Wazi ntoni malunga nenkqubo yonyango lomphezulu wemathiriyeli kumatshini we-CNC?

Kwi-CNC machining, unyango olungaphezulu yinkqubo esetyenzisiweyo ukuphucula imbonakalo kunye nomsebenzi kunye nokuphila ixesha elide kwezinto ezinomatshini.Ezona nkqubo zixhaphakileyo ezisetyenziselwa ukunyanga iindawo ezisetyenziswa kwi-CNC machining ziquka ukucima.Le nkqubo ibandakanya ukususwa kweencam ezibukhali, ii-burrs, okanye nayiphi na imathiriyeli engaphezulu kumphezulu wecandelo lomatshini.I-Deburring iphakamisa ubuhle kunye nokhuseleko lwemveliso yokugqibela.

Ukugudisa:Ukumenyezeliswa kungasetyenziselwa ukugudisa umphezulu wento leyo ekhokelela kwinkangeleko emenyezelayo nebonakalisayo.Yongeza inkangeleko yamacandelo kwaye iyancipha ukukhuhlana kwiindawo.

Ukusila: Isetyenziselwa ukuphelisa ukungafezeki kwimigangatho okanye ukufumana ukunyamezela okuchanekileyo.Oku kubandakanya ukusebenzisa ivili lokusila ukususa izinto kumsebenzi othile.

Anodizing:Yinkqubo ye-electrochemical eyenza umaleko okhuselayo onjenge-oxide kumphezulu wezinto zetsimbi ezifana ne-aluminiyam.Yongeza ukuxhathisa kwi-corrosion kunye ne-aesthetics, ukuqina kunye.

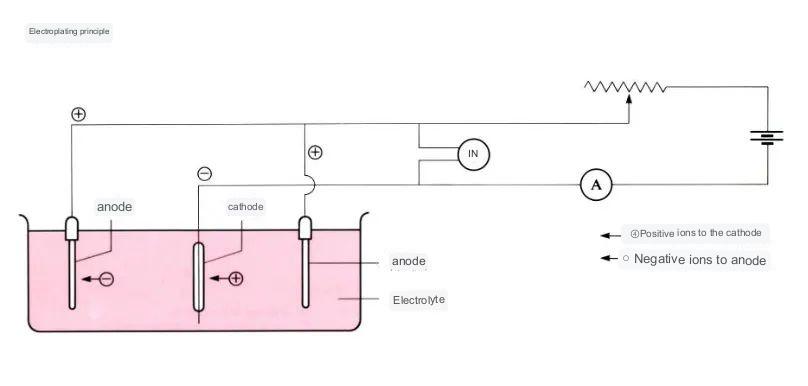

Electroplatingibandakanya ukwandlala umaleko obhityileyo wesinyithi phezu komphezulu wesixhobo.Iphucula ukuxhathisa kwi-corrosion kunye ne-conductivity kunye nokubukeka.

Ukwaleka:Ukugquma komphezulu yinkqubo yokufaka i-anti-corrosion layer okanye ipeyinti kumphezulu wezinto eziphathekayo.Inokubonelela ngokuxhathisa ukubola kunye nokumelana nokunxiba.Iyakwazi nokuphucula i-aesthetics.

Unyango loBubushushu:Oku kubandakanya ukuveza imathiriyeli kubushushu obugqithisileyo kunye nolawulo olupholileyo ukuze kulungiswe ipropathi yabo yomatshini.Le nkqubo iphucula ukuqina kwezinto, ukuqina kunye nokuchasa ukunxiba kunye nokuguqulwa.

Olu nyango lwemigangatho lunokuphucula kakhulu umgangatho uwonke, ukusebenza kunye nobomi obude bezinto zoomatshini be-CNC.Uhlobo lonyango okhetha ukulusebenzisa luxhomekeke kwizinto eziphathekayo, ekujoliswe kuyo, kunye neziphumo ezifunwayo.

Unyango lomphezulu yinkqubo yokwenza ngaphezulu kwesiseko sezinto ezinekhemikhali, zomzimba, kunye neempawu zoomatshini ezahlukileyo kwezo zesiseko.

Injongo yonyango lwangaphezulu kukwanelisa ukuxhathisa ukunxiba, ukubola kunye nezinye iimfuno ezithengiswayo.Ezona ndlela zisetyenziswa rhoqo zokunyanga iindawo ziquka ukucola ngoomatshini, unyango lwemichiza yonyango lobushushu bomphezulu kunye nokutshiza kumphezulu.Ukunyangwa komphezulu yinkqubo yokucoca umphezulu, ukuyitshayela, ukuyikhupha kunye nokukhupha ngaphandle kweqhekeza.Namhlanje, siza kuxubusha inkqubo yonyango olungaphezulu.

Ziziphi iingenelo ezinokuzisa unyango olungaphezulu kwiindawo zomatshini?

