waje..

Abubuwan da ake buƙata:

1. Electroplating yana yiwuwa akan yawancin karafa, amma tsabta da inganci na plating ya bambanta.Waɗannan sun haɗa da tin da nickel.

2. ABS shine mafi yawan filastik da ake amfani da su don lantarki.

3. Nickel yana da guba kuma yana tayar da fata.Ba za a iya amfani da shi a cikin samfuran da aka yi amfani da lantarki ba.

Farashin tsari:

Babu kudin ƙira, amma ana buƙatar kayan aiki don gyara sassan.Kudin lokaci ya dogara da nau'in karfe da zafin jiki.Kudin aiki (matsakaicin matsakaici) ya dogara da takamaiman sassa na plating.Azurfa da platin kayan adon suna buƙatar ƙwararrun ma'aikata saboda yawan buƙatun sa akan bayyanar da dorewa.

Tasirin muhalli:

Electroplating yana amfani da abubuwa masu guba da yawa, waɗanda ke buƙatar haɓaka ƙwararru da karkatar da su don rage tasirin muhalli.

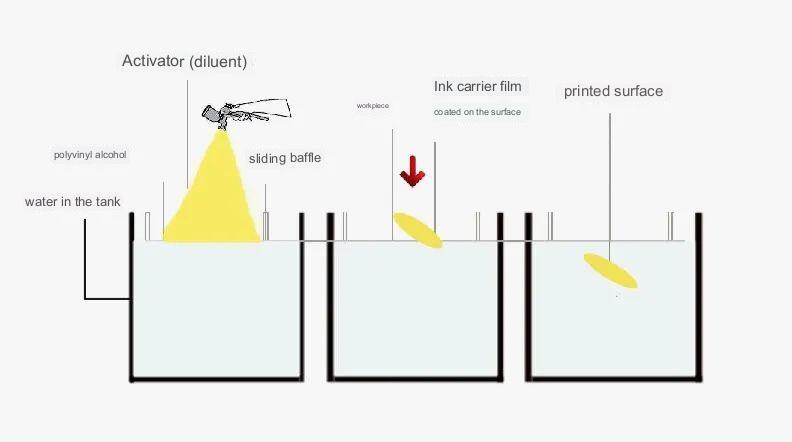

06. Buga Canja wurin Ruwa

-- Canja wurin Hydro Printing --

Ana amfani da matsa lamba na ruwa don canja wurin ƙirar launi zuwa saman saman samfura mai girma uku.Buga canja wurin ruwa ya zama mafi shahara yayin da mutane ke da tsammanin marufi da kayan ado na saman.

Abubuwan da ake buƙata:

Buga canja wurin ruwa yana yiwuwa akan duk kayan aiki mai wuya.Abubuwan da suka dace da feshi kuma sun dace da irin wannan bugu.Allura gyare-gyare dacnc karfe juya sassasun fi kowa.

Farashin tsari: Duk da yake babu ƙira, samfuran da yawa dole ne a canza su da ruwa lokaci guda ta amfani da kayan aiki.Lokacin da ake buƙata kowane zagayowar baya yawanci ya wuce mintuna 10.

Buga canja wurin ruwa ya fi dacewa da muhalli fiye da fesa samfur saboda yana amfani da fentin bugu zuwa mafi girma, don haka rage zubar da shara.

