Ungakanani owaziyo malunga nendlela yokucubungula intambo kwi-CNC machining?

Kwi-CNC machining, iintambo zenziwa ngokusika okanye ukwenza imisebenzi.Nazi iindlela ezimbalwa ezisetyenziswa ngokuqhelekileyo zokusetyenzwa kwentambo ezibonelelwa liqela le-Anebon:

Ukucofa:Le ndlela ibandakanya ukusika iintambo usebenzisa itephu, esisixhobo esine-helical grooves.Ukucofa kungenziwa ngesandla okanye ngokusebenzisa umatshini, kwaye ifanelekile ekudaleni imicu yangaphakathi.

Ukugaya imisonto: Ukugaya imisonto kusebenzisa isixhobo sokusika esijikelezayo esinefluti ezininzi ukwenza imisonto.Yindlela eguquguqukayo enokusetyenziswa kwimisonto yangaphakathi nangaphandle.Ukugaya imisonto kudla ngokukhethwa kwimisonto emikhulu okanye xa iintlobo ngeentlobo zeesayizi kunye neentlobo ziyafuneka.

Ukujika imisonto:Le ndlela ibandakanya ukusebenzisa isixhobo sokusika esisodwa esifakwe kwi-lathe ukudala imicu yangaphandle.Ukujika imisonto ngokuqhelekileyo kusetyenziselwa imisonto emikhulu okanye emide kwaye ifanelekile zombini imisonto ethe tye kunye ne-tapered.

Ukuqengqeleka komsonto:Kwi-thread rolling, i-diye yensimbi eqinile ifaka uxinzelelo kwi-workpiece ukuguqula izinto kunye nokwenza imicu.Le ndlela isebenzayo kwaye ivelisa imicu ephezulu, eyenza ifaneleke kwimveliso ephezulu.

Ukucola umsonto:Ukucola umsonto yinkqubo echanekileyo yomatshini esebenzisa ivili lokusila ukwenza imisonto.Ihlala isetyenziselwa ukuchaneka okuphezulu kunye nokuveliswa kwentambo ephezulu, ngakumbi kwimicu enzima okanye ekhethekileyo.

Xa ukhetha indlela yokulungisa intambo, izinto ezifana nobukhulu bentambo, iimfuno zokuchaneka, iimpawu eziphathekayo, umthamo wemveliso, kunye nokuqwalaselwa kweendleko kufuneka kuthathelwe ingqalelo.

Imbali

Igama lesiNgesi elihambelana ne-screw yi-Screw.Intsingiselo yeli gama itshintshe kakhulu kumakhulu eminyaka yakutshanje.Ubuncinci ngo-1725, lithetha "ukukhwelana".

Ukusetyenziswa komgaqo womsonto kunokulandwa umva kwisixhobo sokuphakamisa amanzi esijikelezayo esenziwe ngumphengululi ongumGrike uArchimedes ngowama-220 BC.

Ngenkulungwane yesi-4 ye-AD, amazwe agudle ulwandle lweMeditera aqala ukusebenzisa umgaqo weebholiti kunye namandongomane koomatshini bokushicilela abasetyenziselwa ukwenza iwayini.Ngelo xesha, imisonto yangaphandle yayisongelwe yonke ngentambo kwi-cylindrical bar, ize ikrolwe ngokwalo phawu, ngoxa imisonto yangaphakathi yayidla ngokuyilwa ngokubethelela imisonto yangaphandle ngezinto ezithambileyo.

Malunga ne-1500, kumzobo wesixhobo sokulungisa intambo esizotywe ngu-Leonardo da Vinci wase-Italiya, kwakusele kukho umbono wokusebenzisa isikrufu sowasetyhini kunye negiya yokutshintshiselana ukwenza imisonto yeepitshi ezahlukeneyo.Ukususela ngoko, indlela yokusika imisonto ngoomatshini iye yaphuhliswa kwishishini laseYurophu lokwenza iiwotshi.

