Zvakawanda sei zvaunoziva nezve nzira yekugadzirisa tambo muCNC machining?

MuCNC machining, tambo dzinowanzo gadzirwa nekucheka kana kuumba mashandiro.Heano mashoma anowanzo shandiswa shinda yekugadzirisa nzira dzakapihwa neAnebon timu:

Kubatisa:Iyi nzira inosanganisira kucheka tambo uchishandisa pombi, chiri chishandiso chine helical grooves.Kubata kunogona kuitwa nemaoko kana kushandisa muchina, uye yakakodzera kugadzira tambo dzemukati.

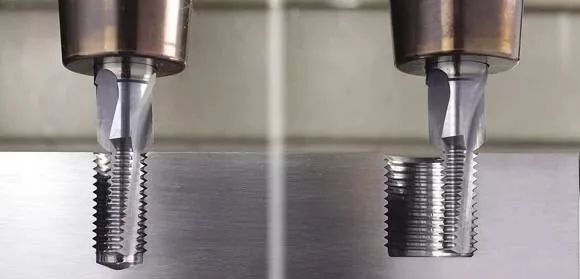

Thread Milling: Kugaya shinda kunoshandisa chinotenderera chekucheka chishandiso chine nyere dzakawanda kugadzira shinda.Iyo inzira inosiyana-siyana inogona kushandiswa kune ese emukati nekunze shinda.Kugaya shinda kunowanzofarirwa shinda hombe kana panodiwa masaizi akasiyana siyana nemhando.

Thread Turning:Iyi nzira inosanganisira kushandisa chigadziro chekucheka-chete chakaiswa pa lathe kugadzira tambo dzekunze.Thread turning inowanzoshandiswa kune hombe kana kureba shinda uye inokodzera ese ari maviri akatwasuka uye tapered shinda.

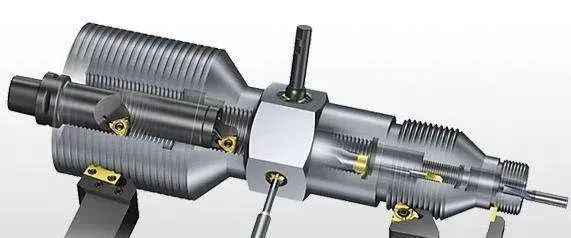

Thread Rolling:Mukukunguruka kweshinda, simbi yakaomeswa inofa inoshandisa kumanikidza kune workpiece kuti iparadze zvinhu uye kugadzira shinda.Iyi nzira inoshanda uye inogadzira tambo dzemhando yepamusoro, zvichiita kuti ive yakakodzera kugadzirwa kwepamusoro-soro.

Kukuya Thread:Kukuya shinda inzira chaiyo yekushandisa iyo inoshandisa vhiri rekukuya kugadzira shinda.Inowanzo shandirwa kwepamusoro-chaiyo uye yemhando yepamusoro kugadzira shinda, kunyanya kune dzakaoma kana hunyanzvi shinda.

Pakusarudza nzira yekugadzira shinda, zvinhu zvakaita sesaizi yeshinda, kurongeka kwezvinodiwa, zvinhu zvemukati, vhoriyamu yekugadzira, uye mari inotariswa zvinofanirwa kuverengerwa.

Nhoroondo

Izwi reChirungu rinoenderana nerokuti Chikurukuru.Zvinorehwa neshoko iri zvachinja zvakanyanya mumazana emakore achangopfuura.Kanenge muna 1725, zvinoreva "kusangana".

Kushandiswa kweiyo tambo musimboti kunogona kurondwa kumashure kune inotenderera mvura-yekusimudza chishandiso chakagadzirwa nenyanzvi yechiGiriki Archimedes muna 220 BC.

Muzana ramakore rechina AD, nyika dziri pedyo neGungwa reMediterranean dzakatanga kushandisa musimboti wemabhaudhi nenzungu kumichina yaishandiswa kubika waini.Panguva iyoyo, shinda dzokunze dzaiputirwa netambo kusimbi yecylindrical, dzozonyorwa maererano nechiratidzo ichi, nepo shinda dzomukati dzaiwanzogadzirwa nokurova shinda dzekunze nezvinhu zvakapfava.

Kuma1500, muchidimbu chetambo yekugadzira tambo yakadhirowewa naItari Leonardo da Vinci, pakanga patove nepfungwa yekushandisa screw yechikadzi uye giya rekuchinjana kugadzira tambo dzemapanji akasiyana.Kubva ipapo, nzira yekucheka shinda nemichina yakatanga muindasitiri yekugadzira wachi yeEurope.

