Kodi mumadziwa bwanji za kapangidwe ka makina?

Mechanical Design ndi nthambi yaumisiri yomwe imagwiritsa ntchito mfundo ndi njira zosiyanasiyana popanga, kusanthula ndi kukhathamiritsa makina ndi zida.Kupanga kwamakina kumaphatikizapo kumvetsetsa cholinga cha gawo kapena dongosolo, kusankha zida zoyenera, poganizira zinthu zosiyanasiyana, monga kupsinjika ndi kupsinjika ndi mphamvu, ndikuwonetsetsa kuti ntchito yodalirika komanso yothandiza.

Kupanga kwamakina kumaphatikizapo kapangidwe ka makina, kapangidwe kake, kapangidwe ka makina ndi kapangidwe kazinthu.Kapangidwe kazinthu kakukhudzana ndi kapangidwe kazinthu zakuthupi monga zinthu zogula, zida zamafakitale ndi zina zogwirika.Kupanga kwamakina, kumbali ina, kumayang'ana kwambiri kupanga makina ngati injini, ma turbines ndi zida zopangira.Kupanga kwa Mechanism kumakhudzana ndi kupanga njira zomwe zimasinthira zolowa kukhala zomwe mukufuna.Mapangidwe apangidwe ndi sitepe yomaliza.Zimakhudzanso kuwunika ndi kapangidwe kazinthu monga milatho, nyumba, ndi mafelemu amphamvu, kukhazikika, chitetezo, komanso kulimba.

Kodi kamangidwe kameneka ndi kotani?

Kamangidwe kake kamakhala ndi njira zosiyanasiyana, monga kuzindikiritsa kafukufuku ndi kusanthula kwavuto, kupanga malingaliro ndi mapangidwe atsatanetsatane ndi ma prototyping, komanso kuyesa ndi kuwunikira.M'magawo awa mainjiniya amagwiritsa ntchito njira ndi zida zosiyanasiyana monga pulogalamu yothandizidwa ndi makompyuta (CAD), finite element analysis (FEA) ndi kuyerekezera kuti atsimikizire ndi kukonza mapangidwewo.

Kodi okonza mapulani ayenera kuganizira zinthu ziti?

Kupanga kwamakina nthawi zambiri kumaphatikizapo zinthu monga kupanga, ergonomics, kutsika mtengo komanso kukhazikika.Akatswiri amayesa kupanga zitsanzo zomwe sizothandiza komanso zogwira mtima, komabe, amayeneranso kuganizira zofuna za wogwiritsa ntchito, momwe chilengedwe chimakhudzira komanso kuchepa kwachuma.

Ndikofunika kukumbukira kuti gawo la kapangidwe ka makina ndi gawo lalikulu komanso losinthika mosalekeza lomwe lili ndi zida zatsopano, matekinoloje ndi njira zomwe zikupangidwa nthawi zonse.Chifukwa chake, opanga makina amayenera kutsitsimutsa luso lawo ndi chidziwitso chawo nthawi zonse kuti akhale patsogolo pa chitukuko chaukadaulo.

Zotsatirazi ndi zidziwitso zamakina opangidwa ndi gulu la engineering la Anebon kuti agawane ndi anzawo.

1. Zomwe zimayambitsa kulephera kwa zida zamakina ndi: kuthyoka kwapang'onopang'ono kapena kuwonongeka kwakukulu kotsalira pamwambamwatsatanetsatane anatembenuza zigawo zikuluzikulu(kuwonongeka kwa corrosion, friction kutopa ndi kuvala) Kulephera chifukwa cha zotsatira za ntchito yabwino.

2. Zomwe zimapangidwira ziyenera kukwaniritsa: zofunikira zopewera kulephera mkati mwa nthawi yodziwika (mphamvu kapena kuuma, nthawi) ndi zofunikira pazochitika zamapangidwe, zofunikira zachuma, zofunikira zochepa, ndi zofunikira zodalirika.

3. Njira zopangira magawo zimaphatikizanso Kulimba mtima, kuuma kwa moyo, njira zokhazikika za kugwedezeka ndi kudalirika.

4. Njira zopangira gawo: kapangidwe kazongopeka, kamangidwe kamphamvu, kapangidwe ka mayeso achitsanzo.

5. Zomwe zimagwiritsidwa ntchito pazigawo zamakina ndizo Zida zamakina zamakina zimaphatikizapo zida za ceramic, zinthu za polima ndi zida zophatikizika.

6. Mphamvu yazida zamakinaamagawidwa kukhala static stress mphamvu komanso kusinthasintha kwamphamvu kupsinjika.

7. Kupsinjika maganizo r = -1 ndi asymmetrical cyclic stress.chiŵerengero cha r = 0 chimasonyeza kupsinjika kwakukulu kwa cyclic.

