1. Bubuchule bokufumana intwana yokutya okunzulu.Kwinkqubo yokuguqula, umsebenzi we-triangular uhlala usetyenziselwa ukucubungula ezinye iiseyile zokusebenza kunye nezangqa zangaphakathi nangaphandle ngaphezu kokuchaneka kwesibini.Ngenxa yokushisa kokusika, ukungqubuzana phakathi kwendawo yokusebenza kunye nesixhobo kubangela ukuba isixhobo sinxibe kunye nokuchaneka ngokuphindaphindiweyo komnini wesixhobo sesikwere, njl., umgangatho unzima ukuqinisekisa.Ukuze kulungiswe ubunzulu obuchanekileyo be-micro-deep, kwinkqubo yokujika, sinokusebenzisa ubudlelwane phakathi kwecala elichaseneyo kunye necala le-oblique likanxantathu njengoko kufuneka ukuhambisa isibambi semela esincinci kwi-engile, ukuze sifikelele ngokuchanekileyo. ubunzulu bokutya obuthe tyaba besixhobo sokuguqula imicro-moving.Injongo, gcina abasebenzi kunye nexesha, qinisekisa umgangatho wemveliso kunye nokuphucula ukusebenza kakuhle.Ixabiso eliqhelekileyo leC620 lesixhobo somphathi wesixhobo ngu-0.05mm kwigridi nganye.Ukuba ufuna ukufumana ubunzulu bokutya obuthe tye obuyi-0.005mm, jonga i-sine trigonometric function table: sinα=0.005/0.05=0.1 α=5o44′ ke susa nje isibambi semela esincinci Xa iyi-5o44', xa uhambisa umzobo wobude. i-disc kwi-knife holder encinci, inokufikelela kwi-micro-movement yesixhobo sokusika ngexabiso elinzulu le-0.005mm kwicala elisecaleni.cnc machining inxalenye

2. Ukusetyenziswa kweteknoloji yokuguqula umva kwiindlela ezintathu zokuvelisa ixesha elide libonisa ukuba kwinkqubo ethile yokuguqula, iteknoloji yokusika i-reverse inokufikelela kwiziphumo ezilungileyo.Le mizekelo ilandelayo yile ilandelayo:

