Aluminium yog cov khoom siv dav siv ntau tshaj plaws thiab siv dav hlau hauv cov hlau tsis muaj hlau, thiab nws cov ntawv thov ntau tseem nthuav dav.Muaj ntau tshaj 700,000 yam khoom siv txhuas ua los ntawm kev siv cov khoom siv txhuas.Raws li kev txheeb cais, muaj ntau tshaj 700,000 hom khoom txhuas, thiab ntau yam kev lag luam xws li kev tsim kho thiab kho kom zoo nkauj kev lag luam, kev lag luam tsheb thauj mus los, kev lag luam aerospace, thiab lwm yam muaj kev xav tau sib txawv.Niaj hnub no, Xiaobian yuav qhia rau koj txog kev siv tshuab ntawm cov khoom siv txhuas thiab yuav ua li cas kom tsis txhob ua deformation.cnc machining qhov chaw

Qhov zoo thiab cov yam ntxwv ntawm aluminium yog raws li nram no:

1. Tsawg ceev.Qhov ceev ntawm txhuas yog li 2.7 g / cm3.Nws qhov ceev tsuas yog 1/3 ntawm hlau lossis tooj liab.

2. High plasticity.Aluminium muaj qhov zoo ductility thiab tuaj yeem ua rau ntau yam khoom los ntawm kev ua haujlwm siab xws li extrusion thiab ncab.

3. Corrosion kuj.Aluminium yog cov hlau tsis zoo heev, thiab cov yeeb yaj kiab oxide tiv thaiv yuav raug tsim los ntawm qhov chaw nyob rau hauv tej yam ntuj tso los yog anodizing, thiab nws muaj zoo corrosion kuj ntau dua li hlau.

4, yooj yim zog.Ntshiab aluminium tsis muaj zog heev, tab sis nws tuaj yeem nce los ntawm anodizing.

5. Kev kho mob yooj yim.Kev kho deg tuaj yeem txhim kho ntxiv lossis hloov cov khoom ntawm txhuas.Cov txheej txheem aluminium anodizing yog qhov paub tab thiab ruaj khov hauv kev ua haujlwm, thiab tau siv dav hauv kev ua cov khoom siv txhuas.

6. Zoo conductivity thiab yooj yim rau recycle.

Kev siv technology ntawm aluminium khoom

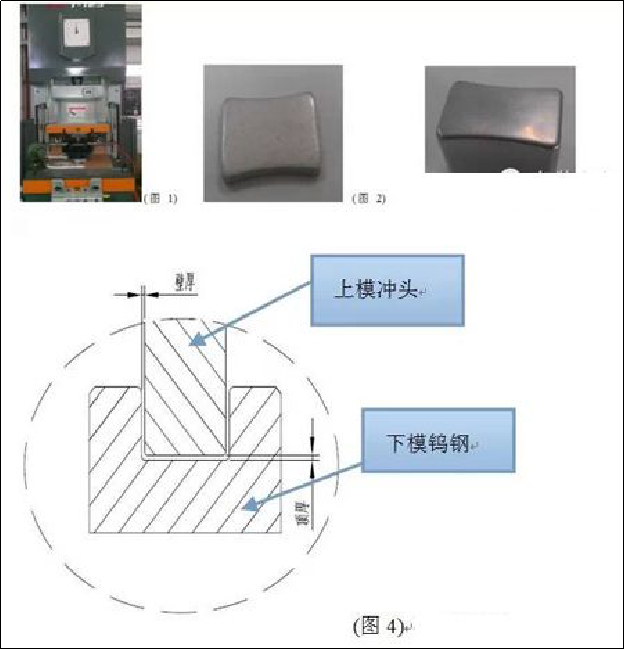

Punching ntawm cov khoom siv aluminium

1. Txias punch

Siv cov khoom siv aluminium pellets.Lub tshuab extrusion thiab tuag yog siv rau ib zaug molding, uas yog tsim rau cov khoom cylindrical los yog cov duab cov khoom uas nyuaj rau kev ua tiav los ntawm cov txheej txheem ncab, xws li oval, square, thiab duab plaub.

Lub tonnage ntawm lub tshuab siv yog muaj feem xyuam rau qhov chaw hla ntawm cov khoom.Qhov sib txawv ntawm lub Upper tuag punch thiab qis tuag tungsten steel yog cov phab ntsa thickness ntawm cov khoom.Thaum lub Upper tuag punch thiab qis tuag tungsten steel raug nias ua ke, qhov sib txawv ntsug mus rau hauv qab qhov chaw tuag yog Rau sab saum toj tuab ntawm cov khoom.aluminium qhov

Qhov zoo: Lub voj voog qhib pwm yog luv luv, thiab tus nqi tsim kho qis dua li ntawm cov duab kos pwm.

