Senhengo yeindastiri, unonyatsonzwisisa here mutsauko uripo pakati pekurapa kwakasiyana kwepamusoro kwezvinhu zvakasiyana siyana?

Kune akasiyana akajairwa epamusoro ekurapa maitiro, anosanganisira asi asina kugumira kune:

Coating:Kuisa mutsetse wakatetepa wezvinhu (zvakadai sepende, enamel, kana simbi) kudzivirira pamusoro, kunatsiridza kunaka, kudzivirira ngura, kana kuwedzera mamwe mabasa.

Plating:Electroplating inosanganisira kuisa simbi yakatetepa pamusoro pe substrate kuti ivandudze kusaora, conductivity, kana kutaridzika.

Kurapa kupisa:Kushandisa inodzorwa kupisa uye kutonhodza maitiro kushandura microstructure uye zvimiro zvesimbi, sekuvandudza kuoma, simba, kana ductility.

Kucheneswa kwepamusoro uye kugadzirira:Kubvisa tsvina, zvinosvibisa, kana oxidation layers kubva pamusoro kuti ive nechokwadi chekunamatira uye kusungirirwa kwemajasi kana kumwe kurapwa kwepamusoro.

Kugadziriswa kwepamusoro:Matekinoroji akaita senge ion implantation, surface alloying, kana laser treatment anoshandiswa kushandura maumbirwo kana chimiro chepamusoro kusimudzira zvivakwa zvakaita sekuoma, kusapfeka, kana kusagadzikana kwemakemikari.

Manyorerwo epamusoro:Kugadzira chaiwo mapatani, grooves, kana maumbirwo pamusoro kuti uvandudze kubata, kuderedza kukweshera, kana kuwedzera kunaka kutaridzika.

Tsanangudzo:

Kurapa kwepamusoro inzira yekugadzira dhizaini yezvinhu zvepasi pachigadziko chine michina yakasiyana, yemuviri, uye yemakemikari zvimiro.

Chinangwa:

Kurapa kwepamusoro kunowanzoitwa kuvandudza kushanda kwechigadzirwa, senge corrosion resistance, durability, kana decoration.Kurapa kwepamusoro kunoitwa nemuchina kugaya, kupisa kwepamusoro kurapwa, kupfapfaidza pamusoro, uye kurapwa kwemakemikari.Kurapa kwepamusoro kunosanganisira kuchenesa, kutsvaira, kubvisa, kubvisa, uye kudzika pamusoro pechishandiso.

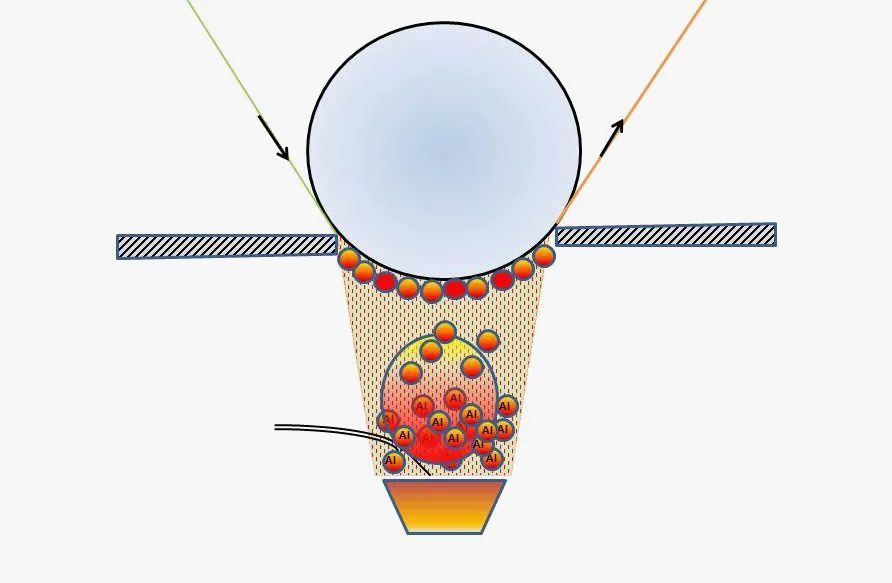

01. Vacuum plating

—— Vacuum Metalizing ——

Vacuum plating inoitika semugumisiro wekuita kwemuviri.Muvacuum, argon inobayiwa uye yobva yarova chinangwa.Chinangwa chinozopatsanurwa kuita mamorekuru ayo adsorbent nezvinhu zvinoitisa, kugadzira yunifomu, yakatsetseka yekutevedzera simbi layer.

