Chii chaunoziva nezve epamusoro kurapwa maitiro emidziyo muCNC machining?

Kune CNC machining, kurapwa kwepamusoro ndiyo nzira inoshandiswa kuvandudza chitarisiko pamwe chete nebasa uye hupenyu hurefu hwezvigadzirwa zvemichina.Maitiro akajairika anoshandiswa kurapa nzvimbo anoshandiswa muCNC machining anosanganisira deburring.Iyi nzira inosanganisira kubviswa kwemapendero akapinza, maburrs, kana chero chinhu chakawandisa kubva pamusoro pechinhu chakagadzirwa nemichina.Deburring inosimudzira aesthetics uye kuchengetedzeka kwechigadzirwa chekupedzisira.

Kupenya:Kupenya kunogona kushandiswa kutsvedzerera huso hwezvinhu izvo zvinoita kuti pave nechitarisiko chinopenya uye chinopenya.Inosimudzira kutaridzika kwezvikamu uye inoderedza kukweshana pazvikamu.

Kukuya: Inoshandiswa kubvisa kusakwana pamusoro pepamusoro kana kuwana kushivirira chaiko.Izvi zvinosanganisira kushandisa vhiri reguyo kubvisa zvinhu kubva pachikamu chebasa.

Anodizing:Iyo electrochemical process inogadzira iyo oxide-yakafanana yekudzivirira layer pamusoro pezvinhu zvesimbi sealuminium.Inowedzera kupikisa kune corrosion pamwe neaesthetics, kuoma uye.

ElectroplatingZvinosanganisira kuisa chidimbu chesimbi pamusoro pechinhu chacho.Inonatsiridza kushorwa nekuora pamwe nekuita uye kutaridzika.

Coating:Surface coating ndiyo maitiro ekuisa anti-corrosion layer kana pendi pamusoro pechinhu.Inogona kupa kupesana nekuora pamwe nekudzivirira kupfeka.Inogonawo kuvandudza aesthetics.

Kurapa Kupisa:Izvi zvinosanganisira kuisa pachena chinhu kune tembiricha yakanyanyisa uye inodzorwa inotonhorera kuitira kuti vagadzirise midziyo yavo.Iyi nzira inovandudza kusimba kwechinhu, kuoma uye kuramba kupfeka uye deformation.

Aya marapirwo enzvimbo anogona kukwidziridza zvakanyanya kunaka kwese, kuita uye hupenyu hurefu hweCNC michina yemuchina.Mhando yekurapa yaunosarudza kushandisa inotsamira pazvinhu, mashandisirwo azvinoitwa, uye mhedzisiro yaunoda.

Kurapa kwepamusoro inzira yekugadzira pamusoro peiyo base zvinhu zvine kemikari, zvemuviri, uye zvemuchina maitiro akasiyana neaya echigadziko.

Chinangwa chekurapa kwepamusoro ndechekugutsa kuramba kupfeka, ngura uye zvimwe zvinodiwa izvo zvinotengeswa.Nzira dzinowanzo shandiswa pakurapa nzvimbo dzinosanganisira mechanical grind, kemikari kurapwa pamusoro pekupisa kupisa uye kumwaya pamusoro.Kurapa kwepamusoro ndiyo nzira yekuchenesa nzvimbo, kuitsvaira, kuibvisa uye kubvisa kunze kwechidimbu.Nhasi, tichakurukura nzira yekurapa kwepamusoro.

Ndezvipi zvinobatsira zvinogona kuunza kurapwa kwepamusoro kune zvikamu zvekugadzira?

Surface area therapy maitiro anogona kuunza akati wandei mabhenefiti kunezvikamu zvakagadzirwa, inosanganisira: Yakavandudzwa Aesthetics: Kurapa kwepamusoro senge sprucing kumusoro, anodizing, plating uye zvakare kupedzisa kunogona kukwidziridza runako rwekuona yezvikamu zvakagadzirwa.Inogona kupa yakatsetseka, inopenya kana yakagadziridzwa kupera, ichivandudza kutaridzika kwechinhu chose.