Muna 1760, hama dzokuBritain J. Wyatt naW. Wyatt vakawana patent yekucheka masiruu ehuni nemudziyo unokosha.Muna 1778, muBritish J. Ramsden akambogadzira shinda yekucheka shinda inotyairwa nehonye giya pair, iyo yaigona kugadzira shinda refu nehupamhi hwepamusoro.Muna 1797, muBritish H. Mozley akashandisa sikuruu yemutungamiri wechikadzi uye giya rekuchinjanisa kushandura shinda dzesimbi dzine mapiji akasiyana palathe yakavandudzwa naye, ndokugadzira nzira yekutanga yekutenderedza shinda.

Mumakore ekuma1820, Maudsley akagadzira batch rekutanga rematepi uye anofira kugadzirwa kweshinda.

Mukutanga kwezana ramakore rechi20, kusimukira kweindasitiri yemotokari kwakawedzera kusimudzira kumisikidzwa kwetambo uye kuvandudzwa kweakasiyana akajeka uye anobudirira nzira dzekugadzira tambo.Yakasiyana-siyana otomatiki yekuvhura misoro yekufa uye matepi anodzikira otomatiki akagadzirwa imwe mushure meimwe, uye shinda yekugaya yakatanga kuiswa.

Mukutanga kwema1930, kukuya kweshinda kwakaonekwa.

Kunyangwe iyo tekinoroji yekutenderedza tekinoroji yaive patent mukutanga kwezana ramakore re19, nekuda kwekuoma mukugadzira mold, budiriro yacho yainonoka.Yakanga isiri iyo kusvika Hondo Yenyika Yechipiri (1942-1945) iyo nekuda kwezvinodiwa zvekugadzira zvombo uye kuvandudzwa kwetambo yekukuya tekinoroji, dambudziko rakagadziriswa.Dambudziko rechokwadi rekugadzira mold rakawana kukurumidza kukura.

Iyo shinda inonyanya kukamurwa kuita tambo yekubatanidza uye tambo yekutumira

Kubatanidza tambo, nzira dzekugadzirisa dzinonyanya: kurovera, kupinza, kukanda, kupepeta, kutenderedza, nezvimwe.

Kune tambo yekutumira, nzira huru dzekugadzirisa ndeidzi: dzakakasharara uye dzakanaka kutendeuka-kukuya, chamupupuri kugaya-yakaoma uye yakanaka kutendeuka, nezvimwe.

Chikamu chekutanga: kucheka shinda

Kazhinji inoreva nzira yekugadzira tambo pazvishandiso zvine maturusi ekugadzira kana maturusi ekurovera, kunyanya zvinosanganisira kutenderedza, kugaya, kubaya uye kugaya shinda, kugaya uye kucheka kwechamupupuri.Kana uchitenderedza, kugaya nekukuya tambo, pese pese pese painotenderera chishandiso, cheni yekufambisa yemuchina wemuchina inova nechokwadi chekuti chishandiso chekutenderera, chigayo chekucheka kana vhiri rekukuya chinofambisa mutobvu nemazvo uye zvakaenzana pamwe neaxis yebasa rekushanda.Kana uchibaya kana shinda, chishandiso (pombi kana kufa) uye workpiece inoita kutenderera kutenderera, uye yekutanga yakaumbwa shinda groove inotungamira chishandiso (kana workpiece) kufamba axially.

1. Kutenderedzwa kweshinda

Kutenderedza shinda palathesi kunogona kushandisa mudziyo wekutenderedza kana muzinga weshinda.Kutenderedza tambo ine dhizaini yekugadzira inoshandura inzira yakajairika yeimwe-chidimbu uye diki-batch kugadzirwa kwe threaded workpieces nekuda kwechimiro chakareruka chechishandiso;kushandura shinda ine shinda yemuzinga chishandiso chine yakakwirira kugadzirwa kwehunyanzvi, asi chimiro cheturusi chakaomarara uye chinokodzera chete kugadzirwa kwepakati uye kwakakura-Kushandura mapfupi mapfupi workpiece ane gomo rakanaka.Kurongeka kwetambo yetrapezoidal kutendeutsa machira akajairwa anogona kungosvika mamakisi 8 kusvika 9 (JB2886-81, zvakafanana pazasi);kugadzirisa tambo paakasarudzika shinda lathes kunogona kuvandudza zvakanyanya kugadzirwa kana kurongeka.

