Koj paub ntau npaum li cas txog txoj kev ua cov xov hauv CNC machining?

Hauv CNC machining, threads feem ntau yog tsim los ntawm kev txiav lossis kev ua haujlwm.Nov yog ob peb txoj hauv kev siv xov ntau los ntawm pab pawg Anebon:

Tapping:Txoj kev no suav nrog kev txiav cov xov uas siv cov kais dej, uas yog cov cuab yeej nrog helical grooves.Tapping tuaj yeem ua tau los ntawm tes lossis siv lub tshuab, thiab nws yog qhov tsim nyog rau kev tsim cov xov sab hauv.

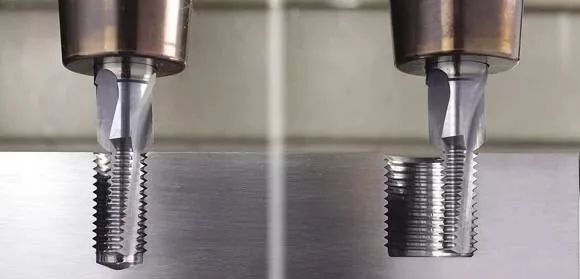

Xov Milling: Xov milling siv lub cuab yeej tig nrog ntau lub tshuab raj los tsim cov xov.Nws yog ib tug ntau yam txoj kev uas yuav siv tau rau ob sab hauv thiab sab nraud threads.Xov milling feem ntau nyiam rau cov xov loj dua lossis thaum muaj ntau yam xov ntau thiab ntau hom xav tau.

Xov Tig:Txoj kev no suav nrog kev siv ib qho kev txiav cov cuab yeej txuas rau ntawm lub tshuab dhos los tsim cov xov sab nraud.Xov tig yog feem ntau siv rau cov xov loj lossis ntev thiab haum rau ob qho tib si ncaj thiab tapered threads.

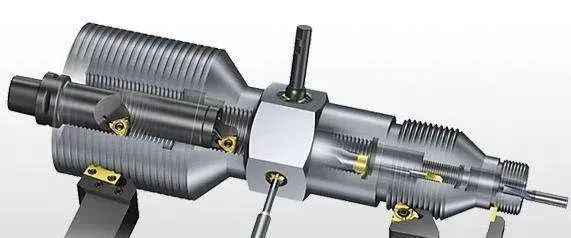

Xov Rolling:Nyob rau hauv xov dov, ib tug hardened steel tuag siv siab rau lub workpiece kom deform cov khoom thiab tsim cov threads.Txoj kev no yog qhov ua tau zoo thiab tsim cov xov zoo zoo, ua rau nws tsim nyog rau cov khoom ntim siab.

Xov sib tsoo:Xov sib tsoo yog txheej txheem machining precision uas siv lub log sib tsoo los tsim cov xov.Nws yog feem ntau ua hauj lwm rau high-precision thiab high-zoo xov ntau lawm, tshwj xeeb tshaj yog rau complex los yog tshwj xeeb threads.

Thaum xaiv cov txheej txheem xov, yam xws li xov loj, qhov yuav tsum tau muaj tseeb, cov khoom siv, ntim ntau lawm, thiab cov nqi txiav txim siab yuav tsum raug coj mus rau hauv tus account.

Keeb kwm

Lo lus Askiv sib raug rau cov ntsia hlau yog Screw.Lub ntsiab lus ntawm lo lus no tau hloov ntau ntau hauv ntau pua xyoo dhau los.Tsawg kawg hauv xyoo 1725, nws txhais tau tias "kev sib raug zoo".

Daim ntawv thov ntawm txoj cai xov tuaj yeem taug qab rov qab mus rau lub tshuab nqa dej uas tsim los ntawm Greek kws tshawb fawb Archimedes hauv 220 BC.

