Lub fixture tsim yog feem ntau nqa tawm raws li cov kev cai ntawm ib tug tej yam txheej txheem tom qab lub machining txheej txheem ntawmcnc machining qhov chawthiabcnc tig qhov chawyog formulated.Thaum tsim cov txheej txheem, qhov ua tau ntawm fixture realization yuav tsum tau txiav txim siab tag nrho, thiab thaum tsim fixtures, yog tias tsim nyog, cov lus qhia rau kev hloov kho ntawm tus txheej txheem kuj tuaj yeem thov.Qhov zoo ntawm qhov tsim ntawm lub fixture yuav tsum tau ntsuas los ntawm seb nws puas tuaj yeem lav qhov kev ua haujlwm zoo ntawm cov khoom ua haujlwm, kev ua haujlwm siab, tus nqi qis, yooj yim nti tshem tawm, kev nyab xeeb kev ua haujlwm, txuag hluav taws xob, thiab kev tsim khoom yooj yim thiab txij nkawm.

1. Cov hauv paus ntsiab lus ntawm kev tsim kho

1. Txaus siab rau kev ruaj ntseg thiab kev cia siab ntawm workpiece positioning thaum siv;

2. Muaj txaus bearing los yog clamping lub zog los xyuas kom meej cov kev ua ntawm lub workpiece ntawm lub fixture;

3. Ua tau raws li qhov yooj yim thiab ceev ua haujlwm hauv cov txheej txheem clamping;

4. Cov khoom tsis zoo yuav tsum muaj cov qauv uas tuaj yeem hloov tau sai, thiab nws yog qhov zoo tshaj kom tsis txhob siv lwm yam cuab yeej thaum muaj xwm txheej txaus;

5. Txaus siab rau qhov kev cia siab ntawm qhov rov ua haujlwm ntawm qhov khoom siv thaum lub sijhawm hloov lossis hloov txheej txheem;

6. Zam cov qauv tsim thiab cov nqi siab kom ntau li ntau tau;

7. Xaiv cov khoom siv raws li cov khoom sib xyaw kom ntau li ntau tau;

8. Tsim lub systematization thiab standardization ntawm lub tuam txhab cov khoom sab hauv.

2. Kev paub yooj yim ntawm kev tsim kho

Lub tshuab cuab yeej cuab tam zoo tshaj plaws yuav tsum ua tau raws li cov hauv qab no:

1. Los xyuas kom meej qhov tseeb machining ntawm lub workpiece, tus yuam sij kom ntseeg tau tias lub machining raug yog xaiv kom raug qhov chaw datum, txoj kev muab tso rau thiab qhov chaw ntawm cov khoom.Yog tias tsim nyog, nws yog ib qho tsim nyog los txheeb xyuas qhov yuam kev ntawm qhov chaw.Nws tseem yog ib qho tsim nyog yuav tsum tau them sai sai rau qhov cuam tshuam ntawm cov qauv ntawm lwm qhov chaw hauv qhov kev sib tw ntawm qhov tseeb machining.Los xyuas kom meej tias lub fixture tuaj yeem ua tau raws li qhov xav tau ntawm machining qhov tseeb ntawm lub workpiece.

2. Txhawm rau txhim kho kev tsim khoom, qhov nyuaj ntawm cov khoom siv tshwj xeeb yuav tsum tau ua kom haum rau lub peev xwm ntau lawm, thiab ntau yam ceev thiab ua haujlwm clamping mechanisms yuav tsum tau siv ntau li ntau tau los xyuas kom meej tias kev ua haujlwm yooj yim, ua kom lub sij hawm luv luv, thiab txhim kho kev tsim khoom.

3. Cov qauv ntawm qhov tshwj xeeb fixture nrog cov txheej txheem kev ua tau zoo yuav tsum yog qhov yooj yim thiab tsim nyog, uas yooj yim rau kev tsim, sib dhos, hloov kho, tshuaj xyuas thiab tu.