Iinkqubo zonyango kwindawo engaphezulu zinokuzisa inani leenzuzoiindawo ezenziwe ngoomatshini, equka: Ukuphuculwa kweAesthetics: Unyango oluphezulu olufana nokuhluma, i-anodizing, i-plating kunye nokugqiba kunokunyusa umtsalane obonakalayo wezinto ezenziwe ngoomatshini.Inokubonelela ngesiphelo esigudileyo, esicwebezelayo okanye esilungiselelweyo, siphucula inkangeleko epheleleyo yento.

Ukuxhathisa umhlwa okuphuculweyo: Unyango oluninzi lwendawo, njenge-anodizing, i-plating, kunye nokugqiba, yenza umaleko okhuselayo kumphezulu wezinto eziphathekayo.Lo maleko usebenza njengomqobo, ukhusela ngokuchasene nenxalenye ekudibaneni nendawo enobungozi, ngoko ke iphucula ukuxhathisa kwayo.

Ukuxhathisa ukunxiba okongeziweyo: Unyango olungaphezulu olunjengonyango lokufudumala okanye ukugqiba kunokonyusa kakhulu ukuxhathisa ukunxitywa kwamalungu anomatshini.Ezi nkqubo zinokuphucula ukuqina, ukuqina kunye nokomelela kwemathiriyeli, zizenze zikhuseleke ngakumbi ekukhuhleni, ukukrazuka kunye nokunxiba.Khuthaza ukuthambisa kwaye unciphise ukuhlikihla: Olunye unyango lwendawo engaphezulu, olufana nokupolisha okanye umaleko onezinto ezikhubekisayo ezisezantsi, kunokunciphisa ingxabano phakathi kwezinto ezihambayo.Oku kubangela inkqubo egudileyo, ithoba ukunxiba, kwaye ikwanyusa ukusebenza ngokupheleleyo kwamalungu omatshini.

Okungcono kakhulu ukumelana neekhemikhali: Ngonyango olungaphezulu, ukuxhathisa kweekhemikhali kumacandelo omatshini kunokongezwa.Oku kunenzuzo ngakumbi xa amacandelo adibana neekhemikhali ezinobutshaba okanye iikhompawundi ezinokuqhekeza imveliso.Ukunyamezelwa okuQinisayo kunye noKuchaneka okuPhakamileyo: Unyango lwakumphezulu olunjengokusila okanye uncedo lokupolisha lufumana ukuchasana okuthe kratya komgangatho kwaye ziqinisekisa ukuchaneka okukhulu kwiindawo ezinomatshini.Oku kubalulekile kwizicelo ezifuna ukuchaneka okuphezulu kunye nokunyamezelana okuqinileyo.

I-Adhesion eyandisiweyo kunye nokuDityaniswa: Ukulungiswa komphezulu kunokudala indawo efanelekileyo yendawo yokuncamathelisa, iipeyinti okanye ezinye iindlela zokubopha.Oku kuvumela ibhondi enamandla ngakumbi kwaye edume ngakumbi phakathi kwezinto ezahlukeneyo, ukuphucula imfezeko yemveliso.Lilonke, iinkqubo zonyango lomphezulu zidlala indima ebalulekileyo ekuphuculeni uphawu, ubomi obude kunye nenkangeleko yaloamacandelo oomatshini, okwenza ukuba bafaneleke ngakumbi kwisicelo abasifunayo kunye nokuphucula umgangatho wabo ophakamileyo.

Iinkqubo ezixhaphakileyo zokunyanga umphezulu zezi:

I-vacuum electroplating, inkqubo ye-electroplating, i-anodizing, i-electrolytic polishing, inkqubo yokushicilela i-pad, inkqubo ye-galvanizing, i-powder coating, ukuprintwa kwamanzi, ukuprintwa kwesikrini, i-electrophoresis, njl.

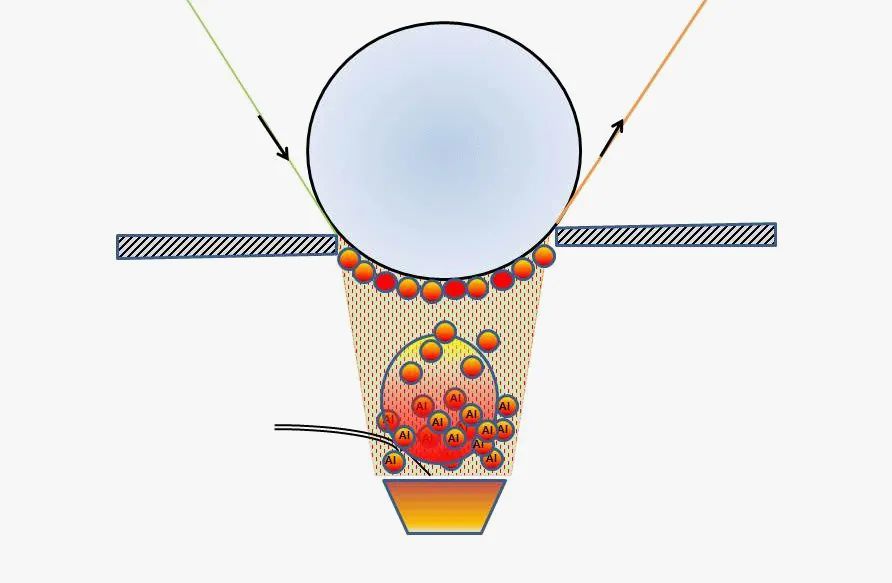

01. Ukucoca ngevacuum

—— Vacuum Metalizing ——

I-vacuum plating inokuchazwa njengenkqubo yokubeka umzimba.Enyanisweni, igesi ye-argon ifakwe kwisimo se-vacuum, i-athomu yegesi ibetha izinto ezikhethiweyo, kwaye izinto ezijoliswe kuzo zahlulwe zibe ziimolekyuli, ezithi zifunxwe zizinto eziqhubayo ukuze zenze iyunifomu kunye nokulinganisa okugudileyo. .