Ngowe-1760, abazalwana baseBritani uJ. Wyatt noW. Wyatt bafumana ilungelo elilodwa lomenzi wechiza lokusika izikrufu zomthi ngesixhobo esikhethekileyo.Ngomnyaka we-1778, iBritish J. Ramsden yakha yenza isixhobo sokusika intambo esiqhutywa yigeya yeentshulube, esinokuthi siqhube imisonto emide ngokuchaneka okuphezulu.Ngo-1797, iBritish H. Mozley yasebenzisa isikrufu sokukhokela esibhinqileyo kunye negiya yokutshintshiselana ukujika imisonto yentsimbi enemitsi eyahlukeneyo kwilathe ephuculwe nguye, kwaye yaseka indlela esisiseko yokujika imisonto.

Ngeminyaka yoo-1820, uMaudsley wenza ibhetshi yokuqala yeetephu kwaye wafela ukusetyenzwa komsonto.

Ekuqaleni kwenkulungwane yama-20, uphuhliso lweshishini leemoto lwakhuthaza ngakumbi ukubekwa emgangathweni kwemisonto kunye nophuhliso lweendlela ezahlukeneyo zokuchaneka kunye neendlela ezisebenzayo zokulungisa imisonto.Iintloko ezahlukeneyo zokuvula ezizenzekelayo zokuvula kunye neetephu ezizenzekelayo ezicuthekayo zayilwa enye emva kwenye, kwaye kwaqala ukusetyenziswa imisonto yokusila.

Ekuqaleni kweminyaka yee-1930, kwavela ukucola intambo.

Nangona iteknoloji yokuqengqa intambo yayinelungelo elilodwa lomenzi ekuqaleni kwenkulungwane ye-19, ngenxa yobunzima bokwenziwa kokungunda, uphuhliso lwalucotha kakhulu.Kwakungekho kwaze kwaba yiMfazwe Yehlabathi yesiBini (1942-1945) ukuba ngenxa yeemfuno zemveliso yezixhobo kunye nophuhliso lweteknoloji yokugaya intambo, ingxaki yasonjululwa.Ingxaki echanekileyo yokwenziwa komngundo iphumelele uphuhliso olukhawulezayo.

Intambo yahlulwe kakhulu ibe yintambo yokudibanisa kunye nentambo yokuhambisa

Ukudibanisa imicu, iindlela zokucubungula ziyintloko: ukucofa, ukuthunga, ukuthunga, ukuqengqeleka, ukuqengqeleka, njl.

Kwintambo yokuhambisa, iindlela eziphambili zokucubungula zezi: ukujika kunye nokuguquguquka okulungileyo-ukugaya, ukugaya isivunguvungu-ukujika kunye nokujika okulungileyo, njl.

Udidi lokuqala: ukusika intambo

Ngokubanzi ibhekisa kwindlela yokusetyenzwa kwemisonto kwizinto zokusebenza ezinezixhobo zokwenza okanye izixhobo ezirhabaxa, ingakumbi eziquka ukujika, ukungqusha, ukucofa kunye nokusila intambo, ukugawula kunye nokusika isaqhwithi.Xa ujika, ukugaya kunye nokugaya imicu, rhoqo xa i-workpiece ijikeleza, ikhonkco lokuhambisa isixhobo somatshini liqinisekisa ukuba isixhobo sokuguqula, i-milling cutter okanye ivili lokugaya lihambisa isikhokelo ngokuchanekileyo kwaye ngokulinganayo kunye ne-axis ye-workpiece.Xa ucofa okanye ukuthunga, isixhobo (itephu okanye ufe) kunye nesixhobo sokusebenza senza intshukumo ejikelezayo, kwaye i-groove yokuqala eyenziwe ngentambo ikhokela isixhobo (okanye i-workpiece) ukuhamba nge-axially.

1. Ukujika imisonto

Ukuguqula imisonto kwilathe kunokusebenzisa isixhobo sokujika okanye ikama.Ukuguqula intambo kunye nesixhobo sokuguqula isicatshulwa yindlela eqhelekileyo yokuvelisa i-single-piece kunye ne-batch encinci ye-workpieces edibeneyo ngenxa yesakhiwo esilula sesixhobo;ukuguqula intambo ngesixhobo sokuhlanganisa intambo inomgangatho ophezulu wemveliso, kodwa isakhiwo sesixhobo sinzima kwaye sifanelekile kuphela kwimveliso ephakathi kunye nenkulu Ukuguqula ii-workpieces ezimfutshane ezinemisonto kunye nepitch entle.Ukuchaneka kwe-pitch ye-trapezoidal thread ekuguquleni i-lathes eqhelekileyo inokufikelela kuphela kumabakala 8 ukuya kwi-9 (JB2886-81, efanayo ngezantsi);ukucutshungulwa kwemisonto kwiintambo ezikhethekileyo kunokuphucula kakhulu imveliso okanye ukuchaneka.