8. Amakhulupirira kuti gawo la BC limadziwika kuti kutopa kwapang'onopang'ono (kutopa kwapang'onopang'ono);CD ndiye gawo lomaliza la kutopa kwa moyo.gawo la mzere wotsatira nsonga ya D likuyimira kulephera kwa moyo kosalekeza kwa chitsanzocho.D ndiye malire okhazikika a kutopa.

9. Njira zowonjezerera mphamvu za ziwalo pamene watopa Kuchepetsa mphamvu ya kupsinjika maganizocnc milled magawopamlingo waukulu kwambiri zotheka (kuchepetsa katundu poyambira poyera) Sankhani zida zokhala ndi mphamvu zotopa kwambiri komanso tchulani njira zochizira kutentha ndi njira zolimbikitsira zomwe zimawonjezera mphamvu zazinthu zotopa.

.

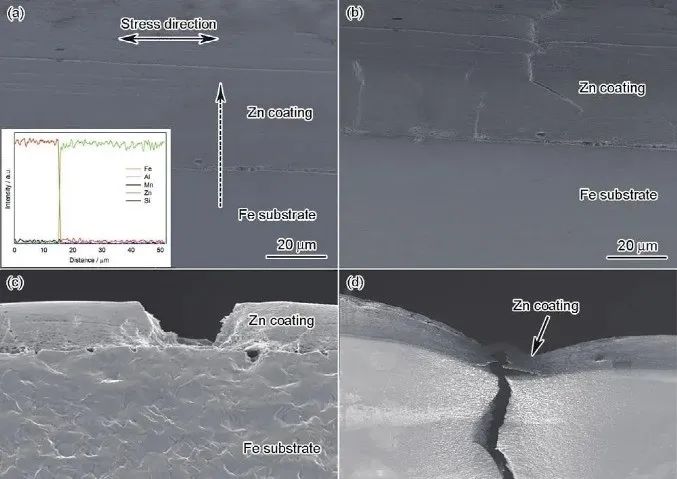

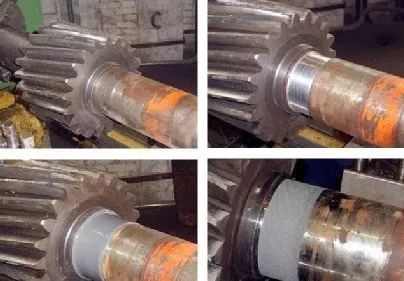

11. Kuvala kwa magawo kumaphatikizapo siteji yothamanga ndi siteji ya kuvala kokhazikika komanso siteji yovala kwambiri.Khama liyenera kuchitidwa kuti muchepetse nthawi yothamangira, kukulitsa nthawi ya kuvala kokhazikika ndikuchedwetsa kuoneka kowopsa kwambiri.

12. Gulu la mavalidwe ndi kuvala kwa Abrasive, kuvala zomatira ndi kutopa kwa dzimbiri, kuvala kukokoloka ndi kuvala kovutitsa.

13. Mafuta amatha kugawidwa m'mitundu inayi yomwe imakhala yamadzimadzi, gasi-olimba, mafuta olimba ndi amadzimadzi amagawidwa m'magulu atatu: mafuta opangidwa ndi calcium nano-based greases lithiamu-based grease, aluminium-based grease, ndi aluminiyamu-based.

14. Muyezo wolumikizira ulusi wa mano ndi makona atatu ofanana omwe ali ndi zinthu zabwino kwambiri zodzitsekera komanso kufalikira kwa ulusi wamakona anayi apamwamba kuposa ulusi wina.Ulusi wa trapezoidal ndiye ulusi wopatsirana womwe umagwiritsidwa ntchito kwambiri.

15. Ulusi wambiri wolumikiza umakhala ndi kuthekera kodzitsekera, chifukwa chake ulusi umodzi umagwiritsidwa ntchito nthawi zambiri.Ulusi wotumizira umafunika kuchita bwino kwambiri kuti utumizidwe kotero kuti ulusi wapatatu, kapena ulusi wapawiri ndi womwe umagwiritsidwa ntchito kwambiri.

16. Kulumikizana kwa bolt kwa mtundu wamba (kupyolera mu dzenje kapena mabowo omwe ali otseguka pazigawo zomwe zalumikizidwa) zolumikizira, kugwirizana kwa stud zomangira, kulumikiza wononga.