Nyob rau hauv lub xyoo pua 4th AD, lub teb chaws raws ntug dej hiav txwv Mediterranean pib siv lub hauv paus ntsiab lus ntawm bolts thiab ceev rau presses siv rau brewing cawu cub.Nyob rau lub sijhawm ntawd, cov xov sab nraud tau muab qhwv nrog hlua rau ib lub cylindrical bar, thiab tom qab ntawd kos raws li lub cim no, thaum cov xov sab hauv feem ntau yog tsim los ntawm hammering ib ncig ntawm cov xov sab nraud nrog cov ntaub ntawv softer.

Nyob ib ncig ntawm 1500, nyob rau hauv cov duab kos duab ntawm cov xov ua cov cuab yeej kos los ntawm Italian Leonardo da Vinci, twb muaj lub tswv yim ntawm kev siv cov poj niam cov ntsia hlau thiab cov iav pauv los ua cov xov sib txawv.Txij thaum ntawd los, txoj kev ntawm mechanically txiav threads tau tsim nyob rau hauv European watchmaking kev lag luam.

Xyoo 1760, cov kwv tij Askiv Askiv J. Wyatt thiab W. Wyatt tau txais daim ntawv pov thawj rau kev txiav ntoo ntsia hlau nrog cov cuab yeej tshwj xeeb.Xyoo 1778, British J. Ramsden ib zaug tau tsim cov xov txiav cov cuab yeej uas tau tsav los ntawm tus cab iav khub, uas tuaj yeem ua cov xov ntev nrog kev ua haujlwm siab.Xyoo 1797, British H. Mozley tau siv tus poj niam ua cov ntsia hlau thiab cov iav sib hloov los tig cov xov hlau nrog cov pitches sib txawv ntawm lub tshuab dhos tau txhim kho los ntawm nws, thiab tsim cov txheej txheem ntawm kev xa xov.

Hauv xyoo 1820, Maudsley tau tsim thawj pawg ntawm cov kais dej thiab tuag rau kev ua xov.

Thaum pib ntawm lub xyoo pua 20th, txoj kev loj hlob ntawm kev lag luam tsheb txuas ntxiv txhawb cov txheej txheem ntawm cov xov thiab kev txhim kho ntawm ntau yam kev ua tiav thiab kev ua haujlwm zoo.Ntau yam tsis siv neeg qhib tuag hau thiab tsis siv neeg shrinking kais tau tsim ib qho tom qab, thiab xov milling pib siv.

Nyob rau hauv thaum ntxov 1930s, xov sib tsoo tshwm sim.

Txawm hais tias cov xov rolling tshuab tau patented nyob rau hauv thaum ntxov 19th caug xyoo, vim hais tias muaj teeb meem nyob rau hauv pwm manufacturing, txoj kev loj hlob qeeb heev.Nws tsis yog txog thaum Tsov Rog Thoob Ntiaj Teb thib Ob (1942-1945) vim tias qhov kev xav tau ntawm kev tsim cov foob pob hluav taws thiab kev tsim cov xov sib tsoo tshuab, qhov teeb meem tau daws.Qhov teeb meem precision ntawm kev tsim pwm tau ua tiav txoj kev loj hlob sai.

Cov xov no tsuas yog muab faib ua cov xov txuas thiab kis xov

Rau kev sib txuas xov, cov txheej txheem ua haujlwm yog: tapping, threading, threading, dov, dov, thiab lwm yam.

Rau kev sib kis xov, cov txheej txheem tseem ceeb yog: ntxhib thiab zoo tig-sib tsoo, cua daj cua dub milling- ntxhib thiab zoo tig, thiab lwm yam.

Thawj qeb: xov txiav

Feem ntau yog hais txog cov txheej txheem ntawm kev ua cov xov ntawm cov khoom ua haujlwm nrog cov cuab yeej sib sau lossis cov cuab yeej siv abrasive, feem ntau suav nrog kev xa, milling, tapping thiab xov sib tsoo, sib tsoo thiab cua daj cua dub.Thaum tig, milling thiab sib tsoo xov, txhua zaus lub workpiece rotates, cov saw hlau kis tau tus mob ntawm lub tshuab cuab yeej xyuas kom meej tias lub cuab tam tig, milling cutter los yog sib tsoo log txav ib tug txhuas kom raug thiab tusyees raws lub axis ntawm lub workpiece.Thaum tapping lossis threading, lub cuab yeej (kais lossis tuag) thiab cov khoom ua haujlwm ua rau cov txheeb ze sib hloov, thiab thawj cov xov groove coj lub cuab yeej (los yog workpiece) txav axially.

