Litlhoko tsa lisebelisoa tsa mochini oa CNC ho lisebelisoa tsa lisebelisoa

Boima bo phahameng le ho hanyetsa ho apara

Ho thatafala ha karolo ea ho itšeha ea sesebelisoa e tlameha ho ba holimo ho feta boima ba thepa ea workpiece.Ha boima ba lisebelisoa tsa sesebelisoa bo phahame, ho molemo hore ho be le ho hanyetsa ha eona ho apara.Ho thatafala ha lisebelisoa ka mocheso oa kamore e tla ba ka holimo ho HRC62.Ho thatafala ho ka ba holimo ho feta ba tloaelehilengLikarolo tsa mochini oa CNC.

Matla a lekaneng le ho tiea

Sesebelisoa se na le khatello e kholo ts'ebetsong ea ho itšeha ho feteletseng.Ka linako tse ling, e sebetsa tlas'a tšusumetso le maemo a vibration.E le ho thibela sesebelisoa ho senya le ho senya, thepa ea lisebelisoa e tlameha ho ba le matla a lekaneng le ho tiea.Ka kakaretso, matla a ho kobeha a sebelisoa ho emela matla a sesebelisoa, 'me boleng ba tšusumetso bo sebelisoa ho emela ho tiea ha lisebelisoa.

ho hanyetsa mocheso o phahameng

Ho hanyetsa mocheso ho bolela ts'ebetso ea lisebelisoa tsa lisebelisoa ho boloka boima, ho roala ho hanyetsa, matla le boima tlas'a mocheso o phahameng.Ke letšoao le ka sehloohong la ho lekanya ts'ebetso ea ho itšeha ea lisebelisoa tsa lisebelisoa.Tshebetso ena e boetse e tsejoa e le boima bo bofubelu ba lisebelisoa tsa lisebelisoa.

Molemo o motle oa mocheso oa mocheso

Ha ho ntse ho e-na le mocheso o moholo oa mocheso oa lisebelisoa tsa lisebelisoa, mocheso o fetisoa ho tloha sesebelisoa, o leng ho loketseng ho fokotsa mocheso oa ho itšeha oa sesebelisoa le ho ntlafatsa ho tšoarella ha sesebelisoa.

Tshebetso e ntle

E le ho nolofatsa ts'ebetso le tlhahiso ea lisebelisoa, lisebelisoa tsa lisebelisoa li hlokeha ho ba le thepa e ntle ea ho sebetsa, e kang ho forging, rolling, welding, cutting and grindability, thepa ea phekolo ea mocheso le mocheso o phahameng oa mocheso oa polasetiki oa thepa ea thepa.Bakeng sa thepa e entsoeng ka samente ea carbide le lisebelisoa tsa ceramic, thepa e ntle ea sintering le khatello ea khatello le tsona lia hlokahala.

Mofuta oa lisebelisoa tsa lisebelisoa

tšepe ea lebelo le holimo

Tšepe ea lebelo le phahameng ke sesebelisoa sa alloy se entsoeng ka W, Cr, Mo le likarolo tse ling tsa alloy.E na le botsitso bo phahameng ba mocheso, matla a phahameng le ho tiea, le tekanyo e itseng ea ho thatafala le ho roala ho hanyetsa, kahoo e loketse ho sebetsana le litšepe tse se nang ferrous le lisebelisoa tse sa tšoaneng tsa tšepe.Ho phaella moo, ka lebaka la theknoloji ea eona e ntle ea ho sebetsa, e loketse ho etsa lisebelisoa tse rarahaneng tsa ho etsa lisebelisoa, haholo-holo phofo ea metallurgy e lebelo le phahameng la tšepe, e nang le thepa ea mechine ea anisotropic le ho fokotsa deformation ea quenching, E loketse ho etsa lisebelisoa tse nepahetseng le tse rarahaneng tsa ho etsa lisebelisoa.

