Malo opangira makina, omwe amadziwikanso kuti malo opangira makina a CNC, ndi chida chokhazikika komanso chosunthika chomwe chimagwiritsidwa ntchito popanga makina osiyanasiyana.

-

Mwachidule: Malo opangira makina amaphatikiza ntchito zingapo kukhala gawo limodzi, kuphatikiza mphero, kubowola, kugogoda, kusanja, ndipo nthawi zina kutembenuka.Zimaphatikiza chida cha makina, chosinthira zida, ndi dongosolo lowongolera kukhala dongosolo limodzi lowonjezera bwino komanso zokolola.

-

Mitundu: Malo opangira makina amabwera m'mitundu yosiyanasiyana, monga vertical Machining centers (VMC) ndi horizontal Machining centers (HMC).Ma VMC ali ndi spindle yolunjika, pomwe ma HMC ali ndi spindle yopingasa.Mtundu uliwonse uli ndi ubwino wake ndipo ndi woyenera ntchito zinazake.

-

Nkhwangwa: Malo opangira makina nthawi zambiri amakhala ndi nkhwangwa zitatu kapena kupitilira apo.Zodziwika kwambiri ndi makina atatu, omwe ali ndi X, Y, ndi Z axs kuti azisuntha mzere.Mitundu yapamwamba imatha kukhala ndi nkhwangwa zina zozungulira (mwachitsanzo, A, B, C) zamakina amitundu yambiri.

-

Kuwongolera kwa CNC: Malo opangira makina amayendetsedwa ndi makina owongolera manambala apakompyuta (CNC).Mapulogalamu a CNC amalola kuwongolera moyenera makinawo, kuphatikiza mayendedwe a zida, mitengo yazakudya, kuthamanga kwa spindle, ndi kutuluka kwazizindikiro.

-

Tool Changer: Malo opangira makina ali ndi zida zosinthira (ATC) zomwe zimalola kusinthanitsa mwachangu komanso kodziwikiratu kwa zida zodulira panthawi yopanga makina.Izi zimathandiza kupanga bwino komanso kosasokonezeka.

-

Kugwira Ntchito: Zida zogwirira ntchito zimasungidwa bwino patebulo la makina opangira makina panthawi yopangira makina.Njira zosiyanasiyana zogwirira ntchito zimagwiritsidwa ntchito, monga ma vises, ma clamp, fixtures, ndi ma pallet system, kutengera ntchito ndi zofunikira.

-

Ntchito: Malo opangira makina amagwiritsidwa ntchito kwambiri m'mafakitale monga zakuthambo, magalimoto, zamankhwala, ndi kupanga wamba.Amagwiritsidwa ntchito pazinthu monga mphero zovuta, kubowola mabowo, kupanga mbiri yeniyeni, ndikupeza kulolerana kolimba.

-

Kupititsa patsogolo: Gawo la makina opanga makina likukula mosalekeza ndi kupita patsogolo kwaukadaulo.Izi zikuphatikiza kusintha kwa kapangidwe ka makina, makina owongolera, matekinoloje a zida zodulira, makina opangira okha, komanso kuphatikiza ndi njira zina zopangira.

Makina opangira makina amaphatikiza mafuta, gasi, magetsi, ndi kuwongolera manambala, ndipo amatha kuzindikira kuphatikizika kwanthawi imodzi kwa ma disks osiyanasiyana, mbale, zipolopolo, makamera, nkhungu ndi magawo ena ovuta ndi zida zogwirira ntchito, ndipo amatha kumaliza kubowola, mphero, kutopa, kukulitsa, reming, Kugogoda kolimba ndi njira zina zimakonzedwa, kotero ndi zida zabwino zopangira makina olondola kwambiri.Nkhaniyi igawana maluso ogwiritsira ntchito malo opangira makina kuchokera kuzinthu izi:

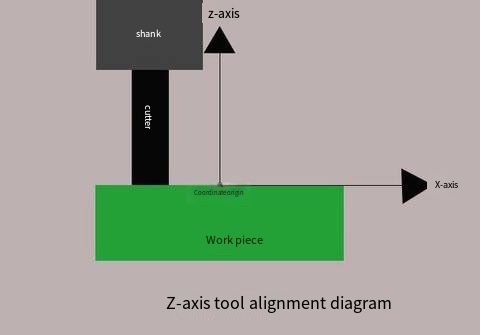

Kodi malo opangira makina amayika bwanji chida?