1. Xov tig

Tig threads ntawm lub tshuab dhos tuaj yeem siv lub cuab yeej tig los yog xov zuag.Tig xov nrog cov cuab yeej sib sau ua ke yog ib txoj hauv kev rau ib-thooj thiab me me-batch ntawm threaded workpieces vim cov qauv yooj yim ntawm cov cuab yeej;tig xov nrog ib tug xov zuag cuab yeej muaj siab ntau lawm efficiency, tab sis lub cuab tam qauv yog complex thiab tsuas yog haum rau nruab nrab thiab loj-scale ntau lawm Tig luv threaded workpieces nrog zoo suab.Lub suab raug ntawm cov xov trapezoidal tig ntawm cov tshuab dhos zoo tib yam tuaj yeem ncav cuag qib 8 txog 9 (JB2886-81, tib yam hauv qab no);ua cov xov ntawm cov xov tshwj xeeb lathes tuaj yeem txhim kho cov khoom tsim tau lossis raug.

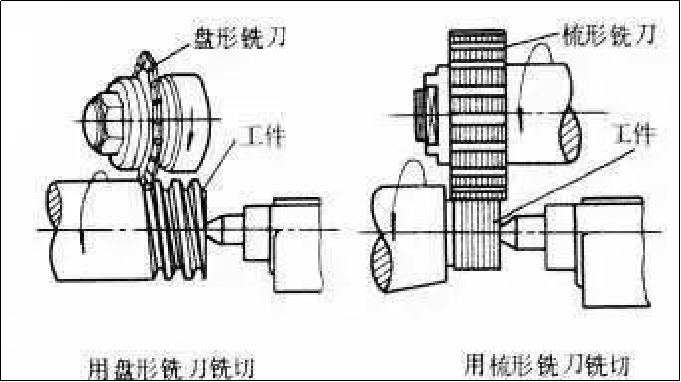

2. Xov milling

Prototype cnc millingnrog ib tug disc cutter los yog zuag cutter ntawm ib tug xov milling tshuab.

Disc milling cutters yog tsuas yog siv rau milling trapezoidal lwm threads ntawm workpieces xws li ntsia hlau rods thiab cab.Lub comb-shaped milling cutter yog siv rau milling sab hauv thiab sab nraud zoo tib yam threads thiab taper threads.Txij li thaum nws yog milled nrog ib tug multi-edged milling cutter thiab qhov ntev ntawm nws qhov chaw ua hauj lwm yog ntau tshaj qhov ntev ntawm cov txheej txheem xov, lub workpiece tsuas yog yuav tsum tau tig rau 1.25 mus rau 1.5 lem mus rau txheej txheem.Ua tiav, cov khoom tsim tau siab.Qhov tseeb ntawm cov xov milling feem ntau tuaj yeem ncav cuag 8-9 qib, thiab qhov roughness yog R5-0.63 microns.Txoj kev no yog tsim rau batch zus tau tej cov threaded workpieces nrog dav precision los yog ntxhib machining ua ntej sib tsoo.

Xov milling cutter machining internal xov

3. Xov sib tsoo

Nws yog tsuas yog siv los ua cov txheej txheem precision threads ntawm hardened workpieces ntawm xov sib tsoo tshuab.Raws li cov duab ntawm tus ntoo khaub lig-section ntawm kev sib tsoo lub log, nws tuaj yeem muab faib ua ob hom: ib kab sib tsoo log thiab ntau txoj kab sib tsoo.Lub suab raug ntawm ib kab sib tsoo log sib tsoo tuaj yeem yog 5-6 qib, qhov roughness yog R1.25-0.08 microns, thiab hnav khaub ncaws ntawm lub log sib tsoo yog yooj yim dua.Txoj kev no yog tsim rau kev sib tsoo precision txhuas screws, xov gauges, worms, me me ntawm threaded workpieces thiab nyem sib tsoo.precision muab cov khoom.