Motsoako o thata

Carbide e entsoeng ka samente e na le boima bo phahameng le ho hanyetsa ho apara.Ha sehaLikarolo tse fetohang tsa CNC, ts'ebetso ea eona e molemo ho feta ea tšepe ea lebelo le phahameng.E tšoarella ka makhetlo a 'maloa ho isa ho makhetlo a mangata ho feta ea tšepe ea lebelo le phahameng, empa ho tiea ha eona hoa fokola.Ka lebaka la ts'ebetso ea eona e ntle ea ho itšeha, e sebelisoa haholo joalo ka lisebelisoa tsa lisebelisoa.

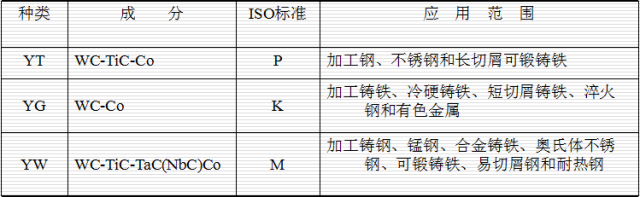

Ho hlophisoa le ho tšoaea li-carbides tse entsoeng ka samente bakeng sa lisebelisoa tsa ho itšeha

Lehare le koahetsoeng

1) Thepa ea ho roala ea mokhoa oa CVD ke TiC, e eketsang nako e telele ea lisebelisoa tsa carbide tse entsoeng ka samente ka makhetlo a 1-3.Botenya ba ho roala;Sekhahla se lerootho;E thusa ho ntlafatsa bophelo ba lebelo.

2) Lisebelisoa tsa ho roala tsa PVD mokhoa oa ho beha mouoane oa 'mele ke TiN, TiAlN le Ti (C, N), e ntlafatsang ho tšoarella ha lisebelisoa tsa carbide tse entsoeng ka samente ka makhetlo a 2-10.Ho roala ho tšesaane;Molomo o bohale;Ho molemo ho fokotsa boima ba 'mele.

★ Botenya bo boholo ba ho roala ≤ 16um

CBN le PCD

Cubic boron nitride (CBN) The hardness and thermal conductivity of cubic boron nitride (CBN) e tlase feela ho taemane, mme e na le botsitso bo phahameng ba mocheso le botsitso bo botle ba lik'hemik'hale.Ka hona, e loketse ho sebetsa tšepe e thata, tšepe e thata, superalloy le carbide e entsoeng ka samente.

Polycrystalline diamond (PCD) Ha PCD e sebelisoa e le sesebelisoa sa ho itšeha, e tšeloa holim'a sekontiri se entsoeng ka carbide, 'me e khona ho qeta lisebelisoa tse sa senyeheng, tse thata tse se nang tšepe le tse sa sebeliseng tšepe tse kang carbide e entsoeng ka samente, lirafshoa, alloy e phahameng ea silicon aluminium.

★ ISO mochini clamp lehare thepa classification ★

Likarolo tsa tšepe: P05 P25 P40

Tšepe e sa hloekang: M05 M25 M40

Tšepe ea tšepe: K05 K25 K30

★ Palo e nyenyane ke, lehare le thata haholoanyane, ho molemo hore ho be le khanyetso ea ho roala ha sesebelisoa, 'me ho hobe le ho feta ho hanyetsa tšusumetso ke.

★ palo e kholoanyane ke, lehare le bonolo, ho molemo ho hanyetsa ts'usumetso le ho hanyetsa ho roala ha sesebelisoa.