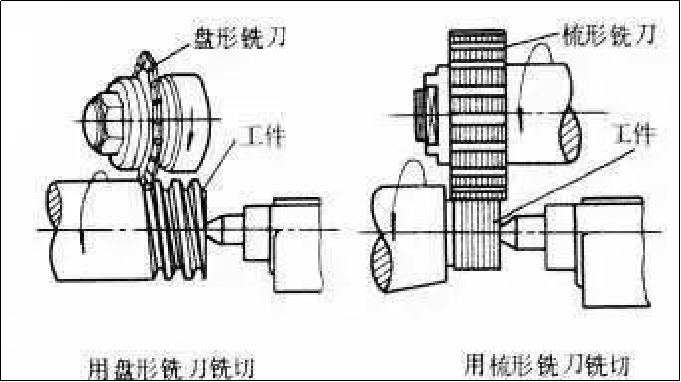

2. Kugaya shinda

Prototype cnc kugayaine disc cutter kana comb cutter pamushini wekugaya shinda.

Disc milling cutters anonyanya kushandiswa kukuya trapezoidal ekunze shinda pane workpieces akadai sikuruu rods uye makonye.Mucheka wakaita muzinga wekugaya unoshandiswa kugaya mukati nekunze shinda dzakajairwa uye taper shinda.Sezvo yakagayiwa ne-multi-edged milling cutter uye kureba kwechikamu chayo chekushanda chakakura kupfuura kureba kweshinda yakagadziriswa, iyo workpiece inongoda kutenderedzwa kwe1.25 kusvika 1.5 inotendeuka kuti igadziriswe.Zvaitwa, zvibereko zvakakwirira.Hurukuro hwekugaya shinda hunogona kusvika pa8-9 mamakisi, uye kushata kwepamusoro iR5-0.63 microns.Iyi nzira yakakodzera kugadzirwa kwebatch ye threaded workpieces ine general chaiyo kana rough machining isati yakuya.

Thread milling cutter machining internal thread

3. Kukuya shinda

Inonyanya kushandiswa kugadzira tambo dzakaomeswa dzemichina yekukuya pamichina yekukuya.Zvinoenderana nechimiro chemuchinjiko-chikamu chegumbo rekukuya, inogona kukamurwa kuva mhando mbiri: imwechete-mutsara grinding vhiri uye akawanda-line grinding vhiri.Iko kurongeka kweiyo mutsara-mutsetse wekukuya vhiri kunogona kuita 5-6 mamakisi, kushata kwepamusoro iR1.25-0.08 microns, uye kupfekedzwa kwevhiri rekukuya kuri nyore.Iyi nzira yakanakira kukuya precision lead screws, shinda geji, makonye, madiki mabhechi eshinda akaiswa maworkpieces uye kukuya yekuyamura.precision yakatendeuka chikamu.

Multi-line grinding wheel grinding yakakamurwa kuita marudzi maviri: longitudinal grinding method uye plunge grinding method.Munzira yokukuya nayo yelongitudinal, kufara kwevhiri kudiki pane kureba kweshinda ichagayiwa, uye shinda inogona kukuyiwa kusvika pakukura kwekupedzisira nekufambisa gumbo kureba kamwe kana kuti kakawanda.Munzira yekucheka-mukati, hupamhi hwevhiri rekukuya hukuru kupfuura urefu hweshinda ichagayiwa.

Gumbo rekukuya rinocheka mukati meiyo workpiece radially, uye workpiece inogona kuvhurika mushure mekuchinja kwe 1.25.Kugadzirwa kwacho kwakakwira, asi kurongeka kwakadzikira zvishoma, uye kupfekedzwa kwegumbo rekukuya kunowedzera kuoma.Iyo plunge grinding nzira yakanakira yekuyamura mapombi ane mabhechi mahombe uye kukuya dzimwe shinda dzekusimbisa.

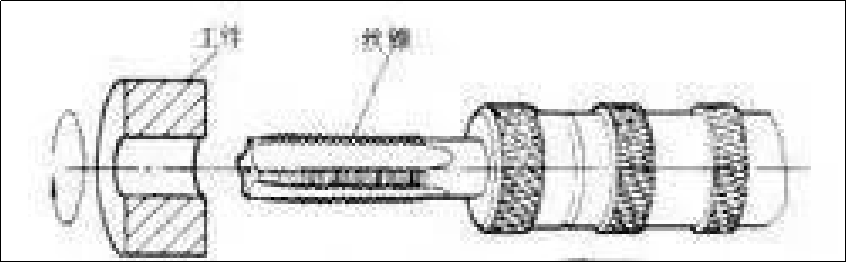

4. Kukuya shinda

Iyo nut-type kana screw-type thread grinder inogadzirwa nezvinhu zvakapfava senge simbi yakakandwa, uye iyocnc kushandura zvikamuyeshinda yakagadziridzwa pane workpiece ine pitch error inotenderedzwa kumberi nekudzokera kumashure kuti ivandudze kunaka kwepitch.Shinda dzemukati dzakaomeswa dzinowanzoitwawo pasi kuti dzibvise deformation uye kunatsiridza huchokwadi.

