Njengelungu leshishini, ngaba uyawuqonda ngenene umahluko phakathi konyango olwahlukileyo lomphezulu lwezixhobo ezahlukeneyo?

Kukho iindlela ezahlukeneyo zonyango oluqhelekileyo lomphezulu, kubandakanywa kodwa kungaphelelanga koku:

Ukwaleka:Ukusebenzisa umaleko obhityileyo wezinto (ezifana nepeyinti, i-enamel, okanye isinyithi) ukukhusela umphezulu, ukuphucula ubuhle, ukuthintela ukubola, okanye ukuphucula imisebenzi ethile.

Ukucwenga:I-Electroplating ibandakanya ukubeka umaleko obhityileyo wesinyithi kumphezulu we-substrate ukuphucula ukuxhathisa ukubola, ukuqhubeleka, okanye ukubonakala.

Unyango lobushushu:Ukusebenzisa ubushushu obulawulwayo kunye neenkqubo zokupholisa ukuguqula i-microstructure kunye neempawu zesinyithi, ezifana nokuphucula ubulukhuni, amandla, okanye i-ductility.

Ukucocwa nokulungisa umphezulu:Ukususa ukungcola, ukungcola, okanye iileyiti ze-oxidation ukusuka kumphezulu ukuqinisekisa ukunamathela ngokufanelekileyo kunye nokudibanisa kweengubo okanye ezinye iindlela zonyango.

Ukulungiswa komphezulu:Ubuchule obunjengofakelo lwe-ion, ingxubevange yomphezulu, okanye unyango lwelaser zisetyenziselwa ukuguqula ukwakheka okanye ubume bomphezulu ukunyusa iipropathi ezinjengobulukhuni, ukunganyangeki, okanye ukunganyangeki kweekhemikhali.

Uthungelwano lomphandle:Ukudala iipateni ezithile, iigrooves, okanye ukuthungwa kumphezulu ukuphucula ukubamba, ukunciphisa ukukhuhlana, okanye ukwandisa inkangeleko yobuhle.

Ingcaciso:

Unyango lomphezulu yinkqubo yokudala umaleko wemathiriyeli engaphezulu kwisiseko esinoomatshini abahlukeneyo, umzimba, kunye neekhemikhali.

Injongo:

Unyango lomphezulu luhlala lwenziwa ukuphucula ukusebenza kwemveliso, njengokunganyangeki kokutya, ukuqina, okanye ukuhombisa.Unyango lomphezulu lwenziwa ngokusila ngoomatshini, unyango lobushushu bomhlaba, ukutshiza komphezulu, kunye nonyango lwekhemikhali.Unyango lomphezulu lubandakanya ukucocwa, ukutshayela, ukukhupha, ukuthoba, kunye nokwehlisa umphezulu wesixhobo sokusebenza.