Disadvantages: Cov txheej txheem ntau lawm yog ntev, cov khoom loj fluctuates heev nyob rau hauv tus txheej txheem, thiab tus nqi zog yog siab.

2. Stretching

Siv cov khoom siv aluminium tawv.Nws yog qhov tsim nyog rau lub cev tsis yog-cylindrical (cov khoom siv txhuas nrog cov khoom nkhaus) kom deformed ntau zaus los ntawm kev siv cov tshuab tuag tas mus li thiab cov pwm kom ua tau raws li qhov xav tau ntawm cov duab.

Qhov zoo: ntau qhov nyuaj thiab ntau yam khoom deformation muaj qhov ruaj khov ntawm qhov kev tswj hwm hauv cov txheej txheem tsim khoom, thiab cov khoom nto yog smoother.

Disadvantages: siab pwm nqi, kuj ntev txoj kev loj hlob voj voog, thiab siab yuav tsum tau rau lub tshuab xaiv thiab precision.

Kev kho deg ntawm cov khoom siv aluminium

1. Sandblasting (steev peening)

Cov txheej txheem ntawm kev ntxuav thiab roughening hlau qhov chaw siv cov kev cuam tshuam ntawm kev kub ceev xuab zeb ntws.

Kev kho saum npoo ntawm txhuas qhov chaw hauv txoj kev no tuaj yeem tau txais qee qhov kev huv huv thiab qhov sib txawv ntawm qhov sib txawv ntawm qhov chaw ua haujlwm, kom cov khoom siv kho tshuab ntawm qhov chaw ua haujlwm tau zoo dua, yog li txhim kho qhov qaug zog ntawm lub workpiece thiab nce. qhov sib txawv ntawm nws thiab txheej.Lub adhesion ntawm lub txheej prolongs lub durability ntawm txheej zaj duab xis, thiab kuj yog conducive rau lub leveling thiab kho kom zoo nkauj ntawm txheej.Cov txheej txheem no peb feem ntau pom hauv ntau yam khoom ntawm Apple.

2. Polishing

Siv tshuab, tshuaj lom neeg lossis electrochemical ua kom txo tau qhov roughness ntawm lub workpiece kom tau txais txoj kev ci ntsa iab, tiaj tus.Cov txheej txheem polishing feem ntau muab faib ua: mechanical polishing, tshuaj polishing, electrolytic polishing.Tom qab txhua yam polishing + electrolytic polishing, aluminium qhov chaw tuaj yeem nyob ze rau daim iav nyhuv ntawm stainless hlau.Cov txheej txheem no ua rau tib neeg muaj kev nkag siab ntawm high-end simplicity thiab fashionable yav tom ntej.

3. Kev kos duab

Hlau hlau kos duab yog cov txheej txheem tsim khoom ntawm kev rov ua ib daim ntawv txhuas tawm ntawm cov kab nrog cov ntawv xuab zeb.Kev kos duab tuaj yeem muab faib ua kev kos duab ncaj, kos duab kos duab, kos duab kos duab, xov kos duab.Cov txheej txheem hlau hlau kos duab tuaj yeem ua kom pom tseeb txhua qhov cim lo lo ntxhuav zoo nkauj, kom cov plaub hau zoo nkauj zoo nkauj tshwm hauv cov hlau matte, thiab cov khoom muaj kev nkag siab ntawm kev zam thiab thev naus laus zis.

4. High gloss txiav

Siv lub tshuab engraving, lub pob zeb diamond riam yog ntxiv dag zog rau ntawm lub ntsiab ncej ntawm lub tshuab engraving rotating ntawm ib tug ceev ceev (feem ntau 20,000 rpm) txiav cov qhov chaw, thiab ib tug hauv zos highlight cheeb tsam yog generated nyob rau saum npoo ntawm cov khoom.Qhov ci ntsa iab ntawm cov ntsiab lus txiav yog cuam tshuam los ntawm qhov nrawm ntawm kev xyaum milling.Qhov kev xyaum nrawm nrawm dua, qhov ci ntsa iab ntawm kev txiav cov ntsiab lus, thiab rov ua dua, qhov tsaus dua thiab yooj yim dua los tsim cov kab txiav.High-gloss thiab high-gloss txiav yog tshwj xeeb tshaj yog siv nyob rau hauv lub xov tooj ntawm tes, xws li iphone5.Nyob rau hauv xyoo tas los no, qee qhov high-end TV hlau thav duab tau txais cov txheej txheem milling high-gloss.Tsis tas li ntawd, anodizing thiab hlau kos cov txheej txheem ua rau TV teeb tag nrho ntawm kev zam thiab thev naus laus zis.