4. Cov cuab yeej siv nrog kev ua haujlwm zoo yuav tsum muaj lub zog txaus thiab nruj, thiab kev ua haujlwm yuav tsum yooj yim, txuag zog, nyab xeeb thiab txhim khu kev qha.Raws li qhov kev pom zoo tias lub hom phiaj tau tso cai thiab muaj kev lag luam thiab siv tau, cov cuab yeej clamping xws li pneumatic thiab hydraulic siab yuav tsum tau siv ntau npaum li qhov ua tau los txo qis kev siv zog ntawm tus neeg teb xov tooj.Lub fixture tseem yuav pab txhawb kev tshem tawm cov nti.Yog tias tsim nyog, cov qauv tshem tawm cov nti tuaj yeem raug teeb tsa los tiv thaiv cov nti los ntawm kev ua haujlwm ntawm qhov chaw ua haujlwm thiab ua rau lub cuab yeej ua kom tsis zoo, thiab tiv thaiv kom tsis txhob cuam tshuam ntawm cov chips los ntawm kev ua kom sov ntau thiab ua rau deformation ntawm cov txheej txheem.

5. Qhov tshwj xeeb fixture nrog kev lag luam zoo yuav tsum siv cov khoom siv thiab cov qauv tsim kom ntau li ntau tau, thiab siv zog kom muaj cov qauv yooj yim thiab siv tau yooj yim los txo cov nqi tsim khoom.Yog li ntawd, qhov tsim nyog kev tshawb fawb thiab kev lag luam ntawm cov txheej txheem fixture yuav tsum tau ua raws li qhov kev txiav txim thiab lub peev xwm tsim khoom thaum lub sijhawm tsim, txhawm rau txhim kho cov txiaj ntsig kev lag luam ntawm cov khoom siv hauv kev tsim khoom.

3. Txheej txheem cej luam ntawm standardization ntawm tooling thiab fixture tsim

1. Cov txheej txheem thiab cov kauj ruam ntawm kev tsim kho

Kev npaj ua ntej tsim Cov khoom qub rau kev tsim kho muaj xws li hauv qab no:

a) Cov ntaub ntawv tseem ceeb xws li daim ntawv ceeb toom tsim, ib feem ntawm cov khoom tiav tiav, kos duab kos duab thiab cov txheej txheem, nkag siab txog cov txheej txheem kev ua haujlwm ntawm txhua tus txheej txheem, qhov chaw thiab clamping scheme, ua cov ntsiab lus ntawm cov txheej txheem dhau los, qhov khoob, cov cuab yeej siv tshuab thiab cov cuab yeej siv hauv ua, Tshuaj ntsuam xyuas cov cuab yeej, machining nyiaj pub dawb thiab txiav nyiaj, thiab lwm yam .;

b) Nkag siab txog cov khoom tsim tawm thiab qhov xav tau ntawm cov khoom siv;

c) Nkag siab txog qhov tseem ceeb ntawm kev ua haujlwm, kev ua haujlwm, kev qhia tshwj xeeb, qhov tseeb thiab qhov sib cuag ntawm cov qauv txuas nrog lub fixture, thiab lwm yam ntawm cov cuab yeej siv tshuab;

d) Cov khoom lag luam ntawm cov khoom siv rau cov khoom siv.

2. Cov teeb meem suav nrog hauv kev tsim cov khoom siv

Fixture tsim feem ntau muaj ib qho qauv, muab cov neeg xav tias cov qauv tsis nyuaj, tshwj xeeb tshaj yog tam sim no qhov nrov ntawm hydraulic fixtures zoo heev simplifies tus thawj mechanical qauv, tab sis yog hais tias tsis muaj cov ntsiab lus xav tau thaum lub sij hawm tsim txheej txheem, tsis tsim nyog teeb meem yuav. inevitably tshwm sim:

a) Qhov nyiaj pub dawb ntawm lub workpiece yuav tsum ua tiav.Qhov loj ntawm qhov khoob loj dhau, ua rau muaj kev cuam tshuam.Yog li ntawd, nws yog ib qho tsim nyog los npaj cov duab ntxhib ua ntej tsim.Cia qhov chaw txaus.

