Iziko lomatshini, elikwabizwa ngokuba liziko lomatshini le-CNC, sisixhobo somatshini esizisebenzelayo nesisebenza ngeendlela ezininzi esisetyenziswa kwishishini lemveliso kwimisebenzi eyahlukeneyo yomatshini.

-

Isishwankathelo: Iziko lomatshini lidibanisa imisebenzi emininzi kwiyunithi enye, kubandakanya ukucola, ukubhola, ukucofa, ukukruqula, kwaye ngamanye amaxesha ukujika.Idibanisa isixhobo somatshini, umtshintshi wesixhobo, kunye nenkqubo yokulawula kwinkqubo enye yokwandisa ukusebenza kakuhle kunye nemveliso.

-

Iindidi: Amaziko omatshini afika kwiindidi ezahlukeneyo, njengamaziko omatshini amileyo (VMC) kunye namaziko omatshini atyebileyo (HMC).Ii-VMCs zinentonga yokusonta ejonge ngokuthe nkqo, ngelixa ii-HMC zinentonga yokusonta ejonge ngokuthe tye.Uhlobo ngalunye lunenzuzo yalo kwaye lufanelekile kwizicelo ezithile.

-

Amazembe: Amaziko Machining ngokuqhelekileyo aneezembe ezintathu okanye ngaphezulu intshukumo.Ezona zixhaphakileyo ngoomatshini bemigca emithathu, enemigca engu-X, Y, kunye no-Z yentshukumo yomgca.Imifuziselo ekwinqanaba eliphezulu inokuba nee-axes ezongezelelweyo ezijikelezayo (umz., A, B, C) kumatshini we-multi-axis.

-

Ulawulo lwe-CNC: Amaziko omatshini alawulwa ziinkqubo zolawulo lwamanani ekhompyutha (CNC).Inkqubo ye-CNC ivumela ulawulo oluchanekileyo lwenkqubo yomatshini, kubandakanywa iintshukumo zesixhobo, amazinga okutya, isantya sokujikeleza, kunye nokuhamba okupholisayo.

-

Isixhobo soTshintsho: Amaziko omatshini axhotyiswe ngokutshintsha izixhobo ezizenzekelayo (ATC) ezivumela utshintshiselwano olukhawulezayo noluzenzekelayo lwezixhobo zokusika ngexesha lomatshini.Oku kwenza imveliso esebenzayo nengenasiphazamiso.

-

Ukusebenza: Izixhobo zokusebenza zigcinwe ngokukhuselekileyo kwitafile yeziko lomatshini okanye ukulungiswa ngexesha lomsebenzi womatshini.Iindlela ezahlukeneyo zokusebenza zisetyenziswa, njenge-vises, i-clamps, i-fixtures, kunye ne-pallet systems, ngokuxhomekeke kwisicelo kunye neemfuno.

-

Izicelo: Amaziko Machining asetyenziswa ngokubanzi kumashishini afana ne-aerospace, izithuthi, unyango, kunye nemveliso jikelele.Baqeshelwe imisebenzi efana neendawo zokusila ezintsonkothileyo, ukugrumba imingxunya, ukwenza iiprofayili ezichanekileyo, kunye nokufezekisa ukunyamezelana okuqinileyo.

-

Ukuqhubela phambili: Ibala lamaziko omatshini lihlala livela ngokuhambela phambili kwetekhnoloji.Oku kubandakanya ukuphuculwa koyilo lomatshini, iinkqubo zokulawula, itekhnoloji yesixhobo sokusika, ukuzenzekelayo, kunye nokudibanisa nezinye iinkqubo zokuvelisa.

Iziko lomatshini lidibanisa i-oyile, igesi, umbane, kunye nolawulo lwamanani, kwaye inokuqonda ukubethelwa kwexesha elinye kwiidiski ezahlukeneyo, iipleyiti, iigobolondo, iikhamera, iimolds kunye nezinye iindawo ezintsonkothileyo kunye nezinto zokusebenza, kwaye inokugqiba ukomba, ukugaya, ukudika, ukwandisa, reming, Ukucofa okungqongqo kunye nezinye iinkqubo ziyacutshungulwa, ngoko sisixhobo esifanelekileyo sokuchaneka okuphezulu.Eli nqaku liza kwabelana ngezakhono zokusetyenziswa kwamaziko omatshini ukusuka kule miba ilandelayo:

Iziko lomatshini lisibeka njani isixhobo?

