U tseba hakae ka screw processing?

Ts'ebetso ea ts'ebetso ea screw hangata e kenyelletsa mehato e fapaneng, ho qala ka lisebelisoa tse tala le ho qetella ka sehlahisoa sa ho qetela.Mona ke tlhaloso e felletseng ea mekhoa e atileng haholo ea ho lokisa li-screw:

Ho Khetha Boitsebiso:

Mokhoa oa ho khetha o qala ka khetho ea lisebelisoa tse loketseng bakeng sa tlhahiso ea li-screws.Lisebelisoa tse tloaelehileng haholo ke tšepe ea carbon, koporo ea tšepe e sa hloekang, koporo, kapa li-alloys tse ling tsa tšepe, tse itšetlehileng ka matla a hlokahalang le ho hanyetsa kutu le litlhoko tse ling bakeng sa kopo.

Sehlooho se batang:

Ts'ebetsong ena, sekheo sa screw se entsoe ka ho forging kapa hlooho e batang.Cold heading ke mokhoa oa ho etsa molamu kapa terata hore e be sebopeho se lakatsehang bakeng sa screw ka ho sebelisa mochini oa hlooho.Mochini oa hlooho o fana ka khatello e phahameng ho theha sekheo sa hau ho sebopeho se chitja o sebelisa hlooho e telele.

Ho Seha Khoele:

Mokhoeng ona o tloahelehileng ho sebelisoa lesela bakeng sa li-screw, screw e sebelisoa ho khaola likhoele kapa li-grooves tsa helical ka har'a sekheo sa screw.Joale sekoti se ts'oaroa ka chuck, ha sesebelisoa sa ho itšeha se sisinyeha ho potoloha axis ho etsa masoba.Mokhoa ona o loketse ho etsa li-screws tse nang le litekanyo tse sa tšoaneng le mefuta ea khoele.

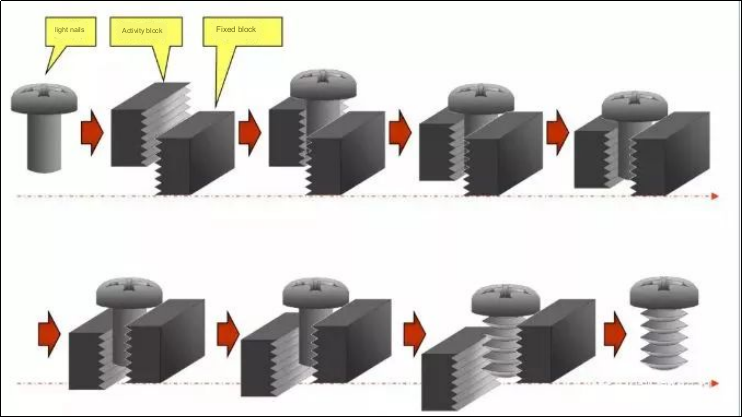

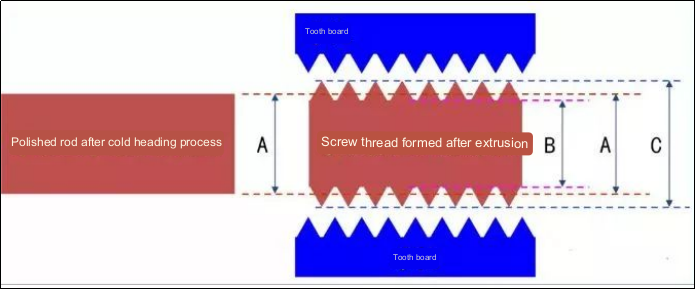

Ho Roala Khoele:

Ho roala likhoele ke mokhoa o fapaneng oa ho etsa likhoele tsa likurufu.The screw blank e behoa pakeng tsa li-dies tse peli tse kentsoeng ebe joale khatello e sebelisoa ho senya lisebelisoa le ho etsa likhoele.Ho roala likhoele ho etsa likhoele tse matla tse nepahetseng haholoanyane 'me hangata li sebelisoa tlhahiso ea molumo o phahameng.