Imathiriyeli esebenzayo:

1. Iintlobo ngeentlobo zezinto eziphathekayo zinokugquma, kubandakanywa isinyithi esiqinileyo kunye neeplastiki ezithambileyo, iiseramics, izinto ezidibeneyo kunye neglasi.Indlela esetyenziswa ngokuqhelekileyo ye-electroplating yi-aluminium, elandelwa lubhedu kunye nesilivere.

2. Imathiriyeli yendalo ayifanelanga ukugqunywa komphunga ngenxa yokuba ukufuma kwimathiriyeli yendalo kunokutshintsha indawo yokufunxa.

Iindleko zenkqubo yindleko yokufakwa komphunga into ekufuneka itshizwe isothulwe, ilayishwe ize ibuyiselwe kwisitshizi, nto leyo ethetha ukuba iindleko zomsebenzi ziyabiza, nangona kunjalo kuxhomekeke kubukhulu kunye nokuntsonkotha kwesixhobo sokusebenza.

Impembelelo yokusingqongileyo: I-vacuum electroplating ibangela iimpembelelo ezincinci zokusingqongileyo, ezifana nefuthe lenkqubo kwindawo engqongileyo.

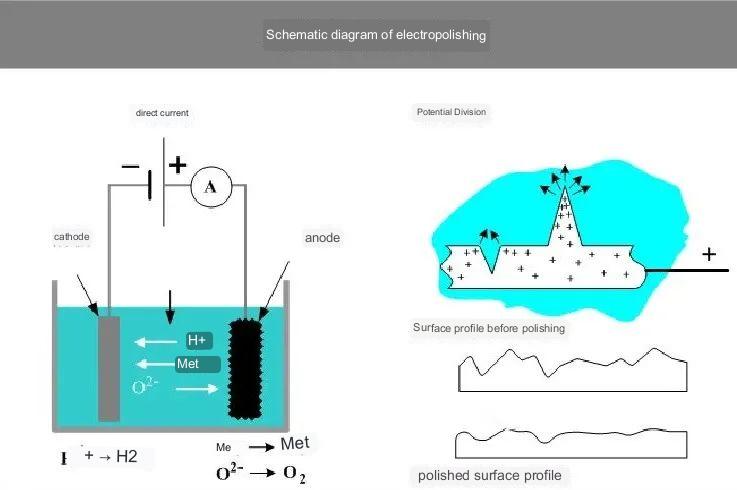

02. Electropolishing

—— Electropolishing ——

Electropolishing ibhekisa kwinkqubo electrochemical apho iiathom kwicnc ukuguqula iindawoezintywiliselwa kwi-electrolyte ziguqulwa zibe ion kwaye zisuswe kumphezulu ngokuhamba kwentlawulo yombane, okukhokelela ekukhupheni ii-burrs ezintle kunye nokuphucula ukuqaqamba komphezulu.

Imathiriyeli esebenzayo:

1. Uninzi lwesinyithi luphuculwe ngokwe-electrolytically kubandakanywa ukupolishwa komphezulu okwenziwa yintsimbi engenastainless yeyona isetyenziswa rhoqo (ingakumbi nge-austenitic stainless grade).

2. Izinto ezihlukeneyo azikwazi ukuhlanjululwa nge-electropolished ngaxeshanye okanye nakwi-solvent efanayo ye-electrolysis.

Iindleko zenkqubo: Yonke inkqubo yokupholisha i-electrolytic iphantse yazenzekela ngokupheleleyo, okuthetha ukuba iindleko zabasebenzi ziphantsi kakhulu.Impembelelo kokusingqongileyo: I-Electrolytic polishing isebenzisa iikhemikhali ezinempembelelo ephantsi.Yonke le nkqubo ifuna nje umlinganiselo omncinci wamanzi, kwaye kulula kakhulu ukuyisebenzisa.Ngaphaya koko, inokuphucula iimpawu zentsimbi engatyiwayo kunye nokulibazisa ukubola kwentsimbi engatyiwayo.