17. Chifukwa cha kugwirizana ulusi chisanadze kumangitsa ndi kupititsa patsogolo mphamvu ndi durability wa kugwirizana.Zimathandizanso kuyimitsa mipata ndi kutsetsereka pakati pa zigawo pambuyo potsegula.Nkhani yaikulu ya kumasuka kwa maulumikizi a ulusi ndikuletsa kusuntha kozungulira mu zomangira pamene zodzaza.(Kulimbana kuti muteteze kumasuka, kukana kwamakina kuti musiye kumasuka, kusungunula ubale woyenda ndi screw-pair)

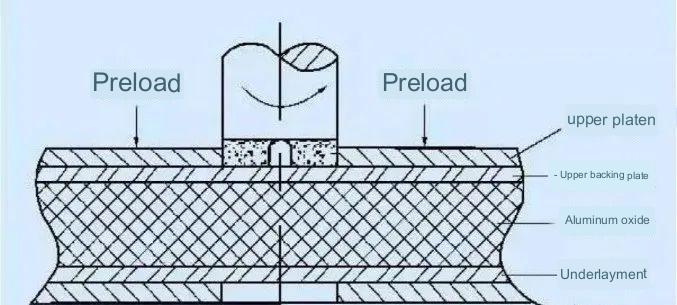

18. Njira zowonjezera mphamvu za kugwirizana kwa ulusi Kuchepetsa kukula kwa kupanikizika komwe kumakhudza mphamvu ya kutopa mu bolt (kuchepetsa kuuma kwa bolt komanso kuonjezera kuuma kwa zigawo zogwirizanitsa) ndikuwongolera kugawidwa kosagwirizana kwa katundu pa bolt. mano a ulusi, kuchepetsa zotsatira za kupsinjika maganizo ndikugwiritsa ntchito njira yopangira.

19. Mtundu wolumikizira Mfungulo Mtundu wolumikizira: lathyathyathya (mbali zonse zili ndi malo ogwirira ntchito) cholumikizira makiyi a semicircular wedge cholumikizira makiyi a tangential.

20. Kutumiza kwa lamba kumatha kugawidwa m'mitundu iwiri: mtundu wa meshing ndi mtundu wa mikangano.

21. Kupsyinjika kwakukulu koyambirira pa lamba ndi pamene mapeto olimba a lamba amayamba kuyendayenda pa pulley yaying'ono.Zovutazo zimasintha 4 pa nthawi ya maphunziro pa lamba.

22. Kuthamanga kwa V-lamba kufala: tensioning chipangizo nthawi zonse, tensioning chipangizo, tensioning chipangizo ntchito tensioning pulley.

23. Chiwerengero cha maulalo a unyolo mu tcheni chodzigudubuza chimakhala chofanana (kuchuluka kwa mano mu sprocket ndi nambala yachilendo) ndipo ulalo wotalikirapo umagwiritsidwa ntchito ngati kuchuluka kwa maunyolo ndi nambala yosamvetseka.

24. Chifukwa tensioning wa unyolo pagalimoto ndi kuonetsetsa kuti meshing si cholakwika ndi kupewa unyolo kugwedera ngati sag pa lotayirira mapeto ndi lalikulu kwambiri komanso kuonjezera meshing mtunda pakati pa unyolo komanso sprocket.

25. Chifukwa cha kulephera kwa giya ndi kusweka kwa dzino, kuvala pa dzino pamwamba (zotseguka zida) kutsekera kwa mano (zotsekedwa zida) Kumata pamwamba pa mano ndi kusinthika kwa pulasitiki (mizere imawoneka pamizere yoyendetsa galimoto ikuwonekera. chiwongolero).

26. Magiya omwe ali ndi kulimba kopitilira 350HBS ndi 38HRS amadziwika kuti ndi magiya olimba kapena, ngati sali, magiya a nkhope yofewa.

27. Kupititsa patsogolo kulondola kwa kupanga ndi kuchepetsa kukula kwa gear kuti achepetse liwiro lomwe amayendamo akhoza kuchepetsa katundu wothamanga.Pofuna kuchepetsa katunduyu mwamphamvu, chipangizochi chikhoza kukonzedwa pamwamba pake.mano a giya amapangidwa kukhala ng'oma kupititsa patsogolo mano a gear.kutumiza kugawa.

28. Kuchuluka kwa mbali yotsogolera ya coefficient ya m'mimba mwake, kumapangitsanso kugwira ntchito bwino, komanso kumachepetsa chitetezo chodzitsekera.

29. Sunthani zida za nyongolotsi.Pambuyo pa kusamuka mudzawona kuti mabwalo ozungulira a phula komanso mabwalo ozungulira akudutsana, komabe zikuwoneka kuti nyongolotsi ya nyongolotsi yasintha, ndipo siyigwirizananso ndi bwalo lake.