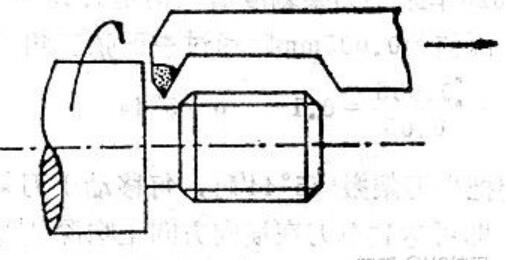

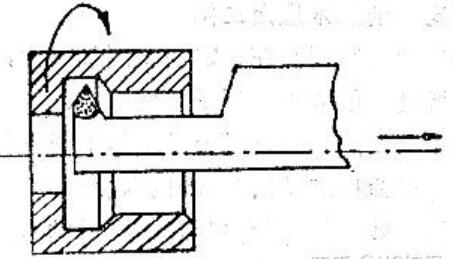

(1) Xa izinto zentambo yokuqhawula i-reverse-cutting i-martensitic steel stainless piece kunye ne-workpiece yangaphakathi nangaphandle yomsonto kunye ne-pitch ye-1.25 kunye ne-1.75 mm, ekubeni i-pitch ye-lathe screw isuswa yi-pitch ye-workpiece, ifunyenwe. ixabiso Lixabiso elingenakuphela.Ukuba intambo yenziwe ngoomatshini ngokuphakamisa umqheba we-counter nut, intambo idla ngokuphulwa.Ngokubanzi, i-lathe yesiqhelo ayinaso isixhobo se-buckle esingalungelelananga, kwaye iseti eyenziwe ngokwayo yediski ithatha ixesha elininzi, ngoko ke ekuqhubekiseni isandi esinjalo.Xa uthunga, kuba njalo.Indlela eyamkelweyo yindlela yokuguqula i-speed-speed egudileyo, kuba i-high-speed-speed-up-up akwanele ukuhoxisa ummese, ngoko ke ukusebenza kakuhle kwemveliso kuphantsi, ifayile yenziwe ngokulula ngexesha lokuguqula, kwaye uburhabaxa bomhlaba bunzima, ngokukodwa ekuqhubeni i-martensite insimbi engenasici efana ne-1Crl3, i-2 Crl3, njl. Xa usika ngesantya esiphantsi, i-sickle phenomenon ivelele ngakumbi.I-reverse-cuttering, i-reverse-cut, kunye ne-contra-direct-direction "ezintathu-reverse" iindlela zokusika ezenziwe kwindlela yokwenza i-machining inokufikelela kwisiphumo esihle sokusika, kuba indlela inokuguqula intambo ngesantya esiphezulu, kunye necala elihambayo Isixhobo si Isixhobo sirhoxiswa ukusuka ekhohlo ukuya ekunene, ngoko ke akukho mva ukuba isixhobo asinakurhoxa xa sisika intambo ngesantya esiphezulu.Indlela ethile yile ilandelayo: Xa intambo yangaphandle isetyenzisiweyo, gaya isixhobo esifanayo sokuguqula intambo yangaphakathi (umzobo 1);

Gaya isixhobo sokuguqula intambo yangaphakathi engasemva (Umfanekiso 2).inxalenye yeplastiki

Phambi komatshini, hlengahlengisa ipleyiti yokuphotha umva kancinci ukuqinisekisa isantya sokujikeleza.Ukuze intambo cutter elungileyo, vala nut yokuvula kunye nokuvala, qalisa phambili kunye nesantya esiphantsi ukuya sipe engenanto, uze ubeke isixhobo intambo ukujika ibe ubunzulu obufanelekileyo cut, unako ukuguqula ukujikeleza.Ngeli xesha, isixhobo sokuguqula sishiywe kwisantya esiphezulu.Ngokusika ummese ngasekunene kunye nokusika inani leemela ngokwale ndlela, intambo enobunzima obuphezulu kunye nokuchaneka okuphezulu kunokwenziwa ngoomatshini.

(2) Kwinkqubo yemveli yokugoba i-reverse knurling, iifayili zentsimbi kunye ne-debris zingenwa ngokulula phakathi kwe-workpiece kunye ne-knurling knurling, ebangela ukuba i-workpiece igxininiswe, ibangele ukuba imigca ihlanganiswe, ipateni ityunyuziwe okanye ighosted; njl.Ukuba indlela entsha yokusebenza yokujika kunye ne-knurling ye-spindle ye-lathe yamkelwe, ukungonakali okubangelwa kukusebenza okugudileyo kunokuthintelwa ngokufanelekileyo, kwaye umphumo obanzi obanzi unokufumaneka.

(3) Ukuguqula ukuguqulwa kwemisonto yetaper yangaphakathi nangaphandle Xa uguqula imisonto ye taper yangaphakathi neyangaphandle ngokuchaneka okuncinci kunye nebhetshi encinci, kunokwenzeka ukusebenzisa ngokuthe ngqo ukusika umva kunye nokulayisha umva ngaphandle kwesixhobo sokubumba.Indlela entsha yokusebenza, ngelixa usika icala lesixhobo, isixhobo sishukunyiswa ngokuthe tye ukusuka kwesobunxele ukuya kwesokudla.Ifayile enqamlezileyo ilula ukuqonda ubunzulu befayile ukusuka kwidayimitha enkulu ukuya kwincinci encinci.Isizathu yifayile.Kukho uxinzelelo lwangaphambili.Uluhlu lwezicelo zolu hlobo olutsha lweteknoloji yokusebenza eguqukayo ekuguquleni iteknoloji isanda ngokubanzi kwaye inokusetyenziswa ngokuguquguqukayo kwiimeko ezahlukeneyo.