Enhanced rust resistance: Mazhinji epamusoro ekurapa kwenzvimbo, senge anodizing, plating, uye kupedzisa, anogadzira danda rekudzivirira pamusoro pechinhu.Iyi dhizaini inoita semhinganidzo, inodzivirira kubva pachikamu kubva pakusangana neyakaora, nekudaro ichiwedzera kusimba kwayo.

Yakawedzera kupfeka kuramba: Kurapa kwepamusoro senge kurapwa kwekudziya kana kupedzisa kunogona kuwedzera zvakanyanya kusakara kwezvikamu zvemichina.Aya maitiro anogona kuvandudza kusimba, kusimba uye zvakare kusimba kwezvinhu, zvichiita kuti dzisanyanya kudzivirirwa pakukwesha, abrasion pamwe nekupfeka.Boost lubrication uye zvakare kuderedza kukwesha: Mamwe marapirwo epamusoro penzvimbo, senge polishing kana layer ine yakaderera-inokwesha zvinhu, inogona kuderedza kukwesha pakati pezvinhu zvinofamba.Izvi zvinokonzeresa maitiro akapfava, anodzikisira kupfeka, uye zvakare inosimudzira kuita kwakazara kwezvikamu zvemuchina.

Zvakawanda zvirinani makemikari kuramba: Kuburikidza nekurapa kwepamusoro, kupikisa kwemakemikari kwezvikamu zvemuchina zvinogona kukwidziridzwa.Izvi zvinonyanya kubatsira kana zvikamu zvakasangana nemakemikari ane hutsinye kana makomisheni anogona kuputsa chigadzirwa.Tighter Tolerances pamwe neYakakwirira Precision: Mishonga yepamhepo senge kugaya kana kupukuta rubatsiro inowana kusimba kweyekupokana uye zvakare kuve nechokwadi chakanyanya kurongeka muzvikamu zvemuchina.Izvi zvakakosha kune zvikumbiro zvinoda kunyatsojeka uye zvakare kushivirira kwakasimba.

Kuwedzeredzwa Kunamatira uye zvakare Bonding: Kugadzirira kwepamusoro kunogona kugadzira nzvimbo yakakodzera yenzvimbo yekunamatira, pendi kana dzimwe nzira dzekubatanidza.Izvi zvinobvumira hukama hwakasimba uye zvakare hwakanyanya mukurumbira pakati pezvinhu zvakasiyana, kuvandudza kutendeseka kwechigadzirwa.Pakazere, maitiro ekurapa epamusoro anoita basa rakakosha mukugadzirisa chimiro, hupenyu hurefu uye zvakare kutarisa kwemachined components, zvichiita kuti zvive zvakanyanya kukodzera kune yavo yavanoshuvira uye nekuvandudza yavo yakazara yemhando yepamusoro.

Iyo inowanzo shandiswa pamusoro pekurapa maitiro ndeaya:

Vacuum electroplating, electroplating process, anodizing, electrolytic polishing, pad printing process, galvanizing process, poda coating, kufambisa mvura kudhinda, screen printing, electrophoresis, nezvimwe.