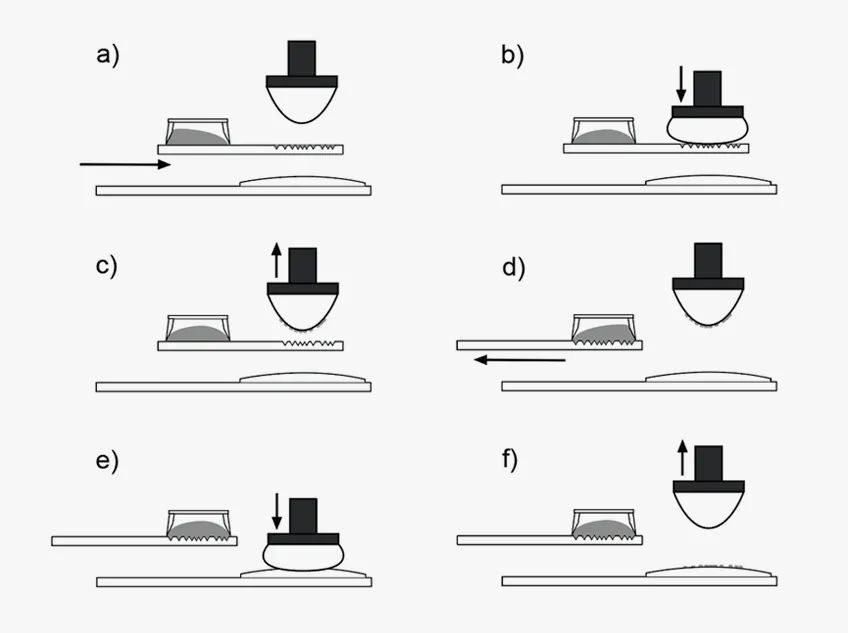

03. Inkqubo yoshicilelo lwephedi

——Ushicilelo lwePad——

Ukukwazi ukuprinta imifanekiso, okubhaliweyo kunye nemizobo kumphezulu wezinto ezinemilo engaqhelekanga iba ngumba obalulekileyo woshicilelo olulodwa.

Imathiriyeli esebenzayo:

Ushicilelo lwe-Pad lukhetho olusebenzayo phantse kuyo nayiphi na imathiriyeli, ngaphandle kwemathiriyeli eqaqadekileyo njenge-silicone pads njenge-PTFE.

Iindleko zenkqubo Iindleko eziphantsi zokungunda kunye neendleko eziphantsi zabasebenzi.

Impembelelo yokusingqongileyo: Njengoko le nkqubo ithintelwe kwii-inki ezinyibilikayo (ezingcoliswe yimichiza eyingozi) kwaye zinempembelelo ebalulekileyo kokusingqongileyo.

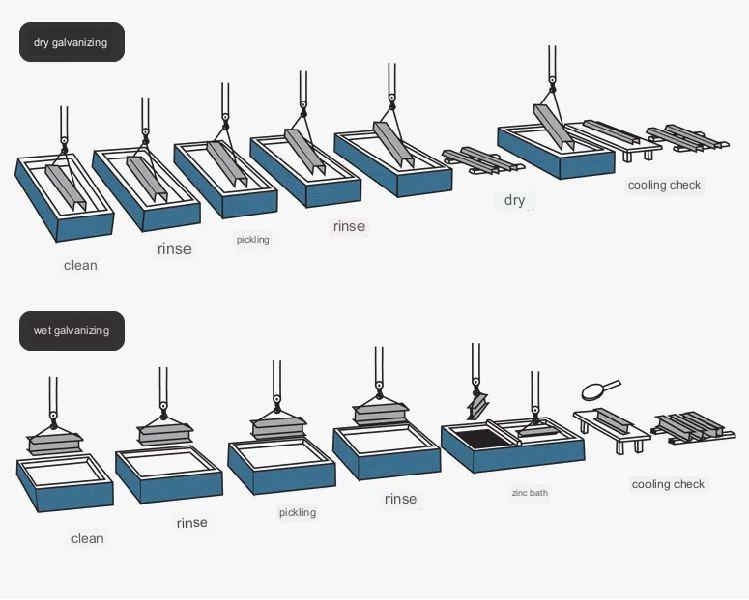

04. Inkqubo yokufaka igalvanizing

—— Ukugalela ——

Itekhnoloji yokunyanga imigangatho egqume umaleko we-zinc ngaphezulu kwe-alloys eyenziwe ngentsimbi ye-aesthetics kunye ne-anti-rust benefits.I-zinc yokwambathisa kumphezulu isebenza njengomaleko okhuselayo we-electrochemical othintela ukubola kwesinyithi.Ezona ndlela zimbini zixhaphakileyo yi- hot-dip galvanizing kunye neGalvanized.

Imathiriyeli esebenzayo:

Ngenxa yokuba i-galvanizing ixhomekeke kwi-metallurgical bonding le nkqubo ifanelekile kunyango lweendawo kwintsimbi kunye nentsimbi.

Iindleko zenkqubo: Akukho xabiso lokungunda, umjikelo omfutshane okanye ixabiso eliphakathi labasebenzi, kuba umgangatho womphezulu we-workpiece unqunywe ubukhulu becala ngonyango olungaphezulu olwenziwa ngesandla phambi kokufakwa kwegalvanizing.

