U tseba hakae ka moralo oa mochini?

Moralo oa Mechini ke lekala la boenjiniere le sebelisang melao-motheo le mekhoa e fapaneng ho rala, ho sekaseka le ho ntlafatsa litsamaiso le likarolo tsa mochini.Moralo oa mochini o kenyelletsa ho utloisisa sepheo se reriloeng sa karolo kapa sistimi, ho khetha thepa e loketseng, ho ela hloko lintlha tse fapaneng, joalo ka khatello ea maikutlo le mathata le matla, le ho netefatsa ts'ebetso e tšepahalang le e sebetsang.

Moralo oa mochini o kenyelletsa moralo oa mochini, moralo oa sebopeho, moralo oa mochini le moralo oa sehlahisoa.Moralo oa sehlahisoa o amana le moralo oa lihlahisoa tsa 'mele joalo ka thepa ea bareki, lisebelisoa tsa indasteri le lintho tse ling tse tšoarehang.Moralo oa mochini, ka lehlakoreng le leng, o shebane le ho theha metjhini e kang lienjineri, li-turbine le lisebelisoa tsa tlhahiso.Moralo oa Mechanism o shebane le ho rala mekhoa e fetolang lintho tse kenang hore e be liphetho tse lakatsehang.Moralo oa sebopeho ke mohato oa ho qetela.E kenyelletsa tlhahlobo le moralo oa meaho e kang marokho, meaho le liforeimi bakeng sa matla a tsona, botsitso, polokeho le nako e telele.

Mokhoa o ikhethileng oa moralo o joang?

Ts'ebetso ea moralo hangata e kenyelletsa mehato e fapaneng, joalo ka ho tsebahatsa lipatlisiso le tlhahlobo ea bothata, tlhahiso ea mehopolo le moralo o felletseng le prototyping, hammoho le tlhahlobo le tlhaloso.Mekhahlelong ena lienjineri li sebelisa mekhoa le lisebelisoa tse fapaneng joalo ka software e thusoang ke komporo (CAD) software, finite element analysis (FEA) le ketsiso ho netefatsa le ho ntlafatsa moralo.

Ke lintlha life tseo baqapi ba lokelang ho nahana ka tsona?

Moralo oa mechini hangata o kenyelletsa likarolo tse joalo ka tlhahiso, ergonomics, ts'ebeliso e ntle ea litšenyehelo hammoho le ts'ebetso.Baenjineri ba leka ho hlahisa mefuta e sa sebetseng hantle feela, empa hape ba tlameha ho nahana ka litlhoko tsa mosebelisi, phello ea tikoloho le meeli ea moruo.

Ke habohlokoa ho hopola hore tšimo ea moralo oa mechine ke tšimo e pharaletseng le e tsoelang pele e tsoelang pele e nang le lisebelisoa tse ncha, theknoloji le mekhoa e ntseng e ntlafatsoa kamehla.Kahoo, baqapi ba mechini ba tlameha ho lula ba nchafatsa tsebo le tsebo ea bona hore ba lule ba le ka pele ho tsoelopele ea theknoloji.

Lintlha tse latelang ke lintlha tsa tsebo mabapi le moralo oa mochini o bokelletsoeng le ho hlophisoa ke sehlopha sa boenjiniere sa Anebon ho arolelana le basebetsi-'moho.

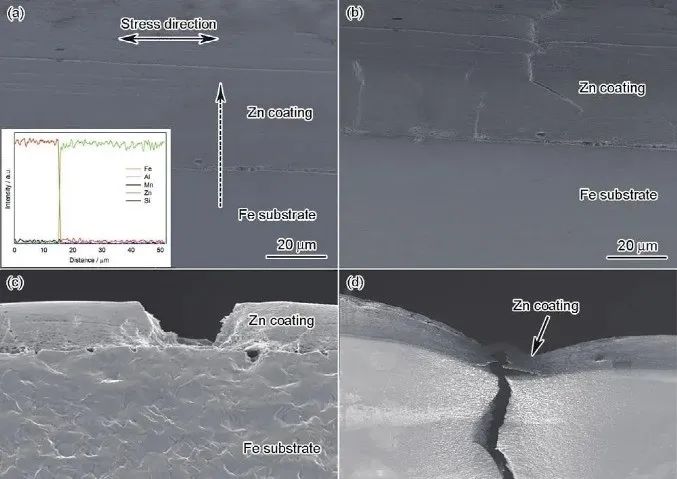

1. Lisosa tsa ho hloleha ha likarolo tsa mochini ke: ho robeha ka kakaretso kapa ho senyeha ho feteletseng ha masala a bokaholimo hoho nepahala ho fetotsoe likarolo(corrosion wear, friction fatigue and wear) Ho hloleha ka lebaka la ditlamorao tsa maemo a tlwaelehileng a ho sebetsa.