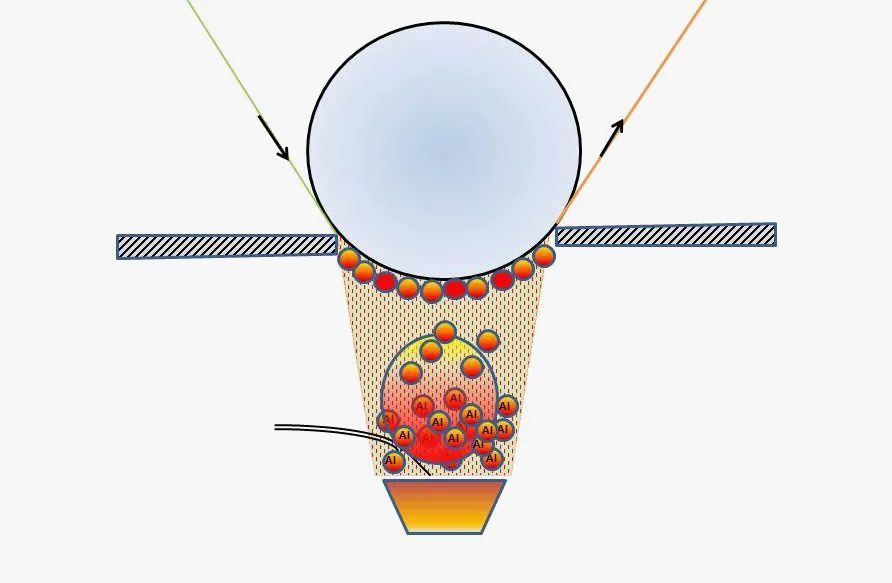

01. Ukucoca ngevacuum

—— Vacuum Metalizing ——

Ukufakwa kwe-vacuum plating kwenzeka ngenxa yenkqubo yomzimba.Kwi-vacuum, i-argon iyatofwa kwaye emva koko ibethe ithagethi.Ithagethi ke ngoko yahlulwe iimolekyuli leyo adsorbent ngempahla conductive, ukudala iyunifomu, egudileyo ukuxelisa umaleko metal.

Imathiriyeli esebenzayo:

1. I-vacuum plating inokwenzeka kuluhlu olubanzi lwezinto ezibandakanya isinyithi, i-composites, i-ceramics, iglasi, kunye neeplastiki ezithambileyo nezilukhuni.I-Aluminiyam yeyona nto ixhaphakileyo yonyango lomphezulu we-electroplating, ilandelwa lubhedu kunye nesilivere.

2. Izinto zendalo azinakwenziwa i-vacuum plated kuba ukufuma kwazo kuya kuphazamisa indawo ye-vacuum.

Iindleko zenkqubo:

Iindleko zabasebenzi ziphezulu kakhulu kwi-vacuum plating ngenxa yokuba i-workpiece kufuneka itshizwe kwaye emva koko ilayishwe, yothulwe, kwaye iphinde itshizwe.Kukwaxhomekeke kwindlela entsonkothe ngayo kwaye inkulu i-workpiece.

Impembelelo yokusingqongileyo:

I-Vacuum Electroplating ifana nokutshiza ngokweempembelelo zayo zokusingqongileyo.

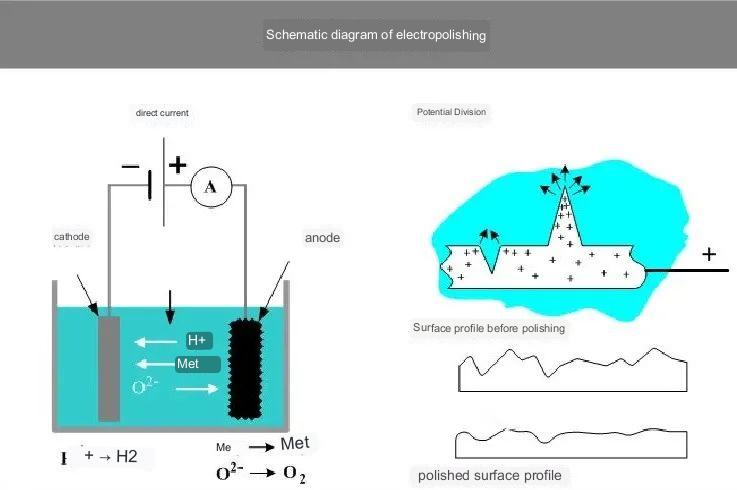

02. Electropolishing

—— Electropolishing ——

I-Electropolishing yinkqubo ye-electrochemical apho ii-athomu ze-workpiece ezifakwe kwi-electrolyte ziguqulwa zibe yi-ion kwaye zisuswe kumphezulu ngenxa yokuhamba kwamandla ombane, ngaloo ndlela kufezekiswa umphumo wokukhupha i-burrs emihle kunye nokwandisa ukukhanya kwendawo yokusebenza.

Imathiriyeli esebenzayo:

1. Uninzi lwezinyithi zinokupholishwa nge-electrolytically, phakathi kwazo ukupolisha komphezulu wensimbi engenasici kusetyenziswa kakhulu (ingakumbi kwi-austenitic nuclear grade stainless steel).

2. Izinto ezahlukeneyo azikwazi ukuhlanjululwa nge-electropolished ngexesha elinye, okanye zifakwe kwi-solvent efanayo ye-electrolytic.

Iindleko zenkqubo:

Yonke inkqubo yokupholishwa kwe-electrolytic igqitywa ngokuzenzekelayo, ngoko ke iindleko zabasebenzi ziphantsi kakhulu.Impembelelo yokusingqongileyo: I-electrolytic polishing isebenzisa iikhemikhali ezinobungozi obuncinci.Yonke le nkqubo idinga umlinganiselo omncinci wamanzi kwaye kulula ukuyisebenzisa.Ukongeza, inokwandisa iipropati zensimbi engenasici kunye nokulibazisa ukubola kwensimbi engenasici.