Kalafo ea Mocheso:

Mekhoa ea kalafo ea mocheso joalo ka ho futhumatsa le ho tima hangata e sebelisoa ho ntlafatsa litšobotsi tsa eona tsa mochini oa screw.Mekhoa ena e eketsa boima, matla le nako e telele eo screw e nang le eona, ho etsa bonnete ba hore e khona ho mamella khatello ea maikutlo le meroalo e mengata.

Qetello ea Bokaholimo:

Ho sebelisoa mekhoa e fapaneng ea ho qeta bokaholimo ho ntlafatsa chebahalo le ts'ebetso ea screw.Lithako tse tloaelehileng tsa holim'a metsi li kenyelletsa plating ea zinc, nickel plating, galvanizing, black oxide coating, kapa passivation.Lisebelisoa tsena li sireletsa khahlanong le kutu, li eketsa ho tšoarella ha thepa, hape li eketsa boleng ba botle.

Tlhahlobo le Taolo ea Boleng:

Litlhahlobo tsa taolo ea boleng li etsoa nakong eohle ea ts'ebetso ho etsa bonnete ba hore li-screw li lumellana le litlhoko tsa lintlha le maemo.Liteko tse kang bophara ba khoele, bolelele ba sekontiri, bophara le boleng ba sephetho, li sebelisetsoa ho netefatsa ho tšoana le ho nepahala.

Delivery and Package:

Ka mor'a hore li-screw li hlahlojoe bakeng sa boleng ba tsona, ka mor'a moo li phuthetsoe 'me li loketse ho tsamaisoa.Liphutheloana li ka etsoa ka linkho tse ngata tse etselitsoeng tšebeliso ea indasteri, kapa lijana tse nyane ho rekisa mabenkele, ho ipapisitsoe le 'maraka oo li reretsoeng ona.

Na u tseba mantsoe a amanang le lisekere?

1. Phapano lipakeng tsa likurufu, linate kapa likurufu tsa liboutu, le lithupaHangata li-screw li bitsoa ka mabitso a tsona a tloaelehileng bakeng sa li-screw, 'me tse nang le likhoele tse ka ntle li ka bitsoa "screws".Sebopeho sa eona hangata se na le mahlakore a mabeli.Ka hare ho bula ke khoele e ka hare e sebetsang le bolt le ho tiisa ho amahanngoalikarolo tsa mochini.Nut ke lebitso le tummeng, 'me lebitso le tloaelehileng haholo e lokela ho ba "nate".

Hlooho ea eona hangata e na le mahlakore a mabeli, ha shank e na le khoele e ka ntle.The screw e nyenyane, 'me hlooho ke elongated hlooho kapa cross-head, joalo-joalo.Shank e kenngoa ka ntle.Li-Studs li lokela ho bitsoa "li-studded tse peli".Lipheletso ka bobeli li na le likhoele tse ka ntle 'me karolo e bohareng hangata e entsoe ka molamu o bentšitsoeng.Karolo e telele ka ho fetisisa ea molamu e kopantsoe le lesoba le bohareng, ha qetello e khutšoanyane e amana le linate.

2. Kemelo e tloaelehileng ea Senyesemane: Screw / Bolt / Fastener (screw / screw) (bolt) (fastener)

3. Tlhaloso ea khoele: ke sebopeho se nang le li-helical protrusions tse homogeneous tse holim'a bokahare kapa bokantle ba ntho.

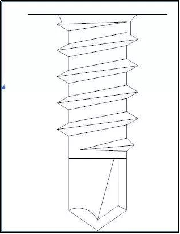

Khoele ea ho itahlela: phunya masoba kopanong ha u ntse u e kopanya, ntle le ho tlanya khoele ka hare ho sebelisa torque e kholoanyane ho kopanya.

Khoele ea ho itšeha: E sebelisoa ka kotloloho ho kopano, screw e phunya le ho tlanya ka nako e le 'ngoe.