2. Likarolo tsa moralo li tlameha ho khona ho fihlela: litlhoko tsa ho qoba ho hloleha ka nako e behiloeng (matla kapa ho satalla, nako) le litlhoko tsa lits'ebetso tsa meralo, litlhoko tsa moruo, litlhoko tsa boleng bo tlase, le litlhoko tsa ho ts'epahala.

3. Likarolo tsa moralo oa likarolo li kenyelletsa litekanyetso tsa Matla, litekanyetso tsa ho satalla maemo a bophelo, litekanyetso tsa botsitso ba ho sisinyeha le litekanyetso tsa ho tšepahala.

4. Mekhoa ea meralo ea likarolo: moralo oa theory, moralo oa mahlale, moralo oa tlhahlobo ea mohlala.

5. Hangata e sebelisoa bakeng sa likarolo tsa mechine ke Lisebelisoa bakeng sa likarolo tsa mechine li kenyelletsa lisebelisoa tsa ceramic, lisebelisoa tsa polymer le lisebelisoa tse kopantsoeng.

6. Matla alikarolo tse entsoeng ka mochinie arotsoe ka matla a static stress hammoho le matla a feto-fetohang a khatello.

7. Tekanyo ea khatello ea maikutlo r = -1 ke khatello ea asymmetrical cyclic.karo-karolelano ea r = 0 e bontša khatello ea kelello e telele.

8. Ho lumeloa hore sethala sa BC se tsejoa e le mokhathala oa khatello (mokhathala o tlase oa potoloho);CD ke mohato oa ho qetela oa mokhathala oa bophelo.karolo ea mola e latelang ntlha ea D e emela boemo bo sa feleng ba ho hloleha ha bophelo ba mohlala.D ke moeli o sa feleng oa mokhathala.

9. Mekhoa ea ho ntlafatsa matla a likarolo ha u khathetse Fokotsa tšusumetso ea khatello ea kelello holikarolo tse omisitsoeng tsa cncho isa tekanyong e kholo ka ho fetisisa e ka khonehang (ho fokotsa moroalo groove e bulehileng) Khetha lisebelisoa tse nang le matla a matla a mokhathala hape u hlalose mekhoa ea phekolo ea mocheso le mekhoa e matlafatsang e eketsang matla a thepa e khathetseng.

10. Khohlano ea li-slide: Khohlano e ommeng ea meeli ea likhohlano, likhohlano tsa mokelikeli le likhohlano tse tsoakiloeng.

11. Mokhoa oa ho apara oa likarolo o kenyelletsa sethaleng sa ho matha le sethala sa ho apara se tsitsitseng le sethaleng se matla sa ho apara.Boiteko bo lokela ho etsoa ho fokotsa nako ea ho matha, ho eketsa nako ea ho apara ka mokhoa o tsitsitseng le ho liehisa ponahalo ea ho apara e boima haholo.

12. Ho hlophisoa ha moaparo ke ho apara ka mokhoa oa abrasive, ho roala sekhomaretsi le mokhathala o senyang, ho roala ha khoholeho le moaparo o ferekanyang.

13. Lisebelisoa li ka aroloa ka mefuta e mene e leng metsi, likhase tsa semi-solid, tse tiileng le tse nang le metsi li khetholloa e le lihlopha tse tharo: likhalase tse thehiloeng ka calcium nano-based greases lithium-based grease, aluminium e thehiloeng grease, le aluminium-based.

14. Mokhoa o tloaelehileng oa ho kopanya khoele ea leino ke kgutlotharo e equilateral e nang le thepa e babatsehang ea ho itšireletsa le ts'ebetso ea phetisetso ea khoele ea phetisetso ea kgutlonne e phahametse likhoele tse ling.likhoele tsa trapezoidal ke khoele ea phetiso e sebelisoang haholo.

15. Bongata ba likhoele tse hokelang li na le bokhoni ba ho its'oara, ka hona likhoele tse le 'ngoe li sebelisoa hangata.Likhoele tsa phetiso li hloka tšebetso e ntle haholo bakeng sa phetiso, ka hona likhoele tse tharo, kapa tse habeli li sebelisoa haholo.

16. Khokahano ea bolt ea mofuta o tloaelehileng (ka lesoba kapa masoba a hinged a bulehileng likarolong tse hokahaneng) likhokahano, likhokahano tsa li-screw, seta khokahano ea screw.