3. Indlela entsha yokusebenza kunye nezixhobo ezintsha zokubhoboza imingxuma emincinci Kwinkqubo yokuguqula, xa umngxuma ungaphantsi kwe-0.6mm, ububanzi be-drill buncinci, ukuqina akubi, isantya sokusika asikho phezulu, kunye nezinto zokusebenza. i-alloy ekwazi ukumelana nobushushu kunye nensimbi engenasici, kwaye ukuxhathisa ukusika kukhulu, ngoko xa ubhobhoza, njengokusetyenziswa kwesondlo sokuhambisa ngoomatshini, i-drill ilula kakhulu ukuphuka, oku kulandelayo kuchaza isixhobo esilula nesisebenzayo kunye nendlela yokutya yesandla.Okokuqala, i-drill chuck yokuqala iguqulwa ibe luhlobo oluthe tye lwe-shank.Xa i-drill encinci ibotshelelwe kwi-chuck ye-drill edadayo, ukugrumba kunokwenziwa ngokutyibilikayo.Ngenxa yokuba indawo engasemva ye-drill bit is straight shank sliding fit, inokuhamba ngokukhululekileyo kumkhono wokutsala.Xa umngxuma omncinci ugrunjwa, i-drill chuck inokubanjwa ngobumnene ngesandla, kwaye i-manual feed micro ingenziwa, kwaye umngxuma omncinci unokukhutshwa ngokukhawuleza.Umgangatho kunye nobungakanani kunye nokwandisa ubomi benkonzo yee-drills ezincinci.I-chuck ye-drill eguquliweyo eneenjongo ezininzi ingasetyenziselwa ukucofa intambo yangaphakathi ye-diameter encinci, i-reaming, njl.

4. I-Anti-vibration kwi-machining yomngxuma onzulu Kwi-machining yemingxuma enzulu, ngenxa ye-aperture encinci, ibha yesixhobo esinesithukuthezi sincinci.Kuyinto engenakuthintelwa ukuvelisa ukungcangcazela xa i-diameter yomngxuma iyi-Φ30~50mm kwaye umngxuma onzulu malunga ne-1000mm.Yeyona isebenzayo kwaye isebenzayo ukukhusela ukungcangcazela kwe-arbor.Indlela yokuqhoboshela izixhaso ezimbini (usebenzisa izinto ezifana nelaphu le-bakelite) kumzimba we-shank, kwaye ubungakanani bufana ngqo nobukhulu bokuvula.Ngethuba lenkqubo yokusika, i-arbor ayinakukwazi ukuxubha ngenxa yokubeka i-slats, kwaye iindawo ezinzulu zomngxuma womgangatho omhle zinokucutshungulwa.inxalenye yomatshini

5. I-anti-break ye-drill encinci yeziko ingaphantsi komngxuma ophakathi kwe-Φ1.5mm xa u-drilling ungaphantsi komngxuma ophakathi we-Φ1.5mm.Indlela elula kwaye esebenzayo yokulwa nekhefu kukuba ungayitshixi i-tailstock xa ubhobhoza umngxuma ophakathi, vumela i-tailstock I-self-weight kunye ne-friction eyenziwa phakathi komphezulu webhedi yomatshini isetyenziselwa ukugrumba umngxuma ophakathi.Xa ukuchasana kokusika kukhulu kakhulu, i-tailstock iya kubuya ngokwayo, ngaloo ndlela ikhusela i-drill center.

6. I-Anti-vibration yokuguqula ii-workpieces ezinqabileyo ezinqabileyo Ngexesha lokujika kwezinto ezinqabileyo ezinqabileyo, ii-vibrations zivame ukuveliswa ngenxa yeempawu zensimbi ezimbi zezinto zokusebenza;ngakumbi xa ujika insimbi engenasici kunye ne-alloys ekwazi ukumelana nobushushu, ukungcangcazela kugqame ngakumbi, uburhabaxa bomphezulu we-workpiece buhlwempuzeke kakhulu, kwaye ubomi benkonzo yesixhobo bufutshane.Ezona ndlela zilula zokwahlula ukothuka kwiimveliso ezininzi zichazwe ngezantsi.

