1. Nws txawj ntse kom tau ib qho me me ntawm cov khoom noj sib sib zog nqus.Nyob rau hauv txoj kev tig, daim duab peb sab muaj nuj nqi feem ntau yog siv los ua ib co workpieces nrog lub puab thiab sab hauv lub voj voog saum toj ob qhov tseeb.Vim lub tshav kub ntawm kev txiav, kev sib txhuam ntawm lub workpiece thiab cov cuab yeej ua rau cov cuab yeej hnav thiab rov ua qhov tseeb ntawm cov cuab yeej square tuav, thiab lwm yam, qhov zoo yog qhov nyuaj rau lav.Yuav kom daws tau qhov tseeb micro-qhov tob tob, nyob rau hauv cov txheej txheem tig, peb tuaj yeem siv kev sib raug zoo ntawm sab nraud thiab oblique sab ntawm daim duab peb sab raws li xav tau los txav cov riam me me ntev ntev ntawm lub kaum sab xis, kom raug ncav cuag. kab rov tav noj qhov tob ntawm micro-tsov tig lub cuab yeej.Lub hom phiaj, txuag kev ua haujlwm thiab sijhawm, ua kom cov khoom zoo thiab txhim kho kev ua haujlwm.Qhov dav dav C620 tshuab dhos cuab yeej tuav tus nqi yog 0.05mm ib daim phiaj.Yog tias koj xav tau cov kab rov tav noj qhov tob ntawm 0.005mm, kos lub sine trigonometric muaj nuj nqi lub rooj: sinα = 0.005/0.05 = 0.1 α = 5o44 ′ yog li cia li txav riam me me thaum nws yog 5o44 ', thaum tsiv lub longitudinally engraved disc ntawm tus tuav riam me me, nws tuaj yeem ncav cuag lub micro txav ntawm cov cuab yeej txiav nrog qhov tob ntawm 0.005mm nyob rau sab nraud.cnc machining qhov chaw

2. Daim ntawv thov ntawm thim rov qab siv tshuab nyob rau hauv peb lub sij hawm ntev ntau lawm ua pov thawj tias nyob rau hauv cov txheej txheem tig, rov qab txiav tshuab tuaj yeem ua tiav cov txiaj ntsig zoo.Cov piv txwv hauv qab no yog raws li nram no:

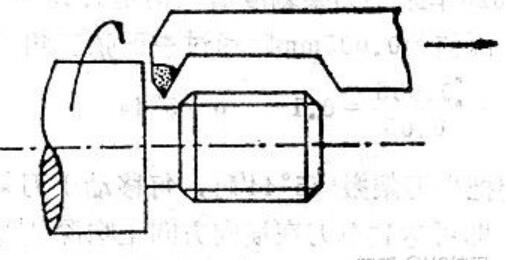

(1) Thaum cov khoom siv rov qab txiav cov xov yog martensitic stainless hlau daim nrog cov xov xov sab hauv thiab sab nraud nrog lub suab ntawm 1.25 thiab 1.75 hli, txij li lub suab ntawm lub tshuab dhos ntsia hlau raug tshem tawm los ntawm lub suab ntawm lub workpiece, qhov tau txais. tus nqi yog tus nqi inexhaustible.Yog hais tias cov xov yog machined los ntawm lifting tus tuav ntawm lub txee lub txiv ntseej, cov xov feem ntau yog tawg.Feem ntau, lub tshuab dhos zoo tib yam tsis muaj cov cuab yeej ua haujlwm tsis zoo, thiab cov txheej txheem ua tus kheej ntawm lub disc yog siv sijhawm ntev, yog li hauv kev ua haujlwm zoo li no.Thaum threading, nws yog feem ntau.Cov txheej txheem tau txais yuav yog qhov qis-ceev du txoj kev tig, vim hais tias lub siab ceev tuaj tos tsis txaus los thim riam, yog li cov khoom siv tau qis, cov ntaub ntawv tau yooj yim tsim thaum tig, thiab qhov roughness ntawm qhov chaw tsis zoo, tshwj xeeb tshaj yog nyob rau hauv kev ua cov martensite stainless hlau xws li 1Crl3, 2 Crl3, thiab lwm yam. Thaum txiav ntawm tsawg ceev, qhov tshwm sim mob yog qhov tseem ceeb.Kev thim rov qab txiav, thim rov qab-txiav, thiab rov qab-txoj kev "peb-rov qab" txiav txoj kev tsim nyob rau hauv machining xyaum ua tau zoo tag nrho cov nyhuv, vim hais tias cov txheej txheem tuaj yeem tig cov xov ntawm kev kub ceev, thiab kev txav mus los ntawm kev txiav. cuab yeej yog Lub cuab tam yog thim rov qab los ntawm sab laug mus rau sab xis, yog li tsis muaj qhov tsis zoo uas lub cuab yeej tsis tuaj yeem thim rov qab thaum txiav cov xov ntawm kev kub ceev.Cov txheej txheem tshwj xeeb yog raws li hauv qab no: Thaum siv cov xov sab nraud, zom ib qho zoo sib xws hauv xov tig lub cuab yeej (Fig. 1);