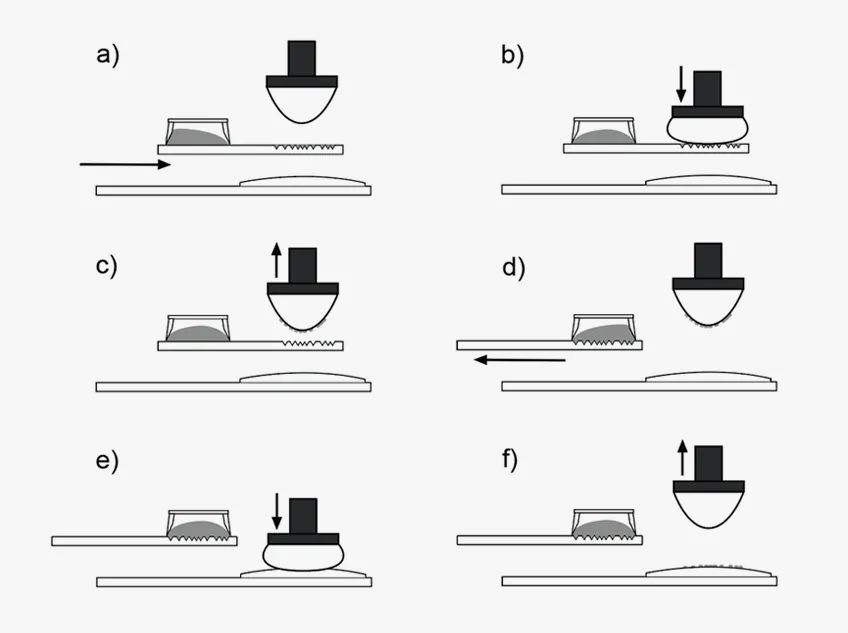

03. Inkqubo yoshicilelo lwephedi

——Ushicilelo lwePad——

Ukwazi ukuprinta okubhaliweyo, imizobo kunye nemifanekiso kumphezulu wezinto ezinemilo engaqhelekanga ngoku kuba lushicilelo olubalulekileyo olukhethekileyo.

Imathiriyeli esebenzayo:

Ukuprintwa kwePad kungasetyenziselwa phantse zonke izinto, ngaphandle kwezinto ezithambileyo kuneepads ze-silicone, ezifana ne-PTFE.

Iindleko zenkqubo:

ixabiso lokungunda eliphantsi kunye nexabiso eliphantsi labasebenzi.

Impembelelo yokusingqongileyo: Ekubeni le nkqubo ilinganiselwe kwiinki ezinyibilikayo (eziqulethe iikhemikhali eziyingozi), inefuthe eliphezulu lokusingqongileyo.

