Ukuchaneka komatshini kusetyenziswa ikakhulu ukubonisa ukucoleka kweemveliso, ezinjecnc ukuguqula iindawokwayeiindawo zokugaya ze-cnc, kwaye ligama elisetyenziselwa ukuvavanya iiparameters zejometri zeendawo ezinomatshini.Ukuchaneka koMatshini kulinganiswa ngebakala lokunyamezelana.Okukhona lincinci ixabiso lebakala, kokukhona liphezulu ukuchaneka.

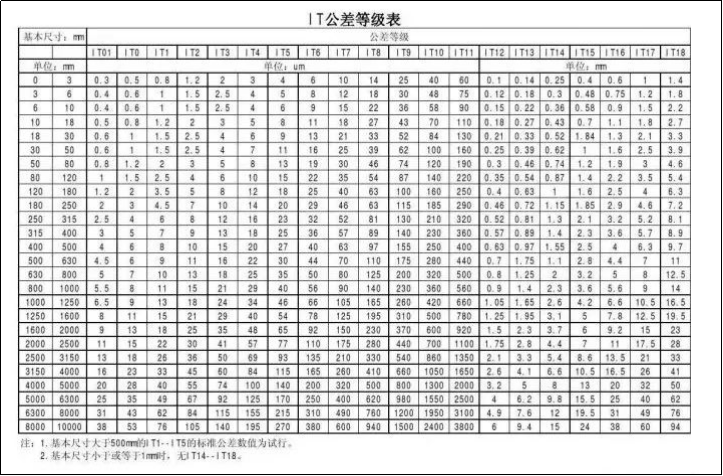

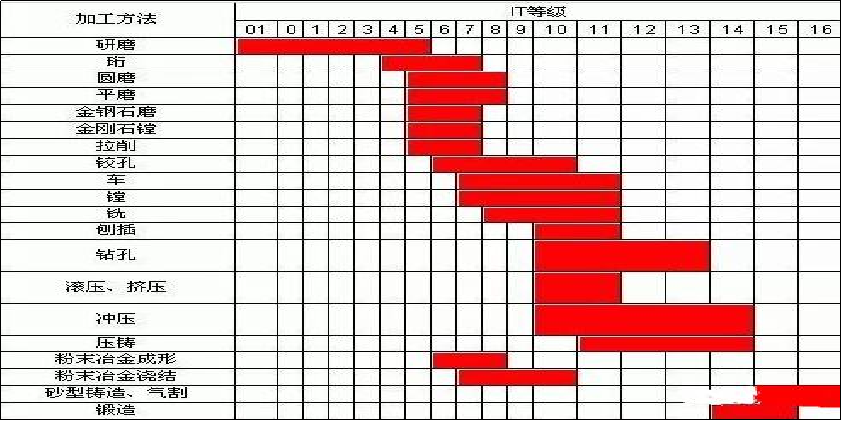

Kukho iiklasi ze-20 zokunyamezelana ukusuka kwi-IT01, i-IT0, i-IT1, i-IT2, i-IT3 ukuya kwi-IT18, apho i-IT01 imele ukuchaneka okuphezulu kwecandelo, i-IT18 imele ukuchaneka kokucubungula okuphantsi kwecandelo, oomatshini bokumbiwa ngokubanzi bobu-IT7, kunye nezolimo jikelele. oomatshini bobakwa-IT8.Ngokwemisebenzi eyahlukeneyo yamacandelo emveliso, ukuchaneka komatshini okufunekayo ukuba kuphunyezwe kuyahluka, kwaye ifom yokucubungula kunye nenkqubo ekhethiweyo nayo yahlukile.Eli phepha lazisa ukuchaneka komatshini wokujika, ukugaya, ukucwangcisa, ukugaya, ukubhobhoza, ukudika kunye nezinye iifom eziqhelekileyo zomatshini.

Ukujika kwe-CNC

Inkqubo yokusika apho i-workpiece ijikeleza kwaye isixhobo sokuguqula sihamba ngendlela echanekileyo okanye i-curve kwindiza.Ukujika ngokuqhelekileyo kuqhutyelwa kwi-lathe, esetyenziselwa ukucubungula iindawo zangaphakathi kunye nezangaphandle ze-cylindrical, ubuso bokugqibela, i-conical surfaces, ukwenza iindawo kunye nemicu yezinto zokusebenza.

Ukuchaneka kokujika ngokuqhelekileyo yi-IT8-IT7, kunye nobunzima bomhlaba ngu-1.6-0.8 μ m.

I-1) Ukuguqulwa okukrakra kuya kwamkela ubunzulu obukhulu bokusika kunye nesantya esikhulu sokutya ukuze kuphuculwe ukusebenza kakuhle ngaphandle kokunciphisa isantya sokusika, kodwa ukuchaneka kwe-machining kunokufikelela kuphela kwi-IT11 kunye nobukhulu bomhlaba ngu-R α 20-10 μ m.

2) Isantya esiphezulu kunye nesantya somxhesho omncinci kunye nobunzulu bokusika kuya kwamkelwa kangangoko kunokwenzeka ukugqiba ukujika kunye nokugqiba ukujika.Ukuchaneka komatshini kunokufikelela kwi-IT10-IT7, kunye nobunzima bomhlaba ngu-R α 10-0.16 μ m.

