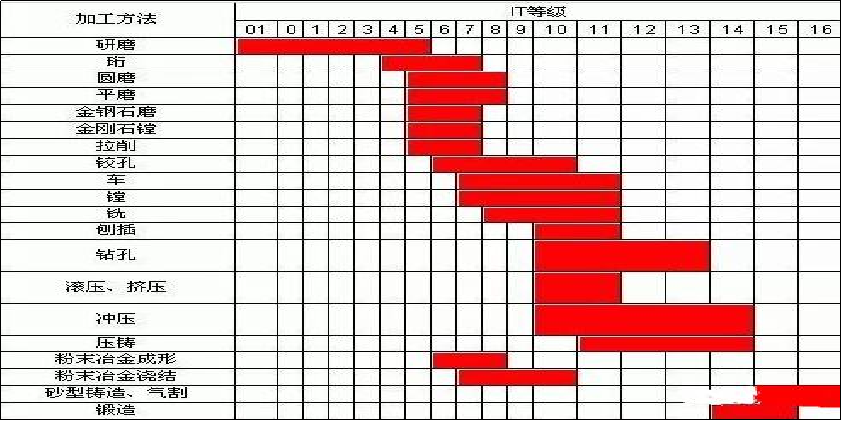

A na-ejikarị nhazi nke ọma eme ihe iji mara ịdị mma nke ngwaahịa, dị kacnc ntụgharị akụkụnacnc egwe ọka akụkụ, na ọ bụ okwu eji enyocha akụkụ geometric nke elu igwe arụnyere. A na-atụle izi ezi nke ịrụ ọrụ site na ọkwa ndidi. Nka ọkwa ọkwa dị ntakịrị, ka izi ezi dị elu.

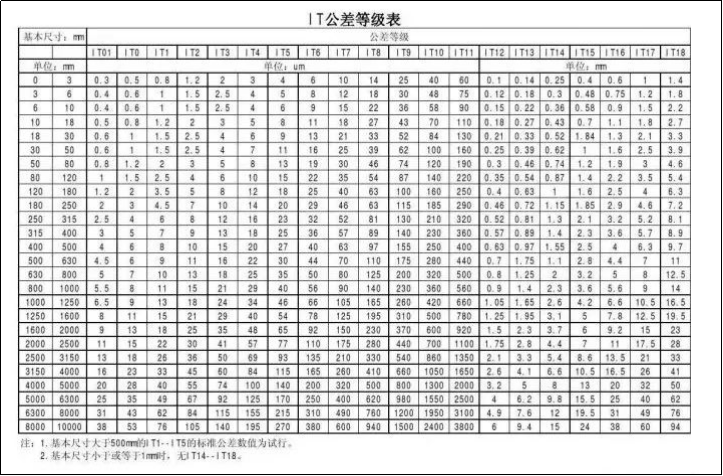

Enwere klaasị nnabata 20 sitere na IT01, IT0, IT1, IT2, IT3 ruo IT18, nke IT01 na-anọchite anya nhazi nhazi kachasị elu nke akụkụ ahụ, IT18 na-anọchite anya nhazi nhazi kachasị ala nke akụkụ ahụ, igwe Ngwuputa n'ozuzu bụ nke IT7, yana ọrụ ugbo n'ozuzu. igwe bụ nke IT8. Dị ka ọrụ dị iche iche nke akụkụ ngwaahịa si dị, nhazi nhazi nke a chọrọ iji nweta dị iche, na ụdị nhazi na usoro ahọpụtara dịkwa iche. Akwụkwọ a na-ewebata izi ezi nke nchigharị nke ntụgharị, igwe igwe, nhazi ihe, ịhịa aka n'ahụ, igwu mmiri, na-agwụ ike na ụdị igwe ndị ọzọ a na-ahụkarị.

CNC na-atụgharị

Usoro ịkpụ nke workpiece na-atụgharị na ngwá ọrụ na-atụgharị na-agagharị n'ahịrị kwụ ọtọ ma ọ bụ akụkụ na ụgbọ elu. A na-eme ntụgharị n'ozuzu na lathe, nke a na-eji mee ihe n'ime ime na mpụga cylindrical, njedebe ihu, conical na-ebupụta, na-akpụ elu na eri nke workpieces.

Ntughari izizi bụkarị IT8-IT7, na ịdị nro dị elu bụ 1.6-0.8 μm.

1) Ntugharị siri ike ga-anakwere nnukwu ihe omimi na nnukwu nri nri iji melite arụmọrụ ntụgharị na-enweghị ibelata ọsọ nke ịkpụ, mana nhazi nhazi nwere ike iru IT11 naanị na ihu igwe dị elu bụ R α 20-10 μ m.

2) A ga-anakwere ọsọ ọsọ dị elu na obere nri nri na mbelata omimi dị ka o kwere mee maka ntụgharị ọkara na-atụgharị ma na-atụgharị. Izi ezi nke igwe nwere ike iru IT10-IT7, na ịdị nro dị elu bụ R 10-0.16 μm.

