Iimfuno zezixhobo zomatshini we-CNC kwizinto zesixhobo

Ubunzima obuphezulu kunye nokumelana nokunxiba

Ubunzima becandelo lokusika isixhobo kufuneka libe phezulu kunobunzima bezinto zokusebenza.Ukuphakama kobunzima besixhobo sesixhobo, bhetele ukuxhathisa kwayo ukunxiba.Ukuqina kwesixhobo kwiqondo lobushushu begumbi kuya kuba ngaphezulu kwe-HRC62.Ubunzima bunokuba phezulu kunobo buqhelekileyoCNC Machining iindawo.

Amandla aneleyo kunye nokuqina

Isixhobo sithwala uxinzelelo olukhulu kwinkqubo yokusika ngokugqithiseleyo.Ngamanye amaxesha, isebenza phantsi kweempembelelo kunye neemeko zokungcangcazela.Ukuthintela isixhobo ekuqhekekeni nasekuphuleni, izixhobo zesixhobo kufuneka zibe namandla okwaneleyo kunye nokuqina.Ngokubanzi, amandla okugoba asetyenziselwa ukumela amandla esixhobo, kwaye ixabiso lempembelelo lisetyenziselwa ukumela ukuqina kwesixhobo.

ukumelana nobushushu obuphezulu

Ukumelana nokushisa kubhekiselele ekusebenzeni kwezixhobo zokusebenza ukugcina ubunzima, ukuxhatshazwa, amandla kunye nokuqina phantsi kobushushu obuphezulu.Yisalathisi esiphambili sokulinganisa ukusebenza kokusika kwezixhobo zesixhobo.Le ntsebenzo ikwabizwa ngokuba bubulukhuni obubomvu bezixhobo zesixhobo.

Ukuqhuba kakuhle kwe-thermal

Ubuninzi be-thermal conductivity yesixhobo sesixhobo, ukushisa okungaphezulu kudluliselwa kwisixhobo, esinceda ukunciphisa ukushisa kwesixhobo kunye nokuphucula ukuqina kwesixhobo.

Ukuqhubekeka kakuhle

Ukuze kube lula ukucutshungulwa kunye nokuveliswa kwezixhobo, izixhobo zesixhobo zifuneka ukuba zibe neempawu ezintle zokucwangcisa, ezifana nokubumba, ukuqengqeleka, ukuwelda, ukusika kunye nokusila, iipropati zonyango lobushushu kunye nobushushu obuphezulu bezinto zeplastiki zezixhobo zesixhobo.Kwi-carbide ene-cemented kunye nezixhobo ze-ceramic izixhobo, i-sintering efanelekileyo kunye neempawu zokwenza uxinzelelo nazo ziyafuneka.

Uhlobo lwezixhobo zesixhobo

isantya esiphezulu sentsimbi

Isantya esiphezulu sentsimbi sisixhobo se-alloy sensimbi esakhiwe yi-W, Cr, Mo kunye nezinye izinto ze-alloy.Inozinzo oluphezulu lwe-thermal, amandla aphezulu kunye nokuqina, kunye neqondo elithile lobunzima kunye nokumelana nokunxiba, ngoko ke ifanelekile ukusetyenzwa kweentsimbi ezingenayo i-ferrous kunye nezixhobo ezahlukeneyo zetsimbi.Ukongeza, ngenxa yetekhnoloji yayo elungileyo, ifanelekile ukwenza izixhobo zokwenza izixhobo ezintsonkothileyo, ngakumbi isinyithi sesinyithi esinesantya esiphezulu, esineempawu zemishini ye-anisotropic kunye nokunciphisa ukucima ukuguqulwa, Ilungele ukwenziwa ngokuchanekileyo kunye nezixhobo zokwenza izinto ezinzima.

