Ukunemba komshini kusetshenziswa ikakhulukazi ukukhombisa ubuhle bemikhiqizo, njengeizingxenye eziphendukayo ze-cncfuthiizingxenye zokugaya ze-cnc, futhi yitemu elisetshenziselwa ukuhlola imingcele yejiyomethri yezindawo ezinomshini.Ukunemba komshini kukalwa ngebanga lokubekezelelana.Uma lincane inani lebanga, liphakama ukunemba.

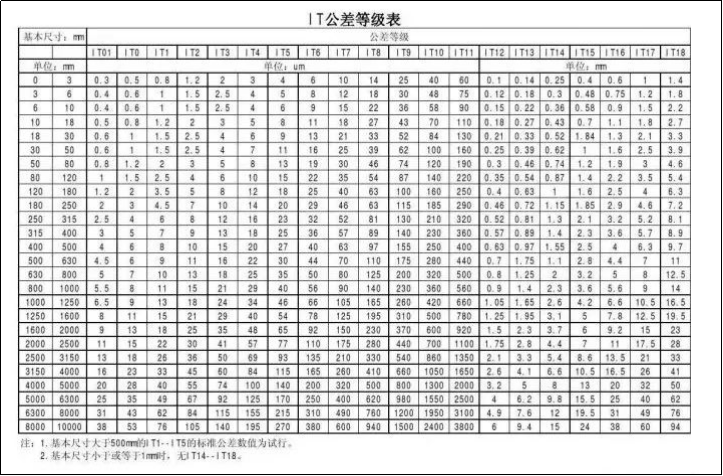

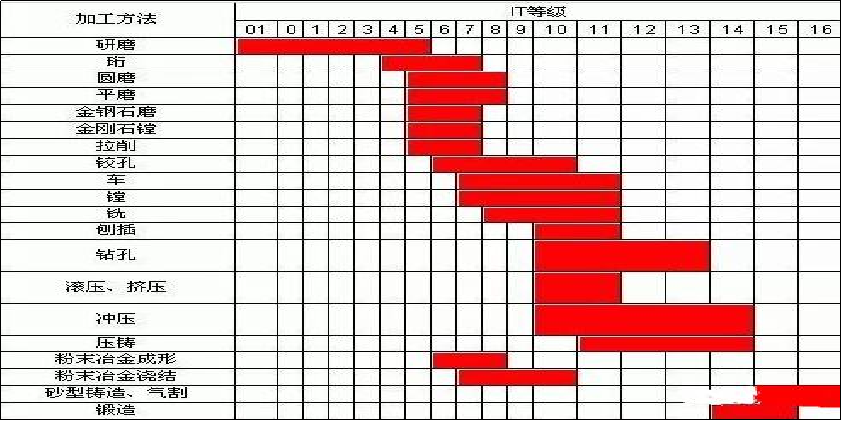

Kunamakilasi angama-20 okubekezelela asuka ku-IT01, IT0, IT1, IT2, IT3 kuya ku-IT18, lapho i-IT01 imele ukunemba okuphezulu kakhulu kokucubungula kwengxenye, i-IT18 imele ukunemba okuphansi kokucubungula kwengxenye, imishini yezimayini ejwayelekile ingeye-IT7, kanye nezolimo jikelele. imishini ingeye-IT8.Ngokwemisebenzi ehlukene yezingxenye zomkhiqizo, ukunemba komshini okudingekayo ukuze kufezwe kuhlukile, futhi ifomu lokucubungula nenqubo ekhethiwe nakho kuhlukile.Leli phepha lethula ukunemba kwemishini yokujika, ukugaya, ukuhlela, ukugaya, ukubhola, ukubhoreka kanye nezinye izinhlobo ezivamile zomshini.

Ukuphenduka kwe-CNC

Inqubo yokusika lapho i-workpiece ijikeleza futhi ithuluzi lokuguqula lihamba ngendlela eqondile noma ijika endizeni.Ukuphenduka kuvame ukwenziwa nge-lathe, esetshenziselwa ukucubungula indawo yangaphakathi nengaphandle yesilinda, ubuso bokuphela, ubuso obuyi-conical, ukwakheka kwezindawo kanye nemicu yezinto zokusebenza.

Ukunemba kokuphenduka ngokuvamile kuyi-IT8-IT7, futhi ubulukhuni bobuso bungu-1.6-0.8 μ m.

1) Ukuphenduka okungalungile kuzothatha ukujula okukhulu kokusika kanye nezinga lokuphakelayo elikhulu ukuze kuthuthukiswe ukusebenza kahle kokuphenduka ngaphandle kokunciphisa isivinini sokusika, kodwa ukunemba komshini kungafinyelela kuphela ku-IT11 futhi ukuhwaqeka kwendawo kungu-R α 20—10 μ m.

2) Isivinini esikhulu kanye nezinga lokudla okuncane kanye nokujula kokusika kuzokwamukelwa ngangokunokwenzeka ukuze kuphendulwe kancane futhi kuqedwe ukuphenduka.Ukunemba komshini kungafinyelela ku-IT10-IT7, futhi ubulukhuni bobuso bungu-R α 10—0.16 μ m.