17. Lebaka la ho hokahanya ha threaded pele ho tiisa ke ho ntlafatsa matla le ho tšoarella ha khokahanyo.E boetse e thusa ho emisa likheo le ho thella lipakeng tsa likarolo ka mor'a ho kenya.Taba ea mantlha ea ho lokoloha ha likhokahano tse kentsoeng ke ho thibela motsamao oa ho potoloha ka har'a likurufu ha li ntse li laetsoe.(Khohlano ea ho thibela ho lokoloha, khanyetso ea mochini ho emisa ho lokoloha, ho qhaqha kamano ea motsamao oa screw-pair)

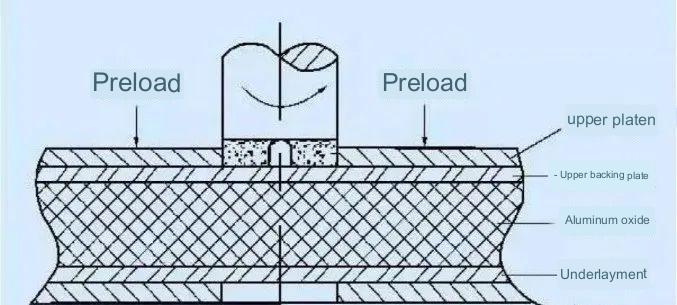

18. Mekhoa ea ho eketsa matla a likhokahano tse nang le likhoele Fokotsa boholo ba khatello ea maikutlo e amang matla a mokhathala bolt (fokotsa ho satalla ha bolt hammoho le ho eketsa boima ba likarolo tse hokahaneng) le ho ntlafatsa kabo e sa lekanang ea mojaro holim'a meno a likhoele, fokotsa phello ea khatello ea maikutlo 'me u sebelise mokhoa o sebetsang oa tlhahiso.

19. Mofuta oa khokahanyo ea senotlolo Mofuta oa khokahanyo ea bohlokoa: e bataletseng (mahlakore ka bobeli a na le bokaholimo ba ho sebetsa) sehokelo sa senotlolo sa semicircular key connector kgokelo ya dikonopo tsa tangential.

20. Phetiso ea lebanta e ka aroloa ka mefuta e 'meli: mofuta oa meshing le mofuta oa likhohlano.

21. Khatello ea pele e kholo ka ho fetisisa lebanta ke moo ntlha e thata ea lebanta e qalang ho potoloha pulley e nyenyane.Khatello e fetoha ka makhetlo a 4 nakong ea thupelo ka lebanta.

22. Tensioning ea V-belt phetisetso: kamehla tensioning sesebelisoa, jarolla ka ho iketsa tensioning, tensioning sesebediswa ho sebelisa tensioning pulley.

23. Palo ea li-chain link ka har'a ketane ea li-roller ka tloaelo e lekana (tekanyo ea meno a sprocket ke palo e makatsang) 'me sehokelo sa ketane se atolositsoeng se sebelisoa ha palo ea lihokelo tsa ketane e le palo e makatsang.

24. Lebaka la ho tsitsipana ha ketane ea ketane ke ho etsa bonnete ba hore meshing ha e na phoso le ho qoba ho sisinyeha ha ketane haeba sag pheletsong e hlephileng e kholo haholo le ho eketsa sebaka sa meshing pakeng tsa ketane hammoho le sprocket.

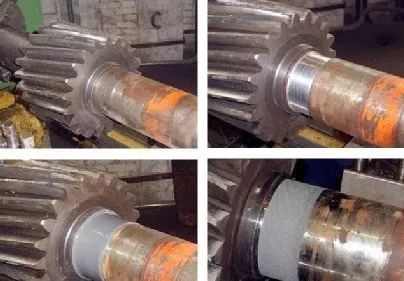

25. Sesosa sa ho hloleha ha gear ke ho robeha ha leino, ho roala holim'a leino (lisebelisoa tse bulehileng) ho koala meno (lisebelisoa tse koetsoeng) Leino holim'a sekhomaretsi le deformation ea polasetiki (maporopo a bonahala meleng ea mabili a ho khanna a hlaha. lebili).

26. Li-gear tse thata ho feta 350HBS le 38HRS li tsejoa e le tse nang le sefahleho se thata kapa, haeba ho se joalo, tse sefahleho se bonolo.

27. Ho ntlafatsa ho nepahala ha tlhahiso le ho fokotsa boholo ba gear ho theola lebelo leo e tsamaeang ka lona ho ka fokotsa mojaro o matla.E le ho fokotsa mojaro ona ka matla, sesebelisoa se ka 'na sa lokisoa ka holim'a sona.meno a gear a thehoa ho ba moropa ho ntlafatsa boleng ba meno a gear.ho kenya kabo.

28. Ha karolo e ka sehloohong ea karolo e ka sehloohong ea coefficient ea bophara e kholoanyane, e na le katleho e kholoanyane, 'me bokhoni ba ho itšireletsa bo fokotsehile.

29. Suthisa thepa ea liboko.Ka mor'a ho falla, u tla hlokomela hore "pitch circles" hammoho le pitch circle li kopana, leha ho le joalo ho hlakile hore pitch line worm ea sebōkō e fetohile, 'me ha e sa ikamahanya le selika-likoe sa eona.