Zvishandiso zvinoshanda:

1. Vacuum plating inogoneka pane zvakasiyana-siyana zvezvinhu zvinosanganisira simbi, macomposites, ceramics, girazi, uye mapurasitiki akapfava uye akaomarara.Aluminium ndiyo yakajairika electroplating pamusoro kurapwa, inoteverwa nemhangura uye sirivheri.

2. Zvinhu zvechisikigo hazvigone kuve vacuum plated nekuti mwando wavo unozokanganisa nharaunda yevacuum.

Mutengo wekuita:

Mutengo wevashandi wakakwira zvakanyanya muvacuum plating nekuti iyo workpiece inofanirwa kupfapfaidzwa uye yobva yaiswa, yoburutswa, uye yopfapfaidzwa zvakare.Izvo zvinoenderanawo nekuti yakaoma uye yakakura sei workpiece iri.

Environmental impact:

Vacuum Electroplating yakafanana nekupfapfaidza maererano nekukanganisa kwayo kwezvakatipoteredza.

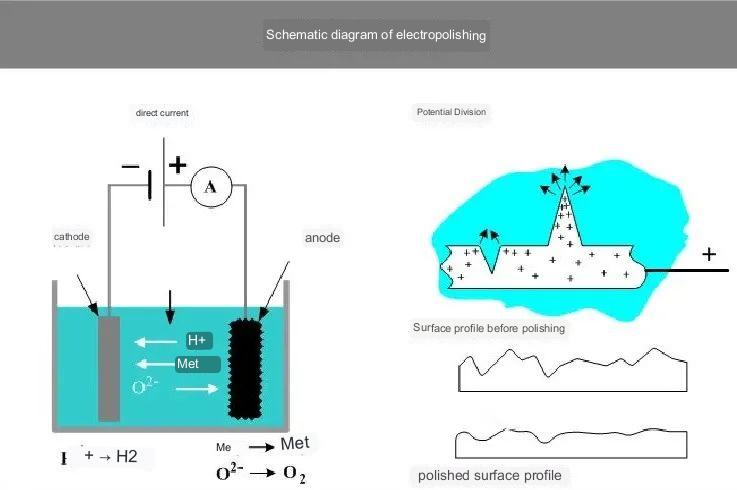

02. Electropolishing

—— Electropolishing ——

Electropolishing inzira ye electrochemical umo maatomu echishandiso akanyudzwa mu electrolyte anoshandurwa kuita ion uye anobviswa kubva pamusoro nekuda kwekupfuura kwemagetsi emagetsi, nekudaro kuwana mhedzisiro yekubvisa mafine burrs uye kuwedzera kupenya kwenzvimbo yebasa.

Zvishandiso zvinoshanda:

1. Masimbi mazhinji anogona kuve akakwenenzverwa nemagetsi, pakati peiyo kupenya kwepamusoro kwesimbi isina tsvina kunonyanya kushandiswa (kunyanya kune austenitic nuclear grade stainless steel).

2. Zvinhu zvakasiyana-siyana hazvigone kuve electropolished panguva imwe chete, kana kunyange kuiswa mune imwechete electrolytic solvent.

Mari yekugadzira:

Iyo yese maitiro e electrolytic polishing inopedzwa otomatiki, saka mutengo wevashandi wakaderera zvakanyanya.Kukanganisa kwezvakatipoteredza: Electrolytic polishing inoshandisa makemikari mashoma anokuvadza.Iyo yose nzira inoda mvura shoma uye iri nyore kushanda.Mukuwedzera, inogona kurebesa zvinhu zvesimbi isina tsvina uye kunonoka kuora kwesimbi isina tsvina.