(1) Xa ujika isangqa sangaphandle sentsimbi engenastainless umngxuma obhityileyo ityhubhu workpiece, umngxuma ungazaliswa chips iinkuni kwaye iplagwe.Kwangaxeshanye, zombini iziphelo workpiece ziplagwe iplagi bakelite, kwaye ke uzipho inkxaso kwisibambi isixhobo endaweni yayo Imelon exhasayo yezinto bakelite inokulungisa arc efunekayo ukwenza ukujika kwentsimbi engenasiphene. intonga ebhityileyo.Le ndlela ilula inokuthintela ngokufanelekileyo ukungcangcazela kunye nokuguqulwa kwentonga ye-slender engenanto ngexesha lokusika.

(2) Xa ujika umngxuma wangaphakathi wesixhobo esimelana nobushushu (i-high-nickel-chromium) ingxubevange enodonga olucekethekileyo, ukuqina kwesixhobo sokusebenza asilunganga, i-shank ibhityile, kwaye kwenzeka into embi kakhulu ngexesha lokusika; nto leyo inoxanduva ngokugqithisileyo lokonakalisa isixhobo kwaye ibangele inkcitho.Ukuba isixhobo esifunxa ukothuka esifana nomtya werabha okanye isipontshi sijikelezwe kwisangqa sangaphandle sesixhobo sokusebenza, umphumo wokothuka unokufezekiswa ngokufanelekileyo.

(3) Xa ujika isangqa sangaphandle se-alloy-resistant-resistant-sleeve workpiece, ngenxa yezinto ezibanzi ezifana nokumelana okuphezulu kwe-alloy-resistant alloy, kulula ukuvelisa ukungcangcazela kunye nokuguqulwa ngexesha lokusika.Ukuba umngxuma werabha okanye intambo yomqhaphu ifakwe kumngxuma wokusebenza, Ukuba i-debris isetyenzisiweyo, ke indlela yokudibanisa kwiziphelo zombini ingasetyenziselwa ukuthintela ngokufanelekileyo ukungcangcazela kunye nokuguqulwa kwendawo yokusebenza ngexesha lenkqubo yokusika, kunye ne-high- umgangatho womsebenzi obhityileyo-olubiyelweyo unokuqwalaselwa.

7. Isixhobo esongezelelweyo sokulwa ne-vibration kulula ukuvelisa i-vibration ngenxa yobunzima bobunzima bomsebenzi wohlobo lwe-shaft emide ngexesha lenkqubo yokusika i-multi-groove, okubangelwa ukungahambi kakuhle kwendawo yokusebenza kunye nomonakalo kwisixhobo.Iseti yezixhobo ezongezelelweyo zokulwa ne-vibration inokusombulula ngokufanelekileyo ingxaki ye-vibration yamacandelo amancinci kwinkqubo ye-grooving (jonga uMzobo 10).Faka isixhobo esizenzele sona ngokwaso ukuze singqine umothuko kwindawo efanelekileyo kwisibambi sesixhobo esisikwere phambi komsebenzi.Emva koko, faka isixhobo sokuguqula i-slot-shaped-shaped-shaped-shaped-shaped-shaped-shaped-shaped-shaped tool kwi-square tool holder, lungisa umgama kunye nomlinganiselo wokunyanzeliswa kwentwasahlobo, uze usebenze.Xa isixhobo sokuguqula sinqumla kwi-workpiece, isixhobo esongezelelweyo sokulwa ne-vibration sibekwe phezu kwendawo yokusebenza ngexesha elifanayo, elilungele ukutshitshiswa.isiphumo.

8. Izinto ezinzima kumatshini zilungiswa kwaye zigqitywe.Xa sikwizinto ezinzima kumatshini ezifana ne-alloys ephezulu yokushisa kunye neentsimbi eziqiniweyo, uburhabaxa bendawo yokusebenza bufuneka ukuba bube yi-Ra0.20-0.05μm, kunye nokuchaneka kwe-dimensional kuphezulu.Ukugqitywa kokugqibela ngokuqhelekileyo kuqhutyelwa kumatshini wokugaya.Yenza i-self-ezenziwe isixhobo esilula se-honing kunye nevili le-honing, kwaye ufumane isiphumo esihle sezoqoqosho ngokuhombisa endaweni yenkqubo yokugaya kwi-lathe.