5. Kubata uye kupinza

Tapping

Iko kushandisa imwe torque kupeta pombi mugomba rezasi rakadhirowewa pane workpiece kugadzirisa shinda yemukati.

Threading

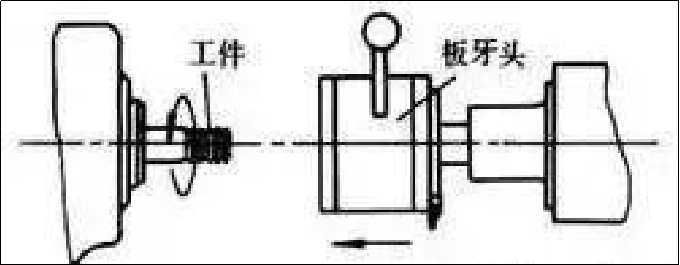

Iko kushandisa difa kucheka shinda yekunze pabhari (kana pombi) workpiece.Kurongeka kwemachina ekutepa kana kupinza kunoenderana nekurongeka kwepombi kana kufa.

Kunyangwe paine nzira dzakawanda dzekugadzirisa tambo dzemukati nekunze, diki-dhayamita dzemukati tambo dzinogona kungogadziriswa nemapombi.Kutepa nekurukisa kunogona kuitwa nemaoko, kana nemalathesi, madhiri, muchina wekutepa uye nemichina yeshinda.

Chikamu chechipiri: thread rolling

Iyo nzira yekugadzira iyo iyo workpiece yakasvibiswa nepurasitiki nekugadzira rolling die kuti uwane shinda.Kukunguruka kweshinda kunowanzoitwa pamuchina wekumonera shinda kana otomatiki lathe ine otomatiki kuvhura uye kuvhara shinda inotenderedza musoro.Shinda dzekunze dzekugadzira misa yemafasteners akajairwa uye mamwe ma threaded connections.Iyo dhayamita yekunze yeshinda yakakungurutswa kazhinji haipfuure 25 mm, kureba hakupfuuri 100 mm, iyo tambo yechokwadi inogona kusvika padanho 2 (GB197-63), uye dhayamita reiyo blank rakashandiswa rinenge rakaenzana nenzwi. dhayamita yeshinda yakagadziriswa.Kutenderedza kazhinji hakugone kugadzira tambo dzemukati, asi kune maworkpiece ane zvinyoro zvinyoro, grooveless extrusion tepi inogona kushandiswa kutonhora-extrude tambo dzemukati (iyo yakakwira dhayamita inogona kusvika 30 mm), uye musimboti wekushanda wakafanana nekutepa.Iyo torque inodiwa kune inotonhora extrusion yemukati tambo ndeye

Kaviri iyo yekutepa, uye iko kurongeka kwemuchina uye mhando yepamusoro zvakakwira zvishoma pane izvo zvekutepa.

Zvakanakira kupeta shinda: ①Kushata kwepamusoro idiki pane kutenderedza, kukuya nekukuya;②Pamusoro peshinda mushure mekukunguruka inogona kuwedzera simba uye kuoma nekuda kwekuoma kwechando;③Kushandiswa kwezvinhu zvakanyanya;④Kugadzirwa kwakapetwa kaviri kana kuchienzaniswa nekucheka kugadzirisa, uye nyore kuita otomatiki;⑤ rolling die life yakareba.Nekudaro, iyo tambo yekutenderedza inoda kuti kuoma kweiyo workpiece zvinhu hakupfuuri HRC40;zvinodiwa zvedimensional kurongeka kwechinhu chisina chinhu chakakwirira;iko kurongeka uye kuoma kweiyo mold inoputika zvakare yakakwirira, uye zvakaoma kugadzira mold;haina kukodzera kukungurutsa shinda ine asymmetric mazino maumbirwo.

Zvinoenderana neyakasiyana-siyana yekukunguruka inofa, tambo yekukungurusa inogona kupatsanurwa mumhando mbiri: shinda yekukungurusa uye shinda.

6. Kukwesha

Mabhodhi maviri anotenderedza mapuranga ane mbiri yeshinda akarongedzerwa akatarisana aine 1/2 pitch yakadzedzereka, iyo static board inogadziriswa, uye bhodhi rinofamba rinogadzira mutsara wemutsara wekufamba unofanana neiyo static board.Apo iyocustom machined zvikamuinodyiswa pakati pemahwendefa maviri, ndiro inofamba inofamba inoenda mberi uye inokwesha workpiece, ichiita kuti pamusoro payo iparadzike kuita tambo (Figure 6 [thread rolling]).