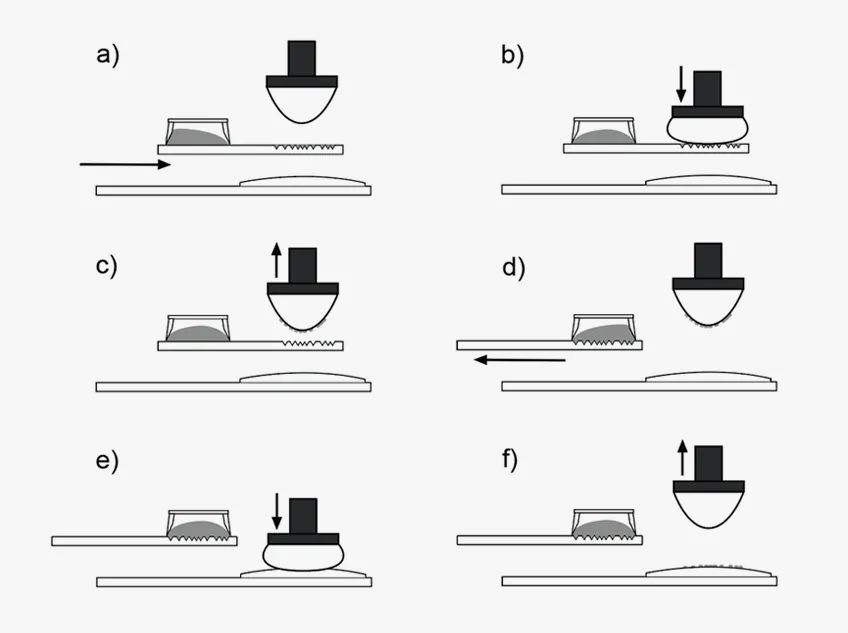

03. Padhi yekudhinda maitiro

——Pad Printing——

Kukwanisa kudhinda zvinyorwa, magirafu nemifananidzo pamusoro pezvinhu zvisina kurongeka zvave kuita kudhinda kwakakosha.

Zvishandiso zvinoshanda:

Kudhinda kwepedhi kunogona kushandiswa kune zvinenge zvese zvinhu, kunze kwezvinhu zvakapfava kupfuura silicone pads, sePTFE.

Mari yekugadzira:

mutengo wakaderera wekuumbwa uye mutengo wakaderera wevashandi.

Kukanganisa kwezvakatipoteredza: Sezvo maitiro aya achingogumira kune ingi dzinonyungudika (dzine makemikari anokuvadza), ine yakanyanya kunaka kwezvakatipoteredza.