5. Anodizing

Anodic oxidation yog hais txog electrochemical oxidation ntawm hlau los yog alloys.Raws li cov khoom siv electrolyte thiab cov txheej txheem tshwj xeeb, txhuas thiab nws cov alloys tsim cov yeeb yaj kiab oxide ntawm cov khoom siv txhuas (anode) vim qhov kev txiav txim ntawm kev siv tam sim no.Anodizing tuaj yeem tsis tsuas yog daws qhov tsis xws ntawm aluminium hardness thiab hnav tsis kam, tab sis kuj ua rau lub neej kev pab cuam ntawm txhuas thiab txhim khu kev zoo nkauj.Nws tau dhau los ua ib feem tseem ceeb ntawm kev kho aluminium nto thiab yog tam sim no siv ntau tshaj plaws thiab ua tau zoo heev.khoom siv tes ua.

6. Ob-xim anode

Ob-xim anodizing hais txog anodizing ntawm ib yam khoom thiab muab cov xim sib txawv rau cov chaw tshwj xeeb.Cov txheej txheem ob-xim anodizing tsis tshua muaj siv hauv TV kev lag luam, vim tias cov txheej txheem nyuaj thiab tus nqi siab;tab sis qhov sib piv ntawm ob xim tuaj yeem ua tau zoo dua qhov zoo ntawm high-end thiab cim tsos ntawm cov khoom.

Cov txheej txheem ntsuas thiab kev txawj ua haujlwm kom txo qis deformation ntawm aluminium ua

Muaj ntau qhov laj thawj rau qhov deformation ntawm aluminium qhov chaw, uas muaj feem xyuam rau cov khoom, cov duab ntawm ib feem, thiab cov xwm txheej ntau lawm.Feem ntau muaj cov hauv qab no: deformation los ntawm kev ntxhov siab sab hauv ntawm qhov khoob, deformation los ntawm kev txiav quab yuam thiab txiav kub, thiab deformation los ntawm clamping quab yuam.

Cov txheej txheem ntsuas los txo cov txheej txheem deformation

1. Txo cov kev ntxhov siab sab hauv ntawm cov plaub hau kab lis kev cai

Ntuj los yog dag dag thiab kev co kev kho mob tuaj yeem tshem tawm cov kev ntxhov siab sab hauv ntawm qhov khoob.Pre-processing kuj yog ib txoj hauv kev zoo.Rau qhov khoob nrog lub taub hau roj thiab pob ntseg loj, vim qhov nyiaj pub dawb loj, qhov deformation tom qab ua tiav kuj tseem loj.Yog tias qhov seem ntawm qhov khoob yog ua ntej ua ntej thiab qhov nyiaj pub dawb ntawm txhua qhov raug txo, nws tuaj yeem tsis tsuas yog txo cov txheej txheem deformation ntawm cov txheej txheem tom ntej, tab sis kuj tso tawm ib feem ntawm cov kev ntxhov siab sab hauv tom qab ua ua ntej rau lub sijhawm. sij hawm.

2. Txhim kho lub peev xwm txiav ntawm lub cuab yeej

Cov khoom siv thiab cov ntsuas geometric ntawm cov cuab yeej muaj qhov cuam tshuam tseem ceeb ntawm kev txiav quab yuam thiab txiav cov cua sov.Kev xaiv kom raug ntawm lub cuab yeej yog qhov tseem ceeb heev los txo cov machining deformation ntawm ib feem.

1) Tsim nyog xaiv cov cuab yeej geometric tsis.

①Rake lub kaum sab xis: Nyob rau hauv cov xwm txheej ntawm kev tuav lub zog ntawm cov hniav, lub rake lub kaum sab xis yog tsim nyog xaiv kom loj dua, ntawm ib sab, nws tuaj yeem zom cov ntug ntse, thiab ntawm qhov tod tes, nws tuaj yeem txo qhov kev txiav deformation, ua cov nti tshem tawm du, thiab tom qab ntawd txo qhov txiav quab yuam thiab txiav kub.Tsis txhob siv cov cuab yeej nrog lub kaum sab xis tsis zoo.