Mokhoa oa ho lokisa screw

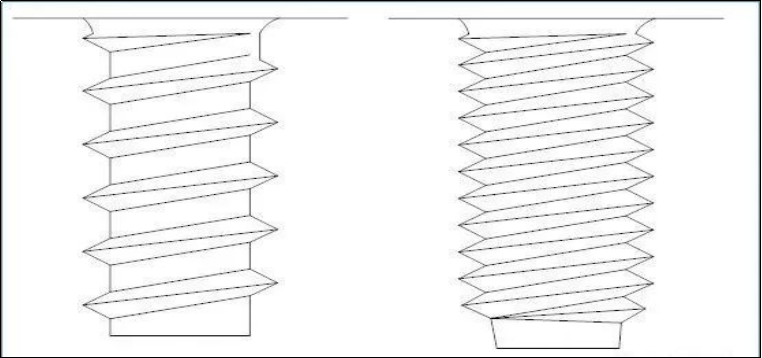

1. Ho reteleha

Etsa thepa ea hau e lumellane le sebopeho seo u se batlang ka ho nka thepa

Melemo: ho nepahala ho phahameng ho machining mme ha ho na meeli ea hlobo

Negatives: litšenyehelo tse phahameng tsa tlhahiso le lebelo le liehang la ho sebetsa

2. Ho qapa

Hlakola thepa ka matla a kantle, e etsa hore e holofale e le hore e thehe sebopeho se batlang.

Melemo: Lebelo la tlhahiso e potlakileng le theko e tlase, e loketseng tlhahiso ea bongata

Ha e lekane: Foromo e thibetsoe ke hlobo le litšenyehelo tsa hlobo bakeng sa lihlahisoa tse rarahaneng haholo li phahame haholo.

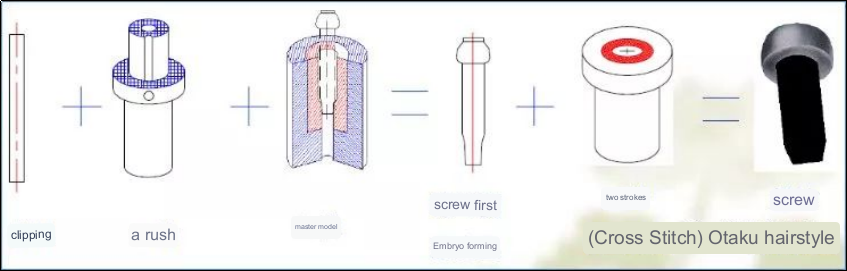

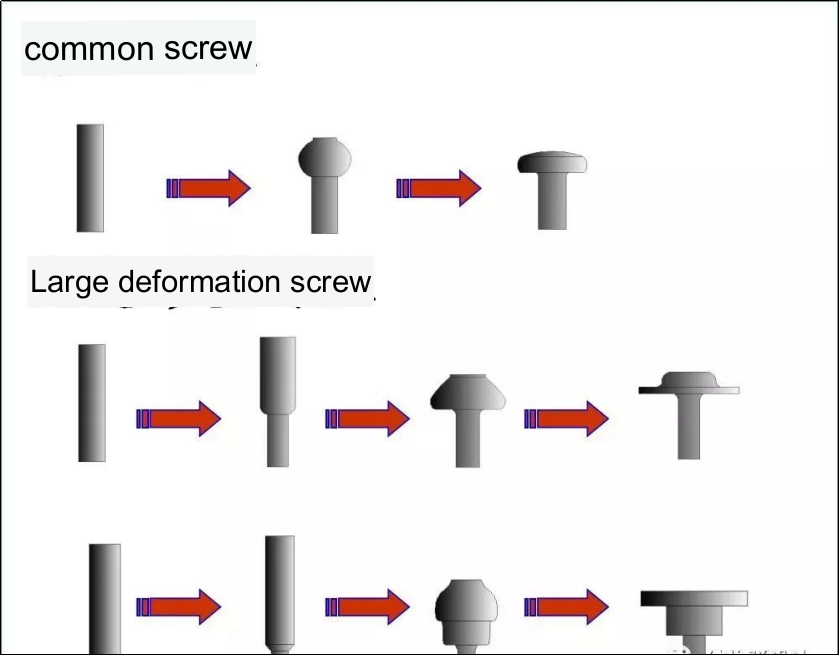

3. Sehlooho se batang

Ke mokhoa oa ho ntša le ho etsa terata ea tšepe ka matla a ka ntle, tlas'a boemo ba hore tšepe ea terata ha e chese.Ts'ebetso ea ho bata ke mofuta oa mokhoa oa ho etsa forgings.