b) nti tshem tawm smoothness ntawm fixture.Vim tias qhov chaw ua haujlwm tsawg ntawm cov cuab yeej siv lub tshuab thaum tsim, lub fixture feem ntau tsim nyob rau hauv ib qho chaw me me.Nyob rau lub sijhawm no, nws feem ntau tsis quav ntsej tias cov ntaub ntawv hlau tsim tawm thaum lub sijhawm machining txheej txheem sib sau ua ke hauv lub ces kaum tuag ntawm cov khoom siv, suav nrog cov dej tsis zoo ntawm cov kua txiav, uas yuav ua rau muaj teeb meem yav tom ntej.Kev ua haujlwm coj teeb meem ntau heev.Yog li ntawd, thaum pib ntawm cov txheej txheem tiag tiag, cov teeb meem tshwm sim thaum lub sijhawm ua haujlwm yuav tsum tau txiav txim siab.Tom qab tag nrho, lub fixture yog raws li kev txhim kho efficiency thiab yooj yim rau kev khiav hauj lwm.

c) Tag nrho qhov qhib ntawm lub fixture.Tsis quav ntsej qhov qhib ua rau nws nyuaj rau tus neeg teb xov tooj rau nruab daim npav, uas yog siv sijhawm thiab siv zog, thiab tus tsim yog taboo.

d) Cov ntsiab cai theoretical ntawm kev tsim kho.Txhua txheej txheej yuav tsum tau mus txog ntau lub sij hawm ntawm clamping thiab loosening kev ua, yog li nws yuav ua tau raws li tus neeg siv cov kev xav tau thaum pib, tab sis cov khoom sib txuas ntxiv yuav tsum muaj nws qhov tseeb tuav, yog li tsis txhob tsim ib yam dab tsi uas tawm tsam txoj cai.Txawm hais tias koj tuaj yeem ua tam sim no los ntawm koob hmoov, nws yuav tsis kav ntev.Kev tsim qauv zoo yuav tsum sawv qhov kev sim ntawm lub sijhawm.

e) Replaceability ntawm positioning ntsiab.Lub hauv paus chaw yog hnyav hnyav, yog li kev hloov pauv sai thiab yooj yim yuav tsum tau xav txog.Nws yog qhov zoo tshaj kom tsis txhob tsim nws ua ib feem loj.

Kev sib sau ntawm kev tsim kho fixture yog qhov tseem ceeb heev.Qee zaum kev tsim qauv yog ib yam, tab sis nws yog lwm yam hauv kev siv tswv yim, yog li kev tsim qauv zoo yog cov txheej txheem txuas ntxiv mus thiab cov ntsiab lus.

Feem ntau siv fixtures feem ntau muab faib ua hom hauv qab no raws li lawv txoj haujlwm:

01 clamping pwm

02 Drilling thiab milling tooling

03 CNC, ntsuas chuck

04 Gas test, dej ntsuas cov cuab yeej

05 Trimming thiab xuas nrig ntaus tooling

06 vuam tooling

07 Polishing fixture

08 Cov cuab yeej sib dhos

09 pad luam ntawv, laser engraving tooling

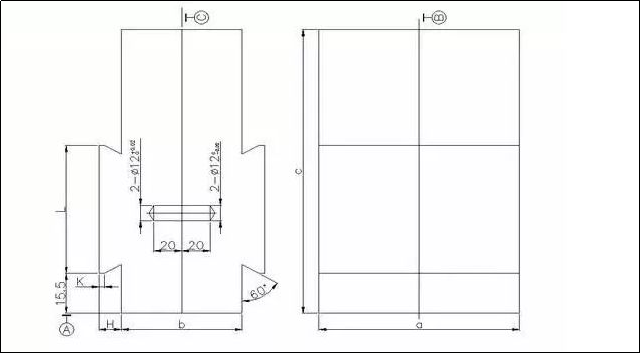

01 clamping pwm

Txhais: Ib qho cuab yeej rau kev tso thiab clamping nrog cov khoom zoo

Cov ntsiab lus tsim:

1. Hom clamping pwm no tsuas yog siv rau vise, thiab nws qhov ntev tuaj yeem txiav raws li qhov xav tau;

2. Lwm qhov chaw pabcuam tuaj yeem tsim los ntawm cov pwm clamping, thiab cov pwm clamping feem ntau txuas nrog vuam;

3. Daim duab saum toj no yog daim duab yooj yim, thiab qhov loj ntawm cov pwm kab noj hniav yog txiav txim siab los ntawm qhov xwm txheej tshwj xeeb;

4. Tightly phim lub positioning tus pin nrog ib txoj kab uas hla ntawm 12mm ntawm qhov tsim nyog txoj hauj lwm ntawm lub movable pwm, thiab positioning lub qhov nyob rau hauv tus coj txoj hauj lwm ntawm lub taag pwm slides kom haum rau positioning tus pin;

5. Lub rooj sib txoos kab noj hniav yuav tsum tau offset thiab loj los ntawm 0.1mm raws li tus qauv txheej txheem ntawm daim duab ntxhib yam tsis muaj shrinkage thaum tsim.

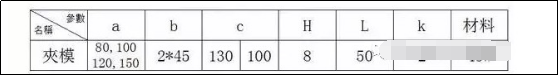

02 Drilling thiab milling tooling

Cov ntsiab lus tsim:

1. Yog tias tsim nyog, qee qhov chaw pabcuam pabcuam tuaj yeem tsim los ntawm cov tub ntxhais ruaj khov thiab nws cov phaj ruaj khov;

2. Cov duab saum toj no yog daim duab qhia yooj yim, thiab qhov xwm txheej tiag tiag yuav tsum tau tsim raws li cov qauv khoom;