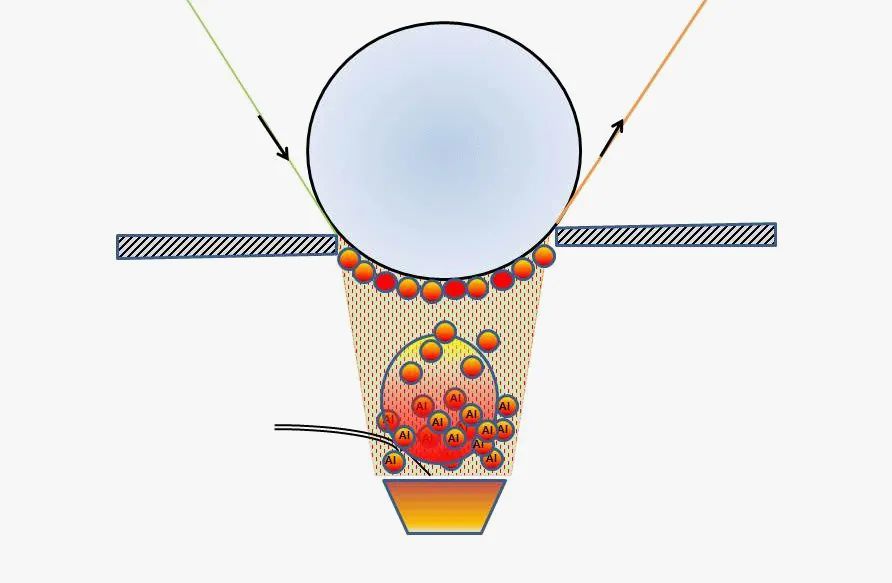

01. Vacuum plating

—— Vacuum Metalizing ——

Vacuum plating inogona kutsanangurwa senzira yekuisa muviri.Muchidimbu, iyo argon gasi inopinzwa munzvimbo yevacuum, maatomu egasi anorova chinhu chesarudzo, uye zvinhu zvakanangwa zvinopatsanurwa kuita mamorekuru, ayo anobva atorwa nezvinoitisa zvinhu kugadzira yunifomu uye yakatsetseka yekutevedzera simbi layer. .

Zvishandiso zvinoshanda:

1. Zvinhu zvakasiyana-siyana zvinogona kuputirwa, kusanganisira simbi yakaoma uye yakapfava mapurasitiki, ceramics, composite zvinhu uye girazi.Nzira inowanzoshandiswa ye electroplating ialuminium, iyo inoteverwa nemhangura nesirivha.

2. Zvishandiso zvechisikigo hazvina kukodzera kuputirwa nemhute nekuda kwekuti hunyoro huri mumidziyo yechisikigo hunogona kushandura nzvimbo yevacuum.

Mutengo wekuita muripo wehupfu hwekuputira chinhu chinofanira kupfapfaidzwa chaburutswa, kutakurwa uye chodzoserwa kupfapfaidza, zvinoreva kuti mari yebasa inodhura, zvisinei zvinoenderana nehukuru uye kuoma kweworkpiece.

Kukanganisa kwezvakatipoteredza: Vacuum electroplating inokonzeresa kushomeka kwezvakatipoteredza, izvo zvakafanana nemhedzisiro yemaitiro panharaunda yakapoteredza.

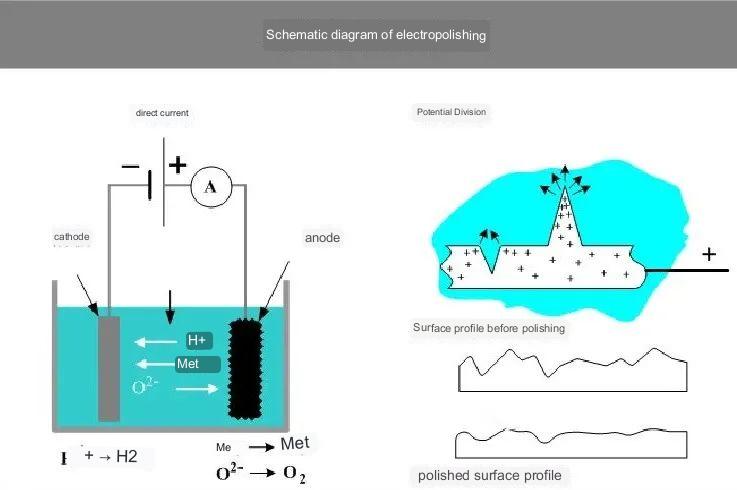

02. Electropolishing

—— Electropolishing ——

Electropolishing inoreva nzira ye electrochemical iyo maatomu ari mucnc kushandura zvikamuiyo inonyudzwa mu electrolyte inoshandurwa kuita ion uye yobva yabviswa kubva pamusoro kuburikidza nekuyerera kwechaji yemagetsi, izvo zvinoguma nekubvisa mafine burrs uye kuwedzera kupenya kwepamusoro.