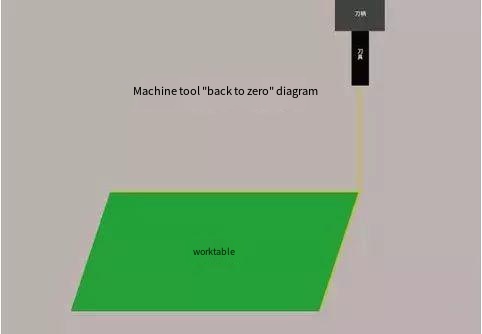

1. Bwererani ku ziro (bwererani ku chiyambi cha chida cha makina)

Musanakhazikitse chidacho, m'pofunika kubwerera ku zero (kubwerera ku chiyambi cha chida cha makina) kuti muchotse deta yogwirizanitsa ntchito yomaliza.Dziwani kuti X, Y, ndi Z nkhwangwa zonse ziyenera kubwerera ku ziro.

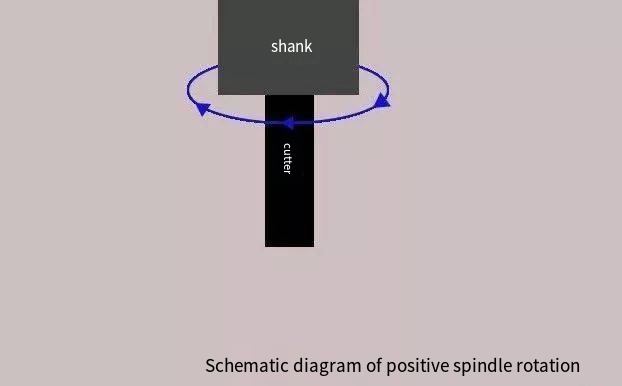

2. Spindle imazungulira kutsogolo

Mu "MDI" mode, spindle imazunguliridwa kutsogolo ndikulowetsa ma code, ndipo liwiro lozungulira limasungidwa pamlingo wapakatikati.Kenako sinthani ku "handwheel" mode, ndikuchita ntchito yoyendetsa chida cha makina posintha ndikusintha liwiro.

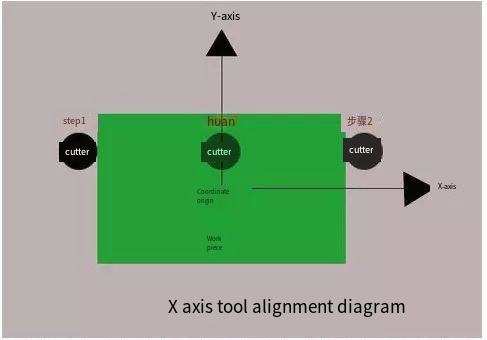

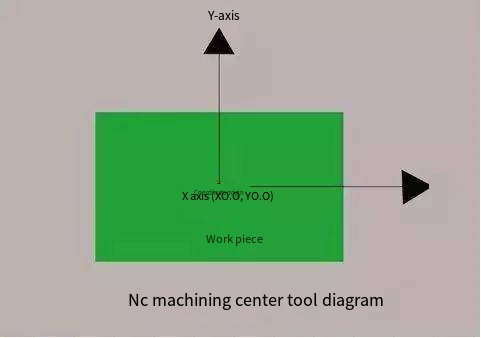

3. Chida chowongolera cha X

Gwiritsani ntchito chidacho kuti mugwire pang'onopang'ono mbali yakumanja ya chogwirira ntchito kuti muchotse makonzedwe achibale a chida cha makina;kwezani chidacho motsatira njira ya Z, kenako sunthani chidacho kumanzere kwa chogwiriracho, ndikusuntha chidacho ndi chogwirira ntchito mpaka kutalika komweko monga kale.Gwirani pang'onopang'ono, kwezani chidacho, lembani mtengo wa X wa mgwirizano wachibale wa chida cha makina, sunthani chidacho mpaka theka la X wachibale, lembani mtengo wa X wa mgwirizano wa makinawo, ndikusindikiza (INPUT). ) kulowa mu coordinate system.