3. Lub tog raj kheej nyob ntawm qhov loj ntawm cov khoom thiab kev ntxhov siab thaum ua, thiab SDA50X50 feem ntau siv;

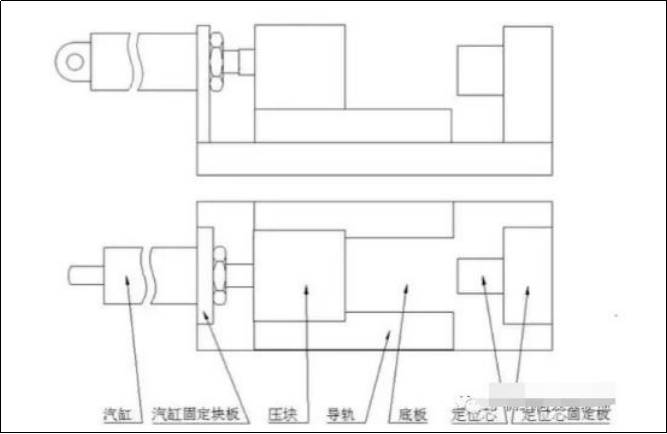

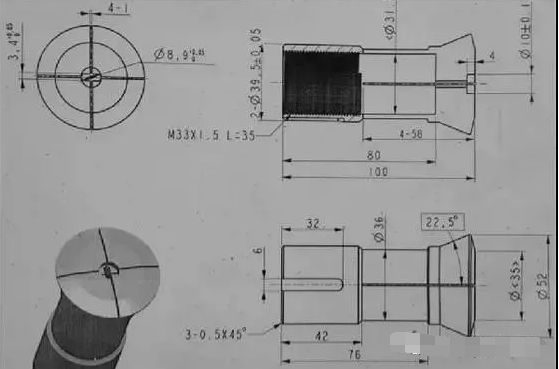

03 CNC, ntsuas chuck

CNC tshuab dhos

Inner collet

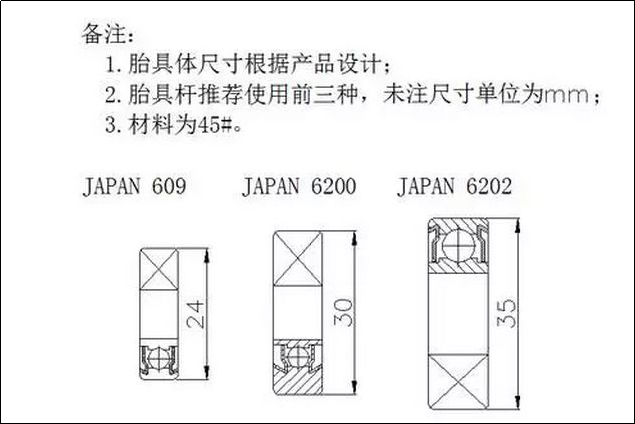

Cov ntsiab lus tsim:

1. Qhov loj me uas tsis tau cim rau hauv daim duab saum toj no yog txiav txim siab raws li qhov loj ntawm lub qhov loj ntawm cov khoom tiag tiag;

2. Lub voj voog sab nrauv uas yog nyob rau hauv kev sib cuag nrog lub puab qhov ntawm cov khoom yuav tsum tau tawm ib tug margin ntawm 0.5mm ntawm ib sab thaum lub sij hawm ntau lawm, thiab thaum kawg nruab rau ntawm lub CNC tshuab cuab tam thiab tiav tig nws mus rau qhov loj los tiv thaiv deformation thiab eccentricity. tshwm sim los ntawm cov txheej txheem quenching;

3. Cov khoom siv ntawm cov khoom sib dhos yog pom zoo kom siv lub caij nplooj ntoos hlav steel, thiab khi pas nrig yog 45 #;

4. Cov xov M20 ntawm txoj hlua khi yog ib txoj xov zoo, uas tuaj yeem hloov kho raws li qhov xwm txheej tiag tiag

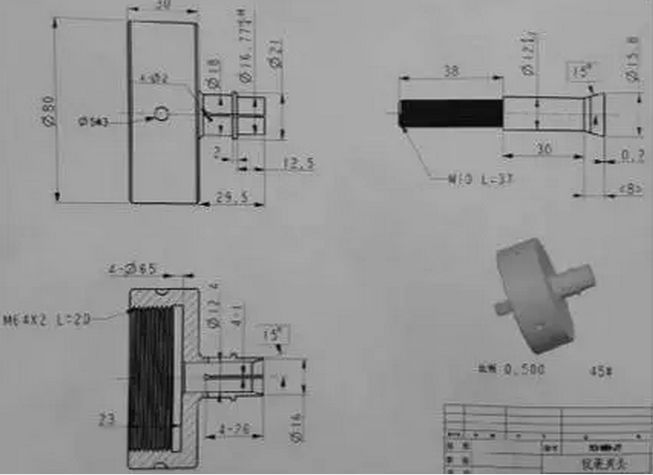

Instrument Inner Beam Chuck

Cov ntsiab lus tsim:

1. Cov duab saum toj no yog ib qho piv txwv siv, thiab qhov sib dhos loj thiab cov qauv raug txiav txim siab raws li qhov tseeb ntawm cov khoom sab nraud thiab cov qauv;

2. Cov khoom siv yog 45 #, quenched.

Instrument sab nrauv chuck

Cov ntsiab lus tsim:

1. Daim duab saum toj no yog ib qho piv txwv siv, thiab qhov loj me yog nyob ntawm qhov loj thiab cov qauv ntawm lub puab qhov ntawm cov khoom;