Impembelelo yokusingqongileyo: Njengoko inkqubo ye-galvanizing inokunyusa ixesha lokuphila kweendawo zentsimbi phakathi kweminyaka engama-40 kunye ne-100 kwaye iphinde ithintele ukubola kunye ne-rust enokuthi yenzeke kuyo, inkqubo ingaba nefuthe ekukhuselweni kwendawo engqongileyo.Ngaphaya koko, i-workpiece efakwe igalati inokubuyiselwa kwitanki ye-zinc nje ukuba ixesha layo lokusebenzisa liphelile kwaye ukusetyenziswa rhoqo kwe-zinc kuhlobo lwe-liquid akubangeli inkunkuma yomzimba okanye yekhemikhali.

05. Inkqubo ye-Electroplating

—— Electroplating ——

Inkqubo yokuncamathelisa umaleko obhityileyo wefilimu yesinyithi kumphezulu wamacandelo ngokusebenzisa i-electrolysis, ukuze kunqandwe i-oxidation yesinyithi, ukomeleza ukuxhathisa ukunxiba ukuguquguquka kokuchasa ukuhombisa ukukhanya, kunye nokuphucula inkangeleko.Umaleko wangaphandle wemali eninzi yeengqekembe nawo unokwabiwa nge-electroplated..

Imathiriyeli esebenzayo:

1. Iintsimbi ezininzi zi-electroplated.Nangona kunjalo, iintsimbi ezahlukeneyo ziza namanqanaba ahlukeneyo okucoceka kunye nokusebenza kakuhle kweplating.Eyona nto idumileyo kwezi zilandelayo: i-tin kunye ne-chromium, isilivere, i-nickel, kunye ne-rhodium.

2. Izinto ezithandwa kakhulu ukuqhuba i-electroplating yi-ABS.ABS.

3. Isinyithi se-nickel akufanele sisetyenziswe kwimveliso ye-electroplate edibana nolusu kuba iyacaphukisa kwaye iyingozi eluswini.

Iindleko zenkqubo: Akukho zindleko zokubumba, nangona kunjalo ukulungiswa kuyafuneka ukukhusela iindleko zexesha lezahlulo zisekwe kubushushu kunye nohlobo lwexabiso lesinyithi okanye labasebenzi (eliphakathi-phezulu) lixhomekeke kuhlobo oluthile lwezixhobo zokucoca, njengezacholo kunye nobucwebe. isilivere, efuna umgangatho ophezulu wobuchule.Ilawulwa ngabasebenzi abanezakhono eziphezulu ngenxa yeemfuno eziphezulu malunga nenkangeleko kunye nokuphila ixesha elide.

Impembelelo yokusingqongileyo ye-electroplating: Isixa esikhulu seekhemikhali eziyityhefu ziqeshwe kwinkqubo ye-electroplating yiyo loo nto ukuphambuka kobuchwephesha kunye nokutsalwa kubalulekile ukunciphisa impembelelo yokusingqongileyo.

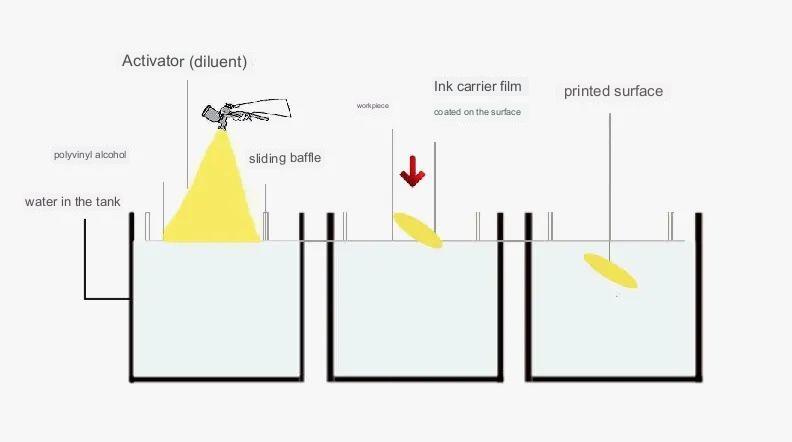

06. Ukushicilelwa kokuhanjiswa kwamanzi

—— Ushicilelo lokuDluliswa kweHydro ——

Bubuchule bokuprinta ipateni yombala kwiphepha lokutshintshela umphezulu wemveliso enomacala amathathu usebenzisa uxinzelelo lwamanzi.Njengoko iimfuno zabantu zokupakishwa kweemveliso kunye nokuhombisa umphezulu ukusetyenziswa koshicilelo-kwimfuno kuya kusasazeka ngakumbi nangakumbi.

Imathiriyeli esebenzayo:

Zonke iintlobo zezinto ezinzima zifanelekile ukuprintwa kwamanzi kunye nezinto ezifanelekileyo zokutshiza kufuneka zilungele ukuprintwa ngamanzi.Ezona zidumileyo ziindawo ezibunjwe ngenaliti kunye nentsimbi.

Iindleko zenkqubo: Akukho xabiso linxulumene nokungunda, nangona kunjalo iimveliso ezininzi kufuneka zidluliselwe emanzini ngaxeshanye ngokusebenzisa izixhobo.ixabiso lilonke alikho ngaphezu kwexesha lomjikelo ngamnye.