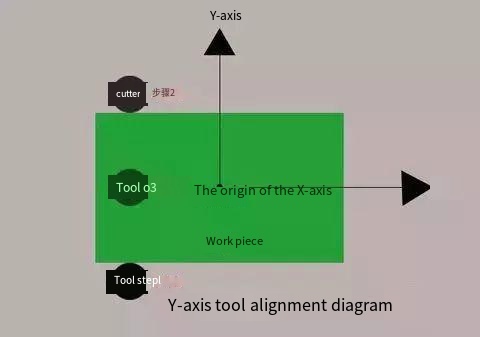

4. Kuyika kwa chida cha Y

Gwiritsani ntchito chidacho kuti mugwire pang'onopang'ono kutsogolo kwa workpiece kuti muchotse makonzedwe apachibale a chida cha makina;kwezani chidacho motsatira njira ya Z, kenako sunthani chida kumbuyo kwa chogwiriracho, ndikusuntha chidacho ndi chogwirira ntchito mpaka kutalika komweko monga kale.Gwirani pang'onopang'ono, kwezani chidacho, lembani mtengo wa Y wa mgwirizano wachibale wa chida cha makina, sunthani chidacho mpaka theka lachibale cha Y, lembani mtengo wa Y wa mgwirizano wa makina onse, ndikusindikiza (INPUT). ) kulowa mu coordinate system.

5. Z yowongolera chida chokhazikitsa

Sunthani chida pamwamba pa workpiece yomwe ikuyang'anizana ndi zero point kumbali ya Z, pang'onopang'ono sunthani chidacho mpaka chikhudze pamwamba pa workpiece mopepuka, lembani mtengo wa Z mu dongosolo logwirizanitsa la chida cha makina panthawiyi. , ndikusindikiza (INPUT) kuti mulowetse mu coordinate system.

6. Kuyimitsa kwa spindle

Imitsani nsongayo kaye, sunthani nsongayo pamalo oyenera, imbani pulogalamu yosinthira, ndipo konzekerani kukonzedwa.

Kodi malo opangira makina amapangidwa bwanji ndi kukonza zida zopunduka?

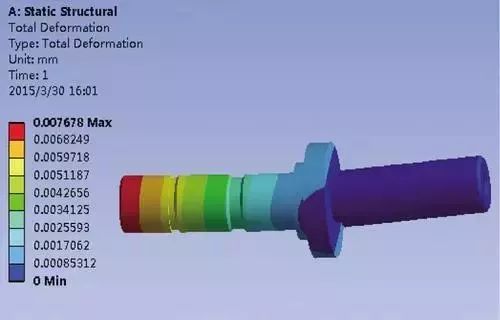

Zaaxis cnc MachiningZigawo zokhala ndi kulemera kopepuka, kusasunthika kosasunthika, ndi mphamvu zofooka, zimapunduka mosavuta ndi mphamvu ndi kutentha panthawi yokonza, ndipo kutsika kwakukulu kwazitsulo kumabweretsa kuwonjezeka kwakukulu kwa mtengo.Pazigawo zotere, choyamba tiyenera kumvetsetsa zomwe zimayambitsa mapindikidwe:

Deformation mokakamiza:

Khoma la mtundu uwu wa mbali ndi woonda, ndipo pansi pa zochita za clamping mphamvu, n'zosavuta kukhala makulidwe osagwirizana pa Machining ndi kudula, ndi elasticity ndi osauka, ndi mawonekedwe a mbali zovuta kubwezeretsa palokha.

Kutentha kwa kutentha:

Chogwiritsira ntchito chimakhala chopepuka komanso chochepa thupi, ndipo chifukwa cha mphamvu ya radial panthawi yodula, imayambitsa kutentha kwa ntchito, motero kumapangitsa kukula kwa workpiece kukhala kolakwika.

Kusintha kwa vibration:

Pansi pa mphamvu yodulira ma radial, magawowa amatha kugwedezeka komanso kusinthika, zomwe zingakhudze kulondola kwa mawonekedwe, mawonekedwe, kulondola kwamalo komanso kuuma kwapamtunda kwa workpiece.

Njira yopangira magawo opunduka mosavuta:

Kwa mbali zopunduka mosavuta zomwe zimayimiridwa ndi mbali zoonda-mipanda, makina othamanga kwambiri ndi kudula ndi kuchuluka kwa chakudya chochepa komanso kuthamanga kwachangu kungagwiritsidwe ntchito kuchepetsa mphamvu yodulira pa workpiece panthawi yokonza, ndipo nthawi yomweyo, kutentha kwakukulu kwambiri. imatayidwa ndi tchipisi towulukira kutali ndi chogwirira ntchito mwachangu kwambiri.Chotsani, potero kuchepetsa kutentha kwa workpiece ndi kuchepetsa mapindikidwe matenthedwe workpiece.