Zvishandiso zvinoshanda:

1. Masimbi mazhinji anokwenenzverwa nemagetsi kusanganisa kukwenenzverwa kwenzvimbo iyo simbi isina tsvina ndiyo inonyanya kushandiswa (kunyanya neaustenitic Stainless grade).

2. Zvinhu zvakasiyana-siyana hazvikwanisi kuve electropolished panguva imwe chete kana kunyange mukati meimwe solvent ye electrolysis.

Mutengo wekuita: Iyo yese electrolytic polishing process inenge yakangoita otomatiki, zvichireva kuti mutengo wevashandi wakaderera zvakanyanya.Kukanganisa kwezvakatipoteredza: Electrolytic polishing inoshandisa yakaderera-impact makemikari.Iyo yese nzira inoda chete huwandu diki hwemvura, uye iri nyore kushandisa.Uyezve, inogona kuwedzera zvimiro zvesimbi isina tsvina pamwe nekunonoka kukora kwesimbi isina tsvina.

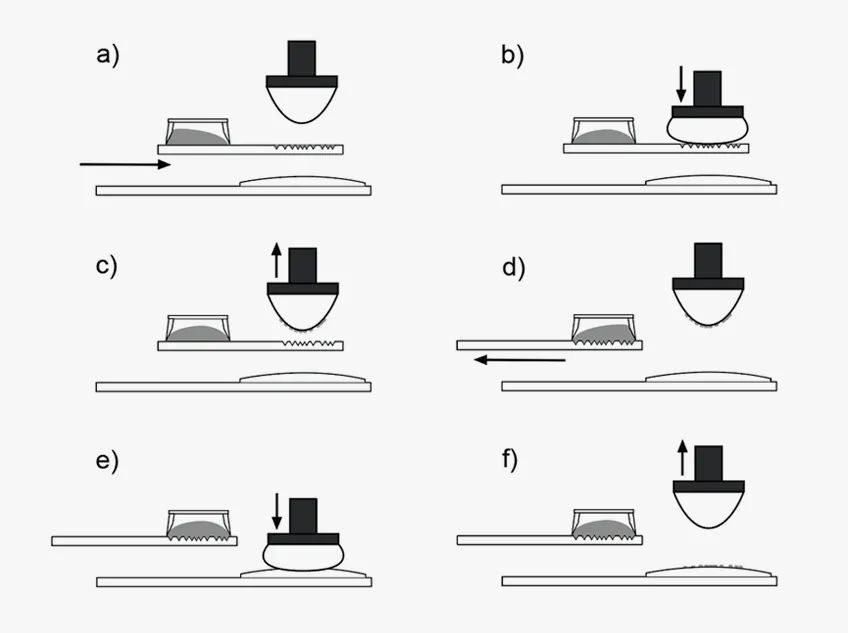

03. Padhi yekudhinda maitiro

——Pad Printing——

Kugona kudhinda mifananidzo, zvinyorwa uye magiraidhi pamusoro pezvinhu zvisina kuumbwa zvakanaka kuri kuita chinhu chakakosha pakudhinda kwakakosha.

Zvishandiso zvinoshanda:

Padhi kudhinda isarudzo inoshanda pane chero chinhu, kunze kwezvinhu zvakapfava sesilicone pads sePTFE.

Mari yekugadzira Mutengo wakaderera wekuumbwa uye mutengo wakaderera wevashandi.