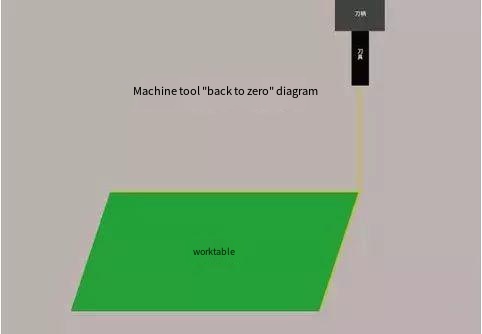

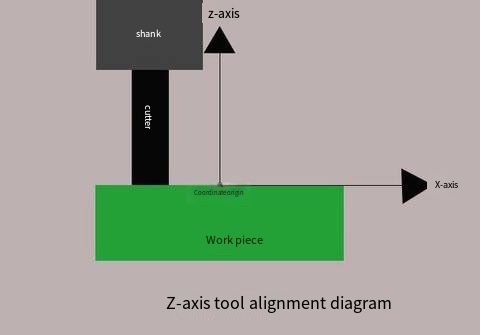

1. Buyela ku-zero (buyela kwimvelaphi yesixhobo somatshini)

Ngaphambi kokumisela isixhobo, kuyimfuneko ukubuyela kwi-zero (buyela kwimvelaphi yesixhobo somatshini) ukwenzela ukuba ucime idatha yokulungelelanisa yokusebenza kokugqibela.Qaphela ukuba i-X, Y, kunye no-Z ii-axes zonke kufuneka zibuyele ku-zero.

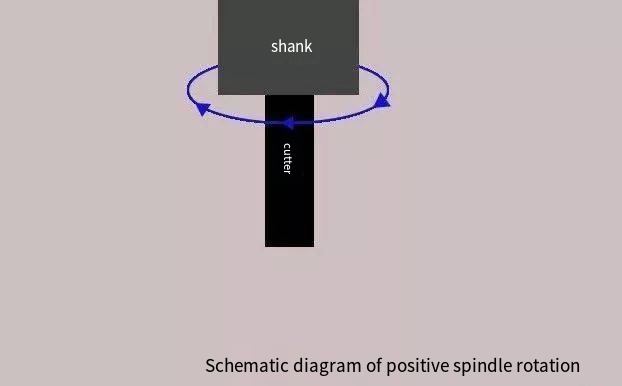

2. I-Spindle ijikeleza phambili

Kwimo ye "MDI", i-spindle ijikeleziswa phambili ngokufaka iikhowudi zomyalelo, kwaye isantya sokujikeleza sigcinwa kwinqanaba eliphakathi.Emva koko tshintshela kwimodi ye "handwheel", kwaye wenze umsebenzi wokuhamba kwesixhobo somatshini ngokutshintsha kunye nokulungelelanisa isantya.