7. Thread rolling

Kune marudzi matatu eshinda inomonereka, tambo yeradial rolling, tangential thread rolling uye musoro unomonereka.

① Radial tambo inotenderedza: 2 (kana 3) shinda inotenderedza mavhiri ane shinda profile akaiswa paparallel shafts, workpiece inoiswa parutsigiro pakati pemavhiri maviri, uye mavhiri maviri anotenderera nekumhanya kwakafanana munzira imwe chete (Mufananidzo 7). [Radial thread rolling]), imwe yacho inoitawo kufamba kweradial feed.Iyo workpiece inotenderera pasi pedhiraivha yeshinda inotenderedza vhiri, uye iyo yepamusoro inoburitswa radially kuita shinda.Kune mamwe masikuru ekutungamirira ayo asingade kurongeka kwepamusoro, nzira yakafanana inogona kushandiswawo kugadzira roll.

②Tangential thread rolling: Iyo inozivikanwawo seyepuraneti shinda inokunguruka, iyo inotenderedza chishandiso ine inotenderera yepakati tambo inotenderedza vhiri uye 3 yakagadziriswa arc-yakaita sewaya mahwendefa (Mufananidzo 8 [tangential thread rolling]).Munguva yekutenderedzwa kweshinda, iyo workpiece inogona kudyiswa nguva dzose, saka chibereko chakakwira kupfuura icho chetambo yekukungurusa uye radial tambo yekukunguruka.

③Kutenderedza musoro tambo kutenderedza: Inoitwa pane otomatiki lathe, uye inowanzo shandiswa kugadzira shinda pfupi pane zvebasa.Kune 3 kusvika 4 tambo inotenderedza mavhiri akagoverwa zvakaenzana padivi rekunze reworkpiece mumusoro unotenderedza (Mufananidzo 9 [shinda inotenderedza musoro]).Munguva yekutenderedzwa kweshinda, workpiece inotenderera, uye musoro unotenderera unodyisa axially kuti ubvise workpiece kunze kweshinda.

8. EDM thread processing

Kugadziriswa kweshinda kunowanzo shandisa machining nzvimbo kana tepi michina uye maturusi, uye dzimwe nguva kubata nemaoko kunogoneka.Nekudaro, mune zvimwe zviitiko zvakakosha, iyo nzira iri pamusoro haisi nyore kuwana yakanaka yekugadzirisa mhedzisiro, sekudikanwa kwekugadzirisa tambo mushure mekupisa kwekupisa kwezvikamu nekuda kwekuregeredza, kana nekuda kwezvipingaidzo zvenyama, sekurovera zvakananga pane simende carbide workpieces.Panguva ino, zvakakosha kufunga nezve machining nzira yeEDM.

Kuenzaniswa nesimbi cnc machiningnzira, kurongeka kweEDM kwakafanana, uye gomba rezasi rinoda kutanga, uye hupamhi hwegomba rezasi hunofanira kugadziriswa maererano nemamiriro ekushanda.Iyo electrode inoda kugadziriswa kuita shinda chimiro, uye electrode inoda kukwanisa kutenderera panguva yekugadzirisa.

"Hunhu hwekutanga, Kuvimbika sehwaro, Kambani yakaperera uye purofiti yakabatana" ipfungwa yaAnebon, kuitira kuti iwe ugone kugadzira nguva dzose uye kutevera kunaka kweChina Wholesale Custom Machining Chikamu-Sheet Metal Chikamu Factory-Auto Chikamu, Anebon yakakurumidza kukura muhukuru uye zita. nekuda kwekuzvipira kwakakwana kweAnebon pakugadzirwa kwemhando yepamusoro, kukosha kukuru kwezvinhu uye mupi mukuru wevatengi.

OEM Mugadziri China Machining Chikamu uye Stamping Chikamu, Kana iwe uchifanirwa kuve nechimwe chezvigadzirwa zveAnebon uye mhinduro, kana kuve nezvimwe zvinhu zvinogadzirwa, ita shuwa kutitumira kubvunza kwako, masampuli kana zvakadzama kudhirowa.Zvichakadaro, tichivavarira kusimudzira boka remabhizinesi epasi rose, Anebon inogara iri pano kutarisira kugamuchira zvinopihwa zvekubatana uye mamwe mapurojekiti emubatanidzwa.

Nguva yekutumira: Jun-19-2023