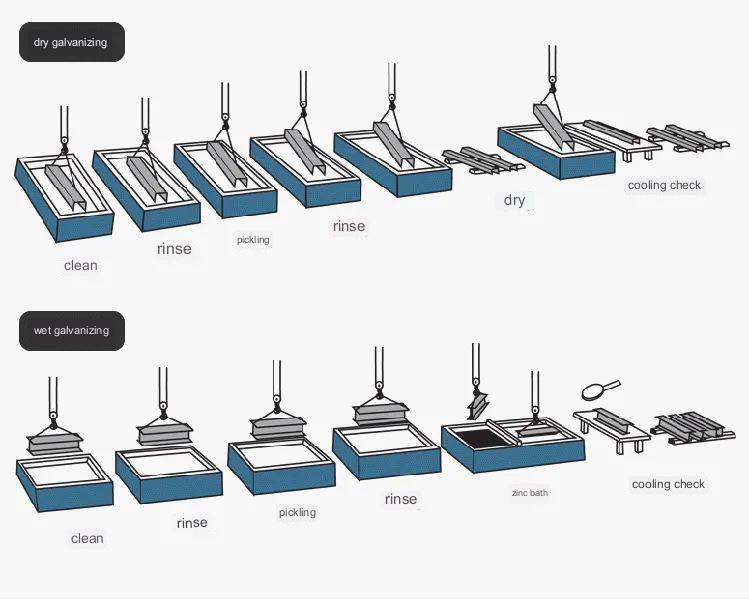

04. Inkqubo yokufaka igalvanizing

—- Ukugalela —-

Unyango lwangaphezulu olusebenzisa umaleko omncinci we-zinc kumphezulu wezinto zentsimbi yealloy.Oku kwenzelwa i-aesthetics, kwaye kwakhona kuneempawu ezichasene ne-rust.I-zinc yokugquma phezu komhlaba isebenza njengomgangatho wokukhusela we-electrochemical ukukhusela ukubola kwesinyithi.I-Hot-dip galvanizing yeyona ndlela isetyenziswayo.

Imathiriyeli esebenzayo:

I-galvanizing yonyango olungaphezulu lwentsimbi kunye nentsimbi kuphela.

Iindleko zenkqubo:

Akukho xabiso lokungunda.Umjikelo omfutshane/iindleko zomsebenzi ophakathi.Umgangatho womphezulu wesiqwenga uxhomekeke ubukhulu becala kulungiselelo lomphezulu owenziwe ngesandla phambi kokugalela.

Inkqubo yokugalela inefuthe elihle kokusingqongileyo.Yandisa ubomi obulindelekileyo beiindawo ezigayiweyo zecncukusuka kwi-40 ukuya kwi-100 iminyaka, kwaye ikhusela ukurusa kunye nokuhlwa.Isiqwenga segalvanized sinokubuyiselwa kwitanki yayo yokufaka igalvanizing xa ifikelele ekupheleni kobomi bayo obuluncedo.Oku akuyi kuvelisa inkunkuma yamachiza okanye yasemzimbeni.

05. Inkqubo ye-Electroplating

—- Electroplating —-

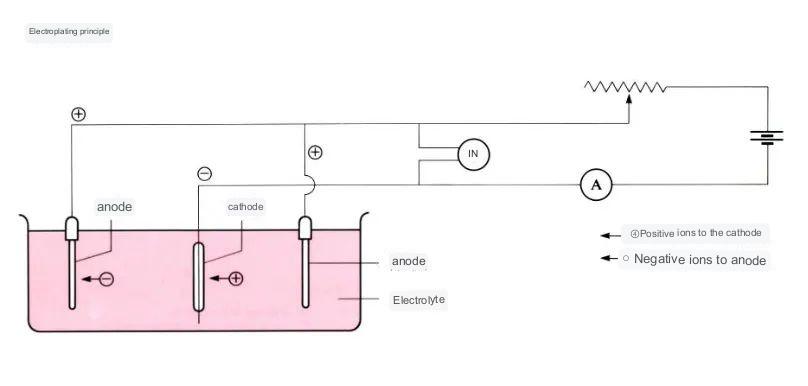

I-Electroplating yinkqubo yokusebenzisa umaleko obhityileyo wesinyithi kwiindawo kusetyenziswa i-electrolysis.Oku kunceda ekuphuculeni ukuxhathisa kwe-corrosion, ukuxhathisa ukunxiba, ukuqhuba kunye nobuhle.Iingqekembe ezininzi zinemigangatho yazo yangaphandle i-electroplated..

Imathiriyeli esebenzayo:

1. I-Electroplating inokwenzeka kwiintsimbi ezininzi, kodwa ukucoceka kunye nokusebenza kakuhle kwe-plating kuyahluka.Ezi ziquka i-tin kunye ne-nickel.

2. I-ABS yeyona plastiki ixhaphakileyo esetyenziselwa i-electroplating.

3. I-nickel inetyhefu kwaye iyacaphukisa ulusu.Ayinakusetyenziswa kwiimveliso ezenziwe nge-electroplated.

Iindleko zenkqubo:

Akukho xabiso lokungunda, kodwa izilungiso ziyafuneka ukulungisa iindawo.Iindleko zexesha zixhomekeke kuhlobo lwetsimbi kunye nobushushu.Iindleko zomsebenzi (uphezulu ophakathi) uxhomekeke kumalungu athile okucwenga.I-Silverware kunye ne-jewelry plating zifuna abasebenzi abanezakhono eziphezulu ngenxa yeemfuno zabo eziphezulu kwinkangeleko kunye nokuqina.