②Relief lub kaum sab xis: Qhov loj ntawm lub kaum sab xis muaj qhov cuam tshuam ncaj qha rau kev hnav ntawm lub ntsej muag thiab qhov zoo ntawm lub tshuab ua haujlwm.Lub thickness txiav yog ib qho tseem ceeb rau kev xaiv lub kaum sab xis clearance.Thaum lub sij hawm milling ntxhib, vim qhov loj pub tus nqi, hnyav txiav load, thiab loj thaum tshav kub kub tsim, lub cuab tam yuav tsum tau zoo tshav kub dissipation tej yam kev mob.Yog li ntawd, lub kaum sab xis clearance yuav tsum tau xaiv kom me me.Thaum zoo milling, txiav ntug yuav tsum tau ntse, kev sib txhuam ntawm lub ntsej muag flank thiab machined nto yog txo, thiab elastic deformation yog txo.Yog li ntawd, lub kaum sab xis clearance yuav tsum loj dua.

③ Helix lub kaum sab xis: txhawm rau ua kom lub milling du thiab txo lub zog milling, lub kaum sab xis ntawm lub helix yuav tsum loj npaum li qhov ua tau.

④Main declination angle: Ua kom txo tau lub ntsiab delination lub kaum sab xis tuaj yeem txhim kho cov cua sov dissipation thiab txo qhov nruab nrab kub ntawm qhov chaw ua haujlwm.

2) Txhim kho cov cuab yeej siv.

① Txo tus naj npawb ntawm cov hniav ntawm cov milling cutter thiab nce qhov chaw nti.Vim yog cov yas loj ntawm cov khoom siv txhuas thiab qhov loj txiav deformation thaum ua, yuav tsum muaj qhov chaw loj nti, yog li lub vojvoog hauv qab ntawm cov nti zawj yuav tsum loj thiab tus lej ntawm cov hniav txiav cov hniav yuav tsum me me.

② Finely zom cov hniav.Tus nqi roughness ntawm qhov txiav ntawm cov hniav cutter yuav tsum tsawg dua Ra = 0.4um.Ua ntej siv rab riam tshiab, koj yuav tsum siv lub pob zeb zoo roj los ua kom lub ntsej muag thiab sab nraub qaum ntawm cov hniav riam ob peb zaug kom tshem tawm cov burrs thiab me ntsis serrations sab laug thaum sharpening cov hniav.Nyob rau hauv txoj kev no, tsis tsuas yog txiav cov cua sov yuav txo tau, tab sis kuj txiav deformation kuj me me.

③ nruj me ntsis tswj tus qauv hnav ntawm lub cuab yeej.Tom qab lub cuab yeej hnav, qhov roughness tus nqi ntawm lub workpiece nce, txiav kub nce, thiab lub workpiece deformation nce.Yog li ntawd, ntxiv rau kev xaiv cov khoom siv nrog kev hnav zoo, cov cuab yeej hnav tus qauv yuav tsum tsis txhob siab dua 0.2mm, txwv tsis pub nws yooj yim los tsim cov ntug.Thaum txiav, qhov kub ntawm lub workpiece feem ntau yuav tsum tsis txhob ntau tshaj 100 ℃ los tiv thaiv deformation.

3. Txhim kho txoj kev clamping ntawm lub workpiece

Rau nyias-walled aluminium workpieces nrog tsis zoo rigidity, cov nram qab no clamping txoj kev yuav siv tau los txo deformation:

①Rau nyias-walled bushing qhov chaw, yog hais tias peb lub puab tsaig lub puab tsaig chuck los yog lub caij nplooj ntoos hlav chuck yog siv rau radial clamping, thaum nws tawm tom qab ua tiav, lub workpiece yuav inevitably deform.Nyob rau lub sijhawm no, txoj kev nias lub ntsej muag axial kawg nrog rigidity zoo dua yuav tsum tau siv.Muab lub puab qhov ntawm ib feem, ua ib tug threaded mandrel, ntxig rau hauv lub puab lub qhov ntawm ib feem, nias lub ntsej muag kawg nrog ib tug cover phaj rau nws, thiab ces zawm nws nrog ib tug txiv ntseej.Thaum machining lub voj voog sab nrauv, clamping deformation tuaj yeem zam tau, kom tau txais kev txaus siab machining raug.