9. Ukulayisha ngokukhawuleza kunye nokukhulula i-mandrels idla ngokudibana neentlobo ezahlukeneyo zeeseti zokuzala kwinkqubo yokujika.Isangqa sangaphandle kunye ne-angle ye-taper yesikhokelo eguqulweyo yendibano yokuthwala.Ngenxa yobukhulu bebhetshi enkulu, ukulayishwa kunye nexesha lokukhulula lingaphezulu kwexesha lokusika.Ixesha elide, impumelelo ephantsi yemveliso.I-mandrel yokulayisha ngokukhawuleza kunye ne-single-knife i-multi-blade (i-hardmetal) yokuguqula izixhobo ezichazwe ngezantsi inokugcina ixesha elincedisayo kwaye iqinisekise umgangatho wemveliso ekuqhutyweni kweengxenye zemikhono ehlukeneyo.Indlela yokuvelisa ngolu hlobo lulandelayo.Yenza elula taper mandrel encinane.Umgaqo kukusebenzisa umkhondo 0.02mm taper ngasemva mandrel.Iseti yokuthwala iqinisiwe kwi-mandrel ngokukhuhlana, kwaye emva koko isixhobo sokuguqula i-multi-blade sisetyenziswe.Emva komjikelezo, i-angle ye-cone ye-15 ° iguqulwa, kwaye indawo yokupaka iqhutyelwa ukususa iindawo ngokukhawuleza kwaye kakuhle, njengoko kuboniswe kuMfanekiso we-14.

10. Ukuguqulwa kweengxenye zetsimbi ezinzima

1 i-smooth surface plugging 5 Iimpompo eziqengqelekayo ezenziwe ngesantya esiphezulu sezixhobo zentsimbi Ukucima ihardware kunye nezinto ezahlukeneyo ezinzima ezidibana nazo kule mveliso ingentla, khetha isixhobo esifanelekileyo sesixhobo kunye nesixa sokusika kunye nesixhobo ii-engile zejometri kunye neendlela zokusebenza zinokufezekisa iziphumo ezilungileyo zoqoqosho ngokubanzi. .Ngokomzekelo, emva kokuba i-square broach iphukile, ukuba iphinda iqaliswe ukuvelisa i-square broach, kungekhona nje umjikelezo wokuvelisa ixesha elide, kodwa neendleko ziphezulu.Kwingcambu ye-broach yokuqala, sisebenzisa i-blade ye-alloy eqinile ye-YM052 ukuyilola ibe yi-negative.Iengile yangaphambili r.=-6 ° ~-8 °, umgca wokusika unokuguqulwa ngokugaya ngokucophelela ngelitye leoli.Isantya sokusika yi-V=10~15m/min.Emva kwesangqa sangaphandle, i-sipe engenanto iyasikwa, kwaye ekugqibeleni intambo yahlulwe ibe rhabaxa kwaye icoleke.), emva kokuxhatshazwa, isixhobo kufuneka sihlaziywe kwaye sihlanjwe emva kokutshitshiswa okutsha kunye nokugaya, kwaye emva koko intambo yangaphakathi yentonga yokudibanisa ilungiswe, kwaye emva koko idibeneyo inqunywe.I-square broach ene-scrap ephukile yalungiswa emva kokujika kwaye yayindala njengentsha.