30. Chifukwa cha kulephera kwa nyongolotsi pagalimoto ndi pitting dzimbiri ndi dzino fractures muzu, dzino pamwamba pa glueing ndi owonjezera kuvala.Kulephera nthawi zambiri kumachitika chifukwa choyendetsa nyongolotsi.

31. Kutayika kwa mphamvu kuchokera kutsekeka kwa nyongolotsi zoyendetsa meshing kuvala Valani kutayika kwa ma bearings komanso kutayika kwa ma splashes amafuta pomwe zigawo zimalowa mu thanki yamafuta zimasonkhezera mafuta.

32. Kuthamanga kwa nyongolotsi kumayenera kuwerengera kutentha kwa kutentha molingana ndi zofunikira zowonetsetsa kuti ma calories pa unit of time ndi ofanana ndi kuchuluka kwa kutentha komwe kumatayidwa pa nthawi yomweyo.

Zothetsera: Onjezani masinki otentha kuti muonjezere malo kuti athetse kutentha.ikani mafani pafupi ndi shaft kuti muwonjezere kutuluka kwa mpweya, kenaka yikani zozama za kutentha mkati mwa bokosi lotumizira.Amatha kulumikizidwa ndi payipi yozizirira yozungulira.

33. Zofunikira pakupanga kondomu ya hydrodynamic ndikuti malo awiri omwe amatsetsereka ayenera kupanga kusiyana kofanana ndi mphero.Maonekedwe awiri omwe amasiyanitsidwa ndi filimu yamafuta ayenera kukhala ndi liwiro lokwanira la kutsetsereka, ndipo kuyenda kwake kuyenera kupangitsa kuti mafuta opaka mafuta ayende pakamwa patali kwambiri mpaka pakamwa kakang'ono.amafunikira kuti mafuta akhale ndi mamasukidwe enaake ndipo kuperekedwa kwa mafuta kumafunika kukhala kokwanira.

34. Mapangidwe omwe ali maziko a mayendedwe ogubuduza ndi mphete yakunja, thupi lamkati la Hydrodynamic, khola.

35. Miyezo itatu ya tapered yodzigudubuza miyendo isanu yokhala ndi mipira yolowera mkati mwa groove 7 yokhala ndi zolumikizira zamakona zozungulira 01, 02, 01 ndi 02 ndi 03 motsatana.D=10mm, 12mm 15mm, 17,mm amatanthauza 20mm d=20mm ndipo 12 ndi ofanana ndi 60mm.

36. Moyo wa chiwerengero choyambirira: 10 peresenti ya mayendedwe mkati mwa mayendedwe osiyanasiyana akuvutika ndi kuwonongeka kwa maenje, pamene 90% ya mayendedwe sakhudzidwa ndi kuwonongeka kwa maenje.Kuchuluka kwa maola ogwira ntchito ndi nthawi ya moyo yomwe ikukhudzidwa.

37. Chiyembekezo champhamvu: kuchuluka komwe kubereka kumatha kuthandizira pamene mlingo wa makinawo uli ndi kusintha kwa 106.

38. Njira yodziwira kasinthidwe kakubereka: Ma Fulcrum awiri amakhazikika ku njira imodzi iliyonse.Mfundo imodzi imakhazikika molunjika, pamene fulcrum ina imatha kusambira mbali zonse ziwiri, pamene ina imathera kusambira kuti ipereke chithandizo.

39. Ma bearings amagawidwa molingana ndi kuchuluka kwa shaft yolemetsa (nthawi yopindika ndi torque) mandrel (mphindi yopindika) ndi Transmission shaft (torque).

Anebon amatsatira lingaliro lofunikira la "Quality ndiye gwero la bizinesi ndipo udindo ukhoza kukhala gwero lake" Pakuchotsera kwakukulu pa Custom precision 5 Axis Lathemakina a cnc, Anebon ali ndi chidaliro kuti tidzapereka zinthu ndi ntchito zapamwamba kwambiri pamtengo wotsika mtengo komanso ntchito yabwino kwambiri ikatha kugulitsa kwa makasitomala.Kuphatikiza apo, Anebon atha kupanga ubale wokhazikika wanthawi yayitali ndi inu.

Chinese Professional China CNC Part ndi Metal Machining Parts, Anebon imadalira zinthu zapamwamba kwambiri, kapangidwe kabwino, ntchito yapadera yamakasitomala komanso mtengo wotsika mtengo kuti makasitomala ambiri ochokera kunja komanso ku US azikhulupirira.Zambiri mwazinthuzo zimatumizidwa kumisika yakunja.

Nthawi yotumiza: Aug-02-2023