Sib tsoo ib qho rov qab xov sab hauv tig lub cuab yeej (Daim duab 2).yas ntu

Ua ntej machining, kho cov ntxaiv ntawm qhov rov qab sib txhuam phaj me ntsis kom ntseeg tau tias qhov rov qab tig ceev.Rau ib tug zoo xov cutter, kaw lub qhib thiab kaw txiv ntseej, pib rau pem hauv ntej thiab qis ceev mus rau lub khoob sipe, thiab ces muab cov xov tig lub cuab tam rau hauv qhov tsim nyog qhov tob ntawm txiav, koj muaj peev xwm thim rov qab kev sib hloov.Lub sijhawm no, lub cuab yeej tig yog sab laug ntawm kev kub ceev.Los ntawm kev txiav cov riam mus rau sab xis thiab txiav cov riam raws li txoj kev no, cov xov uas muaj qhov siab roughness thiab siab precision tuaj yeem raug machined.

(2) Nyob rau hauv cov txheej txheem knurling ib txwm rov qab knurling, cov ntaub ntawv hlau thiab cov khib nyiab tau yooj yim nkag mus rau ntawm lub workpiece thiab knurling riam, ua rau lub workpiece overstressed, ua rau cov kab bundled, tus qauv yog crushed los yog ghosted, lwm..Yog tias txoj kev ua haujlwm tshiab ntawm kev tig thiab knurling ntawm lub tshuab dhos spindle tau txais yuav, qhov tsis zoo los ntawm kev ua haujlwm smoothing tuaj yeem tiv thaiv tau zoo, thiab muaj txiaj ntsig zoo tuaj yeem tau txais.

(3) Rov qab tig ntawm sab hauv thiab sab nraud taper yeeb nkab threads Thaum tig ntau yam sab hauv thiab sab nraud taper yeeb nkab threads nrog tsawg precision thiab tsawg batch, nws muaj peev xwm ncaj qha siv thim rov qab txiav thiab rov qab loading yam tsis muaj pwm ntaus ntawv.Cov txheej txheem tshiab ntawm kev ua haujlwm, thaum txiav sab ntawm lub cuab yeej, lub cuab yeej txav horizontally ntawm sab laug mus rau sab xis.Cov ntaub ntawv transverse yog ib qho yooj yim kom nkag siab qhov tob ntawm cov ntaub ntawv los ntawm txoj kab uas hla loj mus rau txoj kab uas hla me me.Yog vim li cas yog cov ntaub ntawv.Muaj kev ntxhov siab ua ntej.Qhov ntau ntawm cov ntawv thov ntawm hom tshiab no rov qab ua haujlwm thev naus laus zis hauv kev siv tshuab tig tau nce zuj zus thiab tuaj yeem hloov pauv mus rau ntau qhov xwm txheej tshwj xeeb.