(2) Ukukhethwa kwezixhobo zesixhobo sokuguqula kunye nokucima i-hardware 1 Amabakala amatsha afana ne-hard alloy YM052, YM053, YT05, njl., isantya sokusika ngokubanzi singaphantsi kwe-18m / min, kunye nobunzima bomphezulu we-workpiece bunokufikelela kwi-Ra1.6 ~0.80μm.I-2 cubic boron nitride tool FD inokuqhuba zonke iintlobo zentsimbi eqinile kunye neengxenye ezitshiziweyo, ukusika isantya ukuya kwi-100m / min, uburhabaxa bomhlaba ukuya kuthi ga kwiRa0.80 ~ 0.20μm.Isixhobo esihlanganisiweyo se-cubic boron nitride i-DCS-F eveliswe yi-State Capital Machinery Plant kunye neGuizhou No.6 Grinding Wheel Factory nayo inalo msebenzi.Umphumo wokucubungula ubi kakhulu kune-carbide ene-cemented (kodwa amandla awalungile njengaleyo ye-alloy enzima, inzulu kwaye iphantsi kune-alloy enzima, kwaye kulula ukuyonakalisa ukuba isetyenziswe ngokungafanelekanga).Izixhobo ze-ceramic ezi-9, isantya sokusika se-40 ~ 60m / min, amandla ampofu.Zonke ezi zixhobo zingentla zineempawu zazo ekujikeni nasekucimeni iindawo, kwaye kufuneka zikhethwe ngokwemiqathango ethile yokuguqula izinto ezahlukeneyo kunye nobunzima obuhlukeneyo.

3Intsimbi e-1 ephezulu ye-alloy: ibhekisela kwizinto ezixutywayo Isixhobo sentsimbi kunye nentsimbi yokufa (ikakhulukazi iintsimbi ezahlukeneyo zesantya esiphezulu) ezinobunzima obungaphezu kwe-10%.I-2 yensimbi ye-alloy: ibhekisela kwintsimbi yensimbi kunye nentsimbi yokufa kunye nomxholo we-alloying element ye-2 ~ 9%, njenge-9SiCr, i-CrWMn kunye ne-high-force alloy structural steel.I-3 carbon steel: kubandakanywa iintsimbi ezahlukeneyo ze-carbon tool kunye ne-carburized steel ezifana ne-T8, T10, i-15 yensimbi okanye i-20 gauge steel carburizing steel.I-carbon steel, i-microstructure emva kokucima i-martensite epholileyo kunye nenani elincinci le-carbide, iinwele ezinzima ze-HV800 ~ 1000, kunobulukhuni be-WC kunye ne-TiC kwi-carbide ene-cemented kunye ne-A12D3 kwizixhobo ze-ceramic Iphantsi kakhulu, kwaye ishushu kancinci- lukhuni kune-martensite ngaphandle kwezinto ezixutywayo kwaye ngokubanzi ayidluli kuma-200 °C.Njengoko umxholo wezinto zokudibanisa kwintsimbi ukhula, umxholo we-carbide wentsimbi emva kokucima kunye nokunyuka kwenyuka, kwaye uhlobo lwe-carbide luba nzima kakhulu.Ukuthatha i-high-speed steel njengomzekelo, umxholo we-carbides kwi-microstructure emva kokucima kunye nokufudumala kunokufikelela kwi-10-15% (i-volume ratio) kwaye iqulethe i-carbides ye-MC, i-M2C, i-M6 kunye ne-M3, i-2C, njl Ubunzima obuphezulu (HV2800). ), ephezulu kakhulu kunobunzima besigaba esinzima kwizinto eziqhelekileyo zesixhobo.Ukongeza, ngenxa yobukho benani elikhulu lezinto ezidibeneyo, ubulukhuni obushushu be-martensite equlethe izinto ezahlukeneyo zokuxuba bunganyuswa ukuya malunga ne-600 °C.Ukusebenza kanzima kweentsimbi ezilukhuni kunye nobunzima obufanayo akufani, kwaye umehluko mkhulu kakhulu.Phambi kokuguqula iinxalenye zentsimbi eqinileyo, ihlalutywa ukuba yeyolo didi.Lawula iimpawu, khetha izixhobo ezifanelekileyo zesixhobo, isixa sokusika kunye nejiyometri yesixhobo.I-angle inokugqiba ngokutyibilikayo ukujika kweengxenye zentsimbi eqinile.

I-Anebon Metal Products Limited inokubonelela nge-CNC Machining, Die Casting, inkonzo ye-Sheet Metal Fabrication, nceda uzive ukhululekile ukuqhagamshelana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Ixesha lokuposa: Aug-30-2019