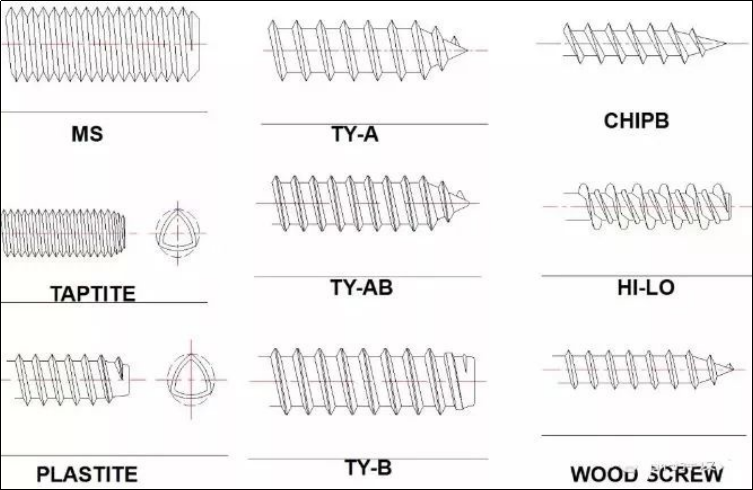

Kenyelletso ea tlhophiso ea mantlha ea li-screw

E le hore u utloisise ka botlalo li-bolts le screws pele, u lokela ho ela hloko mefuta ea tsona, likarolo le mesebetsi ea tsona.