I-alloy eqinile

I-carbide enesamente inobunzima obuphezulu kunye nokumelana nokunxiba.Xa usikaCNC ukuguqula iindawo, ukusebenza kwayo kubhetele kuneyentsimbi yesantya esiphezulu.Ukuqina kwayo kuphindaphindwe kaninzi ukuya kwamashumi aphindwe kabini oko kwentsimbi enesantya esiphezulu, kodwa ukuqina kwempembelelo yayo kubi.Ngenxa yokusebenza kwayo okugqwesileyo kokusika, isetyenziswa ngokubanzi njengesixhobo sesixhobo.

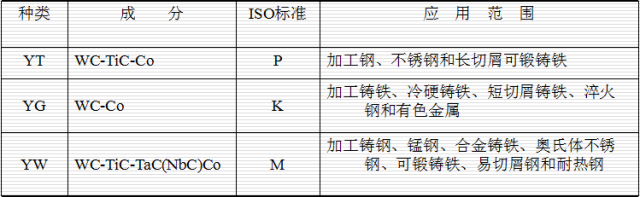

Ukwahlula kunye nokumakishwa kwee-carbides ezine-cemented kwizixhobo zokusika

Iblade ecandiweyo

I-1) Izinto zokugqoka ze-CVD zendlela yi-TiC, eyandisa ukuqina kwezixhobo ze-carbide ze-cemented ngamaxesha angama-1-3.Ubunzima bokugquma;I-edge yokusika ibuthuntu;Kuyanceda ekuphuculeni ubomi besantya.

I-2) Izinto zokugqoka ze-PVD indlela yokubeka umphunga womzimba yi-TiN, i-TiAlN kunye ne-Ti (C, N), ephucula ukuqina kwezixhobo ze-carbide ze-cemented ngamaxesha angama-2-10.Ukwaleka obhityileyo;Uhlangothi olubukhali;Kuyinzuzo ukunciphisa amandla okusika.

★ Ubuninzi bobukhulu bengubo ≤ 16um

CBN kunye nePCD

I-Cubic boron nitride (CBN) Ukuqina kunye ne-thermal conductivity ye-cubic boron nitride (CBN) ingaphantsi kwedayimane kuphela, kwaye inozinzo oluphezulu lwe-thermal kunye nokuzinza okulungileyo kweekhemikhali.Ke ngoko, ifanelekile ukwenza intsimbi eqinile, intsimbi eqinile, i-superalloy kunye ne-cemented carbide.

Idayimani yePolycrystalline (PCD) Xa i-PCD isetyenziswa njengesixhobo sokusika, igalelwa kwi-samente ye-carbide substrate, kwaye inokugqiba ukuguga, ukuqina okuphezulu okungeyontsimbi kunye nezixhobo ezingenayo i-alloy ezifana ne-cemented carbide, i-ceramics, i-silicon ephezulu ye-aluminium alloy.

★ ISO machine clamp blade classification impahla ★

Amalungu entsimbi: P05 P25 P40

Insimbi engenasici: M05 M25 M40

Intsimbi yokuphosa: K05 K25 K30

★ Incinci inani, i-blade inzima ngakumbi, ngcono ukuxhathisa ukunxiba kwesixhobo, kwaye ngakumbi ukuchasana kwempembelelo.

★ Inani elikhulu, i-blade ethambileyo, kokukhona ukuxhathisa impembelelo kunye nokumelana nokunxiba kakubi kwesixhobo.