3. Txoj kev ua haujlwm tshiab thiab cov cuab yeej tshiab rau drilling qhov me me Nyob rau hauv txoj kev tig, thaum lub qhov yog tsawg tshaj li 0.6 hli, txoj kab uas hla ntawm lub laum me me, lub rigidity tsis zoo, txiav ceev tsis nce, thiab cov khoom siv workpiece. yog tshav kub-resistant alloy thiab stainless hlau, thiab txiav kuj yog Loj, yog li thaum drilling, xws li kev siv cov khoom siv kis tau tus mob, lub laum yog yooj yim heev rau tawg, cov hauv qab no piav qhia txog cov cuab yeej yooj yim thiab siv tau thiab phau ntawv pub txoj kev.Ua ntej, tus thawj xyaum chuck yog hloov mus rau hauv ib tug ncaj shank floating hom.Thaum lub laum me me yog clamped rau ntawm lub laum ntab chuck, qhov drilling tuaj yeem ua tau zoo.Vim hais tias sab nraub qaum ntawm lub laum me ntsis yog ib qho ncaj shank zawv zawg haum, nws tuaj yeem txav tau yooj yim hauv lub tes tsho rub.Thaum lub qhov me me yog drilled, lub laum chuck tuaj yeem maj mam tuav ntawm tes, thiab phau ntawv micro pub tuaj yeem pom tau, thiab lub qhov me me tuaj yeem drilled sai sai.Zoo thiab muaj nuj nqis thiab txuas ntxiv lub neej kev pab cuam ntawm kev xyaum me me.Cov kev hloov kho ntau lub hom phiaj chuck kuj tuaj yeem siv rau cov xov me me hauv xov tapping, reaming, thiab lwm yam. (Yog tias lub qhov loj dua yog drilled, tus pin txwv tuaj yeem muab tso rau ntawm lub tes tsho rub thiab lub shank ncaj).

4. Kev tiv thaiv kev vibration hauv qhov sib sib zog nqus machining Hauv qhov sib sib zog nqus machining, vim qhov me me aperture, lub cuab yeej tho txawv yog slender.Nws yog ib qho tsim nyog los tsim kev co thaum lub qhov taub yog Φ30 ~ 50mm thiab qhov tob yog li 1000mm.Nws yog qhov zoo tshaj plaws thiab muaj txiaj ntsig zoo los tiv thaiv kev vibration ntawm arbor.Txoj kev yog muab ob qho kev txhawb nqa (siv cov khoom siv xws li daim ntaub bakelite) rau lub cev shank, thiab qhov loj me yog tib yam li qhov loj me me.Thaum lub sij hawm txiav, lub arbor tsis tshua muaj kev vibration vim qhov chaw ntawm cov slats, thiab qhov tob qhov ntawm qhov zoo tuaj yeem ua tiav.machined qhov

5. Kev tiv thaiv kev tawg ntawm qhov chaw me me laum yog tsawg dua qhov chaw nruab nrab ntawm Φ1.5mm thaum lub qhov drilling tsawg dua qhov nruab nrab ntawm Φ1.5mm.Txoj kev yooj yim thiab siv tau los tiv thaiv kev tawg yog kom tsis txhob xauv lub tailstock thaum drilling qhov chaw nruab nrab, cia lub tailstock Tus kheej qhov hnyav thiab kev sib txhuam tsim los ntawm lub tshuab txaj saum npoo yog siv los laum qhov chaw nruab nrab.Thaum lub txiav tsis kam loj dhau, lub tailstock yuav thim rov qab los ntawm nws tus kheej, yog li tiv thaiv qhov chaw xyaum.

6. Kev tiv thaiv kev vibration ntawm tig nyias-walled workpieces Thaum lub sij hawm tig cov txheej txheem ntawm nyias-walled workpieces, kev vibrations yog feem ntau generated vim tsis zoo steel zog ntawm workpieces;Tshwj xeeb tshaj yog thaum tig stainless hlau thiab tshav kub-resistant alloys, qhov kev co yog qhov tseem ceeb, lub nto roughness ntawm lub workpiece yog tsis tshua muaj neeg pluag, thiab cov kev pab cuam lub neej ntawm lub cuab tam shorten.Txoj kev yooj yim tshaj plaws ntawm kev sib cais kev poob siab hauv ntau qhov kev tsim khoom tau piav qhia hauv qab no.

(1) Thaum tig lub voj voog sab nrauv ntawm cov hlau tsis muaj steel hollow slender tube workpiece, lub qhov tuaj yeem ntim nrog ntoo chips thiab ntsaws.Nyob rau tib lub sijhawm, ob qhov kawg ntawm lub workpiece yog ntsaws nrog lub ntsaws ntsaws, thiab tom qab ntawd cov kev txhawb nqa claw ntawm lub cuab yeej yog hloov nrog Cov kev txhawb nqa melon ntawm cov khoom siv bakelite tuaj yeem kho qhov xav tau arc los ua qhov tig ntawm stainless hlau hollow. rhiab rod.Txoj kev yooj yim no tuaj yeem tiv thaiv kev vibration thiab deformation ntawm hollow slender pas nrig thaum lub sij hawm txiav.