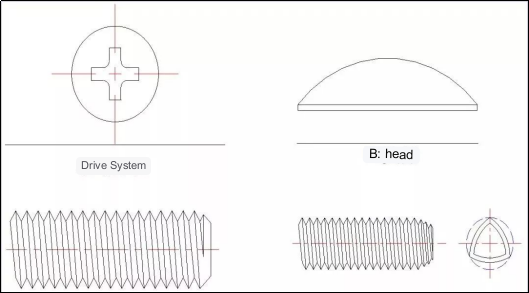

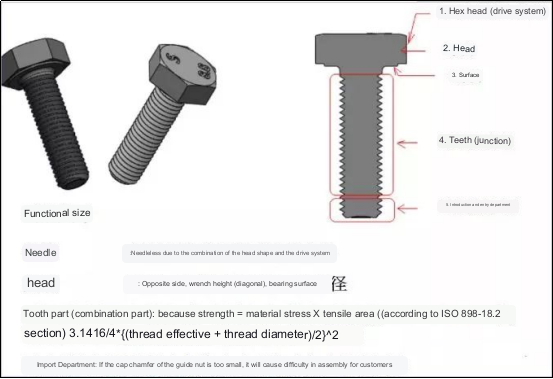

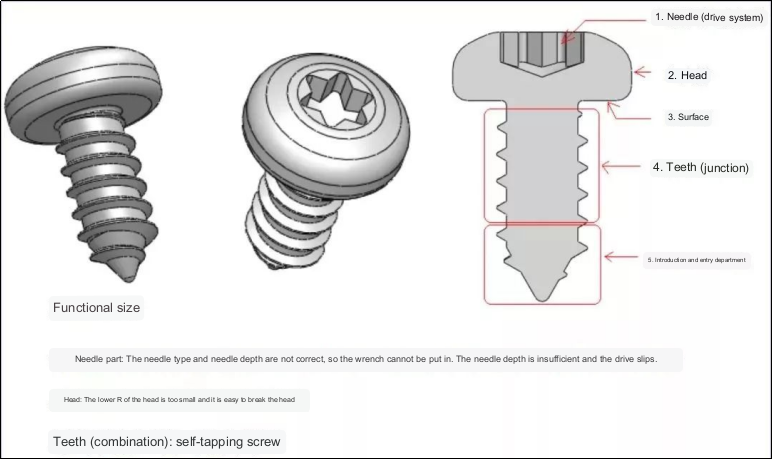

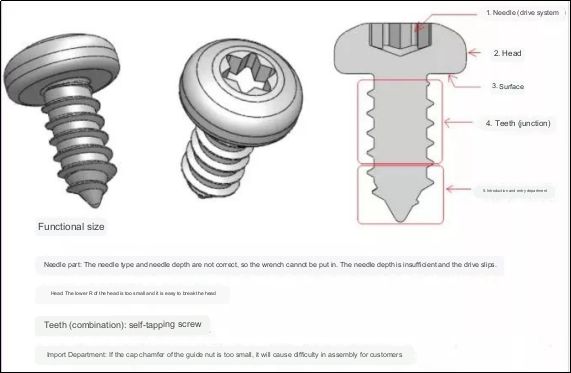

Sistimi ea koloi

B Hlooho

C: Leino la leino

D Lefapha la Thekiso le Tlhaselo

Sekurufu sa mochini

Self tapping screw

Sekurufu sa meno a kgutlotharo

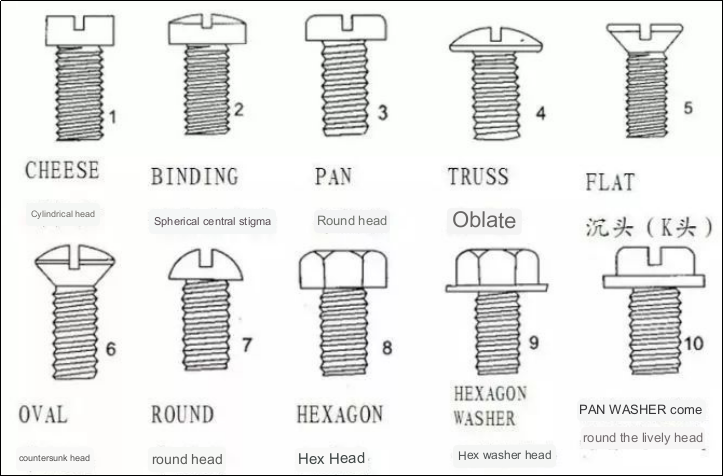

Mofuta oa hlooho ea screw

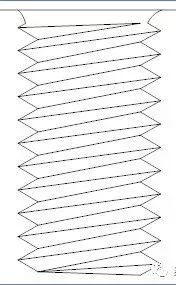

Screw profile

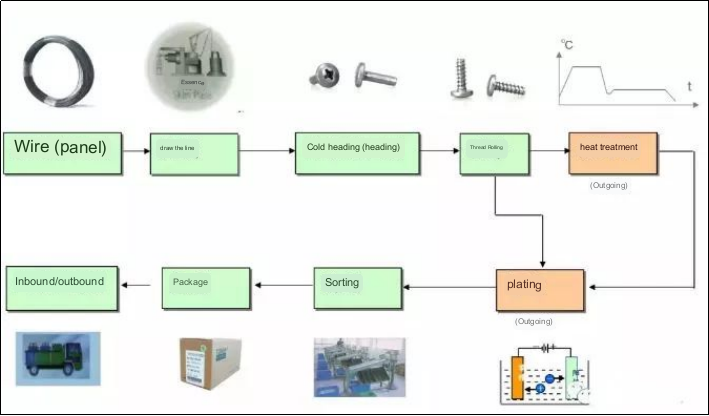

Screw process

Sebopeho se akaretsang sa chate e tjena:

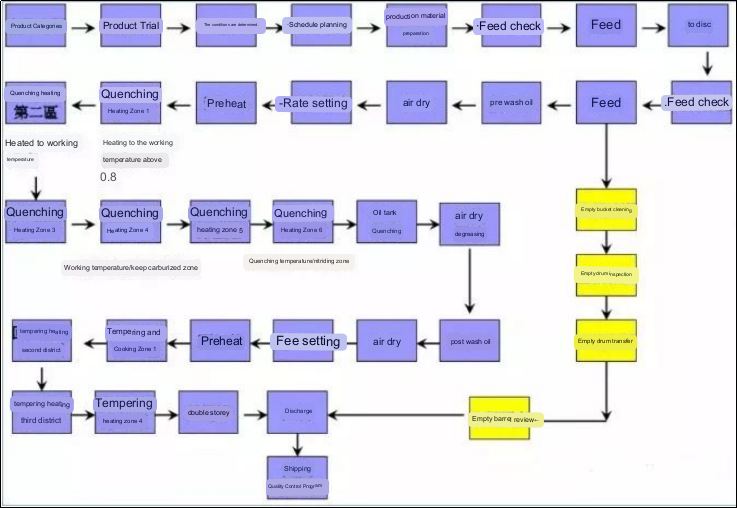

Ts'ebetso ea Disk unit

Molamu oa pele oa mohala o ileng oa rekoa ke mofani oa thepa e tala.Coil hangata e na le tse latelanglikarolo tse entsoeng ka mochine oa cncho kenyelletsa: A, lebitso la lebitso la BC, lebitso la sehlahisoa, tlhahiso ea thepa ea D, nomoro ea sebōpi, nomoro ea beche, bongata kapa boima ba 'mele.Lintho tse ka sehloohong tsa lik'hemik'hale tsa carbon steel discs ke: C Mn, P Si Cu le Al The tse nyane palo ea Cu le Al e sebetsa haholoanyane.

Mokhoa oa ho taka

E le hore re finyelle bophara ba terata eo re e hlokang (joalo ka terata ea ho hula ea 3.5mm).

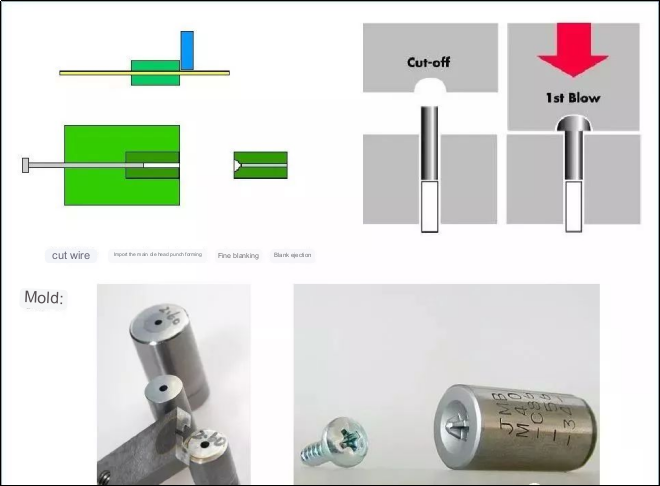

Mokhoa o batang oa sehlooho (sehlooho).

Ka tšebelisano pakeng tsa hlobo, e thehoa.Ntlha ea pele, terata e khaotsoe 'me e halefisoa ka sekoti se se nang letho ho theha hlooho, sefapano sa groove (kapa mofuta o mong oa hlooho) khoele e se nang letho le bophara ba molamu, le likhutlo tse chitja tlas'a hlooho.

Tlhaloso: Hoa khoneha ho e qapa ho latela litlhoko tsa bareki.Mefuta e tloaelehileng ea lihlooho e kenyelletsa lihlooho tsa P, lihlooho tsa B, lihlooho tsa F, lihlooho tsa T, joalo-joalo. Li-cross grooves, plum blossom grooves, hexagonal grooves, le slotted groove kaofela ke mefuta e tloaelehileng ea li-groove.

Tlhaloso: Hoa khoneha ho e qapa ho latela litlhoko tsa bareki.Mefuta e tloaelehileng ea lihlooho e kenyelletsa lihlooho tsa P, lihlooho tsa B, lihlooho tsa F, lihlooho tsa T, joalo-joalo. Li-cross grooves, plum blossom grooves, hexagonal grooves, le slotted groove kaofela ke mefuta e tloaelehileng ea li-groove.

Liphetoho pele le ka mor'a ho hlatsoa meno

Mochini o hlatsoang meno

Rub board (template)

Mokhoa oa phekolo ea mocheso

1. Morero: Ho etsa hore screw e fumane boima bo phahameng le matla ka mor'a sehlooho se batang.

2. Mosebetsi: Lemoha ho itšebetsa ka tšepe ea tšepe, ho ntlafatsa thepa ea mechine ea likarolo tsa tšepe, tse kang ho hanyetsa torsion, ho hanyetsa ho tsitsisa le ho apara ho hanyetsa.3. Sehlopha: A. Annealing: (700 ° C x 4hr): mohaho o molelele - polygon e tloaelehileng.