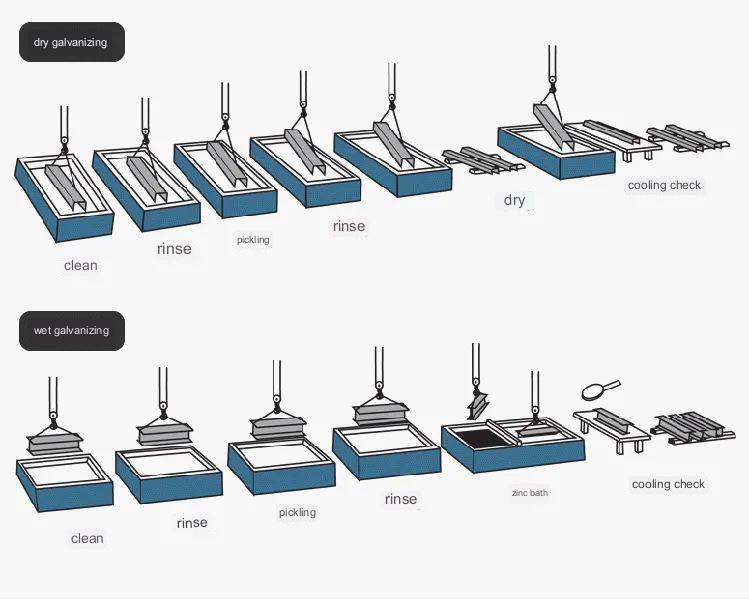

04. Galvanizing process

—- Galvanizing —-

Kurapa kwepamusoro kunoshandisa chidimbu chitete chezingi kumusoro kwealloy simbi zvinhu.Izvi zvinoitirwa aesthetics, uye zvakare ine anti-rust properties.Iyo zinc yekuputira pamusoro inoita seye electrochemical yekudzivirira layer kudzivirira simbi corrosion.Kupisa-dip galvanizing ndiyo nzira huru inoshandiswa.

Zvishandiso zvinoshanda:

Galvanizing mushonga wepamusoro wesimbi nesimbi chete.

Mari yekugadzira:

Hapana mari yekuumbwa.Ipfupi kutenderera / yepakati mutengo wekushanda.Hunhu hwepamusoro hwechimedu hunoenderana zvakanyanya nekugadzirwa kwepamusoro pemanyorerwo kusati kwaita galvanizing.

Iyo galvanizing process ine maitiro akanaka pane zvakatipoteredza.Inowedzera hupenyu hwekutarisiracnc milled partskubva pamakore 40 kusvika ku100, uye inodzivirira kuita ngura nekuora.Iyo galvanized piece inogona zvakare kudzoserwa kune yayo galvanizing tank kana yasvika kumagumo ehupenyu hwayo hunobatsira.Izvi hazvibudise kemikari kana tsvina yemuviri.

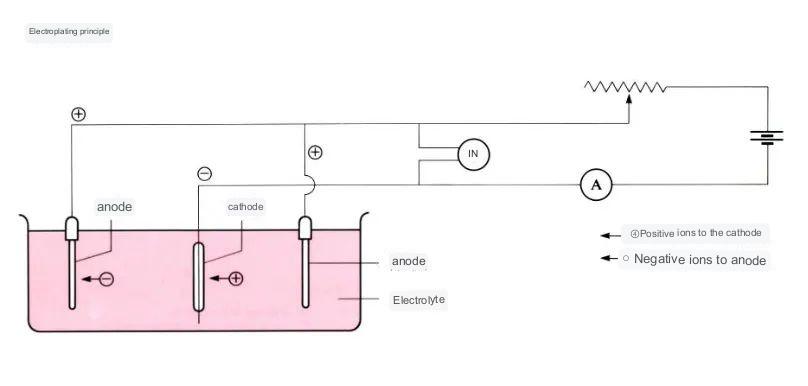

05. Electroplating Process

—- Electroplating —-

Electroplating maitiro ekuisa chidimbu chesimbi kune zvikamu uchishandisa electrolysis.Izvi zvinobatsira kuvandudza corrosion resistance, kupfeka kuramba, conductivity uye aesthetics.Mari zhinji dzine mativi awo ekunze akaiswa electroplated..

Zvishandiso zvinoshanda:

1. Electroplating inogoneka pasimbi zhinji, asi kuchena uye kugona kweplating kunosiyana.Izvi zvinosanganisira tin uye nickel.

2. ABS ndiyo ipurasitiki inonyanya kushandiswa pa electroplating.

3. Nickel ine chepfu uye inogumbura ganda.Haikwanise kushandiswa mune zvigadzirwa zvine electroplated.

Mari yekugadzira:

Hapana mari yekuumbwa, asi zvigadziriso zvinodiwa kugadzirisa zvikamu.Mutengo wenguva unoenderana nemhando yesimbi uye tembiricha.Mutengo webasa (wepakati wakakwira) unoenderana neakananga zvidimbu zveplating.Silverware uye jewelry plating inoda vashandi vane hunyanzvi nekuda kwekuda kwayo kwakanyanya pakutaridzika uye kusimba.

Environmental impact:

Electroplating inoshandisa nhamba yakakura zvinhu zvine muchetura, izvo zvinoda kudhirowa nehunyanzvi uye kuchinjisa kuderedza kukanganiswa kwezvakatipoteredza.