Impembelelo yokusingqongileyo:

I-Electroplating isebenzisa inani elikhulu lezinto eziyityhefu, ezifuna ukutsalwa kobuchule kunye nophambuko ukunciphisa impembelelo yokusingqongileyo.

06. Ushicilelo lokuThunyelwa kwamanzi

—- Ushicilelo lokuGqithisela ngeHydro —-

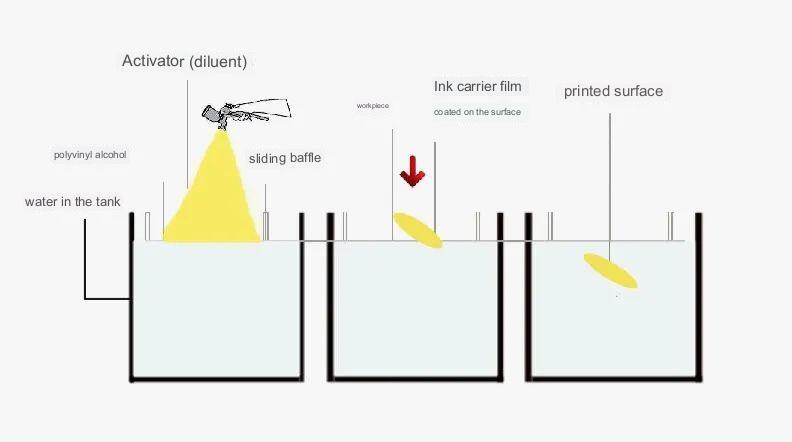

Uxinzelelo lwamanzi lusetyenziselwa ukuhambisa ipateni yombala kumphezulu weemveliso ezinomacala amathathu.Ukuprintwa kokuhanjiswa kwamanzi kuye kwaziwa kakhulu njengoko abantu belindele kakhulu ukupakishwa kunye nokuhombisa umphezulu.

Imathiriyeli esebenzayo:

Ukuprintwa kokudluliselwa kwamanzi kunokwenzeka kuzo zonke izinto ezinzima.Izinto ezifanelekileyo zokutshiza nazo zifanelekile ngolu hlobo lokuprinta.Isitofu esibunjiweyo kunyecnc metal turning partszezona zixhaphakileyo.

Iindleko zenkqubo: Ngelixa kungekho ngundo, iimveliso ezininzi kufuneka zidluliselwe ngamanzi ngaxeshanye kusetyenziswa izilungiso.Ixesha elifunekayo kumjikelo ngamnye alidli ngokudlula kwimizuzu eyi-10.

Ushicilelo lokudluliswa kwamanzi luhambelana nokusingqongileyo kunokutshiza imveliso kuba lusebenzisa ipeyinti yoshicilelo kakhulu, ngaloo ndlela inciphisa ukuvuza kwenkunkuma.

07. Ukuprintwa kweSkrini

—- Ushicilelo lweSkrini —-

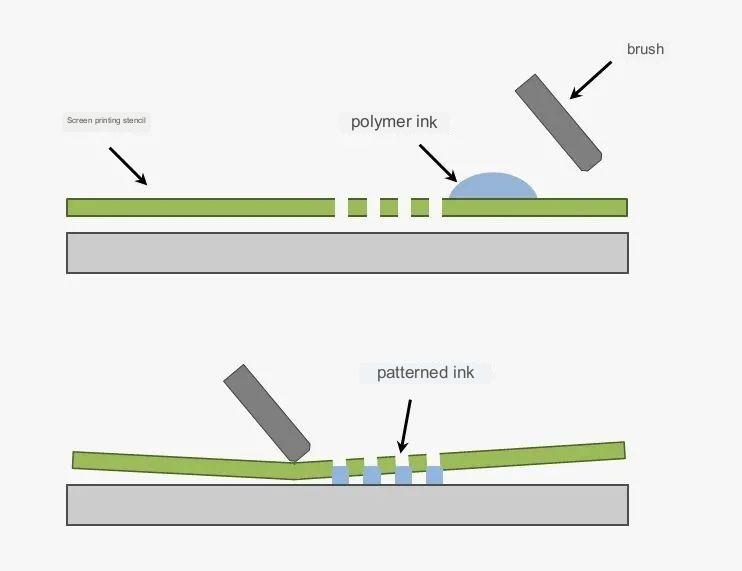

I-inki igqithiselwa ngomnatha kwindawo yegraphic kwi-substrate nge-extrusion.Oku kuvelisa umzobo ofanayo nowokuqala.Isixhobo sokushicilela isikrini kulula ukusisebenzisa, kulula ukwenza iipleyiti kunye nokuprinta, kunye nexabiso eliphantsi.