2. Ukugaya imisonto

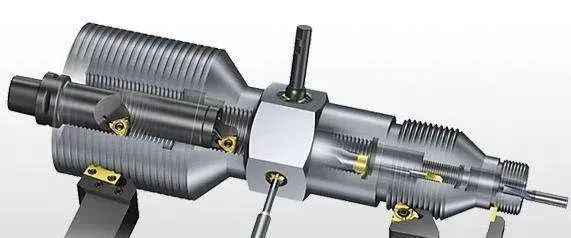

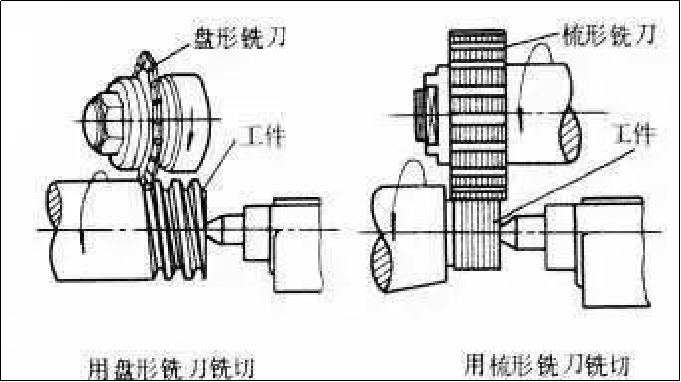

Iprototype cnc millingngesisiki sediski okanye isisiki sekama kumatshini wokusila intambo.

Izisiki zokusila iidiskhi zisetyenziswa ikakhulu kwimisonto yokusila yetrapezoidal yangaphandle kwizinto zokusebenza ezifana nezikrufu kunye neentshulube.Umsiki wokusila omile njengekama usetyenziselwa ukugaya imisonto eqhelekileyo yangaphakathi nangaphandle kunye nemisonto ye-taper.Ekubeni ixutywe nge-multi-edged milling cutter kunye nobude becandelo layo lokusebenza likhulu kunobude bomtya ogqityiweyo, i-workpiece kufuneka ijikelezwe kuphela kwi-1.25 ukuya kwi-1.5 ijika kwi-process.Yenziwe, imveliso iphezulu.Ukuchaneka kwe-pitch yokugaya intambo ngokubanzi kunokufikelela kumabakala angama-8-9, kwaye uburhabaxa bomphezulu yi-R5-0.63 microns.Le ndlela ifanelekile kwimveliso yebhetshi yee-workpieces ezinemisonto ngokuchaneka ngokubanzi okanye umatshini orhabaxa phambi kokugaya.

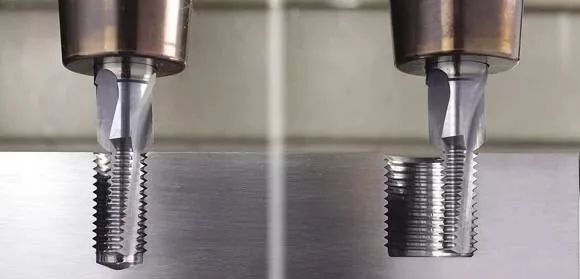

Imisonto yokusila icutha imachining intambo yangaphakathi

3. Ukusila imisonto

Isetyenziselwa ikakhulu ukucubungula imisonto echanekileyo yezixhobo zokusebenza eziqinisiweyo kumatshini wokusila intambo.Ngokwemilo yecandelo le-cross-section yevili lokusila, linokwahlulwa libe ziindidi ezimbini: ivili lokugaya umgca omnye kunye nevili lokugaya i-multi-line.Ukuchaneka kwe-pitch ye-single-line grinding wheel grinding ingaba ngamabakala angama-5-6, uburhabaxa bomhlaba buyi-R1.25-0.08 microns, kunye nokugqoka ivili lokugaya kulula ngakumbi.Le ndlela ilungele ukugalela izikrufu zokukhokela ezichanekileyo, iigeyiji zentambo, iintshulube, iibhetshi ezincinci zemisonto ephothiweyo kunye nokusila.icandelo elijikiweyo elichanekileyo.