2. Lub voj voog sab nrauv uas yog nyob rau hauv kev sib cuag nrog lub puab qhov ntawm cov khoom yuav tsum tau tawm ib tug margin ntawm 0.5mm ntawm ib sab thaum lub sij hawm tsim khoom, thiab thaum kawg nruab rau ntawm lub twj paj nruag tshuab dhos thiab tiav tig nws mus rau qhov loj los tiv thaiv deformation thiab eccentricity tshwm sim. los ntawm cov txheej txheem quenching;

3. Cov khoom siv yog 45 #, quenched.

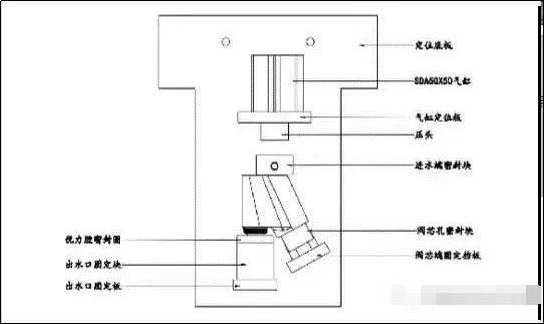

04 Gas test tooling

Cov ntsiab lus tsim:

1. Daim duab saum toj no yog daim duab siv ntawm cov cuab yeej ntsuas roj.Cov qauv tshwj xeeb yuav tsum tau tsim raws li qhov tseeb qauv ntawm cov khoom.Lub tswv yim yog muab cov khoom ntim rau hauv txoj kev yooj yim tshaj plaws, thiab cia qhov chaw uas yuav tsum tau kuaj xyuas cov roj kom paub meej tias nws nruj;

2. Qhov luaj li cas ntawm lub tog raj kheej tuaj yeem hloov kho raws li qhov loj ntawm cov khoom, thiab nws tseem yuav tsum tau txiav txim siab seb qhov mob stroke ntawm lub tog raj kheej tuaj yeem ua tau raws li qhov yooj yim ntawm kev xaiv thiab tso cov khoom;

3. Lub sealing nto uas nyob rau hauv kev sib cuag nrog cov khoom yog feem ntau yog ua los ntawm cov roj hmab zoo heev, NBR roj hmab nplhaib thiab lwm yam ntaub ntawv uas zoo compression.Nyob rau tib lub sijhawm, nws yuav tsum tau muab sau tseg tias yog tias muaj qhov chaw thaiv qhov chaw nyob rau hauv kev sib cuag nrog cov tsos ntawm cov khoom, sim siv cov yas yas dawb dawb thiab siv lawv thaum siv.Lub npog nruab nrab yog npog nrog paj rwb ntaub los tiv thaiv cov tsos ntawm cov khoom puas;

4. Kev taw qhia qhov chaw ntawm cov khoom yuav tsum tau txiav txim siab hauv kev tsim, txhawm rau tiv thaiv kom tsis txhob muaj cov pa tawm ntawm cov khoom nkag mus rau hauv cov kab noj hniav thiab ua rau cov khoom tsis raug.