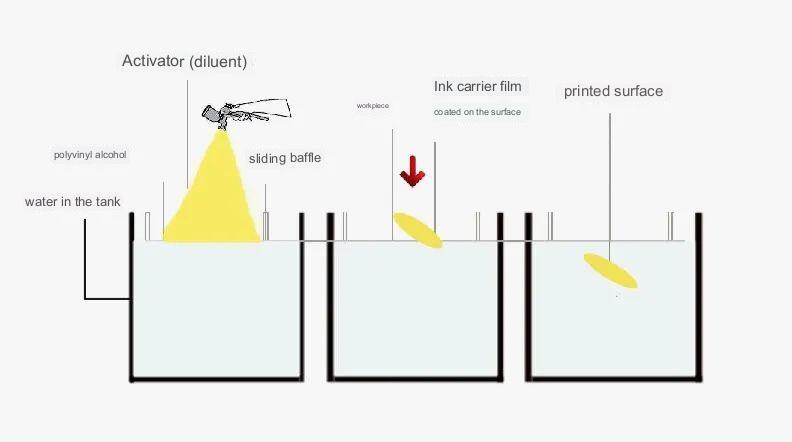

06. Mvura Yekufambisa Kudhinda

—- Hydro Transfer Printing —-

Kudzvinyirirwa kwemvura kunoshandiswa kuendesa pateni yeruvara pamusoro pezvigadzirwa zvematatu-dimensional.Kudhinda kwekufambisa mvura kwave kufarirwa zvakanyanya sezvo vanhu vaine tarisiro yepamusoro yekurongedza nekushongedza kwepasi.

Zvishandiso zvinoshanda:

Kudhinda kwekutumira mvura kunogoneka pane zvese zvakaoma zvinhu.Zvishandiso zvakafanira kupfapfaidza zvakakodzerawo rudzi urwu rwekudhinda.Jekiseni rakaumbwa uyecnc simbi inoshandura zvikamundiwo akanyanya kuwanda.

Mutengo wekuita: Kunyange pasina mold, zvigadzirwa zvakawanda zvinofanirwa kuendeswa nemvura panguva imwe chete uchishandisa zvigadziriso.Nguva inodiwa pamutambo haiwanzopfuura maminitsi gumi.

Kudhinda kwekufambisa kwemvura kune hushamwari hwezvakatipoteredza pane kupfapfaidza chigadzirwa nekuti inoshandisa pendi yekudhinda kusvika pamwero mukuru, nekudaro ichideredza kudonha kwemarara.

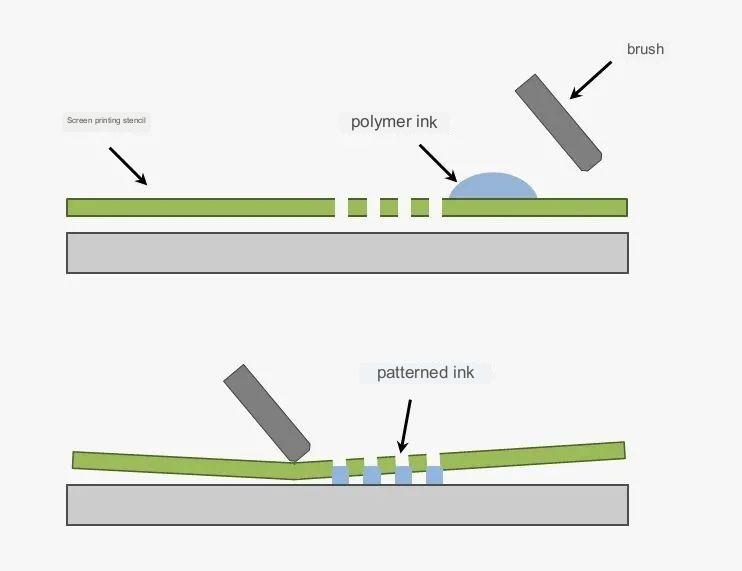

07. Screen Printing

—- Kudhinda Sikirini —-

Iyo inki inotamiswa kuburikidza ne mesh pane graphic chikamu kune substrate ne extrusion.Izvi zvinogadzira iyo chaiyo graphic yakafanana neyeyekutanga.Chidzitiro chekudhinda chidzitiro chiri nyore kushandisa, chiri nyore kugadzira mahwendefa uye kudhinda, uye yakaderera-mutengo.