(2) Thaum tig lub puab qhov ntawm lub tshav kub-resistant (high-nickel-chromium) alloy nyias-walled workpiece, lub rigidity ntawm lub workpiece yog tsis zoo, lub shank yog slender, thiab ib tug loj resonance tshwm sim tshwm sim thaum lub sij hawm txiav, uas yog lub luag haujlwm loj heev rau kev puas tsuaj rau lub cuab yeej thiab ua rau khib nyiab.Yog hais tias ib qho kev poob siab absorbing khoom xws li cov roj hmab sawb los yog daim txhuam cev raug mob nyob ib ncig ntawm lub voj voog ntawm lub workpiece, cov nyhuv shockproof tuaj yeem ua tiav.

(3) Thaum tig lub voj voog sab nraud ntawm lub tshav kub-resistant alloy nyias-walled lub tes tsho workpiece, vim muaj cov ntsiab lus zoo xws li kev ua haujlwm siab ntawm cov cua sov-resistant alloy, nws yooj yim los tsim kev co thiab deformation thaum txiav.Yog hais tias cov roj hmab qhov los yog paj rwb xov yog muab tso rau hauv lub workpiece qhov, Yog hais tias cov khib nyiab yog siv, ces txoj kev clamping ntawm ob qho tag nrho yuav siv tau los tiv thaiv kev vibration thiab deformation ntawm workpiece thaum lub sij hawm txiav, thiab high- zoo nyias-walled workpiece tuaj yeem ua tiav.

7. Cov cuab yeej tiv thaiv kev vibration ntxiv yog ib qho yooj yim los tsim kev vibration vim qhov tsis zoo ntawm lub elongated ncej hom workpiece thaum lub sij hawm ntau zawj txiav txheej txheem, ua rau tsis zoo nto roughness ntawm lub workpiece thiab kev puas tsuaj rau lub cuab yeej.Ib txheej ntawm cov cuab yeej tiv thaiv kev vibration ntxiv tuaj yeem daws tau qhov teeb meem kev vibration ntawm qhov sib luag hauv cov txheej txheem grooving (saib daim duab 10).Nruab cov cuab yeej ua rau nws tus kheej ua rau poob siab nyob rau hauv ib qho chaw tsim nyog ntawm lub cuab yeej square tuav ua ntej ua haujlwm.Tom qab ntawd, nruab qhov yuav tsum tau ua kom zoo li lub cuab yeej tig ntawm lub cuab yeej square, kho qhov kev ncua deb thiab compression npaum li cas ntawm lub caij nplooj ntoos hlav, thiab tom qab ntawd ua haujlwm.Thaum lub cuab yeej tig txiav mus rau hauv qhov chaw ua haujlwm, cov cuab yeej tiv thaiv kev vibration ntxiv tau muab tso rau ntawm qhov chaw ua haujlwm tib lub sijhawm, uas yog qhov zoo rau kev poob siab.nyhuv.

8. Cov khoom siv tshuab nyuaj yog honed thiab tiav.Thaum peb nyob rau hauv cov ntaub ntawv nyuaj-rau-tshuab xws li high-temperature alloys thiab hardened steels, lub nto roughness ntawm lub workpiece yuav tsum tau Ra0.20-0.05μm, thiab qhov seem qhov tseeb kuj siab.Kev ua tiav kawg feem ntau yog nqa tawm ntawm lub tshuab sib tsoo.Ua nws tus kheej yooj yim honing cuab tam thiab honing log, thiab tau txais ib tug zoo economic nyhuv los ntawm honing es tsis txhob ntawm kev sib tsoo txheej txheem ntawm lub tshuab dhos.