② Thaum ua cov txheej txheem nyias-walled thiab nyias-phaj workpieces, nws yog qhov zoo tshaj plaws los siv lub tshuab nqus tsev nqus kom tau txais kev sib faib sib npaug ntawm lub zog clamping, thiab tom qab ntawd txheej txheem nrog me me ntawm kev txiav, uas tuaj yeem tiv thaiv workpiece deformation.

Tsis tas li ntawd, txoj kev ntim khoom kuj tseem siv tau.Txhawm rau kom cov txheej txheem rigidity ntawm nyias-walled workpieces, ib qho nruab nrab tuaj yeem sau rau hauv lub workpiece kom txo cov deformation ntawm lub workpiece thaum clamping thiab txiav.Piv txwv li, urea yaj uas muaj 3% mus rau 6% poov tshuaj nitrate yog poured rau hauv lub workpiece.Tom qab ua tiav, lub workpiece tuaj yeem muab tso rau hauv dej lossis dej cawv, thiab muab tub lim tuaj yeem yaj thiab nchuav tawm.

4. Kev npaj tsim nyog ntawm cov txheej txheem

Thaum lub sij hawm high-ceev txiav, vim qhov loj machining pub thiab cuam tshuam kev txiav, cov txheej txheem milling feem ntau tsim kev co, uas cuam tshuam rau qhov tseeb machining thiab nto roughness.Yog li ntawd, CNC high-speed txiav txheej txheem feem ntau tau muab faib ua: roughing-semi-finishing-pob tshab-clearing-tiav thiab lwm yam txheej txheem.Rau qhov chaw uas yuav tsum tau muaj siab precision, qee zaum nws yog ib qho tsim nyog los ua cov txheej txheem semi-tiav thiab tom qab ntawd ua tiav.Tom qab kev ua haujlwm ntxhib, cov khoom tuaj yeem ua kom txias, tshem tawm cov kev ntxhov siab sab hauv los ntawm kev ua haujlwm ntxhib thiab txo qhov deformation.Qhov nyiaj tshuav tom qab kev ua haujlwm ntxhib yuav tsum ntau dua qhov deformation, feem ntau 1 txog 2 hli.Thaum lub sij hawm ua tiav, qhov kawg ntawm cov khoom yuav tsum tswj hwm qhov kev ua haujlwm zoo ib yam, feem ntau 0.2 ~ 0.5mm, kom lub cuab yeej nyob rau hauv lub xeev ruaj khov thaum lub sij hawm machining txheej txheem, uas tuaj yeem txo qhov kev txiav deformation zoo, tau txais qhov zoo ntawm qhov chaw machining, thiab xyuas kom cov khoom raug.

Kev txawj ua hauj lwm los txo cov machining distortion

Ntxiv nrog rau cov laj thawj saum toj no, cov khoom ntawm aluminium qhov chaw yog deformed thaum ua.Hauv kev ua haujlwm tiag tiag, txoj haujlwm ua haujlwm kuj tseem ceeb heev.

1. Rau qhov chaw uas muaj nyiaj loj machining, thiaj li yuav ua rau lawv muaj cua sov dissipation zoo dua thaum lub sij hawm machining txheej txheem thiab tsis txhob tshav kub concentration, symmetrical machining yuav tsum tau saws thaum lub sij hawm machining.Yog tias daim ntawv tuab 90 hli yuav tsum tau ua tiav rau 60 hli, yog tias ib sab yog milled thiab lwm sab yog milled tam sim ntawd, thiab qhov kawg loj yog ua tiav ib zaug, qhov flatness yuav ncav cuag 5 hli;Yog tias nws tau ua tiav symmetrically nrog rov noj, txhua sab yog ua tiav ob zaug rau Qhov kawg dimension tuaj yeem lav qhov flatness ntawm 0.3mm.stamping qhov

2. Yog tias muaj ntau cov kab noj hniav ntawm cov phaj phaj, nws tsis tsim nyog siv cov txheej txheem ua ntu zus ntawm ib kab noj hniav thiab ib kab noj hniav thaum lub sij hawm ua, uas yuav yooj yim ua rau cov khoom deformed vim tsis muaj kev ntxhov siab.Multi-txheej txheej txheem yog saws, thiab txhua txheej yog ua tiav rau tag nrho cov kab noj hniav nyob rau tib lub sij hawm, thiab tom qab ntawd txheej tom ntej no yog ua tiav kom cov khoom sib npaug sib npaug thiab txo deformation.