Impembelelo yokusingqongileyo: Xa kuthelekiswa nokutshiza kwiimveliso zoshicilelo lokudlulisa amanzi lusebenza ngokupheleleyo iipeyinti zoshicilelo ezinciphisa ithuba lokuvuza kunye nenkunkuma.

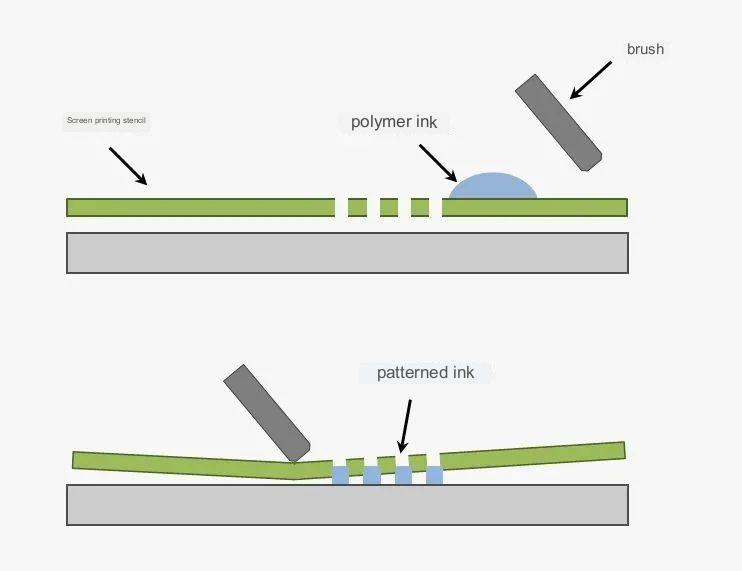

07. Ukuprintwa kwesikrini

—— Ushicilelo lweSkrini ——

Ngokukhutshelwa kwe-scraper, i-inki idluliselwa kumphezulu nge-mesh yayo kwaye yenze umfanekiso ofanayo nowashicilelwa ekuqaleni.Abashicileli besikrini basebenziseka lula, kwaye kulula ukuprinta kunye nokwenza iipleyiti, ngexabiso eliphantsi kunye nokuguquguquka okugqwesileyo.

Izinto zokuprinta ezidla ngokusetyenziswa ziquka iipowusta zeoyile yemibala epeyintwe, amakhadi oshishino, iipowusta ezibotshwe ngamaqweqwe, iimpawu zorhwebo, kunye namalaphu adayiweyo nashicilelweyo.

Imathiriyeli esebenzayo:

Phantse nayiphi na imathiriyeli inokuprintwa kwesikrini, kubandakanya isinyithi, iplastiki, iiseramikhi zephepha, iglasi kunye nokunye.

Iindleko zenkqubo Ixabiso le-mold lincinci, kodwa lixhomekeke kubungakanani bemibala esetyenzisiweyo, ekubeni umbala ngamnye kufuneka udalwe ngokwawo.Iindleko zomsebenzi ziphezulu kakhulu, ngakumbi kwimeko yoshicilelo olunemibala emininzi.

Impembelelo yokusingqongileyo: Ushicilelo lwesikrini ngee-inki ezinemibala ekhanyayo alunampembelelo imbi kokusingqongileyo, nangona kunjalo ii-inki ezenziwe ngePVC kunye ne-formaldehyde zizikhompawundi zekhemikhali eziyityhefu, kwaye zifuna ukuphinda zisetyenziswe kwaye zilahlwe ngexesha elifanelekileyo ukumisa ukungcoliseka kwamanzi. .