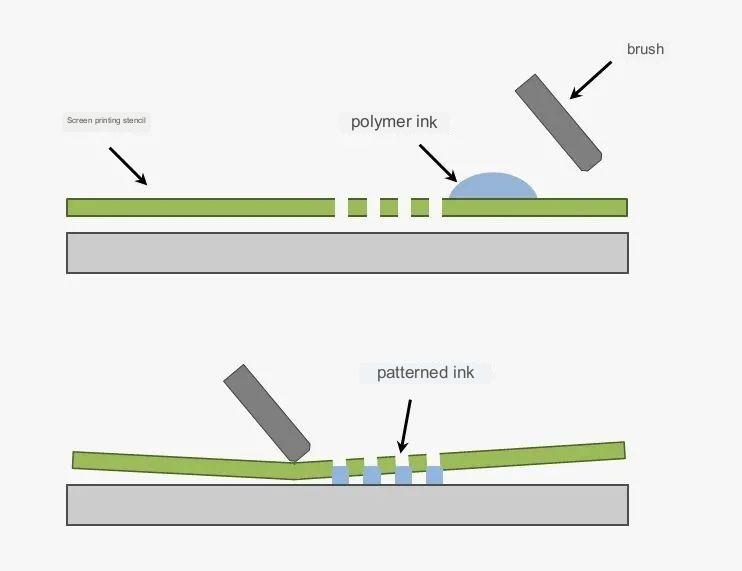

07. Buga allo

-- Buga allo --

Ana canza tawada ta hanyar raga akan sashin hoto zuwa ga substrate ta extrusion.Wannan yana samar da ainihin hoto iri ɗaya kamar na asali.Kayan aikin bugu na allo yana da sauƙin amfani, mai sauƙi don yin faranti da bugawa, da ƙarancin farashi.

Kayayyakin bugu waɗanda aka fi amfani da su sun haɗa da zanen mai kala da fastoci, katunan kasuwanci da murfin daure.

Abubuwan da ake buƙata:

Ana iya yin bugu na allo akan kusan kowane abu, gami da yumbu, gilashi, yumbu da ƙarfe.

Farashin tsari:

Farashin ƙira yana da ƙasa amma har yanzu ya dogara da launukan lamba saboda kowane farantin launi yana buƙatar yin shi daban.Kudin aiki yana da yawa lokacin bugawa a cikin launuka masu yawa.

Tasirin muhalli:

Tawada bugu na allo tare da launuka masu haske suna da ƙarancin tasiri akan yanayi.Koyaya, tawada da ke ɗauke da formaldehyde da PVC sunadaran sinadarai ne masu cutarwa kuma dole ne a sake yin fa'ida ko a zubar da su a kan kari don guje wa gurɓatar ruwa.

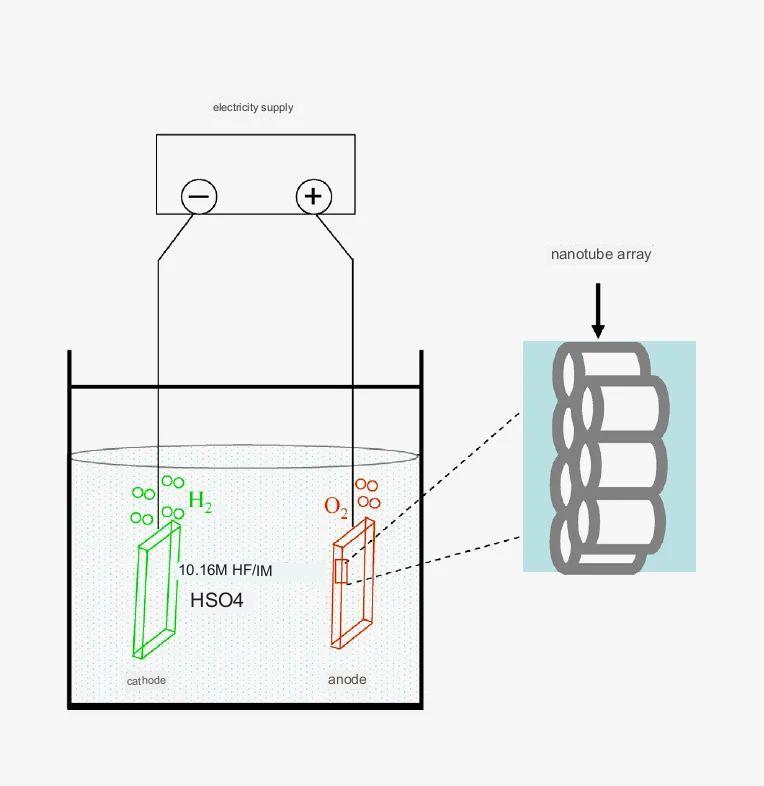

08. Anodizing

--Anodic Oxidation --

A anodic hadawan abu da iskar shaka na aluminum aka yafi dogara ne a kan electrochemical manufa don samar da wani Layer na Al2O3 (aluminum oxide) fim a saman aluminum da aluminum gami.Wannan Layer na fim din oxide yana da halaye na musamman kamar kariya, ado, rufi, da juriya.