Ukugaya ivili lokusila ngemigca emininzi yohlulwe ibe ziindidi ezimbini: indlela yokugaya i-longitudinal kunye nendlela yokugaya.Kwindlela yokugaya i-longitudinal, ububanzi bevili lokusila buncinane kunobude bomsonto oza kucolwa, kwaye umsonto unokucolwa ukuya kutsho kumlinganiselo wokugqibela ngokuhambisa ivili lokusila ngobude kanye okanye izihlandlo eziliqela.Kwindlela yokugaya i-cut-in, ububanzi bevili lokusila bukhulu kunobude bomsonto oza kwenziwa.

Ivili lokusila linqumla kumphezulu we-workpiece radially, kwaye i-workpiece inokucolwa emva kwe-1.25 revolutions.Imveliso iphezulu, kodwa ukuchaneka kuncinci, kwaye ukugqoka kwevili lokugaya kunzima ngakumbi.Indlela yokugaya i-plunge ilungele iitephu zokusila ngeebhetshi ezinkulu kunye nokusila imisonto ethile ukuze kuqiniswe.

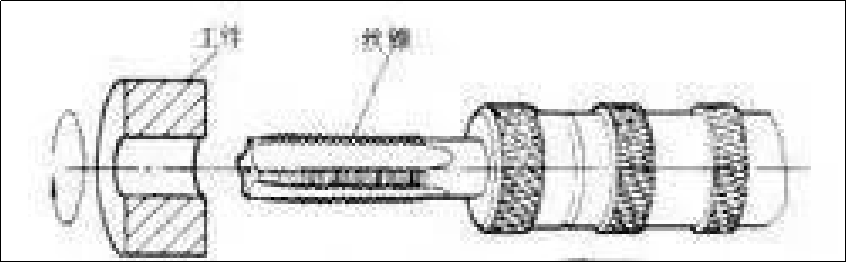

4. Ukusila imisonto

I-nut-type okanye i-screw-type thread grinder yenziwe ngezinto ezithambileyo ezifana nentsimbi, kunye necnc ukuguqula iindawoyentambo ecutshungulwayo kwi-workpiece enemposiso ye-pitch ijikeleziswa kwizalathiso zangaphambili kunye nokubuyisela umva ukuphucula ukuchaneka kwe-pitch.Iintambo zangaphakathi eziqiniweyo zihlala ziphantsi ukuze ziphelise i-deformation kunye nokuphucula ukuchaneka.

5. Ukucofa kunye nokuthunga

Ukucofa

Kukusebenzisa itorque ethile ukujija impompo kumngxuma osezantsi ogrunjwe kwangaphambili kwisixhobo sokusebenza ukuqhubekekisa umsonto wangaphakathi.

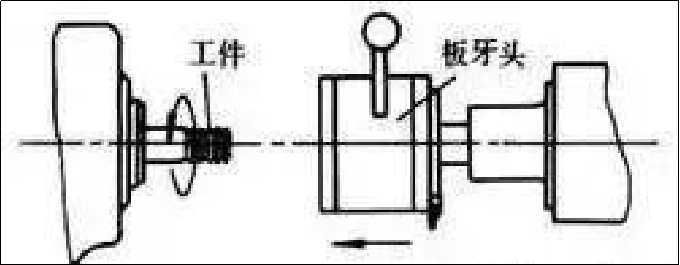

Umsonto

Kukusebenzisa i-die ukusika intambo yangaphandle kwibar (okanye umbhobho) workpiece.Ukuchaneka komatshini wokucofa okanye ukuthunga kuxhomekeke ekuchanekeni kompompo okanye kufa.

Nangona zininzi iindlela zokulungisa imisonto yangaphakathi nangaphandle, imisonto yangaphakathi ene-diameter encinci inokucutshungulwa kuphela ngeetephu.Ukucofa kunye nokuthunga kunokwenziwa ngesandla, okanye ngeentambo, oomatshini bokucoca, oomatshini bokucofa kunye noomatshini bokuthunga.