Multi-line sib tsoo log sib tsoo yog muab faib ua ob hom: longitudinal sib tsoo txoj kev thiab plunge sib tsoo txoj kev.Nyob rau hauv txoj kev sib tsoo longitudinal, qhov dav ntawm kev sib tsoo lub log yog me dua qhov ntev ntawm cov xov yuav tsum tau hauv av, thiab cov xov tuaj yeem ua hauv av mus rau qhov kawg loj los ntawm kev txav lub log sib tsoo longitudinally ib zaug lossis ob peb zaug.Nyob rau hauv txoj kev txiav-hauv kev sib tsoo, qhov dav ntawm kev sib tsoo lub log yog ntau dua qhov ntev ntawm cov xov yuav hauv av.

Lub log sib tsoo txiav rau hauv qhov chaw ntawm lub workpiece radially, thiab lub workpiece tuaj yeem ua hauv av tom qab txog 1.25 revolutions.Cov khoom tsim tau siab, tab sis qhov tseeb yog me ntsis qis, thiab kev hnav khaub ncaws ntawm kev sib tsoo log yog qhov nyuaj dua.Txoj kev sib tsoo plunge yog tsim rau kev sib tsoo cov kais dej nrog cov khoom loj thiab sib tsoo qee cov xov rau fastening.

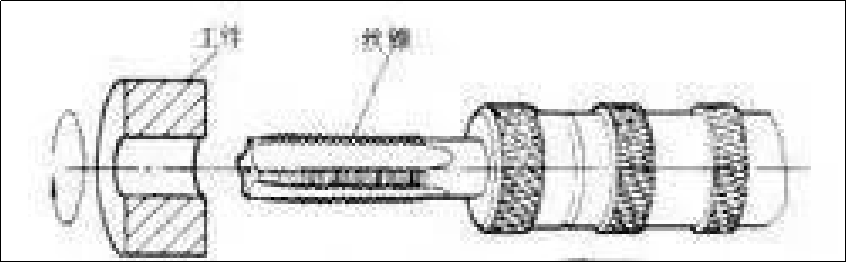

4. Xov sib tsoo

Cov txiv ntseej-hom lossis ntsia hlau-hom xov grinder yog ua los ntawm cov ntaub ntawv mos xws li cam khwb cia hlau, thiab covcnc tig qhov chawntawm cov txheej txheem xov ntawm lub workpiece uas muaj lub suab yuam kev yog tig rau pem hauv ntej thiab rov qab cov lus qhia los txhim kho lub suab raug.Hardened internal threads feem ntau kuj hauv av kom tshem tawm deformation thiab txhim kho qhov tseeb.

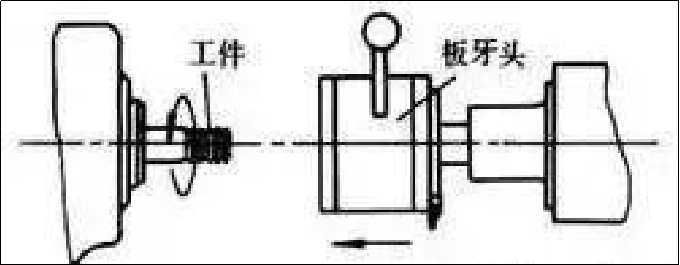

5. Tapping thiab threading

Tapping

Nws yog siv ib qho torque los txhuam tus kais dej rau hauv lub qhov pre-drilled hauv qab ntawm lub workpiece los ua cov xov sab hauv.

Xov

Nws yog siv cov tuag los txiav cov xov sab nraud ntawm lub bar (los yog yeeb nkab) workpiece.Lub machining raug ntawm tapping los yog threading nyob ntawm qhov tseeb ntawm tus kais los yog tuag.