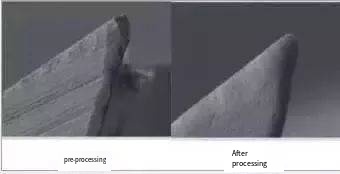

Chifukwa chiyani zida zopangira makina ziyenera kuchotsedwa?

Zida za CNC sizili mwachangu momwe zingathere, chifukwa chiyani chithandizo cha passivation?M'malo mwake, kugwiritsa ntchito zida sizomwe aliyense amamvetsetsa, koma njira yopititsira patsogolo moyo wautumiki wa zida.Limbikitsani mtundu wa zida mwa kusalaza, kupukuta, kubweza ndi njira zina.Izi ndizochitika mwachizolowezi chida chikagwiritsidwa ntchito bwino komanso chisanayambe kupaka.

▲Kufanizirana kwa zida

Mipeniyo imanoledwa ndi gudumu lopera isanamalizidwe, koma kumalitsa kumapangitsa kuti mipata yaying'ono ikhale yosiyana.Pamene makina opangira makina akugwira ntchito yodula kwambiri, kusiyana kwa microscopic kumawonjezeka mosavuta, zomwe zidzafulumizitsa kuvala ndi kuwonongeka kwa chida.Ukadaulo wamakono wodulira uli ndi zofunika kwambiri pa bata ndi kulondola kwa chida, chifukwa chake chida cha CNC chiyenera kupitilira musanayambe kupaka kuonetsetsa kulimba ndi moyo wautumiki wa ❖ kuyanika.Ubwino wa chida passivation ndi:

1. Kanizani chida kuvala thupi

Pa kudula ndondomeko, pamwamba pa chida adzakhala pang'onopang'ono kuvala kutali ndimwambo cnc workpiece, ndipo m'mphepete mwa kudula kumakhalanso kosavuta kusinthika kwa pulasitiki pansi pa kutentha kwakukulu komanso kuthamanga kwambiri panthawi yodula.The passivation mankhwala a chida angathandize chida kusintha rigidity ndi kuteteza chida kutaya ntchito kudula kwake msanga.

2. Sungani mapeto a workpiece

Ma Burrs pamphepete mwa chida amapangitsa kuti zida zivale ndipo pamwamba pa makina opangira makina azikhala ovuta.Pambuyo pa chithandizo cha passivation, m'mphepete mwa chidacho udzakhala wosalala kwambiri, kupukuta kudzachepetsedwa moyenerera, ndipo mapeto a pamwamba a workpiece adzakhalanso bwino.

3. Yabwino poyambira chip kuchotsa

Kupukutira zitoliro za chida kumatha kupititsa patsogolo kukongola kwapamwamba komanso kutulutsa chip.Kusalala kwa chitoliro kumapangitsa kuti chip chisamuke bwino, komanso njira yodulira yokhazikika imatha kuchitika.Pambuyo pa passivation ndi kupukuta kwa CNC chida pakati Machining, mabowo ang'onoang'ono ambiri adzasiyidwa pamwamba.Mabowo ang'onoang'ono awa amatha kuyamwa madzi odula kwambiri panthawi yokonza, zomwe zimachepetsa kwambiri kutentha komwe kumapangidwa panthawi yodula komanso kumathandizira kwambiri kuthamanga kwa makina.

Kodi malo opangira makina amachepetsera bwanji kuuma kwa malo ogwirira ntchito?

The pamwamba roughness wa ziwalo ndi chimodzi mwa mavuto ambiri aCNC makinamalo, zomwe zimasonyeza mwachindunji processing khalidwe.Mmene kulamulira pamwamba roughness wa mbali processing, choyamba tiyenera kupenda mozama zimayambitsa roughness pamwamba, makamaka kuphatikizapo: zida zizindikiro chifukwa pa mphero;matenthedwe matenthedwe kapena pulasitiki mapindikidwe chifukwa kudula kulekana;chida ndi makina pamwamba kukangana pakati.

Posankha roughness pamwamba pa workpiece, sayenera kungokwaniritsa zofunikira za ntchito pamwamba pa gawolo, komanso kuganizira za kulingalira kwachuma.Pansi pa kukumana ndi ntchito yodula, mtengo wokulirapo wa roughness wa pamwamba uyenera kusankhidwa momwe mungathere kuti muchepetse ndalama zopangira.Monga executor wa kudula Machining pakati, chida ayenera kulabadira yokonza tsiku ndi nthawi yake akupera kupewa osayenera pamwamba roughness chifukwa kwambiri zosamveka chida.