3) Ukujika okunembayo okunesivinini esiphezulu kwezingxenye zensimbi ezingenayo insimbi enethuluzi lokujika ledayimane elipholishelwe kahle ku-lathe enembe kakhulu kungenza ukunemba komshini kufinyelele ku-IT7-IT5, futhi ubuhwaba obungaphezulu bungu-R α 0.04—0.01 μ m.Lolu hlobo lokuphenduka lubizwa ngokuthi “i-mirror turning”.

I-CNC Milling

Ukugaya kubhekisela ekusetshenzisweni kwamathuluzi azungezayo ama-multi edge ukusika izingcezu zokusebenza, okuyindlela yokucubungula esebenza kahle kakhulu.Ilungele indiza yomshini, i-groove, izindawo ezihlukahlukene zokwakha (njenge-spline, igiya kanye nentambo) kanye nendawo ekhethekile yokufa.Ngokuya ngendlela efanayo noma ephambene nesivinini sokunyakaza okuyinhloko kanye nesiqondiso sokuphakelayo kocezu lokusebenza ngesikhathi sokugaya, ingahlukaniswa ibe yi-milling eya phambili kanye ne-reverse milling.

Ukunemba komshini wokugaya ngokuvamile kungafinyelela ku-IT8~IT7, futhi ubulukhuni bangaphandle bungu-6.3~1.6 μ m.

1) Ukunemba komshini ngesikhathi sokugaya okumaholoholo yi-IT11~IT13, futhi ubulukhuni obungaphezulu bungu-5~20 μ m.

2) Ukunemba komshini IT8~IT11 kanye nobulukhuni bobuso obungu-2.5~10 ekugayweni okunembayo okuyingxenye μ m.

3) Ukunemba komshini ngesikhathi sokugaya okunembayo yi-IT16~IT8, futhi ubulukhuni obungaphezulu bungu-0.63~5 μ m.

Ukuhlela

Ukuhlela kuyindlela yokusika esebenzisa iplanethi ukwenza umnyakazo ovundlile ohambisanayo ohambisanayo endaweni yokusebenza, esetshenziselwa ikakhulukazi ukucubungula izingxenye zekhonta.

Ukunemba komshini wokuhlela ngokuvamile kungafinyelela ku-IT9~IT7, futhi ubulukhuni bendawo bungu-Ra6.3~1.6 μ m.

I-1) Ukunemba komshini oshubile kungafinyelela ku-IT12~IT11, futhi ubulukhuni bangaphezulu bungu-25~12.5 μ m.

2) Ukunemba kwemishini yokuqeda i-semi finishing kungafinyelela ku-IT10~IT9, futhi ubulukhuni obungaphezulu bungu-6.2~3.2 μ m.

3) Ukunemba kokuhlela kokuqeda kungafinyelela ku-IT8~IT7, futhi ubulukhuni obungaphezulu bungu-3.2~1.6 μ m.

ukugaya

Ukugaya kubhekisela endleleni yokucubungula yokusebenzisa amathuluzi abrasive kanye ne-abrasive ukusika izinto ezingaphezu kwengxenye yomsebenzi, okungeyokuqedela futhi esetshenziswa kakhulu embonini yokukhiqiza imishini.

Ukugaya kuvame ukusetshenziselwa ukuqeda kancane nokuqeda, ngokunemba kwe-IT8~IT5 noma ngaphezulu, futhi ubulukhuni obungaphezulu buvamise ukuba ngu-1.25~0.16 μ m.

1) Ubulukhuni obungaphezulu bokugaya ngokunemba ngu-0.16~0.04 μ m.

2) Ubulukhuni bomhlaba bokugaya obunembe kakhulu bungu-0.04-0.01 μ m.

3) Ubulukhuni obungaphezulu kwesibuko sokugaya bungafinyelela ku-0.01 μ M ngezansi.

Ukubhoboza

Ukubhoboza kuyindlela eyisisekelo yokucubungula imbobo.Ukubhoboza kuvame ukwenziwa emishinini yokubhoboza namalatha, noma emishinini eyisicefe noma emishinini yokugaya.

Ukunemba komshini wokumba kuphansi uma kuqhathaniswa, ngokuvamile kufinyelela ku-IT10, futhi ubulukhuni bangaphandle ngokuvamile bungu-12.5~6.3 μ m.Ngemuva kokubhoboza, ukubuyisela kabusha nokuphinda kusetshenziswe kabusha kuvame ukusetshenziselwa ukuqeda kanye nokuqeda.

Okuyisicefe

I-Boring iwuhlobo lwenqubo yokusika i-diameter yangaphakathi esebenzisa ithuluzi lokukhulisa imbobo noma enye i-contour eyindilinga.Ibanga lesicelo salo ngokuvamile lisuka kumshini ongemuhle kuya ekuqedeni.Ithuluzi elisetshenziswayo livamise ukuba yithuluzi elilodwa eliyisicefe (elibizwa ngebha eyisicefe).

I-1) Ukunemba okuyisicefe kwezinto zensimbi ngokuvamile kungafinyelela ku-IT9~IT7, futhi ubulukhuni obungaphezulu bungu-2.5 ~ 0.16 μ m.

2) Ukunemba komshini wokunemba okuyisicefe kungafinyelela ku-IT7~IT6, futhi ubulukhuni obungaphezulu bungu-0.63~0.08 μ m.

Isikhathi sokuthumela: Nov-22-2022