Kukanganisa kwezvakatipoteredza: Sezvo maitiro aya achingowanikwa kumainki anonyungudika (ayo akasvibiswa nemakemikari anokuvadza) uye ane kukanganisa kwakakosha kwezvakatipoteredza.

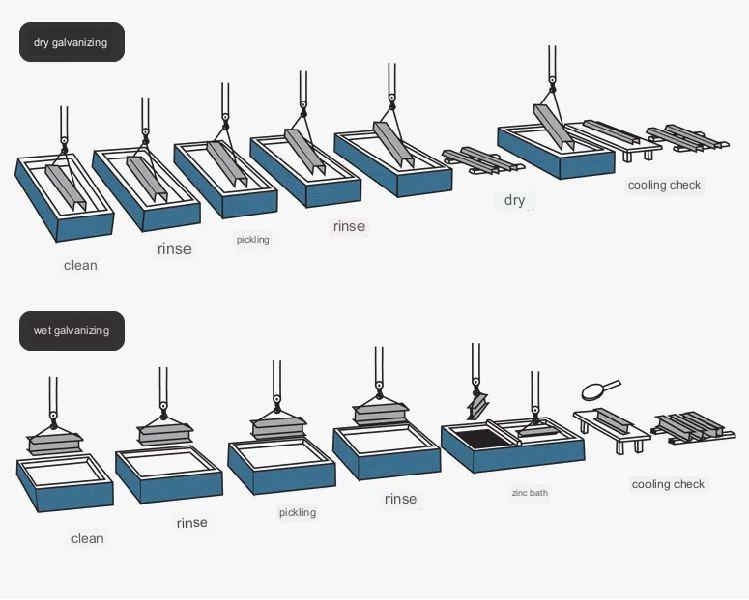

04. Galvanizing process

—— Galvanizing ——

Tekinoroji yekurapa nzvimbo inopfeka zingi yakaturikidzana pamusoro pealloys yakagadzirwa nesimbi yeaesthetics uye anti-rust mabhenefiti.Iyo zinc yakanamira pamusoro inoita seye electrochemical kudzivirira layer inodzivirira kukora kwesimbi.Nzira mbiri dzinonyanyo shandiswa dzinopisa-dip galvanizing uye Galvanized.

Zvishandiso zvinoshanda:

Nekuti galvanizing inotsamira pane metallurgical bonding iyi nzira yakakodzera kurapwa kwenzvimbo pasimbi nesimbi.

Mutengo wekuita: Hapana mold mutengo, pfupi kutenderera kana yepakati mutengo wekushanda, sezvo mhando yepasi pane workpiece inonyanya kutsanangurwa nepamusoro kurapwa kunoitwa nemaoko kusati kwaita galvanizing.

Kukanganisa kwezvakatipoteredza: Sezvo maitiro ekuvheneka achigona kuwedzera hupenyu hwezvikamu zvesimbi nepakati pemakore makumi mana kusvika zana uye zvakare kudzivirira kukora uye ngura zvinogona kuitika pazviri, maitiro anogona kuve nemhedzisiro pakuchengetedzwa kwenzvimbo.Uyezve iyo workpiece yakave yakabatiswa inogona kudzoserwa kutangi rezinc kana nguva yayo-yekushandisa yapera uye kugara uchishandisa zinc muchimiro chemvura hakukonzeri tsvina yemuviri kana kemikari.