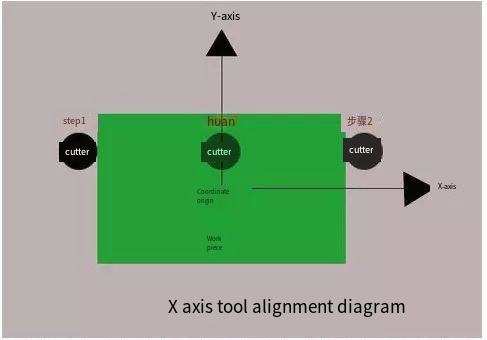

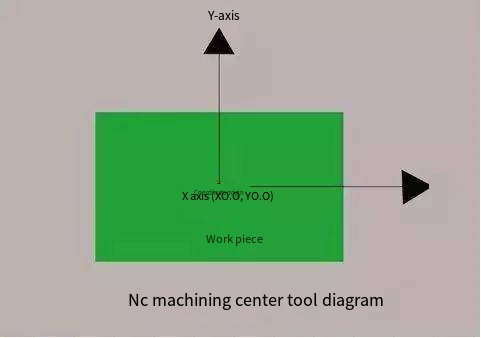

3. X ukusetwa kwesixhobo sesalathiso

Sebenzisa isixhobo ukuba uchukumise kancinci kwicala lasekunene lomsebenzi ukucima ulungelelwaniso olunxulumene nesixhobo somatshini;phakamisa isixhobo ecaleni kolwalathiso lwe-Z, emva koko uhambise isixhobo uye ngasekhohlo kwendawo yokusebenza, kwaye uhambise isixhobo kunye nesixhobo sokusebenza phantsi ukuya kumphakamo ofanayo nangaphambili.Bamba kancinci, phakamisa isixhobo, bhala phantsi ixabiso le-X lolungelelwaniso lwesixhobo somatshini, hambisa isixhobo kwisiqingatha solungelelwaniso lwe-X, bhala phantsi ixabiso le-X lolungelelwaniso olupheleleyo lwesixhobo somatshini, kwaye ucinezele (INPUT). ) ukufaka inkqubo yolungelelwaniso.

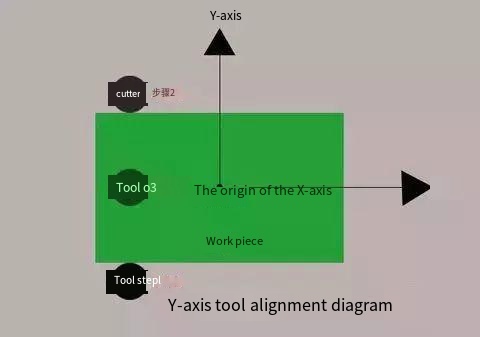

4. Ulungiselelo lwesixhobo sesalathiso

Sebenzisa isixhobo ukubamba ngobunono phambi kwendawo yokusebenza ukucima ulungelelwaniso olunxulumene nesixhobo somatshini;phakamisa isixhobo ecaleni kolwalathiso lwe-Z, emva koko uhambise isixhobo ngasemva kwendawo yokusebenza, kwaye uhambise isixhobo kunye nomsebenzi wezantsi ukuya kumphakamo ofanayo nangaphambili.Chukumisa kancinci, phakamisa isixhobo, bhala phantsi ixabiso le-Y lolungelelwaniso lwesixhobo somatshini, hambisa isixhobo kwisiqingatha solungelelwaniso lwe-Y, bhala phantsi ixabiso le-Y lolungelelwaniso olupheleleyo lwesixhobo somatshini, kwaye ucinezele (INPUT ) ukufaka inkqubo yolungelelwaniso.

5. Ukusetha isixhobo se-Z

Shenxisa isixhobo kumphezulu womsebenzi ojongene nenqaku elingu-zero kwicala lika-Z, hambisa isixhobo ngokucothayo de sichukumise umphezulu wendawo yokusebenza kancinci, bhala ixabiso le-Z kwinkqubo yolungelelwaniso yesixhobo somatshini ngeli xesha. , kwaye cinezela (INPUT) ukufaka igalelo kwindlela yolungelelaniso.

6. Ukumisa i-spindle

Misa i-spindle kuqala, hambisa i-spindle kwindawo efanelekileyo, fowunela inkqubo yokucubungula, kwaye ulungiselele ukusetyenzwa okusesikweni.

Ingaba iziko lomatshini livelisa kwaye lisebenza njani iindawo ezinokukhubazeka?

