1. Z-direction chida chokhazikitsa pakati Machining

Nthawi zambiri pali njira zitatu zokhazikitsira zida za Z-direction zamalo opangira makina:

1) Njira yokhazikitsira zida zamakina 1

Njira yokhazikitsira chida ichi ndikuwunika motsatizana mgwirizano wapakati pakati pa chida chilichonse ndi chogwirira ntchito mu makina opangira zida zamakina kudzera pakukhazikitsa zida panthawi.CNC Machining magawondiCNC kutembenuza magawo.Masitepe ake enieni ogwirira ntchito ndi awa.

(1) Yerekezerani kutalika kwa chida, pezani chida chachitali kwambiri ngati chida cholozera, pangani zida zowongolera Z, ndikugwiritsa ntchito mtengo wokhazikitsira zida (C) panthawiyi monga mtengo wa Z wa dongosolo logwirizanitsa ntchito, ndi H03= 0 pa nthawi ino.

(2) Ikani zida T01 ndi T02 pa spindle motsatizana, ndipo dziwani mfundo za A ndi B monga kutalika kwa chipukuta misozi pogwiritsa ntchito zida.(Njira iyi siyimayezera mwachindunji kubwezeredwa kwa zida, koma ndi yosiyana ndi njira 3 yotsimikiziridwa ndi zida zotsatizana.)

(3) Lembani utali wa chipukuta misozi (chida chachitali kwambiri kutalika kwa chida chotsalira) patsamba lokhazikitsira.Zizindikiro zabwino ndi zoipa zimatsimikiziridwa ndi G43 ndi G44 mu pulogalamuyi, ndipo panthawiyi imayimiridwa ndi G44H-.Mukamagwiritsa ntchito G43, kubweza kwautali ndi mtengo woipa.

Njira yokhazikitsira chida ichi ili ndi zida zapamwamba zoyendetsera bwino komanso zolondola, komanso ndalama zochepa, koma ndizosautsa kulemba zikalata zamachitidwe, zomwe zimakhudzana ndi bungwe lopanga.

2) Njira yokhazikitsira zida zamakina 2

Masitepe ogwiritsira ntchito njira yokhazikitsira chida ichi ndi awa:

(1) Mayendedwe a XY mayendedwe ndi ofanana ndi kale, ikani mtengo wosinthira mu chinthu cha XY mu G54, ndikuyika chinthu cha Z kukhala ziro.

(2) Bwezerani T1 yomwe imagwiritsidwa ntchito pokonza ndi tsinde lalikulu, gwiritsani ntchito chipika choyezera kuti mugwirizane ndi Z, werengani Z1 mtengo wa Z1 wa makina opangira makina opangira makina opangira makina, ndipo lembani kutalika kwa malipiro a H1 pambuyo pake. kuchepetsa kutalika kwa block gauge.

(3) Ikani T2 pa shaft yayikulu, igwirizanitse ndi chowerengera, werengani Z2, chotsani kutalika kwa block gauge ndikudzaza H2.

(4) Poyerekeza, gwiritsani ntchito ma block gauges kuti mugwirizane ndi zida zonse, ndikudzaza Hi mutachotsa kutalika kwa ma block gauges.

(5) Pokonza mapulogalamu, gwiritsani ntchito njira zotsatirazi kubweza:

T1;

G91 G30 Z0;

M06;

G43 H1;

G90 G54 G00 X0 Y0;

Z100;

…(Zotsatirazi ndi kukonza kwa chida cha No. 1 mpaka kumapeto)

T2;

G91 G30 Z0;

M06;

G43 H2;

G90 G54 G00 X0 Y0;

Z100;

…(Zonse zokonzedwa mu mpeni wa No.2)

…M5;

M30;

3) Kukonzekera kwa zida zapa-makina + pazida zamakina

Njira iyi yokhazikitsira chida ndikugwiritsa ntchito chosinthira chida kuyeza molondola miyeso ya axial ndi radial ya chida chilichonse kunja kwa chida cha makina, kudziwa kutalika kwa chipukuta misozi cha chida chilichonse, ndiyeno gwiritsani ntchito chida chachitali kwambiri pa chida cha makina kuti muchite Z To. kuyika zida, dziwani dongosolo logwirizanitsa ntchito.

Njira yokhazikitsira chida ichi ili ndi kukhazikika kwapamwamba kwa zida zolondola komanso zogwira mtima, ndipo ndi yabwino pokonzekera zikalata zantchito ndi bungwe lopanga, koma ndalamazo ndizokulirapo.

2. Kulowetsa kwa data yokhazikitsa zida

(1) Chida chokhazikitsa zida zomwe zapezedwa molingana ndi zomwe zili pamwambapa, ndiye kuti, X, Y, ndi Z zomwe zidachokera pamakina olumikizirana pamakina, ziyenera kuyikidwa pamanja mu G54 ~ G59 kuti zisungidwe.Njira zogwirira ntchito ndi izi:

①Dinani 【MENU OFFSET】kiyi.

②Dinani batani la cholozera kuti musunthire kuCNC mphero zigawondiCNC kutembenuza magawokugwirizanitsa dongosolo G54~G59 kuti ikonzedwe.