Izinto zokuprinta ezisetyenziswa ngokuqhelekileyo ziquka imizobo yeoli yombala kunye neepowusta, amakhadi oshishino kunye nezigqubuthelo ezibotshiweyo.

Imathiriyeli esebenzayo:

Ukuprintwa kwesikrini kunokwenziwa phantse kuyo nayiphi na imathiriyeli, kubandakanywa iiseramics, iiglasi, iiseramics kunye nentsimbi.

Iindleko zenkqubo:

Ixabiso lokungunda liphantsi kodwa lisaxhomekeke kwimibala yamanani kuba ipleyiti yombala nganye kufuneka yenziwe ngokwahlukileyo.Iindleko zabasebenzi ziphezulu xa kushicilelwa ngemibala emininzi.

Impembelelo yokusingqongileyo:

Ii-inki zokuprinta kwesikrini ezinemibala ekhanyayo zinefuthe eliphantsi kokusingqongileyo.Nangona kunjalo, ii-inki ezine-formaldehyde kunye ne-PVC ziikhemikhali eziyingozi kwaye kufuneka zihlaziywe okanye zilahlwe ngexesha elifanelekileyo ukuphepha ukungcoliswa kwamanzi.

08. Anodizing

—— iAnodic Oxidation ——

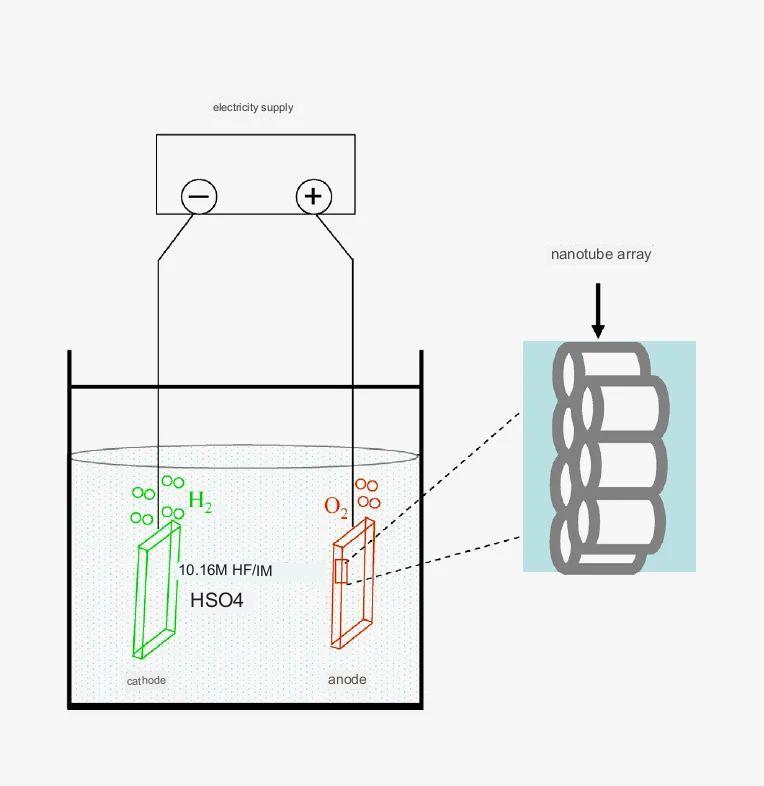

I-anodic oxidation ye-aluminium isekelwe ikakhulu kumgaqo we-electrochemical ukwenza umaleko we-Al2O3 (i-aluminium oxide) ifilimu phezu kwe-aluminium kunye ne-aluminium alloy.Olu luhlu lwefilimu ye-oxide luneempawu ezikhethekileyo ezifana nokukhuselwa, ukuhlobisa, ukugquma, kunye nokumelana nokunxiba.