Zvishandiso zvekudhinda zvinowanzo shandiswa zvinosanganisira pendi yemafuta eruvara nemaposta, makadhi ebhizinesi nemavhavha akasungwa.

Zvishandiso zvinoshanda:

Kudhinda skrini kunogona kuitwa pachinenge chero chinhu, kusanganisira ceramics, girazi, ceramics nesimbi.

Mari yekugadzira:

Mutengo weMould wakaderera asi uchiri kutsamira pahuwandu hwemavara nekuti ndiro yega yega yemavara inoda kugadzirwa yakaparadzana.Mari yebasa yakakwira kana uchidhinda mune-multi-color.

Environmental impact:

Ingi yekudhinda skrini ine mavara akareruka ine yakaderera kukanganisa nharaunda.Zvisinei, ingi dzine formaldehyde nePVC makemikari anokuvadza uye dzinofanira kushandiswa patsva kana kuraswa panguva yakakodzera kudzivirira kusvibiswa kwemvura.

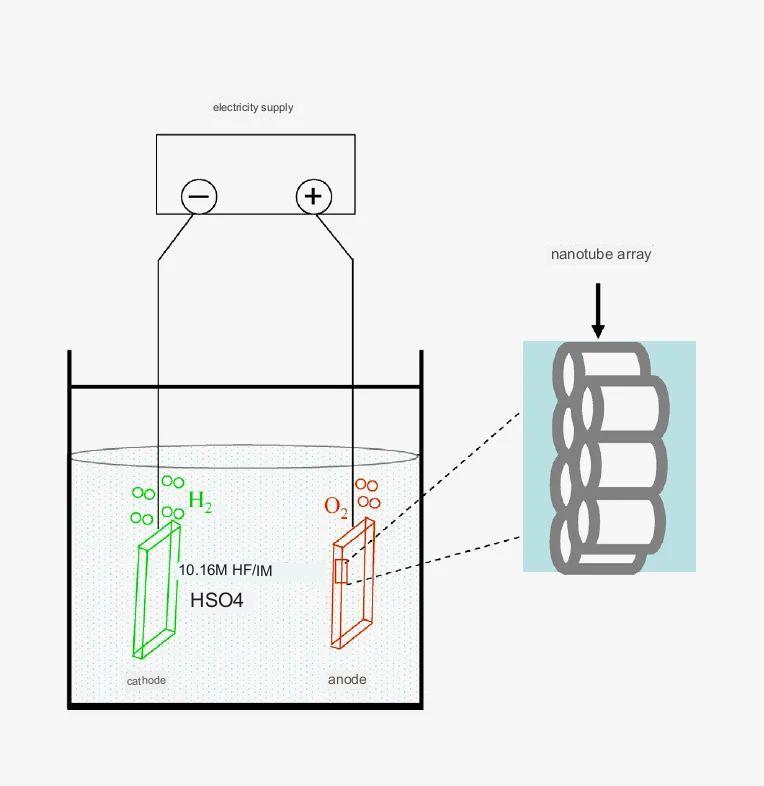

08. Anodizing

—— Anodic Oxidation ——

Iyo anodic oxidation yearuminiyamu inonyanya kuenderana neiyo electrochemical musimboti kuti iite layer yeAl2O3 (aluminium oxide) firimu pamusoro pearuminiyamu nealuminium alloy.Iyi firimu yeoxyde ine hunhu hwakakosha sekudzivirira, kushongedza, kuvhara, uye kupfeka kuramba.