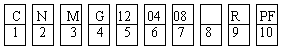

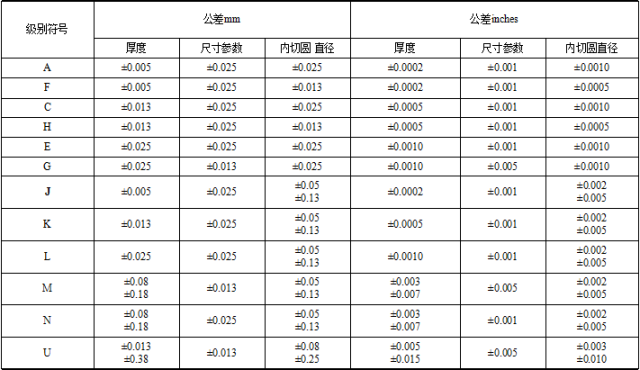

E fetoleloa ho ba mohlala oa blade le melao ea boemeli ba ISO

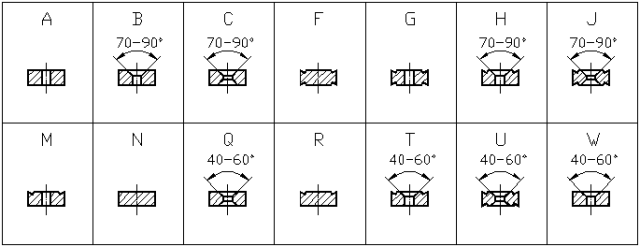

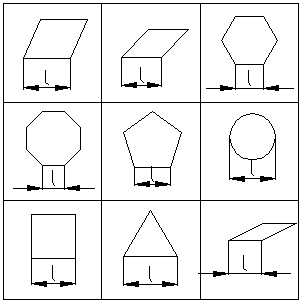

1. Khoutu e emelang sebopeho sa lehare

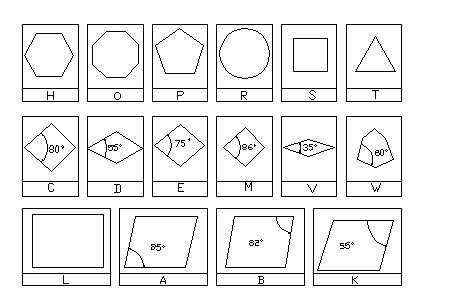

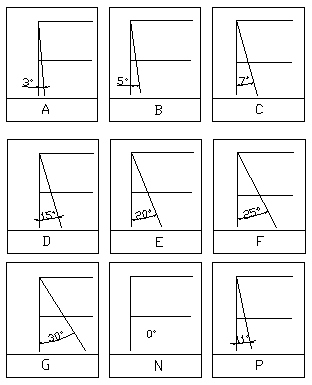

2. Khoutu e emelang lehlakoreng le ka morao la moeli o ka sehloohong oa ho itšeha

3. Khoutu e emelang mamello ea lehlakore la lehare

4. Khoutu e emelang mofuta oa ho pshatleha le ho tiisa chip ea lehare

5. E emetsoe ke bolelele ba ho itšeha

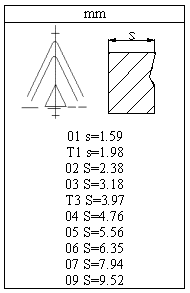

6. Khoutu e emelang botenya ba lehare

7. Khoutu e emelang bohale ba polishing le R angle

Moelelo oa lipalo tse ling

8 e bua ka khoutu e bontšang litlhoko tse khethehileng;

9 e emela khoutu ea tataiso ea phepelo, mohlala, khoutu R e emela phepelo e nepahetseng, khoutu L e emela phepelo e ka ho le letšehali, 'me khoutu ea N e emela phepelo ea mahareng;

10 e emela khoutu ea mofuta oa chip breaking groove;

11 e emela khoutu ea thepa ea k'hamphani ea lisebelisoa;

lebelo la ho seha

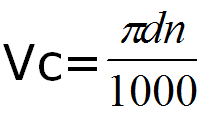

Mokhoa oa ho bala oa lebelo la ho itšeha Vc:

Ka foromo:

D - bophara ba rotary ea workpiece kapa ntlha ea sesebelisoa, yuniti: mm

N - lebelo la ho potoloha la sesebelisoa kapa sesebelisoa, yuniti: r/min

The Lebelo la ho Machining Thread with Ordinary Lathe

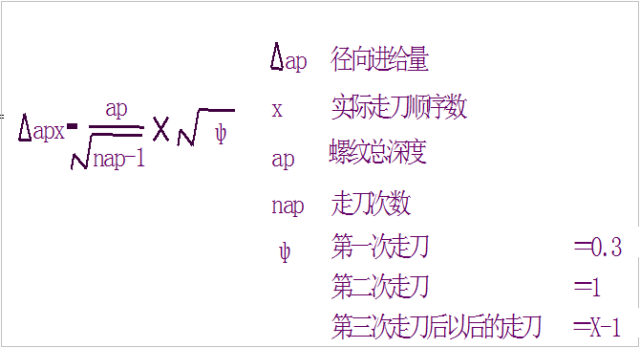

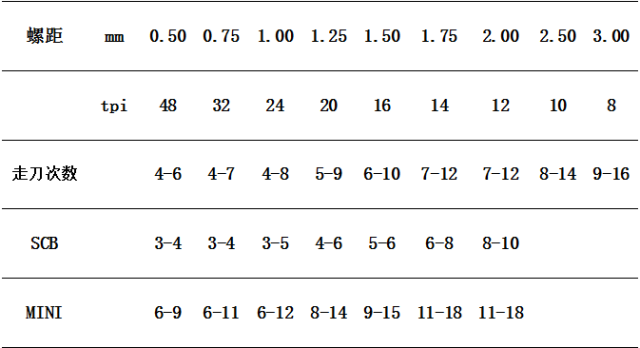

Spindle speed n bakeng sa khoele e thinyetsang.Ha o seha khoele, lebelo la ho ohla la lesela le angoa ke lintlha tse ngata, tse kang boholo ba khoele ea khoele (kapa loto) ea sesebedisoa, litšobotsi tsa ho phahamisa le ho theola koloi ea koloi, le lebelo la ho kenya khoele.Ka hona, bakeng sa litsamaiso tse fapaneng tsa CNC, ho na le liphapang tse itseng lebelong la ho ohla n bakeng sa khoele ea ho thinya.E latelang ke mokhoa oa ho bala lebelo la ho ohla ha o fetola likhoele ho li-lathes tse akaretsang tsa CNC:

Ka foromo:

P - sekontiri sa khoele kapa tataiso ea khoele ea workpiece, unit: mm.

K - inshorense ea coefficient, ka kakaretso 80.

Palo ea botebo bo bong le bo bong ba phepelo bakeng sa khoele ea machining

Palo ea litsela tsa lisebelisoa tsa khoele

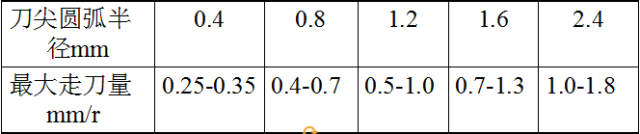

1) Ho sebetsa ka thata

Mokhoa oa ho bala o matla oa phepelo ea mochini o thata: f rough=0.5 R

Moo: R —— ntlha ea sesebelisoa arc radius mm

F -- kaba machining sesebelisoa fepa mm

2) Ho qetela

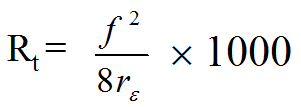

Ka foromo: Rt —— botebo ba contour µ m

F —— Sekhahla sa phepelo mm/r

r ε —— Radius ea sesebelisoa ntlha arc mm

Phapang karohano le ho qetela ho phethola ho latela sekhahla sa phepelo le chip breaking groove

F ≥ 0,36 ho sebetsa ka thata

0.36 > f ≥ 0.17 semi finishing

F < 0.17 qeta ho sebetsa

Ha se thepa ea lehare empa ke chip breaking groove e amang ho sebetsa ka thata le ho qetela ha lehare.Mohatla o bohale o bohale haeba chamfer e ka tlase ho 40um.

Nako ea poso: Nov-29-2022