1. Z-direction tool setting ye machining center

Pane kazhinji nzira nhatu dzeZ-direction chishandiso kuseta yemachining nzvimbo:

1) On-muchina chishandiso kuseta nzira 1

Ichi chishandiso chekumisikidza nzira ndeyekuteedzera hukama hwehukama pakati pechishandiso chega chega uye chishandiso mumushini wemuchina wekugadzirisa system kuburikidza nekugadzirisa chishandiso panguva.CNC machining zvikamuuyeCNC inoshandura zvikamu.Matanho ayo chaiwo ekushanda ndeaya anotevera.

(1) Enzanisa kureba kwechishandiso, tsvaga chishandiso chakareba sechishandiso chekutarisa, ita Z-direction tool setting, uye shandisa kukosha kwechishandiso (C) panguva ino sekukosha kweZ kweiyo workpiece coordinate system, uye H03= 0 panguva ino.

(2) Isa maturusi T01 uye T02 pachirungiso, uye tarisa kukosha kweA uye B sehurefu hwekuripira kukosha kuburikidza nekugadzirisa chishandiso.(Iyi nzira haiyere zvakananga muripo wemidziyo, asi yakasiyana nenzira yechitatu inotemerwa nekutevedzana kwezvishandiso.)

(3) Zadza muripo wehurefu hwakatemerwa (urefu hwechishandiso chakareba kubvisa kureba kwechishandiso kwasara) papeji yekuseta.Zviratidzo zvakanaka uye zvisina kunaka zvinotsanangurwa neG43 neG44 muchirongwa, uye panguva ino inowanzomiririrwa neG44H—.Paunenge uchishandisa G43, kureba muripo mutengo wakashata.

Iyi nzira yekumisikidza yezvishandiso ine yakakwira maturusi ekuseta kunyatsoita uye nemazvo, uye kushoma kwekudyara, asi hazvikodzeri kunyora magwaro ekuita, ayo ane chimwe chinokanganisa kusangano rekugadzira.

2) On-muchina chishandiso kuseta nzira 2

Matanho chaiwo ekushanda kweiyi chishandiso kuseta nzira ndeaya anotevera:

(1) Iyo XY yekumisikidza nzira yakangofanana neyakare, isa kukosha kwekubvisa muchinhu cheXY muG54, uye isa chinhu cheZ kusvika zero.

(2) Tsiva T1 inoshandiswa kugadzirisa neshaft hombe, shandisa iyo block geuge kuwiriranisa iyo Z kutungamira, verenga iyo Z kukosha Z1 yemuchina wemuchina wekubatanidza system mushure mekuoma kwakakodzera, uye zadza mukureba muripo H1 mushure. kubvisa urefu hwe block gauge.

(3) Isa T2 pane shaft huru, igadzirise ne block gauge, verenga Z2, bvisa kureba kweiyo block geuge uye uzadze H2.

(4) Nekufananidza, shandisa ma block geuges kurongedza ese maturusi ezvishandiso, uye zadza muHi mushure mekubvisa kureba kwe block geji.

(5) Pakuronga, shandisa nzira dzinotevera kubhadhara:

T1;

G91 G30 Z0;

M06;

G43 H1;

G90 G54 G00 X0 Y0;

Z100;

…(Ichi chinotevera chishandiso-pasi kugadzirisa cheNo. 1 chishandiso kusvika kumagumo)

T2;

G91 G30 Z0;

M06;

G43 H2;

G90 G54 G00 X0 Y0;

Z100;

…(Zvose zviri mukati meNo.2 banga)

…M5;

M30;

3) Off-muchina chishandiso presetting + pane-muchina chishandiso kuseta

Iyi nzira yekumisikidza maturusi ndeyekushandisa presetter yemudziyo kuyera nemazvo axial uye radial dimens yechishandiso chega chega kunze kwechishandiso chemuchina, kuona kureba kwekubhadharwa kwechishandiso chega chega, wobva washandisa chishandiso chakareba pane muchina wekuita Z To. kugadzika kwechishandiso, sarudza iyo workpiece kurongedza system.

Iyi nzira yekumisikidza yekushandisa ine yakakwira turusi yekumisikidza kurongeka uye kunyatsoita, uye yakanakira kugadzirira kwemaitiro magwaro uye sangano rekugadzira, asi mari yacho yakakura.

2. Input of tool setting data

(1) Chishandiso chekuseta data chakawanikwa zvinoenderana nemashandiro ari pamusoro, kureva, X, Y, uye Z kukosha kwekwakabva programming coordination system mumuchina wekubatanidza system, inofanira kuiswa nemaoko muG54~G59 yekuchengetedza.Matanho ekushanda ndeaya anotevera:

①Dzvanya【MENU OFFSET】kiyi.

②Dzvanya kiyi yecursor kuti uende kune iyoCNC milling zvikamuuyeCNC inoshandura zvikamukuronga system G54~G59 kuti igadziriswe.

③ Dzvanya 【X】 kiyi yekuisa X ronga kukosha.

④Dzvanya【INPUT】kiyi.