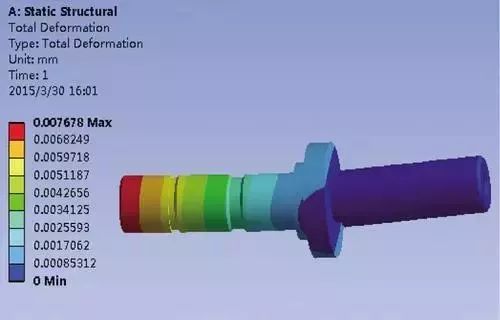

Kubai-axis cnc machiningiindawo ezinobunzima obulula, ubungqongqo obuhlwempuzekileyo, kunye namandla abuthathaka, zikhubazeka ngokulula ngamandla kunye nobushushu ngexesha lokusetyenzwa, kwaye izinga eliphezulu lokusetyenzwa kwenkunkuma likhokelela ekwenyukeni okukhulu kweendleko.Kwiindawo ezinjalo, kufuneka siqale siqonde oonobangela botshintsho:

Ukuguqulwa okuphantsi kwamandla:

Udonga lwalolu hlobo lwamacandelo luncinci, kwaye phantsi kwesenzo sokunyanzelisa amandla, kulula ukuba nobukhulu obungalinganiyo ngexesha lokucoca kunye nokusika, kwaye i-elasticity ihlwempuzekile, kwaye imilo yamacandelo kunzima ukuyibuyisela ngokwayo.

Utshintsho lobushushu:

I-workpiece ilula kwaye incinci, kwaye ngenxa yamandla e-radial ngexesha lokusika, iya kubangela ukuguqulwa kwe-thermal ye-workpiece, ngaloo ndlela yenza ubungakanani bomsebenzi obungachanekanga.

Ukuguqulwa kweVibration:

Ngaphantsi kwesenzo samandla okusika i-radial, iinxalenye zixhomekeke kwi-vibration kunye nokuguqulwa, okuya kuchaphazela ukuchaneka kwe-dimensional, imilo, ukuchaneka kwendawo kunye nobunzima bomhlaba bomsebenzi.

Indlela yokucubungula yamalungu akhubazeka lula:

Kwiindawo ezikhubazekayo ngokulula ezimelwe ngamacandelo amancinci, i-high-speed machining kunye nokusika ngesantya esincinci sokutya kunye nesantya esiphezulu sokusika singasetyenziselwa ukunciphisa amandla okusika kwi-workpiece ngexesha lokucubungula, kwaye kwangaxeshanye, uninzi lobushushu bokusika. ichithwa ziitshiphusi ezibhabha zisuka kwindawo yokusebenza ngesantya esiphezulu.Thatha, ngaloo ndlela unciphisa ubushushu bomsebenzi kunye nokunciphisa i-thermal deformation ye-workpiece.

Kutheni kufuneka kugqitywe izixhobo zeziko lomatshini?

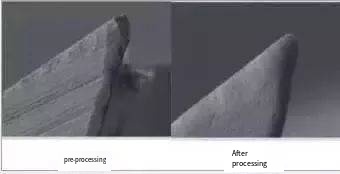

Izixhobo ze-CNC azikho ngokukhawuleza, kutheni unyango lwe-passivation?Enyanisweni, ukugqithiswa kwesixhobo akusiyo into eqondwa ngumntu wonke, kodwa indlela yokuphucula ubomi benkonzo yezixhobo.Ukuphucula umgangatho wesixhobo ngokugudisa, ukupolishwa, ukuchithwa kunye nezinye iinkqubo.Le yinkqubo eqhelekileyo emva kokuba isixhobo sicolwe kakuhle naphambi kokugquma.

▲Ukuthelekiswa kwesixhobo sokugqitha

Iimela zilolwa ngevili lokusila phambi komkhiqizo ogqityiweyo, kodwa inkqubo yokulolwa iya kubangela izithuba ezincinci kumanqanaba ahlukeneyo.Xa i-machining center yenza i-high-speed cutting, i-gap microscopic iya kwandiswa ngokulula, eya kukhawulezisa ukugqoka kunye nomonakalo wesixhobo.Itekhnoloji yanamhlanje yokusika ineemfuno ezingqongqo kuzinzo kunye nokuchaneka kwesixhobo, ngoko ke isixhobo se-CNC kufuneka sigqitywe ngaphambi kokugquma ukuze kuqinisekiswe ukuqina kunye nobomi benkonzo yokugquma.Iingenelo zokugqitha isixhobo zezi:

1. Ukuxhathisa isixhobo sokunxiba

Ngexesha lenkqubo yokusika, umphezulu wesixhobo uya kugqithwa ngokuthe ngcembei-cnc workpiece yesiko, kwaye i-cut cut iphinde ixhomekeke kwi-deformation yeplastiki phantsi kobushushu obuphezulu kunye noxinzelelo oluphezulu ngexesha lokusika.Ukunyangwa kwe-passivation yesixhobo kunokunceda isixhobo sokuphucula ukuqina kwayo kwaye sithintele isixhobo ukuba silahlekelwe yintsebenzo yayo yokusika ngaphambi kwexesha.