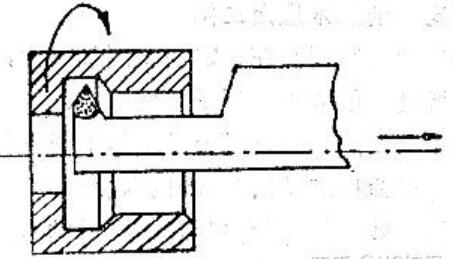

9. Kev thauj khoom ceev thiab tshem tawm mandrels feem ntau ntsib ntau hom kev coj tus kheej hauv cov txheej txheem tig.Lub voj voog sab nrauv thiab inverted qhia taper lub kaum sab xis ntawm cov kabmob sib dhos.Vim qhov loj batch loj, lub sijhawm thauj khoom thiab tshem tawm yog ntau tshaj li lub sijhawm txiav.Ntev, tsawg ntau lawm efficiency.Qhov ceev-loading mandrel thiab ib rab riam ntau lub ntsej muag (hardmetal) tig cov cuab yeej tau piav qhia hauv qab no tuaj yeem txuag lub sijhawm pabcuam thiab ua kom cov khoom lag luam zoo hauv kev ua haujlwm ntawm ntau yam kabmob lub tes tsho.Cov txheej txheem ntau lawm yog raws li nram no.Ua ib qho yooj yim me me taper mandrel.Lub hauv paus ntsiab lus yog siv 0.02mm kab ntawm taper nyob rau sab nraum qab ntawm mandrel.Cov kabmob teeb tsa yog nruj ntawm lub mandrel los ntawm kev sib txhuam, thiab tom qab ntawd siv ib rab riam ntau lub ntsej muag tig yog siv.Tom qab lub voj voog, lub kaum sab xis ntawm 15 ° yog thim rov qab, thiab qhov chaw nres tsheb yog nqa tawm kom tshem tawm cov khoom sai thiab zoo, raws li pom hauv daim duab 14.

10. Tig ntawm hardened steel qhov chaw

(1) Ib qho piv txwv tseem ceeb ntawm hardened steel tig 1 Reconstruction of high speed steel W18Cr4V hardened broach (kho tom qab tawg) 2 homemade non-standard thread plug gauge (hardening hardware) 3 quenching hardware and spraying turning of 4 pieces of quenching hardware du nto plugging 5 Xov dov kais dej ua los ntawm kev kub ceev steel cov cuab yeej Rau lub quenching hardware thiab ntau yam khoom nyuaj qhov chaw nyob rau hauv lub saum toj no ntau lawm, xaiv cov cuab yeej tsim nyog thiab txiav tus nqi thiab cov cuab yeej Geometric ces kaum thiab cov txheej txheem ntawm kev ua hauj lwm yuav ua tau zoo tag nrho cov nyiaj txiag tau. .Piv txwv li, tom qab lub square broach tawg, yog hais tias nws yog re-launched los tsim ib tug square broach, tsis tsuas yog lub manufacturing voj voog ntev, tab sis kuj tus nqi yog siab.Nyob rau hauv lub hauv paus ntawm tus thawj broach, peb siv cov hniav ntawm lub hard alloy YM052 sharpen nws mus rau hauv ib tug tsis zoo.Pem hauv ntej lub kaum sab xis r.= -6 ° ~ -8 °, txiav ntug tuaj yeem tig los ntawm kev sib tsoo nrog roj pob zeb.Kev txiav ceev yog V = 10 ~ 15m / min.Tom qab lub voj voog sab nrauv, qhov khoob khoob khoob yog txiav, thiab thaum kawg cov xov tau muab faib ua ntxhib thiab nplua.), tom qab lub roughing, lub cuab tam yuav tsum tau remed thiab av tom qab lub tshiab sharpening thiab sib tsoo, thiab ces lub internal xov ntawm lub connector pas nrig yog npaj, thiab ces lub sib koom tes yog trimmed.Ib qho square broach nrog cov khoom tawg tau kho tom qab tig thiab nws zoo li qub.

