A cikin machining, don haɓaka ingancin sarrafawa da maimaita daidaito, ya zama dole don zaɓar daidai da ƙayyade kayan aikin da ya dace.Ga wasu ƙalubale da mashin ɗin wahala, zaɓin kayan aiki yana da mahimmanci musamman.

1. Hanyar kayan aiki mai sauri

1. Hanyar kayan aiki mai sauri

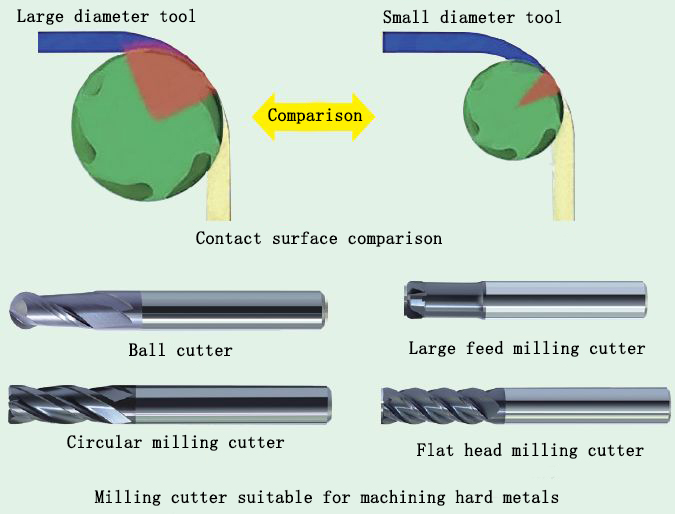

Tsarin CAD / CAM yana samun daidaitattun yankewa ta hanyar sarrafa tsayin baka na kayan aikin yankan a cikin babban hanyar kayan aikin cycloid mai sauri.Lokacin da mai yankan niƙa ya yanke zuwa kusurwa ko cikin wasu hadaddun siffofi na geometric, adadin cin wuka ba zai karu ba.Don cin gajiyar wannan ci gaban fasaha, masana'antun kayan aiki sun ƙirƙira da haɓaka manyan injinan niƙa ƙananan diamita.Ƙananan diamita milling cutters iya yanke ƙarin workpiece kayan a cikin wani lokaci naúrar ta amfani da high-gudun kayan aiki hanyõyi, da kuma samun mafi girma karfe kau kudi.

A lokacin machining, da yawa lamba tsakanin kayan aiki da surface na workpiece iya sa kayan aiki da sauri kasawa.Ingantacciyar ƙa'idar babban yatsan hannu ita ce amfani da abin yankan niƙa tare da diamita na kusan 1/2 na mafi ƙarancin ɓangaren aikin.Lokacin da radius na mai yankan niƙa ya fi girman girman mafi girman ɓangaren aikin, akwai dakin kayan aiki don matsawa hagu da dama, kuma za'a iya samun ƙaramin kusurwar cin abinci.Masu yankan niƙa na iya amfani da ƙarin yankan gefuna da ƙimar abinci mafi girma.Bugu da ƙari, lokacin da aka yi amfani da mai yankan niƙa tare da diamita na 1/2 na kunkuntar sashi na aikin aikin, za a iya ajiye kusurwar ƙananan ƙananan ba tare da ƙara juyawa mai yankewa ba.

Har ila yau, taurin na'ura yana taimakawa wajen sanin girman kayan aikin da za a iya amfani da su.Misali, lokacin yankan kan na'ura mai tauri 40, diamita na abin yankan niƙa ya kamata ya zama <12.7mm.Yin amfani da na'urar yanka tare da diamita mafi girma zai haifar da babban ƙarfin yanke wanda zai iya wuce ƙarfin na'ura, wanda zai haifar da zance, nakasawa, ƙarancin ƙasa, da gajeriyar rayuwar kayan aiki.

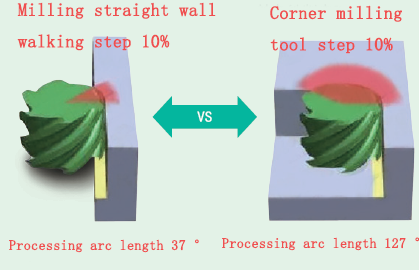

Lokacin amfani da sabuwar hanyar kayan aiki mai sauri, sautin abin yankan niƙa a kusurwa daidai yake da na yankan layi madaidaiciya.Sautin da mai yankan niƙa ya yi yayin aikin yanke iri ɗaya ne, wanda ke nuni da cewa ba a taɓa fuskantar babban girgizar zafi da injina ba.Mai yankan niƙa yana yin kururuwa a duk lokacin da ya juya ko ya yanke cikin kusurwa, wanda ke nuna cewa ana iya buƙatar rage diamita na abin yanka don rage kusurwar cin abinci.Sautin yankan ya kasance ba canzawa, yana nuna cewa matsa lamba akan abin yankan niƙa daidai ne kuma baya jujjuyawa sama da ƙasa tare da canjin juzu'i na kayan aikin.Wannan saboda kwanar wuka yana dawwama.