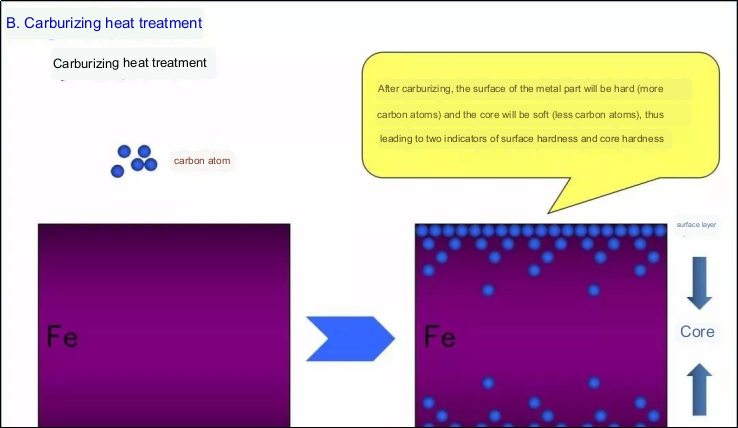

Sebopeho sa ho sebetsa se batang B. Phekolo ea mocheso oa carburizing (ho eketsa carbon ho litšepe ho ntlafatsa boima ba bona ba holim'a metsi) bakeng sa lisebelisoa tse nang le khase e tlaase.

C. Ho tima le ho futhumatsa mocheso kalafo (u se ke ua eketsa likarolo ho tšepe, fetola sebopeho sa ka hare sa tšepe ka ho fetola mocheso ho fumana thepa e ntle ea mechine).

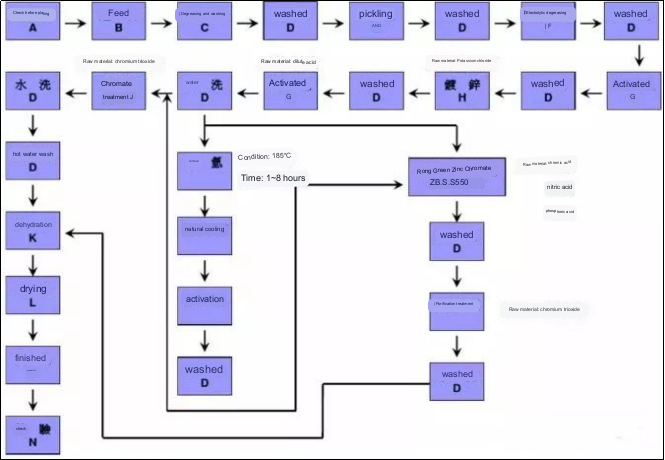

Mokhoa oa Electroplating

Ka mor'a electroplating, bokaholimo ba sehlahisoa bo ka koaheloa ka 'mala o lakatsehang le phello e khahlanong le oxidation.

Sepheo sa Anebon ke ho utloisisa ho senyeha ho hoholo ha thepa le ho fana ka tšehetso e holimo ho bareki ba malapeng le ba kantle ho naha ka pelo eohle bakeng sa 2022 High Quality Stainless Steel Aluminium High Precision Custom Made.Ho fetoha ha CNC, Milling, Machining Spare Part for Aerospace, E le hore re atolose 'maraka oa rona oa machaba, Anebon e fana haholo ka bareki ba rona ba mose ho maoatle likarolo tsa mechine ea boleng bo holimo, likarolo tse silafetseng le tšebeletso ea ho fetola cnc.

China wholesale China Machinery Parts and CNC Machining Service, Anebon e ts'ehetsa moea oa "boqapi, kutloano, mosebetsi oa sehlopha le ho arolelana, litsela, tsoelo-pele ea pragmatic".Re fe monyetla 'me re tla be re tla paka bokhoni ba rona.Ka thuso ea hau e mosa, Anebon e lumela hore re ka theha bokamoso bo khanyang le uena hammoho.

Nako ea poso: Aug-08-2023