Abubuwan da ake buƙata:

Aluminum, aluminum gami da sauransucnc machining aluminum sassa

Kudin tsari: A cikin tsarin samarwa, yawan amfani da ruwa da wutar lantarki yana da girma sosai, musamman a cikin tsarin iskar oxygen.Yawan zafin na'urar da kanta yana buƙatar ci gaba da sanyaya ta hanyar zagayawa da ruwa, kuma yawan wutar da ake amfani da shi a kowace ton yakan kasance kusan digiri 1000.

Tasirin muhalli:

Anodizing bai yi fice ba ta fuskar ingancin makamashi, yayin da ake samar da electrolysis na aluminum, tasirin anode kuma yana haifar da iskar gas da ke da illa ga yanayin sararin samaniyar ozone.

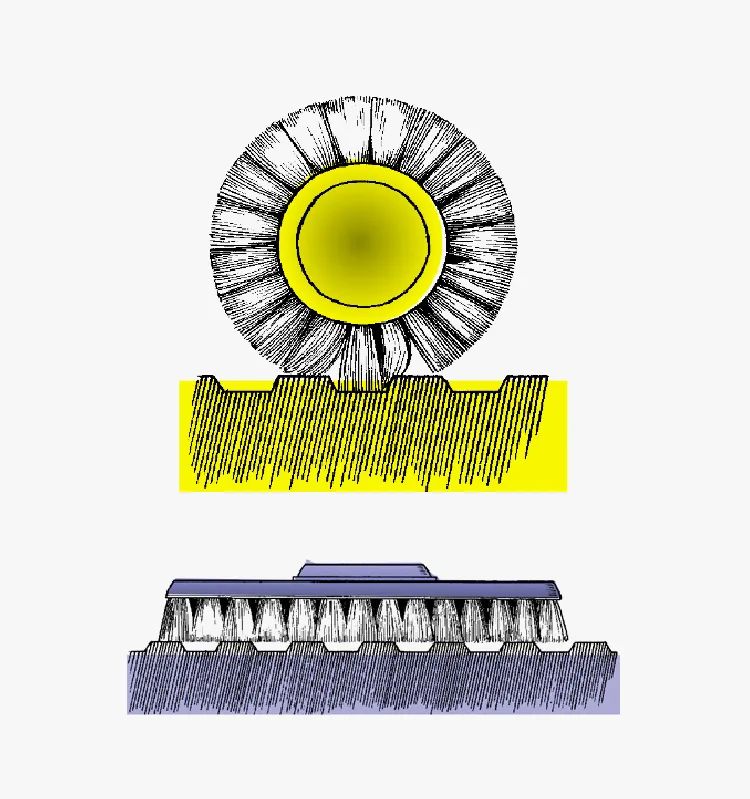

09. Ƙarfe zane

—- Karfe Waya ——

Hanya ce ta jiyya da ke samar da layi akan saman aikin ta hanyar niƙa samfurin don cimma tasirin ado.Dangane da rubutu daban bayan zane na waya, ana iya raba shi zuwa: zane madaidaiciya, zane-zane waya, da swirling.

Abubuwan da ake buƙata:

Kusan duk kayan ƙarfe na iya amfani da tsarin zana waya ta ƙarfe.