30. Sesosa sa ho hloleha ha koloi ea seboko ke ho senyeha ha sekoti le ho robeha ha metso ea leino, sekhomaretsi sa leino le ho roala ho feteletseng.Ho hloleha hangata ho bakoa ke ho khanna liboko.

31. Ho lahleheloa ke matla ho tsoa ho koaletsoeng worm drive meshing wear loss Apara tahlehelo ea li-bearings hammoho le tahlehelo ea li-splash tsa oli ha likarolo li kena ka tankeng ea oli li hlohlelletsa oli.

32. Mokhanni oa sebōkō o tlameha ho bala tekanyo ea mocheso ho latela tlhoko ea ho netefatsa hore litekanyetso tsa calorific ka unit of time li lekana le mocheso oa mocheso o qhatsoeng ka nako e le 'ngoe.

Litharollo: Eketsa licheso tsa mocheso ho eketsa sebaka sa ho qhala mocheso.kenya li-fan haufi le shaft e le ho eketsa phallo ea moea, ebe u kenya lisinki tsa mocheso ka har'a lebokose la phetisetso.Li ka kopanngoa le phaephe ea ho pholisa e potolohang.

33. Litlhoko tse hlokahalang bakeng sa ho theha lubrication ea hydrodynamic ke hore libaka tse peli tse thellang li tlameha ho theha lekhalo le bōpehileng joaloka chedge.Libaka tse peli tse arohaneng ke filimi ea oli li lokela ho ba le lebelo le lekaneng le lekanyelitsoeng la ho thella, 'me ho tsamaea ha eona ho lokela ho etsa hore oli e tlotsang e phalle molomong o moholo ho ea molomong o monyenyane.ho hlokahala hore oli e be le viscosity e itseng 'me phepelo ea oli e hlokeha hore e lekane.

34. Sebopeho seo e leng motheo oa ho roala li-bearings ke lesale la ka ntle, 'mele oa ka hare oa Hydrodynamic, cage.

35. Li-roller tse tharo tse nang le li-bearings tse hlano tsa bolo tse nang le li-bearings tse tebileng tsa groove tse 7 tse nang le li-angular contact cylindrical roller bearings 01, 02, 01 le 02 le 03 ka ho latellana.D=10mm, 12mm 15mm, 17,mm e bolela 20mm d=20mm le 12 e lekana le 60mm.

36. Bophelo ba litekanyetso tsa motheo: karolo ea 10 lekholong ea li-bearings ka har'a li-bearings tse fapa-fapaneng li na le tšenyo ea likoti, athe 90% ea libere ha e amehe ke tšenyo ea likoti.Nako ea lihora tse sebetsoang ke nako ea bophelo eo ho behoang ho eona.

37. Tekanyetso ea motheo ea matla: chelete eo ho beleha ho khonang ho e tšehetsa ha tekanyo ea motheo ea mochine e nepahetse ka 106 revolutions.

38. Mokhoa oa ho khetholla tlhophiso ea ho beha: li-Fulcrum tse peli li tsitsitse ka tsela e le 'ngoe.Ntlha e 'ngoe e tsitsitsoe ka mahlakoreng a mabeli, ha fulcrum e 'ngoe e qetella e sesa ka mahlakoreng ka bobeli, ha e' ngoe e qetella e sesa bakeng sa ho fana ka tšehetso.

39. Li-bearings li arotsoe ho ea ka palo ea moroalo oa moroalo (motsotso oa ho khumama le torque) mandrel (motsotso oa ho khumama) le Transmission shaft (torque).

Anebon e khomarela mohopolo oa mantlha oa "Boleng ke motheo oa khoebo mme boemo e ka ba motheo oa eona" Bakeng sa theolelo e kholo ho Custom precision 5 Axis Lathe.likarolo tse entsoeng ka mochine oa cnc, Anebon e na le ts'epo ea hore re tla fana ka lihlahisoa le lits'ebeletso tsa boleng bo holimo ka theko e tlase le ts'ebeletso e ntle haholo ea kamora ho rekisa ho bareki.Ho feta moo, Anebon e tla khona ho theha kamano e matla ea nako e telele le uena.

Karolo ea China ea Setsebi sa Chaena ea CNC le Likarolo tsa Metal Machining, Anebon e itšetlehile ka lihlahisoa tsa boleng bo holimo, moralo o phethahetseng, tšebeletso e ikhethang ea bareki le litšenyehelo tse theko e tlaase ho fumana tšepo ea palo e kholo ea bareki ba tsoang linaheng tse ling le US.Boholo ba lihlahisoa li romelloa limmarakeng tsa mose ho maoatle.

Nako ea poso: Aug-02-2023