Udidi lwesibini: ukuqengqeleka komsonto

Indlela yokucubungula apho i-workpiece ikhubazeke ngeplastiki ngokubumba i-fay rolling die ukufumana iintambo.Ukuqengqeleka komsonto ngokuqhelekileyo kuqhutywa kumatshini wokuqengqeleka kwemisonto okanye kwilathe ezenzekelayo enentloko eqengqelekayo yokuvula kunye nokuvala intambo.Imisonto yangaphandle yokuveliswa kobunzima bezibophelelo eziqhelekileyo kunye nolunye udibaniso olunemisonto.Ububanzi bangaphandle bomsonto ojikeleziweyo abukho ngaphezu kwe-25 mm ubude, ubude abukho ngaphezu kwe-100 mm, ukuchaneka kwentambo kunokufikelela kwinqanaba le-2 (GB197-63), kwaye ububanzi bendawo engenanto esetyenzisiweyo ilingana ngokulinganayo ne-pitch. Idayamitha yomsonto owenziweyo.Ukuqengqeleka ngokuqhelekileyo akukwazi ukucubungula imisonto yangaphakathi, kodwa kwizinto zokusebenza ezinemathiriyeli ethambileyo, iimpompo ze-grooveless extrusion zingasetyenziselwa ukukhupha imisonto yangaphakathi ebandayo (ubukhulu bedayamitha inokufikelela malunga ne-30 mm), kwaye umgaqo wokusebenza ufana nokucofa.I-torque efunekayo kwi-extrusion ebandayo yemisonto yangaphakathi imalunga

Ukuphinda kabini oko kucofa, kunye nokuchaneka komatshini kunye nomgangatho womphezulu ungaphezulu kancinci kunowo wokucofa.

Izinto ezilungileyo zokuqengqeleka komsonto: ① Uburhabaxa bomphezulu buncinci kunobo bokujika, ukungqusha kunye nokusila;② Umphezulu wentambo emva kokuqengqeleka unokunyusa amandla kunye nobunzima ngenxa yokuqina okubandayo;③Ukusetyenziswa kwezinto eziphezulu;④Imveliso iphindwe kabini xa kuthelekiswa nokusetyenzwa kokusika, kwaye kulula ukuzenzela;⑤ ukuqengqeleka kobomi bude kakhulu.Nangona kunjalo, intambo yokuqengqeleka ifuna ukuba ukuqina kwesixhobo sokusebenza akudluli kwi-HRC40;imfuno yokuchaneka kwe-dimensional ye-blank iphezulu;ukuchaneka kunye nobunzima bokubumba i-rolling nayo iphezulu, kwaye kunzima ukuvelisa i-mold;ayifanelekanga ukuqengqeleka imicu enemilo yezinyo e-asymmetric.

Ngokweendlela ezahlukeneyo zokufa, ukuqengqeleka komsonto kunokohlulwa kube ziindidi ezimbini: ukuqengqeleka komsonto kunye nokuqengqeleka kwentambo.

6. Ukuhlikihla

Iibhodi ezimbini eziqengqelekayo ezinemisonto eneprofayili yomsonto zicwangciswe ngokuchaseneyo enye nenye nge-1/2 yepitch egxadazayo, ibhodi engashukumiyo ilungisiwe, kwaye ibhodi eshukumayo yenza intshukumo ehambelanayo ehambelanayo ehambelana nebhodi emileyo.Xa iiindawo ezenziwe ngoomatshiniiyondliwa phakathi kwamacwecwe amabini, ipleyiti ehamba phambili iqhubela phambili kwaye ihlikihle i-workpiece, yenza umphezulu wayo weplastiki ukhubazeke ukwenza imicu (Umfanekiso 6 [ukuqengqeleka komsonto]).

7. Ukuqengqeleka komsonto

Kukho iintlobo ezi-3 zokuqengqeleka kwentambo, ukuqengqeleka kwentambo ye-radial, ukuqengqeleka komsonto kunye nentloko eqengqelekayo.