(2) Kev xaiv cov cuab yeej siv rau kev xa thiab quenching hardware 1 Cov qib tshiab xws li cov alloy nyuaj YM052, YM053, YT05, thiab lwm yam., qhov kev txiav ceev yog qis dua 18m / min, thiab qhov roughness ntawm lub workpiece tuaj yeem ncav cuag Ra1.6. ~ 0.80m.2 cubic boron nitride cuab tam FD tuaj yeem ua txhua yam ntawm cov hlau tawv tawv thiab cov khoom txau, txiav ceev txog 100m / min, nto roughness txog Ra0.80 ~ 0.20μm.Cov khoom sib xyaw cubic boron nitride DCS-F tsim los ntawm Lub Xeev Peev Machinery Cog thiab Guizhou No.6 Sib Tsoo Wheel Factory kuj muaj qhov ua tau zoo no.Cov nyhuv ua haujlwm yog qhov phem dua li ntawm cov cemented carbide (tab sis lub zog tsis zoo li ntawm cov tawv tawv, nws yog qhov tob dua thiab pheej yig dua li cov tawv alloy, thiab nws yooj yim rau kev puas tsuaj yog tias nws siv tsis raug).9 cov cuab yeej ceramic, txiav ceev ntawm 40 ~ 60m / min, lub zog tsis zoo.Tag nrho cov cuab yeej saum toj no muaj lawv tus kheej cov yam ntxwv hauv kev tig thiab quenching qhov chaw, thiab yuav tsum tau xaiv raws li qhov tshwj xeeb ntawm kev tig cov khoom sib txawv thiab qhov sib txawv hardness.

(3) Kev xaiv ntawm ntau hom hardened steel qhov chaw thiab cov cuab yeej cuab tam Sib txawv cov ntaub ntawv ntawm hardened steel qhov chaw nyob rau hauv tib lub hardness, qhov yuav tsum tau rau cov cuab yeej ua tau zoo sib txawv kiag li, raws li loj raws li nram no peb pawg;1 siab alloy steel: hais txog alloying ntsiab Tool steel thiab tuag steel (tseem ntau yam kev kub ceev steels) nrog tag nrho cov loj ntawm ntau tshaj 10%.2 alloy steel: hais txog cov cuab yeej hlau thiab cov hlau tuag nrog cov ntsiab lus alloying ntawm 2 ~ 9%, xws li 9SiCr, CrWMn thiab siab zog alloy cov qauv hlau.3 carbon steel: suav nrog ntau yam khoom siv roj carbon steel thiab carburized steel xws li T8, T10, 15 steel lossis 20 gauge steel carburizing steel.Rau cov pa roj carbon steel, lub microstructure tom qab quenching yog tempered martensite thiab ib tug me me ntawm carbide, tawv plaub hau HV800 ~ 1000, tshaj hardness ntawm WC thiab TiC nyob rau hauv cemented carbide thiab A12D3 nyob rau hauv ceramic cov cuab yeej nws yog tsawg dua, thiab nws yog kub tsawg- nyuaj tshaj martensite tsis muaj alloying ntsiab thiab feem ntau tsis tshaj 200 ° C.Raws li cov ntsiab lus ntawm cov ntsiab lus alloying hauv cov hlau nce, cov ntsiab lus carbide ntawm cov hlau tom qab quenching thiab tempering nce, thiab hom carbide yuav nyuaj heev.Siv cov hlau ceev ceev ua piv txwv, cov ntsiab lus ntawm carbides hauv microstructure tom qab quenching thiab tempering tuaj yeem ncav cuag 10-15% (ntim piv) thiab muaj carbides ntawm MC, M2C, M6 thiab M3, 2C, thiab lwm yam. High hardness (HV2800 ), uas yog siab tshaj qhov hardness ntawm lub hard point theem nyob rau hauv cov khoom siv dav dav.Tsis tas li ntawd, vim muaj ntau cov ntsiab lus alloying, kub hardness ntawm martensite uas muaj ntau yam alloying ntsiab tuaj yeem nce mus txog 600 ° C.Lub zog ua haujlwm ntawm hardened steels nrog tib macrohardness tsis zoo ib yam, thiab qhov sib txawv yog loj heev.Ua ntej tig hardened steel qhov chaw, nws yog tsom mus rau cov qeb ntawd.Master tus yam ntxwv, xaiv cov khoom siv tsim nyog, txiav nyiaj thiab cov cuab yeej geometry.Lub kaum sab xis tuaj yeem ua kom tiav qhov tig ntawm cov hlau tawv tawv.

Anebon Hlau Khoom Limited tuaj yeem muab CNC Machining, Tuag Casting, Sheet Hlau Fabrication kev pabcuam, thov koj xav tiv tauj peb.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Post lub sij hawm: Aug-30-2019