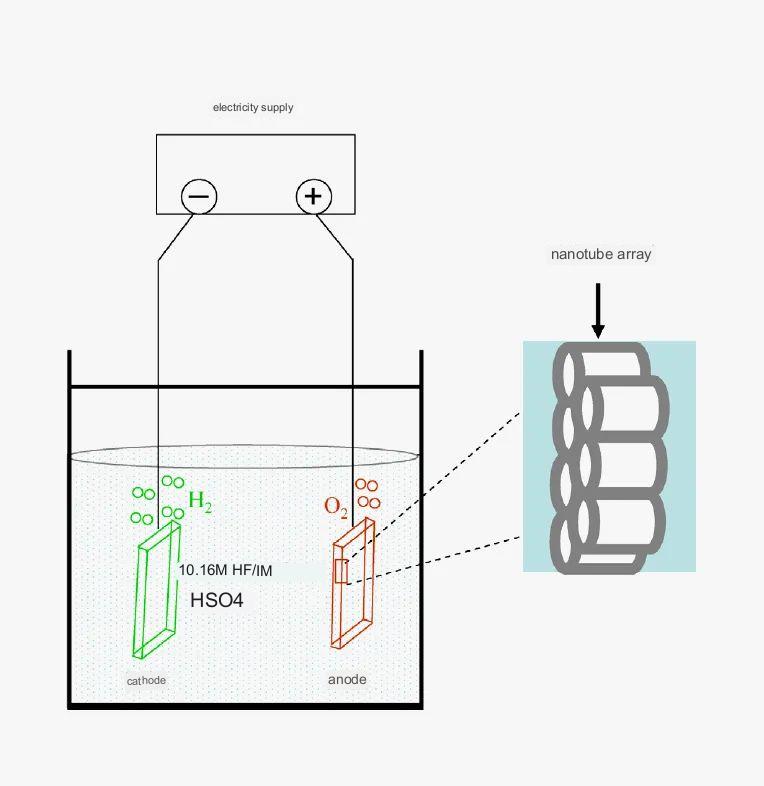

08. Anodizing

—— iAnodic Oxidation ——

Inkqubo ye-anodic oxidation ye-aluminium ngokuyinhloko isekelwe kwingcamango ye-electrochemical ukudala umaleko obhityileyo ongaphantsi owenziwe yifilimu ye-Al2O3 (i-aluminium oxide) kwi-aluminium kunye ne-aluminium alloy.Ioksidi ineempawu ezahlukileyo ezifana nokukhuselwa kumhlwa, ukuhonjiswa, ukugquma kunye nokuxhathisa ukunxiba.

Imathiriyeli esebenzayo:

I-aluminiyam, ingxubevange ye-aluminiyam, kunye nezinye iimveliso ze-aluminiyam

Iindleko zenkqubo: Kwinkqubo yokuvelisa ukusetyenziswa kombane kunye namanzi kuninzi, ngakumbi ngexesha lenkqubo ye-oxidation.Usetyenziso lwamandla ngoomatshini ngokwawo lufuna ukupholiswa rhoqo ngamanzi abalekayo.Ukusetyenziswa kwamandla ngetoni nganye ngokuqhelekileyo malunga ne-1000 degrees.

Iimpembelelo zokusiNgqongileyo: I-anodizing ayiyodwanga ngokokusebenza kakuhle kwamandla.Nangona kunjalo, kwinkqubo yokuvelisa i-electrolysis ye-aluminiyam i-anode reaction ivelisa iigesi ezineziphumo ezibi kwi-Ozone layer.

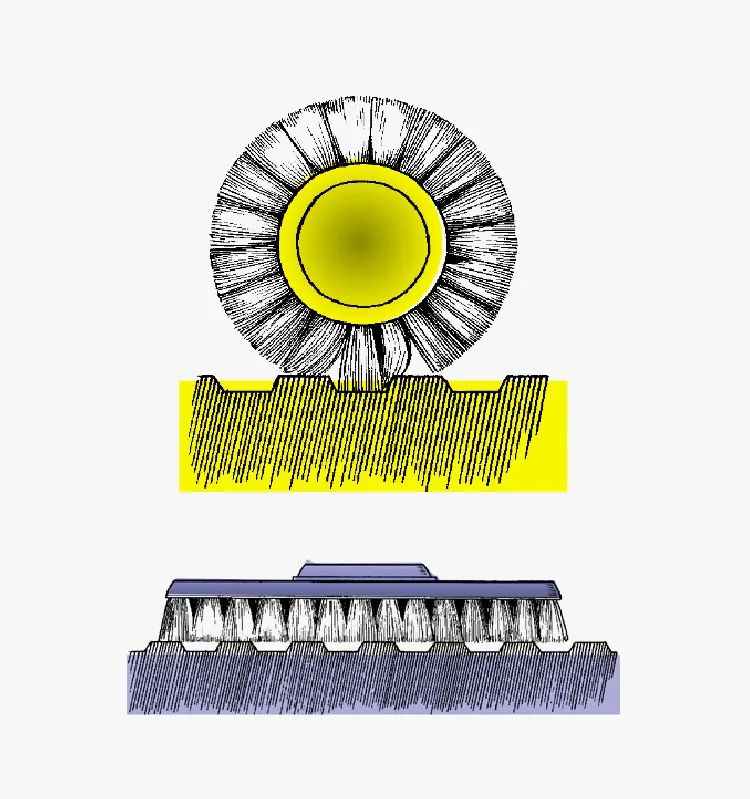

09. Umzobo wentsimbi yentsimbi

—— Iintambo zentsimbi ——

Yindlela yonyango engaphezulu eyenza imigca ebusweni bomsebenzi ngokusila into ukuze ifumane impembelelo ekhangayo.Ngokwezakhiwo ezahlukahlukeneyo emva komzobo wentambo, inokwahlulwa ibe: umzobo wentambo ethe tye, umzobo wentambo engalungelelananga, ityathanga, kunye nokujikeleza.

Izinto ezifanelekileyo: Phantse zonke izinto zetsimbi zinokusebenzisa inkqubo yokuzoba intambo yentsimbi.

Iindleko zenkqubo: Indlela yenkqubo ilula, izixhobo zichanekile, ukusetyenziswa kwezinto eziphathekayo kuncinci kakhulu, ixabiso lincitshiswe ngokufanelekileyo, kwaye inzuzo yemali iphezulu.

Impembelelo yokusingqongileyo: iimveliso zetsimbi ezicocekileyo, akukho peyinti okanye naluphi na uhlobo lwezixhobo zeekhemikhali eziphezu komhlaba, i-600 degrees yokushisa ephezulu ayinyibiliki, ayivelisi iigesi ezinobuthi, ihlangabezana nokhuseleko lomlilo kunye neemfuno zokusingqongileyo.