3. Txo qhov txiav quab yuam thiab txiav cov cua sov los ntawm kev hloov cov nyiaj txiav.Ntawm peb lub ntsiab lus ntawm kev txiav nyiaj, qhov nyiaj rov qab-kev koom tes muaj kev cuam tshuam zoo rau kev txiav quab yuam.Yog tias qhov nyiaj pub dawb machining loj dhau lawm, qhov txiav quab yuam ntawm ib qho dhau los loj heev, uas yuav tsis tsuas yog deform cov khoom, tab sis kuj cuam tshuam rau lub rigidity ntawm lub tshuab cuab tam spindle thiab txo cov durability ntawm lub cuab yeej.Yog hais tias tus nqi ntawm cov riam yuav tsum tau noj los ntawm lub nraub qaum yog txo, qhov kev tsim khoom yuav raug txo kom tsawg.Txawm li cas los xij, kev kub ceev milling yog siv hauv CNC machining, uas tuaj yeem kov yeej qhov teeb meem no.Thaum txo qhov kev txiav rov qab, tsuav yog tias cov khoom noj tau nce ntxiv raws li qhov nrawm ntawm cov cuab yeej siv lub tshuab yog nce, qhov txiav quab yuam tuaj yeem txo qis thiab kev ua haujlwm tau zoo tuaj yeem ua rau tib lub sijhawm.

4. Qhov kev txiav txim ntawm riam txav yuav tsum tau them sai sai rau.Rough machining qhia txog kev txhim kho machining efficiency thiab caum tus nqi tshem tawm ib lub sijhawm.Feem ntau, kev txiav milling tuaj yeem siv tau.Ntawd yog, cov khoom siv ntau dhau ntawm qhov seem ntawm qhov khoob raug tshem tawm ntawm qhov ceev tshaj plaws thiab lub sijhawm luv tshaj plaws, thiab cov duab geometric contour yuav tsum tau ua kom tiav yog tsim.Thaum ua tiav hais txog kev ua haujlwm siab thiab ua haujlwm siab, nws raug nquahu kom siv down milling.Vim hais tias lub thickness ntawm cutter hniav maj mam txo los ntawm qhov siab tshaj plaws mus rau xoom thaum lub sij hawm down milling, lub degree ntawm kev ua hauj lwm hardening yog heev txo, thiab cov degree ntawm deformation ntawm ib feem kuj txo.

5. Thin-walled workpieces yog deformed vim clamping thaum lub sij hawm ua, thiab txawm tiav yog unavoidable.Txhawm rau txo qhov deformation ntawm lub workpiece mus rau qhov tsawg kawg nkaus, koj tuaj yeem loosen lub xovxwm ua ntej ua tiav qhov loj kawg, kom lub workpiece tuaj yeem rov qab mus rau nws qhov qub qub, thiab tom qab ntawd nias nws me ntsis, tsuav yog lub workpiece tuaj yeem ua tau. clamped (tag nrho).Raws li kev xav ntawm tes), cov txiaj ntsig zoo tshaj plaws tuaj yeem tau txais los ntawm txoj kev no.Nyob rau hauv ib lo lus, qhov kev txiav txim ntawm lub clamping quab yuam yog qhov zoo dua rau ntawm qhov chaw txhawb nqa, thiab lub clamping quab yuam yuav tsum tau siv nyob rau hauv cov kev taw qhia ntawm zoo rigidity ntawm lub workpiece.Ntawm qhov chaw ntawm kev ua kom ntseeg tau tias lub workpiece tsis xoob, qhov me me ntawm lub zog clamping, qhov zoo dua.

6. Thaum machining qhov chaw nrog cov kab noj hniav, sim tsis txhob cia lub milling cutter plunge ncaj qha mus rau hauv ib feem zoo li lub laum thaum machining cov kab noj hniav, ua rau qhov chaw tsis txaus rau lub milling cutter kom haum raws li cov chips thiab tsis zoo nti tshem tawm, ua rau overheating, expansion. thiab tawg ntawm qhov chaw.Riam, riam tawg thiab lwm yam tshwm sim tsis zoo.Ua ntej laum lub qhov nrog lub laum ntawm tib qhov loj li lub milling cutter los yog ib qho loj dua, thiab tom qab ntawd milling nrog lub milling cutter.Xwb, CAM software tuaj yeem siv los tsim cov kev pabcuam helical rundown.

Anebon Hlau Khoom Limited tuaj yeem muab CNC Machining, Tuag Casting, Sheet Hlau Fabrication kev pabcuam, thov koj xav tiv tauj peb.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Post lub sij hawm: Jun-16-2022