⑤Dzvanya 【Y】 kiyi yekuisa Y kurongedza kukosha.

⑥Dzvanya【INPUT】kiyi.

⑦ Dzvanya 【Z】 kiyi yekuisa Z kuronga kukosha.

⑧Dzvanya【INPUT】kiyi.

(2) Iko kukosha kwemuripo wemidziyo inowanzoiswa mumuchina wekushandisa chirongwa chisati chagadziriswa neMDI (manual data input).General oparesheni matanho ndeaya anotevera:

①Dzvanya【MENU OFFSET】kiyi.

②Dzvanya kiyi yekufamba kwecursor kune nhamba yemuripo.

③Pinza muripo mutengo.

④Dzvanya【INPUT】kiyi.

3. Muedzo wekucheka nzira yekugadzira banga

Muedzo wekucheka nzira inzira yakapusa yekumisikidza nzira, asi inosiya mamakisi pane workpiece, uye iko iko iko kugadzika iko kwakaderera.Inokodzera kugadzika kwezvishandiso panguva yakaoma machining ezvikamu.Yayo yekushandisa yekumisikidza nzira yakafanana neyeiyo mechanical edge finder.

4. Lever dial gauge tool setting

Chishandiso chekumisikidza kurongeka kweiyo lever dial chiratidzo chakakwira, asi iyi nzira yekushanda inonetsa uye kushanda kwayo kwakadzikira.Inokodzera kugadzika kwechishandiso chegomba rekupedzisa (pamusoro), asi haina kukodzera kune rough machining gomba.

Iyo nzira yekumisikidza yezvishandiso ndeiyi inotevera: shandisa iyo magineti wachi yekukwevera iyo lever dial chiratidzo kune spindle yenzvimbo yekugadzira, uye ita iyo geji musoro padhuze nemadziro egomba (kana cylindrical pamusoro).Mukati mekukanganisa, senge 0.02, zvinogona kutariswa kuti nzvimbo yekutenderera yechirungiro inopindirana nepakati pegomba rakayerwa panguva ino, uye inopinza iyo X uye Y inoronga kukosha mumuchina wekubatanidza system panguva ino muG54.

5. Tool setting muZ direction

Tichifunga nezvekugadzirwa kwechishandiso chekumisikidza, iyo yekumusoro pamusoro peiyo workpiece inowanzotorwa semabviro eiyo Z kutungamira kweiyo workpiece coordinate system.Kana iyo yekumusoro pamusoro pechikamu ichi hutsinye uye isingakwanise kushandiswa sechishandiso chekumisikidza, iyo vise kana workbench inogona zvakare kushandiswa seyakabva iyo Z kutungamira kweiyo workpiece coordinate system, uye ipapo kureba kweworkpiece kunogadziriswa. kumusoro muG54 kana kuti yakawedzerwa coordinate system yekuzadza. Z-direction machine tool setting inonyanya kusanganisira Z-direction measuring instrument setting, tool setting block tool setting uye yekuedza yekucheka nzira yekugadzirisa midziyo nedzimwe nzira.

6. Chigadziro chekushandisa neZ-direction yekuyera chiridzwa

Chishandiso chekumisikidza kurongeka kweiyo Z-direction yekuyeresa chiridzwa chakakwira, kunyanya kana akawanda maturusi akaiswa pamushini uri muchigayo machining centre, iko kugadzika kwezviyo kwakakwira, mari idiki, uye inokodzera chikamu chimwe chete. processing.

1) Z-direction chishandiso kuseta panguva imwe-chishandiso machining yenzvimbo yekugadzira

Single-chishandiso machining munzvimbo yekugadzira machining yakafanana nedambudziko rekuti hapana kureba muripo wekugadzirisa chishandiso pamushini wekugaya weCNC.Matanho acho ndeaya:

(1) Tsiva chishandiso chichashandiswa kugadzirisa;

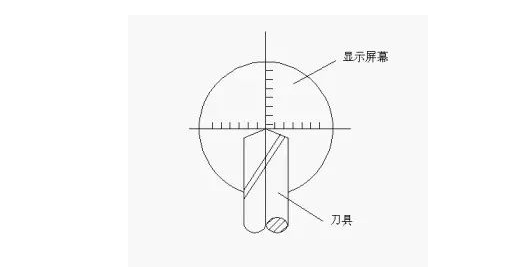

(2) Fambisa chishandiso kumusoro kwechishandiso, kuyera chinhambwe pakati pechishandiso uye chishandiso chine Z-direction yekuyeresa chiridzwa, uye rekodha iyo Z-axis yekuverenga Z yemuchina wemuchina (mechanicha) coordinate system;

(3) Bvisa kukosha kweZ kubva paurefu hweZ-direction yekuyeresa chiridzwa panguva ino (se50.03mm), wobva wazadza kukosha kwakayerwa muZ chinhu che OFFSETSETTING-> coordinate system–> G54;

(4) Mhanyai G90 G54G0 X0 Y0 Z100;tarisa kana kurongeka kwacho kwakarurama

Nguva yekutumira: Jan-09-2023