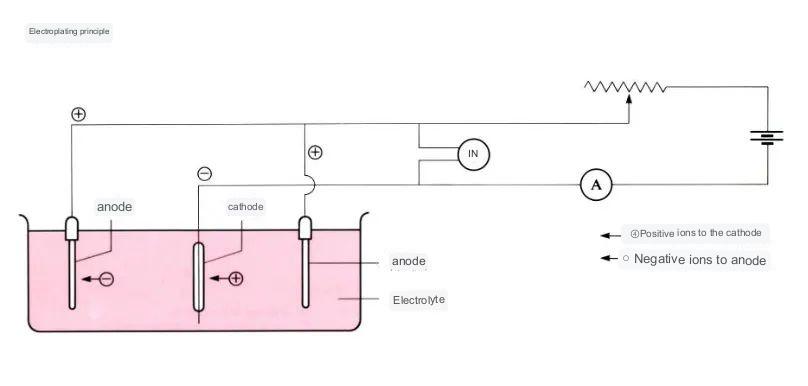

05. Electroplating process

—— Electroplating ——

Maitiro ekuisa chidimbu chesimbi firimu pamusoro pezvikamu kuburikidza ne electrolysis, kuitira kumisa simbi oxidation, kusimudzira kusakara kwekupfeka conductivity yechiedza chekuratidzira corrosion resistance, uye kugadzirisa chitarisiko.Iyo yekunze dhizaini yemari yakawanda inogona zvakare kuve electroplated..

Zvishandiso zvinoshanda:

1. Simbi zhinji dzakaiswa electroplated.Nekudaro, simbi dzakasiyana dzinouya neakasiyana mazinga ekuchena uye plating kushanda.Iyo inonyanya kufarirwa pane idzi ndeiyi inotevera: tin uye chromium, sirivheri, nickel, uye rhodium.

2. Nyaya inonyanya kufarirwa kuita electroplating ndeye ABS.ABS.

3. Nickel simbi haifanirwe kushandiswa kugadzira electroplate zvigadzirwa zvinosangana neganda nekuti zvinogumbura uye zvinokuvadza ganda.

Mutengo wekuita: Iko hakuna mari yekuumbwa, zvisinei zvigadziriso zvinodikanwa kuchengetedza zvikamu zvenguva mari zvinoenderana nekushisa uye rudzi rwesimbi kana mutengo webasa (yepakati-yakakwira) zvinoenderana nerudzi chairwo rwezvinhu zveplating, senge zvishongo uye. silverware, iyo inoda hunyanzvi hwepamusoro.Inotungamirirwa nevashandi vane unyanzvi hwepamusoro nekuda kwezvido zvepamusoro maererano nechitarisiko uye hupenyu hurefu.

Kukanganisa kwezvakatipoteredza kwe electroplating: Huwandu hukuru hwemakemikari ane muchetura anoshandiswa mukuita kwe electroplating ndosaka kutsauka kwehunyanzvi uye kubvisa kwakakosha kudzikisa kukanganisa kwezvakatipoteredza.

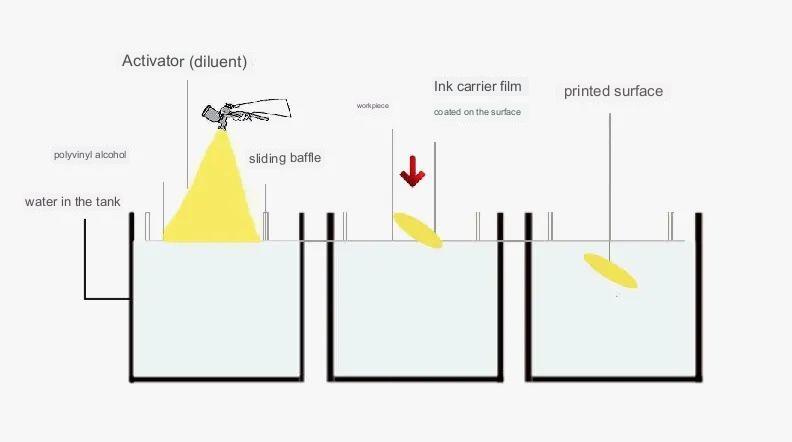

06. Kudhinda kwekutumira mvura

—— Hydro Transfer Printing ——

Inyanzvi yekudhinda peteni yeruvara pabepa rekutamisa pamusoro pechigadzirwa chemativi matatu uchishandisa mvura yekumanikidza.Sekuda kwevanhu kurongedza zvigadzirwa uye kushongedzwa kwenzvimbo, kushandiswa kwekudhinda-pane-kudiwa kuri kuramba kuchipararira.