Imathiriyeli esebenzayo:

I-aluminium, i-alloy ye-aluminium kunye nezinyecnc machining iinxalenye aluminiyam

Iindleko zenkqubo: Kwinkqubo yokuvelisa, ukusetyenziswa kwamanzi kunye nombane kukhulu kakhulu, ngakumbi kwinkqubo ye-oxidation.Ukusetyenziswa kobushushu bomatshini ngokwawo kufuneka kupholiswe ngokuqhubekayo ngamanzi ajikelezayo, kwaye ukusetyenziswa kwamandla ngetoni kudla malunga ne-1000 degrees.

Impembelelo yokusingqongileyo:

I-Anodizing ayigqwesileyo ngokubhekiselele ekusebenzeni kakuhle kwamandla, ngelixa ukuveliswa kwe-aluminium electrolysis, i-anode effect iphinda ivelise iigesi ezineziphumo ezibi kwi-ozone ye-atmospheric.

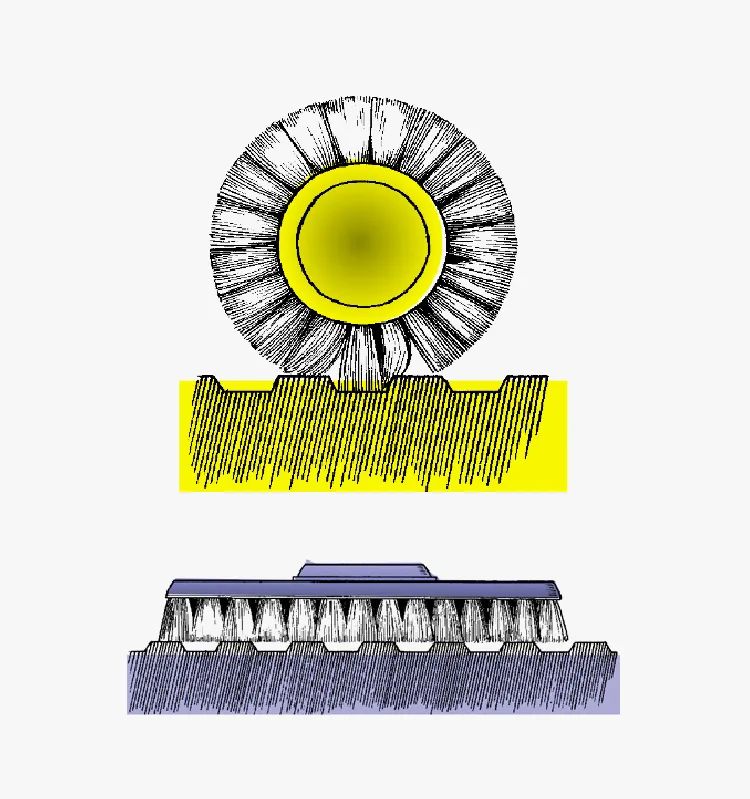

09. Umzobo wentsimbi yentsimbi

—— Iintambo zentsimbi ——

Yindlela yonyango engaphezulu eyenza imigca phezu kwendawo yokusebenza ngokugaya imveliso ukufezekisa umphumo wokuhlobisa.Ngokweendlela ezahlukeneyo zokuthungwa emva komzobo wocingo, lunokwahlulwa lube: umzobo wocingo oluthe tye, umzobo wocingo oluphithizelayo, amazinki, kunye nokujikeleza.

Imathiriyeli esebenzayo:

Phantse zonke izinto zetsimbi zingasebenzisa inkqubo yokudweba ucingo lwentsimbi.