① Ukuqengqeleka kwentambo yeRadial: 2 (okanye 3) amavili aqengqelekayo anemisonto eneprofayili yomsonto afakwe kwishafu ezinxuseneyo, indawo yokusebenza ibekwe kwinkxaso phakathi kwamavili amabini, kwaye amavili amabini ajikeleza ngesantya esifanayo kwicala elinye (Umfanekiso 7). [Ukuqengqeleka komsonto weRadial]), enye yazo yenza intshukumo yokutya kweradial.I-workpiece ijikeleza phantsi komqhubi wevili elijikelezayo, kwaye umphezulu we-radially extruded ukwenza imicu.Kwezinye izikrufu ezikhokelayo ezingadingi kuchaneka okuphezulu, indlela efanayo ingasetyenziselwa ukwenza umqulu.

②I-Tangential thread rolling: Eyaziwa nangokuthi i-thread thread rolling, isixhobo esijikelezayo sinevili elijikelezayo elijikelezayo kunye neepleyiti zocingo ezi-3 ezimile okwe-arc (Umfanekiso 8 [i-tangential thread rolling]).Ngexesha lokuqengqeleka kwentambo, i-workpiece inokondliwa ngokuqhubekayo, ngoko ke imveliso iphezulu kuneyokuqengqeleka kwentambo kunye ne-radial thread rolling.

③Ukuqengqeleka kwentambo yentloko: Yenziwa kwilathe ezenzekelayo, kwaye isetyenziswa ngokubanzi ukucubungula imisonto emifutshane kwizinto zokusebenza.Kukho i-3 ukuya kwi-4 yamavili ajikelezayo asasazwa ngokulinganayo kwi-periphery yangaphandle ye-workpiece kwintloko eqengqelekayo (Umfanekiso 9 [intloko eqengqelekayo]).Ngethuba lokujikeleza intambo, i-workpiece ijikeleza, kwaye intloko ejikelezayo idla i-axially ukuze iqhube i-workpiece ngaphandle kwentambo.

8. EDM processing thread

Ukusetyenzwa komsonto okuqhelekileyo kusetyenziswa amaziko omatshini okanye izixhobo zokucofa kunye nezixhobo, kwaye ngamanye amaxesha ukucofa ngesandla kuyenzeka.Nangona kunjalo, kwezinye iimeko ezikhethekileyo, le ndlela ingasentla ayilulanga ukufumana iziphumo ezilungileyo zokusebenza, ezifana nesidingo sokucwangcisa imisonto emva kokunyangwa kobushushu bamalungu ngenxa yokungakhathali, okanye ngenxa yokunyanzeliswa kwezinto eziphathekayo, njengokucofa ngokuthe ngqo kwi-workpieces ye-carbide enesamente.Ngeli xesha, kuyimfuneko ukuqwalasela indlela yokwenza i-EDM.

Xa kuthelekiswa nemetal cnc machiningindlela, umyalelo we-EDM uyafana, kwaye umngxuma ophantsi kufuneka uqhutywe kuqala, kwaye ububanzi bomngxuma ophantsi kufuneka bubekwe ngokwemiqathango yokusebenza.I-electrode idinga ukucutshungulwa kwimilo yentambo, kwaye i-electrode kufuneka ikwazi ukujikeleza ngexesha lokucubungula.

"Umgangatho wokuqala, ukunyaniseka njengesiseko, inkampani enyanisekileyo kunye nenzuzo efanayo" ngumbono ka-Anebon, ukuze ukwazi ukudala ngokungaguquguqukiyo kwaye ulandele ukugqwesa kweChina i-Wholesale Custom Machining Part-Sheet Metal Part Factory-Auto Part, iAnebon yakhula ngokukhawuleza ngobukhulu kunye negama. ngenxa yokuzinikela ngokupheleleyo kwe-Anebon kwimveliso ekumgangatho ophezulu, ixabiso elikhulu lempahla kunye nomnikezeli omkhulu wabathengi.

I-OEM Manufacturer China Machining Part and Stamping Part, Ukuba kufuneka ube nayo nayiphi na imveliso ye-Anebon kunye nezisombululo, okanye ube nezinye izinto eziza kuveliswa, qiniseka ukuba usithumelele imibuzo yakho, iisampulu okanye imizobo enzulu.Ngeli xesha, ijolise ekuphuhliseni ibe liqela leshishini lamazwe ngamazwe, i-Anebon iya kuhlala ilapha ukuze ijonge phambili ekufumaneni unikezelo lwamaphulo adibeneyo kunye nezinye iiprojekthi zentsebenziswano.

Ixesha lokuposa: Jun-19-2023