2. Gcina isiphelo se-workpiece

IiBurrs kumda wokusika wesixhobo ziya kubangela ukunxiba kwesixhobo kwaye umphezulu womsebenzi owenziwe ngoomatshini uya kuba rhabaxa.Emva kokunyangwa kwe-passivation, umda wokusika wesixhobo uya kuba lula kakhulu, ukutshiza kuya kuncitshiswa ngokufanelekileyo, kwaye ukugqitywa komphezulu we-workpiece kuya kuphuculwa.

3. Ukususwa kwetshiphu yegroove

Ukukhazimlisa izixhobo zefluti kunokuphucula umgangatho womphezulu kunye nokusebenza kokukhutshwa kwetshiphu.Okukhona ugudileyo umphezulu wefluti, kokukhona ukukhutshwa kwetshiphu, kunye nenkqubo yokusikwa engaguqukiyo inokufezekiswa.Emva kokupasa kunye nokupholishwa kwesixhobo se-CNC kwiziko lomatshini, imingxuma emininzi encinci iya kushiywa phezu komhlaba.Le mingxunya mincinci inokufunxa ngakumbi ulwelo lokusika ngexesha lokucutshungulwa, okunciphisa kakhulu ubushushu obuveliswa ngexesha lokusika kwaye iphucule kakhulu isantya sokusebenza komatshini.

Iziko lomatshini linciphisa njani uburhabaxa bomphezulu wesixhobo sokusebenza?

Uburhabaxa bomphezulu bamalungu yenye yeengxaki eziqhelekileyo zeCNC machiningamaziko, ebonisa ngokuthe ngqo umgangatho wokucubungula.Indlela yokulawula uburhabaxa bomphezulu wokulungiswa kwamalungu, kufuneka siqale sihlalutye nzulu oonobangela boburhabaxa bomphezulu, ikakhulu kubandakanywa: iimpawu zesixhobo ezibangelwa ngexesha lokusila;i-thermal deformation okanye i-plastic deformation ebangelwa ukuhlukana kokusika;isixhobo kunye nomatshini wokubetha umphezulu phakathi.

Xa ukhetha ubuninzi bomphezulu we-workpiece, akufanele kufezekise iimfuno zokusebenza kwendawo yecandelo, kodwa kuqwalaselwe ingqiqo yezoqoqosho.Ngaphantsi kwesiseko sokuhlangana nomsebenzi wokusika, ixabiso elikhulu lereferensi yobunzima bomphezulu kufuneka likhethwe kangangoko ukunciphisa iindleko zokuvelisa.Njengomabi weziko lomatshini wokusika, isixhobo kufuneka sinikele ingqalelo ekugcinweni kwemihla ngemihla kunye nokusila ngexesha elifanelekileyo ukuphepha uburhabaxa obungafanelanga bomhlaba obubangelwa sisixhobo esibi kakhulu.

Kufuneka lenze ntoni iziko lomatshini emva kokugqiba umsebenzi?

Ngokubanzi, iinkqubo zokusetyenzwa kwesixhobo somatshini kumaziko omatshini ziphantse zifane.Umahluko omkhulu kukuba iziko lomatshini ligqibezela zonke iinkqubo zokusika ngokusebenzisa i-clamping yexesha elinye kunye nomatshini ozenzekelayo oqhubekayo.Ke ngoko, iziko lomatshini kufuneka lenze "umsebenzi osemva".

1. Yenza unyango lokucoca.Emva kokuba iziko lomatshini ligqibe umsebenzi wokusika, kuyimfuneko ukususa iitshiphusi ngexesha, usule uthixo womatshini, kwaye ugcine isixhobo somatshini kunye nokusingqongileyo kucocekile.