Txawm hais tias muaj ntau txoj hauv kev rau kev ua cov xov sab hauv thiab sab nraud, cov xov me me ntawm sab hauv tsuas tuaj yeem ua tiav los ntawm cov kais dej.Tapping thiab threading tuaj yeem ua los ntawm tes, lossis los ntawm lathes, laum presses, tapping machine thiab threading machines.

Qhov thib ob qeb: xov dov

Ib txoj kev ua haujlwm uas lub workpiece yog plastically deformed los ntawm kev sib sau dov tuag kom tau cov xov.Xov dov feem ntau yog nqa tawm ntawm lub tshuab dov los yog lub tshuab dhos tsis siv neeg nrog qhib thiab kaw xov dov taub hau.Sab nraud threads rau huab hwm coj ntau lawm ntawm tus qauv fasteners thiab lwm yam threaded sib txuas.Sab nraud txoj kab uas hla ntawm cov xov dov feem ntau tsis ntau tshaj 25 hli, qhov ntev tsis ntau tshaj 100 hli, cov xov raug tuaj yeem ncav cuag qib 2 (GB197-63), thiab txoj kab uas hla ntawm qhov khoob siv yog kwv yees sib npaug ntawm lub suab. txoj kab uas hla ntawm cov txheej txheem xov.Rolling feem ntau tsis tuaj yeem ua cov xov sab hauv, tab sis rau cov khoom siv nrog cov khoom muag, cov grooveless extrusion kais tuaj yeem siv los ua kom txias-extrude internal threads (qhov siab tshaj plaws txoj kab uas hla tuaj yeem ncav cuag li 30 hli), thiab txoj haujlwm ua haujlwm zoo ib yam li tapping.Lub torque yuav tsum tau rau txias extrusion ntawm internal threads yog hais txog

Ob zaug ntawm tapping, thiab qhov tseeb machining thiab nto zoo yog me ntsis siab dua cov tapping.

Qhov zoo ntawm cov xov dov: ①Qhov saum npoo roughness yog me dua li ntawm txoj siav, milling thiab sib tsoo;②Qhov saum npoo ntawm cov xov tom qab dov tuaj yeem ua kom lub zog thiab tawv tawv vim qhov txias txias;③ Cov khoom siv siab heev;④ Cov khoom tsim tau yog ob npaug piv nrog kev txiav, thiab yooj yim rau automate;⑤ dov tuag lub neej ntev heev.Txawm li cas los xij, cov xov dov yuav tsum muaj qhov hardness ntawm cov khoom siv ua haujlwm tsis tshaj HRC40;qhov yuav tsum tau ua rau qhov tseeb qhov tseeb ntawm qhov khoob yog siab;qhov precision thiab hardness ntawm dov pwm kuj siab, thiab nws yog ib qho nyuaj rau tsim cov pwm;Nws tsis haum rau dov threads nrog asymmetric hniav duab.

Raws li qhov sib txawv dov tuag, xov dov tuaj yeem muab faib ua ob hom: xov dov thiab xov dov.

6. Rubbing

Ob lub xov rolling boards nrog xov profile yog teem rov qab rau ib leeg nrog 1/2 pitch staggered, lub static board yog tsau, thiab lub rooj tsavxwm txav ua rau reciprocating linear motion parallel rau lub static board.Thaum lubkev cai machined qhov chawyog noj ntawm ob daim hlau, lub phaj txav txav mus rau pem hauv ntej thiab rub lub workpiece, ua rau nws nto plastically deformed los ua threads (Daim duab 6 [xov dov]).

7. Xov dov

Muaj 3 hom xov dov, radial xov dov, tangential xov dov thiab dov taub hau xov dov.

① Radial xov dov: 2 (los yog 3) xov dov lub log nrog cov xov profile yog ntsia rau ntawm qhov sib npaug ntawm cov ncej, cov khoom ua haujlwm tau muab tso rau ntawm kev txhawb nqa ntawm ob lub log, thiab ob lub log tig ntawm tib lub nrawm hauv tib qho kev taw qhia (Daim duab 7 [Radial thread rolling]), ib qho uas tseem ua rau radial feed motion.Lub workpiece rotates nyob rau hauv lub tsav ntawm lub xov dov log, thiab saum npoo yog radially extruded rau daim threads.Rau qee cov hlau lead uas tsis tas yuav tsum muaj qhov siab, ib txoj kev zoo sib xws kuj tuaj yeem siv rau yob txoj kev.