3) Ukuguqulwa kwesantya esiphezulu sokuguqulwa kwamalungu ensimbi angenayo i-nonferrous enedayimane yokuguqula isixhobo esiphuculwe ngokucokisekileyo kwi-lathe ephezulu echanekileyo inokwenza ukuchaneka kwe-machining ukufikelela kwi-IT7-IT5, kunye noburhabaxa bomhlaba yi-R α 0.04-0.01 μ m.Olu hlobo lokujika lubizwa ngokuba “yimirror turning”.

CNC Milling

I-Milling ibhekisa kusetyenziso lwezixhobo ezijikelezayo zomphetho omninzi ukusika ii-workpieces, eyindlela esebenza kakhulu yokusebenza.Ifanelekile kwi-plane yomatshini, i-groove, iindawo ezahlukeneyo zokubumba (ezifana ne-spline, i-gear kunye nentambo) kunye nomgangatho okhethekileyo wokufa.Ngokwendlela enye okanye echaseneyo yesantya esiphambili sentshukumo kunye nesalathiso sokutya kwesixhobo sokusebenza ngexesha lokusila, inokwahlulwa ibe yi-milling eya phambili kunye ne-reverse milling.

Ukuchaneka komatshini wokugaya kunokufikelela ngokubanzi kwi-IT8~IT7, kwaye uburhabaxa bomphezulu yi-6.3 ~ 1.6 μ m.

1) Ukuchaneka kwe-machining ngexesha lokugaya i-IT11 ~ IT13, kunye nobunzima bomhlaba yi-5 ~ 20 μ m.

2) Ukuchaneka komatshini IT8 ~ IT11 kunye noburhabaxa bomphezulu 2.5 ~ 10 kwi-semi precision milling μ m.

3) Ukuchaneka kwe-machining ngexesha lokugaya ngokuchanekileyo yi-IT16 ~ IT8, kunye nobunzima bomhlaba ngu-0.63 ~ 5 μ m.

Ukucwangcisa

Ukucwangciswa yindlela yokusika esebenzisa isicwangcisi ukwenza intshukumo ethe tyaba yesalamane ehambelanayo kwisixhobo sokusebenza, esisetyenziswa kakhulu ekusetyenzweni kwecontour yamalungu.

Ukuchaneka komatshini wokucwangcisa ngokubanzi kunokufikelela kwi-IT9 ~ IT7, kwaye uburhabaxa bomphezulu yiRa6.3 ~ 1.6 μ m.

1) Ukuchaneka komatshini wokuchaneka kunokufikelela kwi-IT12 ~ IT11, kunye nobunzima bomhlaba yi-25 ~ 12.5 μ m.

2) Ukuchaneka kwe-semi final machining kunokufikelela kwi-IT10 ~ IT9, kunye nobunzima bomhlaba ngu-6.2 ~ 3.2 μ m.

3) Ukuchaneka kokugqiba ukucwangciswa kunokufikelela kwi-IT8 ~ IT7, kunye nobunzima bomhlaba ngu-3.2 ~ 1.6 μ m.

ukusila

Ukugaya kubhekiselele kwindlela yokucubungula yokusebenzisa izixhobo ezinqabileyo kunye nezixhobo zokuqhawula ukusika izinto ezingaphezulu kwi-workpiece, eyeyokugqiba kwaye isetyenziswa ngokubanzi kumashishini okuvelisa oomatshini.

Ukusila ngokuqhelekileyo kusetyenziselwa ukugqiba i-semi kunye nokugqiba, ngokuchaneka kwe-IT8 ~ IT5 okanye nangaphezulu, kwaye uburhabaxa bomhlaba ngokuqhelekileyo bu-1.25 ~ 0.16 μ m.

1) Uburhabaxa bomphezulu bokusila ngokuchanekileyo ngu-0.16 ~ 0.04 μ m.

2) Uburhabaxa bendawo yokusila obucokisekileyo ngu-0.04-0.01 μ m.

3) Uburhabaxa bomphezulu bokugaya isibuko bunokufikelela kwi-0.01 μ M ngaphantsi.

Ukugrumba

Ukugrumba yindlela esisiseko yokucutshungulwa komngxuma.Ukugrumba kuhlala kuqhutywa koomatshini bokomba kunye neentambo, okanye koomatshini abadikayo okanye oomatshini bokusila.

Ukuchaneka komatshini wokugaya kuphantsi, ngokuqhelekileyo kufikelela kwi-IT10, kwaye uburhabaxa bomphezulu ngokuqhelekileyo yi-12.5 ~ 6.3 μ m.Emva kokugrumba, ukubuyisela kwakhona kunye nokuphinda kusetyenziswe rhoqo ukugqiba isiqingatha kunye nokugqiba.

Kuyadika

Ukudika luhlobo lwenkqubo yokusika i-diameter yangaphakathi esebenzisa isixhobo sokwandisa umngxuma okanye enye i-contour ejikelezayo.Uluhlu lwesicelo ngokuqhelekileyo lusuka kwi-semi rough machining ukuya ekugqibeleni.Isixhobo esisetyenziswayo siqhele ukuba sisixhobo esikruqulayo somphetho omnye (esibizwa ngokuba yibhar ekruqulayo).

I-1) Ukuchaneka kwe-boring yezinto zetsimbi kunokufikelela ngokubanzi kwi-IT9 ~ IT7, kunye nobunzima bomhlaba ngu-2.5 ~ 0.16 μ m.

2) Ukuchaneka komatshini wokuchaneka ngokuchanekileyo kunokufikelela kwi-IT7 ~ IT6, kunye nobunzima bomhlaba ngu-0.63 ~ 0.08 μ m.

Ixesha lokuposa: Nov-22-2022