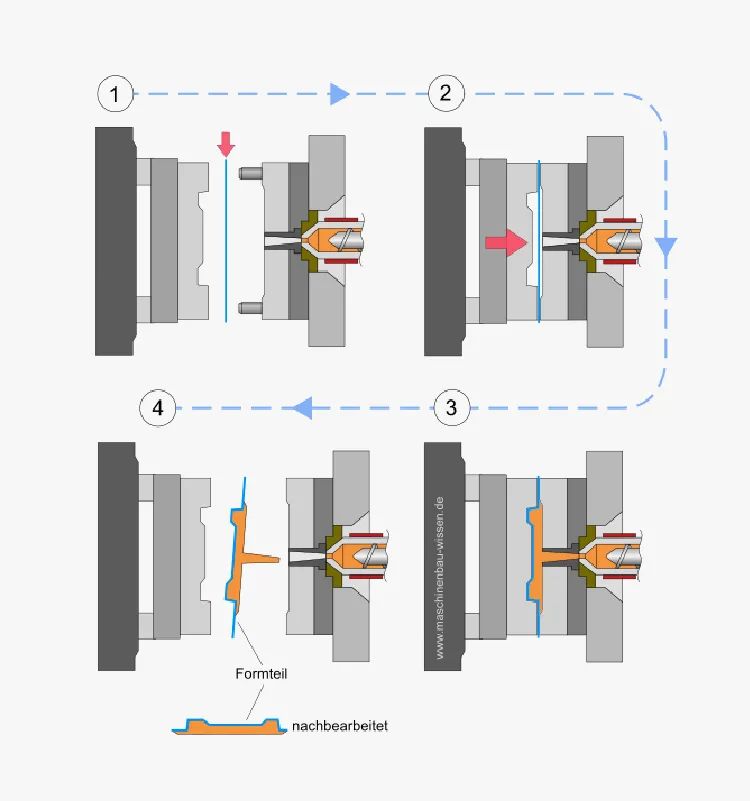

10. In-mold Decoration

—- In-Mold Decoration-IMD —-

Le ndlela yokubumba ibandakanya ukufaka i-pattern-printed metal diaphragm kwi-metal mold, ukufaka i-resin kwi-mold, ukudibanisa i-diaphragm kunye, kunye nokudibanisa i-resin kunye ne-pattern-printed metal diaphragm ukwenza imveliso yokugqibela.

Imathiriyeli esebenzayo:

Pumphezulu we-lastic

Iindleko zenkqubo:

Kufuneka kuphela ukuvula iseti enye yokubumba.Oku kunokunciphisa iindleko kunye neeyure zomsebenzi, i-High-automatic Production, i-Simplified Manufacturing Process, i-One-Time Injection Molding Method, kunye nokufezekisa ukubumba kunye nokuhlobisa ngokufanayo.

Impembelelo yokusingqongileyo:

Itekhnoloji ihambelana nokusingqongileyo kwaye iluhlaza, kwaye inqanda ungcoliseko olubangelwa yi-electroplating yemveli kunye nokupeyinta.

Iindleko zenkqubo:

Indlela yenkqubo ilula, izixhobo zilula, ukusetyenziswa kwezinto eziphathekayo kuncinci kakhulu, iindleko ziphantsi, kwaye inzuzo yezoqoqosho iphezulu.

Impembelelo yokusingqongileyo:

Iimveliso zetsimbi ezicocekileyo, akukho peyinti okanye nayiphi na imichiza ephezu komhlaba, i-600 degrees ephezulu yokushisa ayitshisi, ayivelisi iigesi ezinobuthi, ihlangabezana nokukhuselwa komlilo kunye neemfuno zokusingqongileyo.

Gcina uphucula, ukuze uqinisekise ukuba imveliso ihambelana nemigangatho yemarike kunye nabathengi.I-Anebon inenkqubo yokulawula umgangatho ekuqinisekiseni umgangatho ophezulu we-2022 wokuthengisa okushushu Amacandelo e-ABS Plastic Drilling CNC Machining Turning Part Service, Trust Anebon kwaye uya kufumana izibonelelo ezininzi.Nceda uthathe ixesha lokufikelela kuthi ukuze ufumane ulwazi oluthe kratya, i-Anebon iqinisekisa ukuba sikunika ingqalelo epheleleyo imini yonke.

Izixhobo ezizezinye zeendawo zokusila ezikumgangatho ophezulu, iintsimbi ezijike iintsimbi ezenziwe yiChina Anebon.Iimveliso ezivela e-Anebon ziye zafumana ukuqondwa okunyukayo kubathengi baphesheya kwaye ziseke ubudlelwane bexesha elide kunye nobudlelwane kunye ne-Anebon.I-Anebon iya kunika inkonzo esemgangathweni ophezulu kumthengi ngamnye.Samkela ngokufudumeleyo abahlobo abatsha ukuba bazibandakanye ne-Anebon kwaye benze izibonelelo ezifanayo.

Ixesha lokuposa: Jul-18-2023