Zvishandiso zvinoshanda:

Aluminium, aluminium alloy uye zvimwecnc machining aluminium zvikamu

Mutengo wekugadzira: Mukugadzira, kushandiswa kwemvura nemagetsi kwakakura, kunyanya mukuita oxidation.Kupisa kwekupisa kwemuchina pachawo kunoda kuramba kuchitonhodzwa nekutenderera kwemvura, uye kushandiswa kwesimba patani kunowanzo kutenderedza 1000 madhigirii.

Environmental impact:

Anodizing haina kushamisira maererano nekushanda kwesimba, nepo mukugadzirwa kwealuminum electrolysis, iyo anode effect inogadzirawo magasi ane mhedzisiro inokuvadza paatmospheric ozone layer.

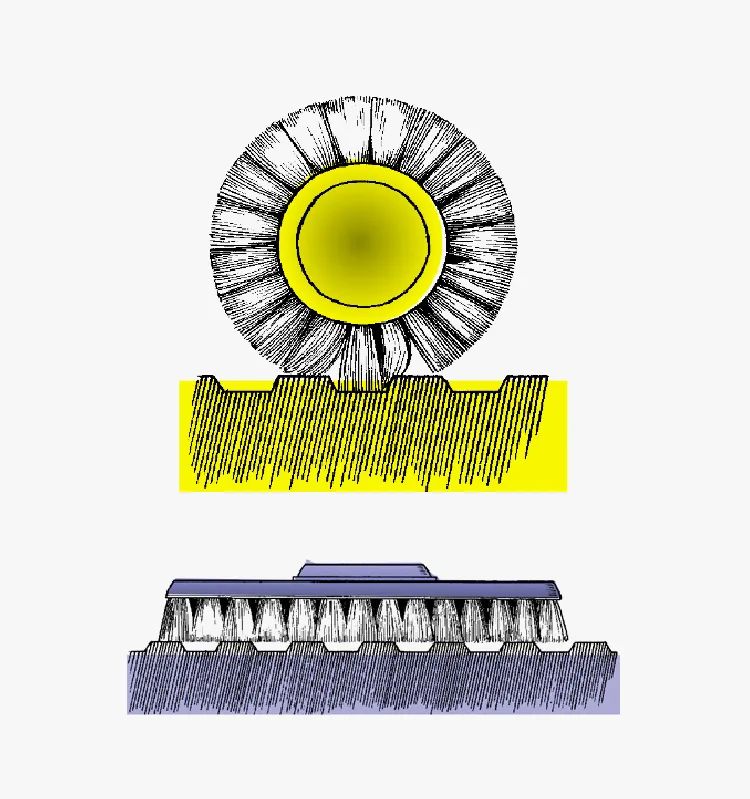

09. Metal wire drawing

—— Metal Wired ——

Iyo nzira yekurapa yepamusoro inoumba mitsara pamusoro peiyo workpiece nekukuya chigadzirwa kuti iwane yekushongedza maitiro.Zvinoenderana neakasiyana maumbirwo mushure mekudhirowa waya, inogona kupatsanurwa kuita: kudhirowa kwewaya yakatwasuka, chaotic waya yekudhirowa, marata, uye inotenderera.

Zvishandiso zvinoshanda:

Zvinenge zvese simbi zvinhu zvinogona kushandisa simbi waya yekudhirowa maitiro.