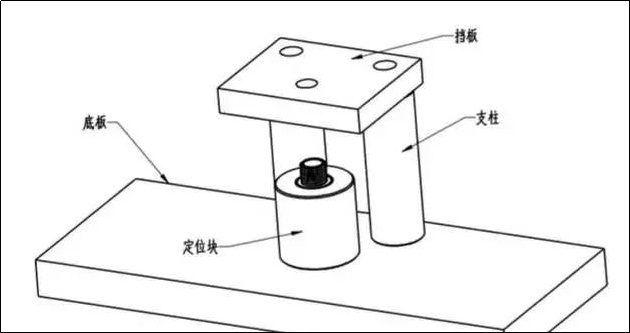

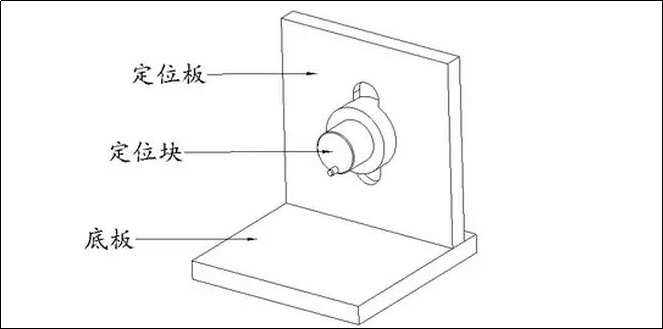

05 xuas nrig ntaus tooling

Cov ntsiab lus tsim: Daim duab saum toj no qhia txog cov qauv ntawm cov cuab yeej xuas nrig ntaus.Kev ua haujlwm ntawm cov phaj hauv qab yog los pab txhim kho ntawm lub workbench ntawm lub tshuab xuas nrig ntaus;kev ua haujlwm ntawm qhov chaw thaiv yog kho cov khoom, cov qauv tshwj xeeb yog tsim raws li qhov tseeb ntawm cov khoom, thiab qhov chaw nruab nrab yog nyob ib puag ncig los pab txhawb thiab ruaj ntseg xaiv thiab tso cov khoom;kev ua haujlwm ntawm baffle yog los pab txhawb cov khoom kom raug cais tawm ntawm rab riam phom;Tus ncej ua raws li ib tug ruaj baffle.Cov haujlwm sib dhos thiab qhov ntev ntawm cov khoom tau hais los saum toj no tuaj yeem tsim raws li qhov tseeb ntawm cov khoom.

06 vuam tooling

Cov cuab yeej vuam siv feem ntau yog siv los txhim kho txoj hauj lwm ntawm txhua yam khoom siv hauv vuam sib dhos thiab tswj cov txheeb ze ntawm txhua qhov sib dhos hauv vuam sib dhos.Nws cov qauv yog feem ntau yog ib qho chaw thaiv, uas yuav tsum tau tsim raws li qhov tseeb qauv ntawmaluminium machining qhov chawthiabtooj dag machining qhov chaw.Nws yog tsim nyog sau cia tias thaum cov khoom raug muab tso rau hauv lub vuam cuab yeej, nws tsis raug tso cai los tsim ib qho chaw kaw ntawm cov cuab yeej los tiv thaiv qhov siab ntawm qhov chaw kaw thaum lub sij hawm vuam cua sov txheej txheem los ntawm kev cuam tshuam qhov loj ntawm qhov chaw tom qab vuam. .

07 Polishing fixture

08 Cov cuab yeej sib dhos

Cov cuab yeej sib dhos yog siv los ua ib qho cuab yeej rau qhov chaw pabcuam thaum lub sij hawm sib dhos ntawm cov khoom.Nws lub tswv yim tsim yog tias cov khoom tuaj yeem nqa tau yooj yim thiab muab tso rau raws li cov qauv sib dhos ntawm cov khoom sib dhos, lub ntsej muag ntawm cov khoom tsis tuaj yeem raug puas tsuaj thaum lub sij hawm sib dhos, thiab cov khoom tuaj yeem npog nrog paj rwb ntaub los tiv thaiv cov khoom thaum lub sij hawm. siv.Hauv kev xaiv cov khoom siv, sim siv cov khoom tsis yog xim hlau xws li cov kua nplaum dawb.

09 pad luam ntawv, laser engraving tooling

Cov ntsiab lus tsim: Tsim cov qauv kev tso npe ntawm cov cuab yeej raws li cov ntawv xav tau ntawm qhov tseeb ntawm cov khoom.Kev mloog yuav tsum tau them rau qhov yooj yim ntawm kev noj thiab tso cov khoom thiab kev tiv thaiv ntawm cov khoom zoo li.Qhov chaw thaiv qhov chaw thiab cov cuab yeej pabcuam muab tso rau hauv kev sib cuag nrog cov khoom yuav tsum tau ua los ntawm cov khoom tsis yog xim hlau xws li cov kua nplaum dawb..

Post lub sij hawm: Dec-26-2022