Kodi malo opangira makinawo achite chiyani akamaliza ntchitoyo?

Nthawi zambiri, njira zopangira zida zamakina zamakina zimakhala zofanana.Kusiyanitsa kwakukulu ndikuti malo opangira makina amamaliza njira zonse zodulira pogwiritsa ntchito nthawi imodzi ndikuwongolera kokhazikika.Chifukwa chake, malo opangira makinawa amayenera kuchita "Ntchito Zam'mbuyo".

1. Chitani zoyeretsa.Malo opangira makina akamaliza ntchito yodula, ndikofunikira kuchotsa tchipisi munthawi yake, kupukuta mulungu wamakina, ndikusunga chida cha makina ndi chilengedwe choyera.

2. Kuti muyang'ane ndikusintha zowonjezera zowonjezera, choyamba, tcherani khutu kuti muyang'ane chofufutira chamafuta pa njanji yowongolera, ndipo m'malo mwake mutenge nthawi ngati wavala.Yang'anani momwe mafuta opangira mafuta ndi ozizira.Ngati turbidity ichitika, iyenera kusinthidwa munthawi yake.Ngati mulingo wamadzi ndi wotsika kuposa sikelo, uyenera kuwonjezeredwa.

3. Njira yotsekera iyenera kukhala yokhazikika, ndipo magetsi ndi magetsi akuluakulu pagawo lopangira zida zamakina ziyenera kuzimitsidwa.Ngati palibe zochitika zapadera ndi zofunikira zapadera, mfundo yobwerera ku zero poyamba, pamanja, inching, ndi automatic iyenera kutsatiridwa.Malo opangira makinawo ayeneranso kuthamanga pa liwiro lotsika, liwilo lapakati, ndiyeno kuthamanga kwambiri.Nthawi yothamanga kwambiri komanso yapakati sikuyenera kukhala yochepera mphindi 2-3 musanayambe kugwira ntchito.

4. Sinthani ntchito.Sichiloledwa kugogoda, kuwongola kapena kukonza chogwirira ntchito pa chuck kapena pamwamba.M'pofunika kutsimikizira kuticnc mphero zigawondipo chidacho chimamangika musanapitirire ku sitepe yotsatira.Zida za inshuwaransi ndi chitetezo pazida zamakina siziyenera kupatulidwa ndikusunthidwa mosasamala.The kwambiri kothandiza processing kwenikweni otetezeka processing.Monga zida zogwirira ntchito bwino, ntchito ya malo opangira zinthuzo iyenera kukhala yololera komanso yokhazikika ikatsekedwa.Izi sizongokonza ndondomeko yomwe yatsirizidwa, komanso kukonzekera koyambira kotsatira.

Anebon imatha kupereka mayankho apamwamba kwambiri, mtengo wampikisano komanso kampani yabwino kwambiri yamakasitomala.Anebon komwe akupita ndi "Mwabwera kuno movutirapo ndipo tikukupatsani kumwetulira kuti mutenge" kwa Good Wholesale Vendors Precision Part CNC Machining Hard Chrome Plating Gear, Kutsatira mfundo yabizinesi yaying'ono yothandizana, tsopano Anebon yapeza mbiri yabwino pakati pathu. ogula chifukwa cha makampani athu abwino kwambiri, katundu wabwino komanso mitengo yampikisano.Anebon landirani ndi manja awiri ogula ochokera kunyumba kwanu ndi kutsidya kwa nyanja kuti mugwirizane nafe pazotsatira zofanana.

Ogulitsa Ogulitsa Zabwino Kwambiri ku China adapanga chitsulo chosapanga dzimbiri, gawo lolondola kwambiri la 5 oxis Machining ndi ntchito za cnc mphero.Zolinga zazikulu za Anebon ndikupatsa makasitomala athu padziko lonse lapansi zabwino, mtengo wampikisano, kutumiza wokhutira ndi ntchito zabwino kwambiri.Kukhutira kwamakasitomala ndicho cholinga chathu chachikulu.Takulandirani kuti mudzacheze ndi showroom yathu ndi ofesi.Anebon akhala akuyembekezera kukhazikitsa ubale wabizinesi ndi inu.

Nthawi yotumiza: May-22-2023