②Tangential xov dov: Kuj hu ua planetary xov dov, cov cuab yeej dov muaj ib lub hauv paus xov dov lub log thiab 3 tsau arc-shaped hlau daim hlau (Daim duab 8 [tangential xov dov]).Thaum lub sij hawm xov dov, lub workpiece tuaj yeem noj tsis tu ncua, yog li cov khoom tsim tau siab dua li cov xov dov thiab radial xov dov.

③ Rolling taub hau xov dov: Nws yog nqa tawm ntawm lub tshuab dhos tsis siv neeg, thiab feem ntau yog siv los ua cov xov luv luv ntawm workpieces.Muaj 3 mus rau 4 xov dov lub log sib npaug sib npaug ntawm sab nraud ntawm lub workpiece hauv lub taub hau dov (Daim duab 9 [xov dov lub taub hau]).Thaum lub sij hawm xov dov, lub workpiece tig, thiab lub taub hau dov axially dov lub workpiece tawm ntawm cov xov.

8. EDM xov ua

Kev ua cov xov zoo ib txwm siv cov chaw machining lossis tapping cov cuab yeej thiab cov cuab yeej, thiab qee zaum phau ntawv tapping kuj ua tau.Txawm li cas los xij, hauv qee qhov tshwj xeeb, txoj kev saum toj no tsis yooj yim kom tau txais txiaj ntsig zoo, xws li yuav tsum tau ua cov xov tom qab kev kho cua sov ntawm qhov chaw vim kev tsis saib xyuas, lossis vim muaj kev txwv ntawm cov khoom siv, xws li tapping ncaj qha rau ntawm cemented carbide workpieces.Nyob rau lub sijhawm no, nws yog ib qho tsim nyog los xav txog txoj kev machining ntawm EDM.

Piv nrog rauhlau cnc machiningtxoj kev, qhov kev txiav txim ntawm EDM yog tib yam, thiab lub qhov hauv qab yuav tsum tau drilled ua ntej, thiab txoj kab uas hla ntawm lub qhov hauv qab yuav tsum tau txiav txim siab raws li kev ua haujlwm.Cov electrode yuav tsum tau ua tiav rau hauv cov xov zoo, thiab cov electrode yuav tsum muaj peev xwm tig tau thaum ua haujlwm.

"Zoo pib, Honesty raws li lub hauv paus, Sincere lub tuam txhab thiab kev sib nrig sib profit" yog Anebon lub tswv yim, yog li ntawd koj muaj peev xwm tsim tsis tu ncua thiab nrhiav kev zoo rau Tuam Tshoj Lag luam wholesale Custom Machining Part-Sheet Hlau Part Factory-Auto Part, Anebon sai sai loj hlob nyob rau hauv loj thiab lub npe vim Anebon qhov kev mob siab rau kev tsim khoom zoo tshaj plaws, tus nqi loj ntawm cov khoom thiab cov neeg siv khoom zoo.

OEM Chaw tsim tshuaj paus Tuam Tshoj Machining Part thiab Stamping Part, Yog hais tias koj yuav tsum muaj ib yam ntawm Anebon cov khoom thiab cov kev daws teeb meem, los yog muaj lwm yam khoom yuav tsum tau ua, nco ntsoov xa peb cov lus nug, cov qauv los yog nyob rau hauv qhov tob drawings.Lub caij no, aiming los txhim kho mus rau hauv ib tug thoob ntiaj teb kev lag luam pab pawg neeg, Anebon yuav ib txwm nyob ntawm no tos ntsoov yuav tau txais kev muab kev koom tes ventures thiab lwm yam kev koom tes tej yaam num.

Post lub sij hawm: Jun-19-2023