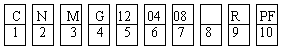

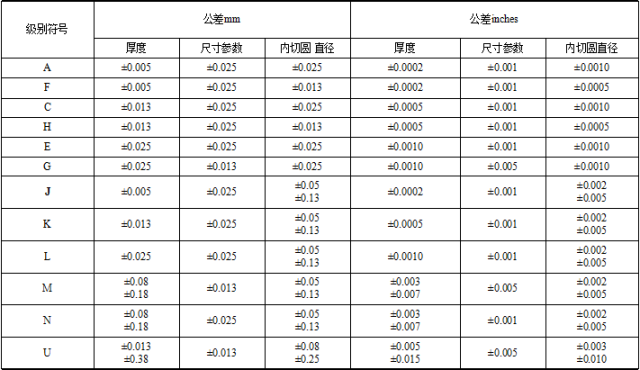

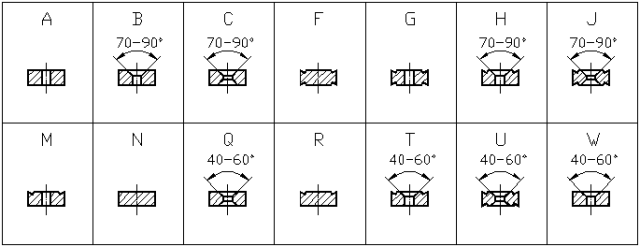

Iguqulelwa kwimodeli ye-blade kunye nemithetho yokumelwa kwe-ISO

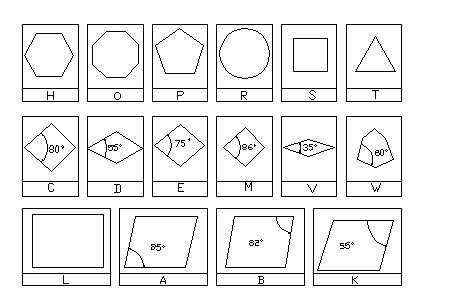

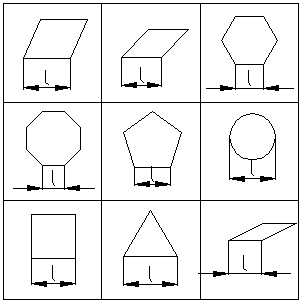

1. Ikhowudi emele imilo yeblade

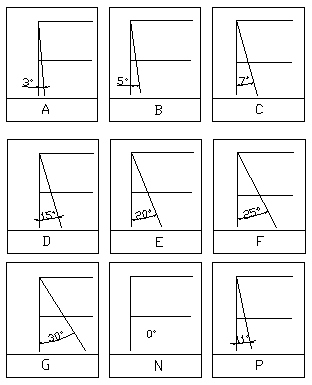

2. Ikhowudi emele i-angle yangasemva ye-main cut edge

3. Ikhowudi emele ukunyamezela kwe-dimensional ye-blade

4. Ikhowudi emele ukuqhekezwa kwetshiphu kunye nefomu yokuyibamba yencakuba

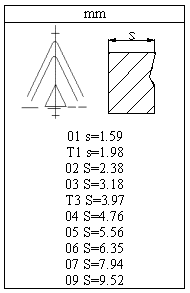

5. Imelwe ngobude bokusika

6. Ikhowudi emele ubukhulu be-blade

7. Ikhowudi emele i-edge yokupholisa kunye ne-R angle

Intsingiselo yamanye amanani

Isi-8 sibhekisa kwikhowudi ebonisa iimfuno ezizodwa;

I-9 imele ikhowudi yesalathiso sesondlo, umzekelo, ikhowudi R imele ukutya okulungileyo, ikhowudi L imele isondlo sasekhohlo, kwaye ikhowudi N imele ukutya okuphakathi;

I-10 imele ikhowudi yohlobo lwe-chip breaking groove;

I-11 imele ikhowudi yezinto eziphathekayo yenkampani yesixhobo;

isantya sokusika

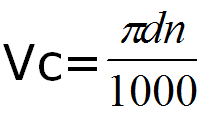

Ifomula yokubala yesantya sokusika Vc:

Kwifomula:

D - i-diameter ye-rotary ye-workpiece okanye i-tip yesixhobo, iyunithi: mm

N - isantya esijikelezayo somsebenzi okanye isixhobo, iyunithi: r/min

Isantya soMsonto woMachining kunye neLathe eqhelekileyo

Isantya sokusonta n sokujika intambo.Xa usika intambo, isantya sokusonta selathe sichatshazelwa zizinto ezininzi, ezinjengobungakanani bepitch yentambo (okanye ilothe) yesixhobo sokusebenza, iimpawu zokuphakamisa nokwehliswa kwemoto yokuqhuba, kunye nesantya sokudibanisa intambo.Ke ngoko, kwiinkqubo ezahlukeneyo ze-CNC, kukho iiyantlukwano ezithile kwisantya sokusonta n sokujika intambo.Oku kulandelayo yifomula yokubala isantya sokusonta xa ujika imisonto kwiileyile ze-CNC ngokubanzi:

Kwifomula:

I-P - i-pitch pitch okanye i-lead ye-workpiece thread, iyunithi: mm.

K - i-inshurensi yomlinganiso, ngokubanzi ngama-80.

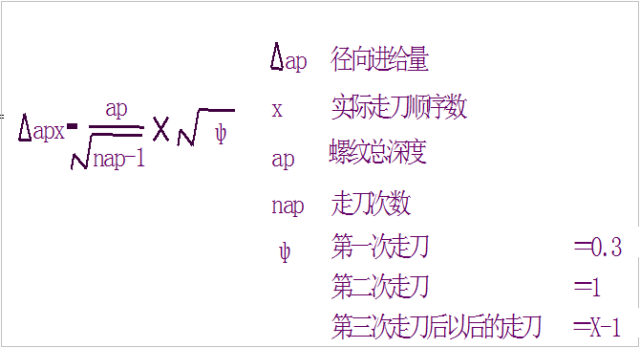

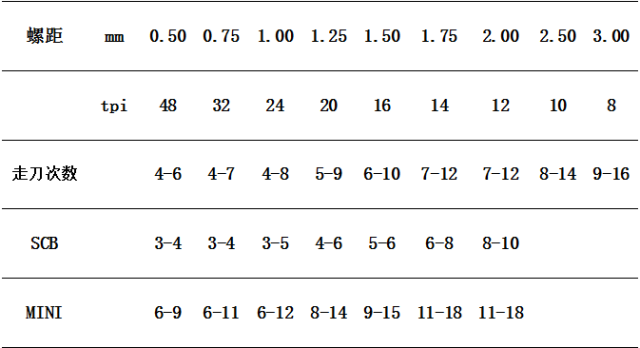

Ukubalwa ubunzulu feed nganye ukuze machining thread

Inani leendlela zesixhobo sokuthunga

1) Umatshini orhabaxa

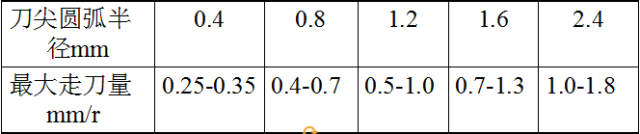

Ifomula yokubala enobungqina bokutya komatshini orhabaxa: f rough=0.5 R

Apho: R —— incam yesixhobo arc radius mm

F —— rough Machining isixhobo feed mm

2) Ukugqiba

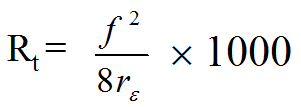

Kwifomula: Rt —— ubunzulu becontour µ m

F —— Umlinganiselo wesondlo mm/r

r ε —— Ireyidi yesixhobo sencam arc mm

Ukwahlula ukujikajika okurhabaxa kunye nokugqiba ngokwesantya sokutya kunye ne-chip breaking groove

F ≥ 0.36 machining rough

0.36 > f ≥ 0.17 isiqingatha sokugqiba

F < 0.17 ukugqiba machining

Ayisiyonto yeblade kodwa yi-chip breaking groove echaphazela uburhabaxa kunye nokugqiba ukwenziwa kweblade.I-edge yokusika ibukhali ukuba i-chamfer ingaphantsi kwe-40um.

Ixesha lokuposa: Nov-29-2022