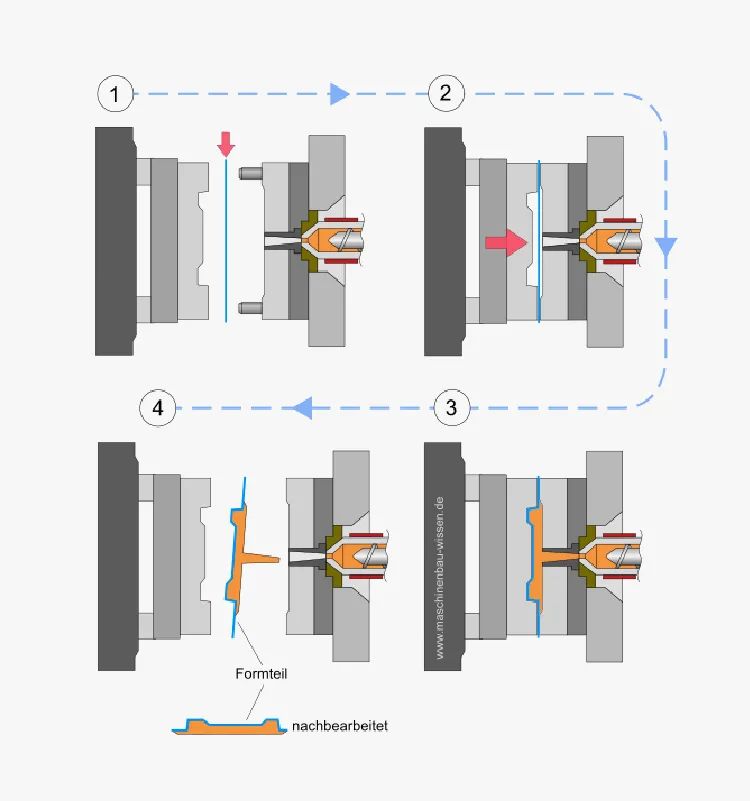

10. In-mold Decoration

—- In-Mold Decoration-IMD —-

Iyi nzira yekuumba inosanganisira kuisa pateni-yakadhindwa simbi diaphragm muforoma yesimbi, kubaya resin muforoma, kubatanidza diaphragm pamwe chete, uye kubatanidza resin nepeteni-yakadhindwa simbi diaphragm kuita chigadzirwa chekupedzisira.

Inoshanda zvinhu:

Plastic pamusoro

Mari yekugadzira:

Inongoda kuvhura imwe seti yezviumbwa.Izvi zvinogona kuderedza mutengo uye maawa ekushanda, Yakakwira-otomatiki Kugadzira, Yakareruka Kugadzira Maitiro, Imwe-Nguva Yejekiseni Molding Method, uye kuwana zvese kuumba nekushongedza panguva imwe chete.

Environmental impact:

Iyo tekinoroji inoshamwaridzana nharaunda uye yakasvibira, uye inodzivirira kusvibiswa kwechinyakare electroplating uye pendi zvinokonzeresa.

Mari yekugadzira:

Nzira yekugadzira iri nyore, midziyo iri nyore, kushandiswa kwezvinhu zvishoma, mutengo wakaderera, uye kubatsirwa kwehupfumi kwakakwirira.

Environmental impact:

Zvigadzirwa zvesimbi zvakachena, pasina pendi kana chero makemikari zvinhu zviri pamusoro, 600 madhigirii akakwira tembiricha haipisi, haiburitse magasi ane muchetura, inosangana nekudzivirira moto uye kuchengetedzwa kwezvakatipoteredza zvinodiwa.

Ramba uchivandudza, kuitira kuti uve nechokwadi chekuti chigadzirwa chiri kuenderana nezviyero zvemusika uye vatengi.Anebon ine yemhando yekudzora sisitimu iripo kuti ive yemhando yepamusoro 2022 inopisa yekutengesa Zvikamu zveABS Plastic Drilling CNC Machining Turning Part Service, Vimba Anebon uye iwe uchawana akawanda mabhenefiti.Ndokumbira utore nguva yekusvika kwatiri kuti uwane rumwe ruzivo, Anebon inovimbisa iwe kutarisisa kwedu kuzere zuva rese.

Auto spare parts of high-quality milling parts, simbi yakatendeuka zvikamu zvinogadzirwa neChina Anebon.Zvigadzirwa kubva kuAnebon zvakawedzera kuzivikanwa kubva kune vatengi kunze kwenyika uye zvakagadzira hukama hwenguva refu uye hunobatsira pamwe neAnebon.Anebon ichapa yemhando yepamusoro sevhisi kumutengi wega wega.Isu tinotambira neushamwari shamwari nyowani kuti dzibatane neAnebon uye kugadzira mabhenefiti.

Nguva yekutumira: Jul-18-2023