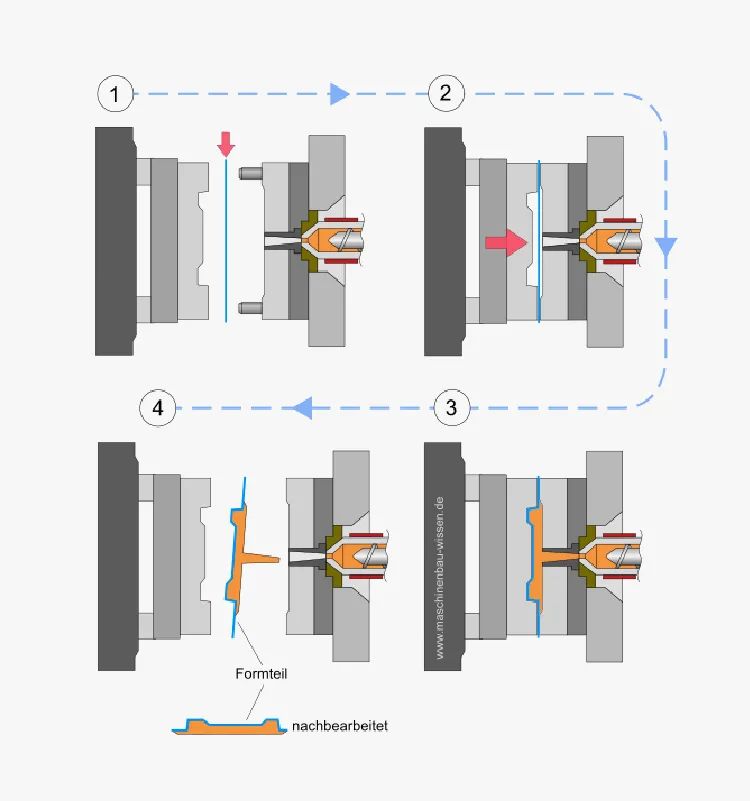

10. In-mold Ado

-- In-Mold Decoration-IMD —-

Wannan hanyar gyare-gyaren ta ƙunshi shigar da diaphragm na ƙarfe da aka buga a cikin ƙirar ƙarfe, shigar da resin a cikin ƙirar, haɗa diaphragm tare, da haɗa resin da ƙirar ƙarfe da aka buga don samar da samfur na ƙarshe.

Abubuwan da ake buƙata:

Pm surface

Farashin tsari:

Bukatar buɗe saitin gyare-gyare ɗaya kawai.Wannan na iya rage farashi da sa'o'in aiki, Babban Haɓakawa ta atomatik, Tsarin Samar da Sauƙaƙe, Hanyar gyare-gyaren allura na lokaci ɗaya, da cimma duka gyare-gyare da adon iri ɗaya.

Tasirin muhalli:

Fasahar ta dace da muhalli da kore, kuma tana guje wa gurɓatar da lantarki da fenti na gargajiya ke haifarwa.

Farashin tsari:

Hanyar tsari yana da sauƙi, kayan aiki yana da sauƙi, kayan amfani da kayan aiki kadan ne, farashin yana da ƙananan ƙananan, kuma amfanin tattalin arziki yana da yawa.

Tasirin muhalli:

Samfuran ƙarfe mai tsabta, babu fenti ko kowane sinadarai a saman, zafin jiki na digiri 600 ba ya ƙonewa, baya haifar da iskar gas mai guba, ya sadu da kariyar wuta da bukatun kare muhalli.

Ci gaba da ingantawa, don tabbatar da cewa samfurin ya yi daidai da ƙa'idodin kasuwa da abokan ciniki.Anebon yana da tsarin kula da inganci a wurin don tabbatar da ingantattun 2022 ɓangarorin tallace-tallace masu zafi don ABS Plastic Drilling CNC Machining Juya Sashin Sabis, Trust Anebon kuma zaku sami ƙarin fa'idodi.Da fatan za a ɗauki lokaci don tuntuɓar mu don ƙarin bayani, Anebon yana ba ku tabbacin kulawar mu a duk tsawon rana.

Kayan kayan gyaran motoci na kayan niƙa masu inganci, ƙarfe da aka juya daga China Anebon.Samfuran daga Anebon sun sami karɓuwa daga abokan ciniki a ƙasashen waje kuma sun kafa dangantaka mai dorewa da fa'ida tare da Anebon.Anebon zai ba da sabis mafi inganci ga kowane abokin ciniki.Muna maraba da sabbin abokai don shiga tare da Anebon da ƙirƙirar fa'idodin juna.

Lokacin aikawa: Yuli-18-2023