③Dinani【X】kiyi kuti mulowetse X kuti mugwirizane.

④Dinani 【INPUT】kiyi.

⑤Dinani 【Y】 kiyi kuti mulowetse Y kuti mugwirizane.

⑥Dinani【INPUT】kiyi.

⑦Dinani 【Z】makiyi kuti mulowetse Z yogwirizanitsa mtengo.

⑧Dinani【INPUT】kiyi.

(2) Mtengo wolipirira zida nthawi zambiri umalowetsedwa mu chida cha makina musanayambe kukonza zolakwika ndi MDI (zolowera pamanja).Masitepe a general operation ndi awa:

①Dinani 【MENU OFFSET】kiyi.

②Dinani pa kiyi yosinthira cholozera ku nambala ya chipukuta misozi.

③Ndalama zolipirira.

④Dinani 【INPUT】kiyi.

3. Njira yodulira mipeni yoyeserera

Kuyesa kudula njira ndi njira yosavuta yokhazikitsira chida, koma idzasiya zizindikiro pa workpiece, ndipo kulondola kwachikhazikitso ndi kochepa.Ndi oyenera chida chokhazikitsa pa akhakula Machining wa mbali.Njira yake yokhazikitsira zida ndi yofanana ndi yopeza m'mphepete mwa makina.

4. Lever dial gauge chida chokhazikitsa

Chida chokhazikitsa kulondola kwa chizindikiro cha lever dial ndichokwera, koma njira yogwirira ntchitoyi ndi yovuta ndipo mphamvu zake ndizochepa.Ndizoyenera kuyika zida za dzenje lomaliza (pamwamba), koma sizoyenera ku dzenje lopangira makina.

Njira yokhazikitsira chida ili motere: gwiritsani ntchito maginito owonera kuti mukope chizindikiro choyimba cholumikizira ku spindle ya malo opangira makina, ndikupangitsa mutu wa geji kukhala pafupi ndi khoma la dzenje (kapena cylindrical surface).Mkati mwa cholakwikacho, monga 0.02, zitha kuganiziridwa kuti malo ozungulira a spindle amagwirizana ndi pakati pa dzenje loyezera panthawiyi, ndikulowetsa X ndi Y kugwirizanitsa mfundo mu makina opangira makina panthawiyi mu G54.

5. Chida chokhazikitsa njira ya Z

Poganizira manufacturability wa kukhazikitsa zida, pamwamba pamwamba pa workpiece kawirikawiri amatengedwa ngati chiyambi cha Z malangizo a workpiece coordinate system.Pamene kumtunda kwa gawolo kumakhala kovuta kwambiri ndipo sikungagwiritsidwe ntchito ngati chida chokhazikitsa, vise kapena workbench ingagwiritsidwe ntchito ngati chiyambi cha Z malangizo a ndondomeko ya workpiece, ndiyeno kutalika kwa workpiece kumakonzedwa. m'mwamba mu G54 kapena njira yowonjezera yolumikizira kuti mudzaze. Makina opangira makina a Z-direction makamaka akuphatikizapo Z-direction kuyezera chida chokhazikitsa zida, kukhazikitsa zida zoyika zida ndi njira yodulira zida ndi njira zina.

6. Kuyika kwa chida ndi Z-direction kuyeza chida

Chida chokhazikitsa kulondola kwa chida choyezera njira ya Z ndichokwera, makamaka ngati zida zingapo zimayikidwa pamakina pamilling center, zida zoyika zida ndizambiri, ndalamazo ndizochepa, ndipo ndizoyenera gawo limodzi. kukonza.

1) Kuyika kwa chida cha Z-direction panthawi yachida chimodzi cha makina opangira makina

Single-chida Machining pakati Machining ndi ofanana ndi vuto kuti palibe chipukuta misozi kutalika kwa chida pa makina CNC mphero.Njira zake ndi izi:

(1) Sinthani chida chomwe chidzagwiritsidwe ntchito pokonza;

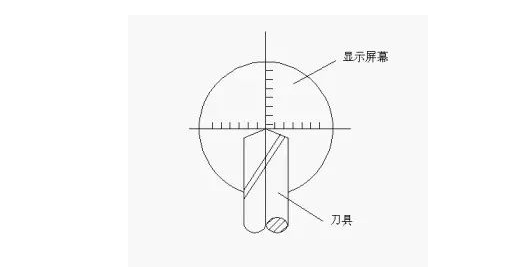

(2) Sunthani chida pamwamba pa workpiece, kuyeza mtunda pakati pa workpiece ndi chida choyezera Z-directional, ndi kulemba Z-axis kuwerenga Z ya makina amakono (makina) ogwirizanitsa dongosolo;

(3) Chotsani mtengo wa Z kuchokera kutalika kwa chida choyezera cha Z-direction panthawiyi (monga 50.03mm), ndiyeno lembani mtengo woyezera mu chinthu cha Z cha OFFSETSETTING->coordinate system–>G54;

(4) Thamangani G90 G54G0 X0 Y0 Z100;fufuzani ngati makonzedwewo ali olondola

Nthawi yotumiza: Jan-09-2023