2. Ukuhlolwa kunye nokutshintshwa kwezinto ezincedisayo, okokuqala, qwa lasela ukuba ukhangele i-oil wiper kwi-rail yesikhokelo, kwaye uyitshintshe ngexesha ukuba igugile.Jonga ubume beoyile yokuthambisa kunye nesipholisi.Ukuba i-turbidity iyenzeka, kufuneka itshintshwe ngexesha.Ukuba umgangatho wamanzi ungaphantsi komlinganiselo, kufuneka wongezwe.

3. Inkqubo yokuvala kufuneka ibekwe emgangathweni, kwaye unikezelo lwamandla kunye nombane oyintloko kwiphaneli yokusebenza yesixhobo somatshini kufuneka icinywe ngokulandelelana.Ukungabikho kweemeko ezikhethekileyo kunye neemfuno ezikhethekileyo, umgaqo wokubuyela kwi-zero kuqala, i-manual, i-inching, kunye ne-automatic kufuneka ilandelwe.Iziko lomatshini kufuneka libaleke ngesantya esiphantsi, isantya esiphakathi, emva koko sibaleke ngesantya esiphezulu.Ixesha eliphantsi kunye nesantya esiphakathi akufanele libe ngaphantsi kwemizuzu engama-2-3 ngaphambi kokuqala ukusebenza.

4. Ukulungelelanisa umsebenzi.Akuvumelekanga ukunkqonkqoza, ukulungisa okanye ukulungisa i-workpiece kwi-chuck okanye phezulu.Kuyimfuneko ukuqinisekisa ukubaiindawo zokugaya ze-cnckwaye isixhobo siyabotshwa phambi kokuba siqhubele phambili kwinyathelo elilandelayo.I-inshurensi kunye nezixhobo zokukhusela ukhuseleko kwisixhobo somatshini akufanele zichithwe kwaye zihanjiswe ngaphandle kwesizathu.Eyona ndlela isebenzayo kukuqhubekeka ngokukhuselekileyo.Njengesixhobo sokusebenza esisebenzayo, ukusebenza kweziko lokucubungula kufuneka kube nengqiqo kwaye kusemgangathweni xa ivaliwe.Oku akukona nje ukugcinwa kwenkqubo egqityiweyo yangoku, kodwa kunye nokulungiswa kwesiqalo esilandelayo.

I-Anebon inokubonelela ngokulula ngezisombululo ezikumgangatho ophezulu, ixabiso elikhuphisanayo kunye neyona nkampani ingcono yabathengi.Indawo ekufikela kuyo i-Anebon “Uza apha ngobunzima kwaye sikunika uncumo oluzokuthatha” kubathengisi abaLungileyo abaLungileyo abaLungileyo kwiNdawo yeCNC Machining Hard Chrome Plating Gear, Ukubambelela kumgaqo weshishini elincinci leenzuzo ezifanayo, ngoku iAnebon iphumelele igama elihle phakathi kwethu. abathengi ngenxa yeenkampani zethu ezilungileyo, iimpahla ezisemgangathweni kunye nokhuphiswano lwamaxabiso.I-Anebon yamkele ngokufudumeleyo abathengi abasuka ekhayeni lakho naphesheya kweelwandle ukusebenzisana nathi ukufumana iziphumo ezifanayo.

Good Abathengisi China ngomatshini intsimbi stainless, ngokuchanekileyo 5 axis machining inxalenye kunye neenkonzo cnc milling.Ezona njongo ziphambili ze-Anebon kukubonelela abathengi bethu kwihlabathi liphela ngomgangatho olungileyo, ixabiso elikhuphisanayo, unikezelo olwaneleyo kunye neenkonzo ezibalaseleyo.Ukwaneliseka koMthengi yeyona njongo yethu iphambili.Siyakwamkela ukuba undwendwele igumbi lethu lomboniso kunye neofisi.I-Anebon ijonge phambili ekusekeni ubudlelwane beshishini nawe.

Ixesha lokuposa: May-22-2023