10. Ukuhlobisa kwi-mold

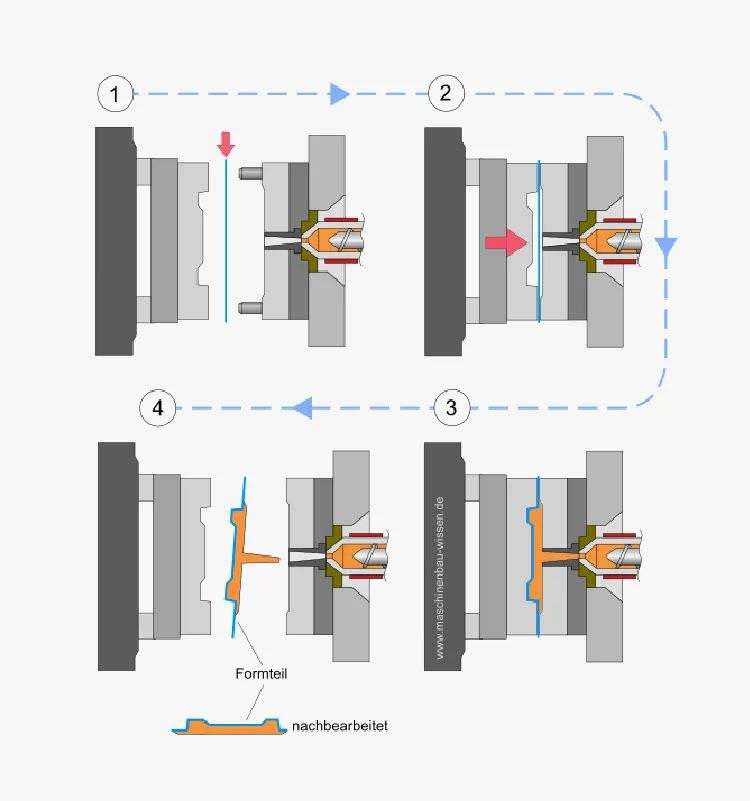

—— In-Mold Decoration-IMD ——

Bubuchule bokubumba obubeka i-diaphragm eprintiweyo yepateni kanye kwisingundo sentsimbi kunye nokungunda, ifaka i-resin yokubumba kanye kwi-metal mildew kunye nokungunda kunye nokudibanisa i-diaphragm, kwaye yenza i-diaphragm eprintiweyo kunye intlaka edityanisiweyo kunye nokuqiniswa kanye kwimveliso egqityiweyo.

Imveliso efanelekileyo: indawo yeplastiki

Cokisa iindleko: funa nje uvule ingqokelela yokungunda kunye nokungunda, okunokuthi kucuthe iindleko kunye neeyure zabantu, imveliso ephezulu ezenzekelayo, inkqubo yokwenziwa lula, indlela yokubumba isitofu sexesha elinye, kunye nokufumana ukubumba kunye nokuhombisa xeshanye.

Impembelelo yokusingqongileyo: Obu bugcisa bale mihla bunobuhlobo nokusingqongileyo kunye nokusingqongileyo, kuthintela ukungcoliseka okubangelwa kukupeyintwa okuqhelekileyo kunye nokufakwa kwe-electroplating.

Izinto ezilungileyo ze-Anebon ziintlawulo ezincitshisiweyo, iqela lengeniso eliguqukayo, i-QC ekhethekileyo, iifektri ezomeleleyo, iinkonzo ezikumgangatho ophezulu ze-cnc machining machining amacandelo e-aluminium okwenza inkonzo kunye ne-cnc machining yokuguqula iindawo zokwenza inkonzo.I-Anebon ibeke injongo kwi-Innovation System eqhubekayo, ukuveliswa kwezinto ezintsha, i-elite innovation kunye nokuveliswa kwecandelo, ukunika umdlalo ogcweleyo kwiinzuzo ezipheleleyo, kunye nokuphucula rhoqo ukuxhasa okugqwesileyo.

Imveliso ye-Anebon eNtsha yaseTshayina iTshixa i-Lock-Hole Machine kunye ne-Aluminiyam Window Lock Hole Processing Machine, i-Anebon inomgca opheleleyo wemveliso, umgca wokuhlanganisa, inkqubo yokulawula umgangatho, kwaye okona kubaluleke kakhulu, ngoku i-Anebon inobuchwephesha belungelo elilodwa lomenzi wechiza kunye namava obugcisa kunye neqela lemveliso, inkonzo yokuthengisa enamava. iqela.Ngazo zonke izibonelelo zabantu, siza kudala “uphawu lwenayiloni oluhloniphekileyo lwamazwe ngamazwe lwenayiloni monofilaments”, kwaye sisasaza urhwebo lwethu kuzo zonke iimbombo zehlabathi.Besisoloko sihamba kwaye sizame konke okusemandleni ethu ukunceda abathengi baseAnebon.

Ixesha lokuposa: Jul-29-2023