3) Mgbanwe nkenke dị elu nke akụkụ igwe anaghị agba nchara na ngwaọrụ ntụgharị diamond na-egbu maramara nke ọma na lathe dị elu nwere ike ime ka igwe nrụpụta rute IT7-IT5, na ịdị nro dị elu bụ R α 0.04-0.01 μ m. A na-akpọ ụdị ntụgharị a "ntụgharị enyo".

CNC-egwe ọka

Milling na-ezo aka n'iji ngwá ọrụ dị iche iche na-agbagharị agbagharị iji belata workpieces, nke bụ usoro nhazi nke ọma. Ọ dabara maka machining ụgbọ elu, uzo, dị iche iche na-akpụ na-ebupụta (dị ka spline, gia na eri) na pụrụ iche elu nke anwụ. Dị ka otu ma ọ bụ na-abụghị direction nke isi ije ọsọ na workpiece ndepụta ntụziaka n'oge egwe ọka, ọ nwere ike kewara n'ihu-egwe ọka na agbara-egwe ọka.

The machining izi ezi nke egwe ọka nwere ike n'ozuzu iru IT8 ~ IT7, na elu roughness bụ 6.3 ~ 1.6 μm.

1) The machining ziri ezi n'oge siri ike egwe ọka bụ IT11 ~ IT13, na elu roughness bụ 5 ~ 20 μ m.

2) Machining ziri ezi IT8 ~ IT11 na elu roughness 2.5 ~ 10 na ọkara nkenke-egwe ọka μ m.

3) The machining izi ezi n'oge nkenke-egwe ọka bụ IT16 ~ IT8, na elu roughness bụ 0.63 ~ 5 μ m.

Atụmatụ

Planing bụ a ọnwụ usoro na-eji a planer ka kehoraizin ikwu linear reciprocating ngagharị na workpiece, nke a na-bụ-eji maka contour nhazi nke akụkụ.

The machining izi ezi nke planing nwere ike n'ozuzu iru IT9 ~ IT7, na elu roughness bụ Ra6.3 ~ 1.6 μ m.

1) Roughing machining ziri ezi nwere ike iru IT12 ~ IT11, na elu roughness bụ 25 ~ 12.5 μ m.

2) The ọkara finishing machining ziri ezi nwere ike iru IT10 ~ IT9, na elu roughness bụ 6.2 ~ 3.2 μ m.

3) The nkenke nke imecha planing nwere ike iru IT8 ~ IT7, na elu roughness bụ 3.2 ~ 1.6 μ m.

egweri

Egweri na-ezo aka na usoro nhazi nke iji abrasive na abrasive ngwá ọrụ na-ebipụ ngafe ihe na workpiece, nke bụ nke agwụcha na ọtụtụ-eji na igwe na-emepụta ụlọ ọrụ.

A na-ejikarị egweri eme ihe maka ọkara imecha na imecha, na izi ezi nke IT8 ~ IT5 ma ọ bụ ọbụna karịa, na elu roughness bụ n'ozuzu 1.25 ~ 0.16 μ m.

1) The elu roughness nke nkenke egweri bụ 0.16 ~ 0.04 μ m.

2) Ultra ziri ezi egweri elu roughness bụ 0.04-0.01 μ m.

3) Ọdịdị elu nke igwe enyo nwere ike iru 0.01 μ M n'okpuru.

Ịkụ ala

Ịkụ ala bụ ụzọ bụ isi nke nhazi oghere. A na-ejikarị igwe na-egwupụta ihe na igwe lathes, ma ọ bụ n'igwe na-agwụ ike ma ọ bụ igwe-egwe ọka.

The machining izi ezi nke mkpọpu ala dịtụ ala, na-erukarị IT10, na elu roughness bụ n'ozuzu 12.5 ~ 6.3 μm. Mgbe mkpọpuchara, a na-ejikarị reaming na reaming emecha ọkara na imecha.

Na-agwụ ike

Na-agwụ ike bụ ụdị usoro igbutu dayameta dị n'ime nke na-eji ngwá ọrụ gbasaa oghere ma ọ bụ akụkụ okirikiri ndị ọzọ. Ngwa ya na-abụkarị site na igwe siri ike ruo n'imecha. Ngwá ọrụ a na-ejikarị na-abụkarị otu akụkụ na-agwụ ike (a na-akpọ mmanya na-agwụ ike).

1) The na-agwụ ike izi ezi nke ígwè ihe nwere ike n'ozuzu iru IT9 ~ IT7, na elu roughness bụ 2.5 ~ 0.16 μ m.

2) The machining izi ezi nke nkenke na-agwụ ike nwere ike iru IT7 ~ IT6, na elu roughness bụ 0.63 ~ 0.08 μ m.

Oge nzipu: Nov-22-2022