2. Milling kananan sassa

Babban abin yankan niƙan abinci ya dace da niƙa na ƙananan sassa, wanda zai iya haifar da tasirin guntu, yana sa ya yiwu a yi niƙa a ƙimar abinci mafi girma.

A cikin aiki na karkace niƙa ramuka da milling hakarkarinsa, da kayan aiki ba makawa zai sa ƙarin lamba tare da machining surface, da kuma yin amfani da babban feed milling abun yanka na iya rage girman lamba tare da workpiece, game da shi rage yankan zafi da kuma kayan aiki nakasawa .

A cikin waɗannan nau'ikan sarrafawa guda biyu, babban abin yankan niƙa yana yawanci cikin yanayin rufewa yayin yankan.Sabili da haka, matsakaicin matakin yankan radial ya kamata ya zama 25% na diamita na mai yankan niƙa, kuma matsakaicin zurfin yankan Z na kowane yankan yakamata ya zama 2% na diamita na mai yankan niƙa.cnc machining part

A cikin ramin niƙa mai karkace, lokacin da mai yankan niƙa ya yanke cikin workpiece tare da shingen shinge mai karkace, kusurwar yankan karkace shine 2 ° ~ 3 ° har sai ya kai zurfin yanke Z na 2% na diamita na abin yankan niƙa.

Idan babban mai yankan niƙa yana cikin buɗaɗɗen yanayi yayin yankan, matakin tafiyarsa na radial ya dogara da taurin kayan aikin.Lokacin milling kayan aiki tare da taurin HRC30-50, matsakaicin matakin yankan radial ya kamata ya zama 5% na diamita na milling;lokacin da taurin abu ya fi HRC50, matsakaicin matakin yankan radial da matsakaicin Z a kowace faci Zurfin yankan shine 2% na diamita na mai yankan niƙa.aluminum part

3. Nika madaidaiciya ganuwar

Lokacin niƙa tare da haƙarƙari mai faɗi ko madaidaiciyar bango, yana da kyau a yi amfani da yankan baka.Masu yankan Arc tare da gefuna 4 zuwa 6 sun dace musamman don niƙan bayanan martaba na madaidaiciya ko sassa masu buɗewa.Yawan adadin ruwan wukake na mai yankan niƙa, mafi girman adadin ciyarwar da za a iya amfani da shi.Koyaya, mai shirye-shiryen mashin ɗin har yanzu yana buƙatar rage lamba tsakanin kayan aiki da saman kayan aikin da amfani da ƙaramin yankan radial.Lokacin yin aiki akan kayan aikin injin tare da rashin ƙarfi mara kyau, yana da fa'ida don amfani da abin yankan niƙa tare da ƙaramin diamita, wanda zai iya rage lamba tare da saman kayan aikin.cnc milling part

Matakin yankewa da zurfin yankan na'urar milling mai ɗimbin gefuna iri ɗaya ne da na babban abin yankan niƙa.Ana iya amfani da hanyar kayan aiki na cycloid don tsage kayan da aka taurare.Tabbatar cewa diamita na abin yankan niƙa yana da kusan kashi 50% na faɗin tsagi, ta yadda mai yankan ya sami isasshen sarari don motsawa, kuma tabbatar da cewa kusurwar mai yankan ba zai karu ba kuma ya haifar da zafi mai tsanani.

Mafi kyawun kayan aiki don ƙirar ƙira ya dogara ba kawai akan kayan da aka yanke ba, har ma akan nau'in yankewa da hanyar niƙa.Ta hanyar inganta kayan aiki, yanke saurin gudu, ƙimar ciyarwa da ƙwarewar shirye-shirye, ana iya samar da sassa da sauri kuma mafi kyau a ƙananan farashin injin.

Anebon Metal Products Limited na iya samar da mashin ɗin CNC, simintin gyare-gyare, sabis na ƙirar ƙarfe, da fatan za a iya tuntuɓar mu.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Lokacin aikawa: Afrilu-28-2020