Zvishandiso zvinoshanda:

Mhando dzose dzemhando dzakaoma dzakakodzerwa nekudhinda mvura yekufambisa uye zvinhu zvakakodzera kupfapfaidza zvinofanira kunge zvakakodzera kudhinda nemvura.Iyo inonyanya kufarirwa inhengo dzakaumbwa nemajekiseni pamwe chete nesimbi.

Mutengo wekuita: Hapana mutengo une chekuita ne mold, zvisinei zvigadzirwa zvakawanda zvinofanirwa kuendeswa kumvura panguva imwe chete nekushandisa zvigadziriso.mutengo wakazara hausi kudarika huwandu hwenguva pane kutenderera.

Kukanganisa kwezvakatipoteredza: Mukuenzanisa nekupfapfaidza pane zvigadzirwa kudhindisa kwemvura kudhinda kunoshanda zvizere kudhinda pendi izvo zvinoderedza mukana wekudonha uye tsvina.

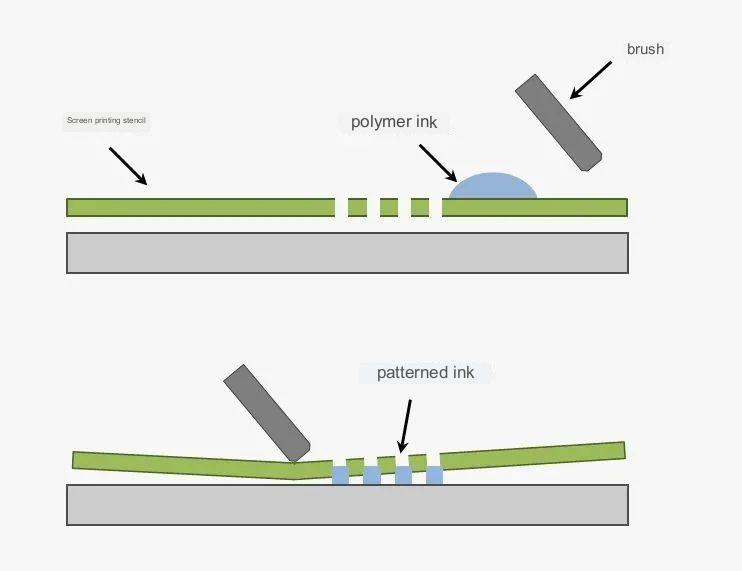

07. Screen kudhinda

—— Kudhinda Screen ——

Nekuwedzeredza kweiyo scraper, inki inotamirwa kumusoro kuburikidza nemambure ayo uye inoumba iwo chaiwo mufananidzo wakadhindwa pakutanga.Masikirini anodhinda ari nyore mushandisi-ane hushamwari, uye ari nyore kudhinda nekugadzira mahwendefa, ane mutengo wakaderera uye kuchinjika kwakanakisa.

Zvishandiso zvekudhinda zvinowanzo shandiswa zvinosanganisira mapepa ekupenda emafuta eruvara, makadhi ebhizinesi, zvivharo zvakasungwa, zviratidzo zvezvinhu, pamwe chete nemicheka yakadhayiwa uye yakadhindwa.

Zvishandiso zvinoshanda:

Zvinenge chero zvinhu zvinogona kudhindwa skrini, kusanganisira simbi, plastiki, mapepa ekeramics, girazi nezvimwe.

Mutengo wekuita Mutengo we mold ishoma, asi ichiri kuenderana nehuwandu hwemavara anoshandiswa, sezvo rumwe ruvara runofanira kugadzirwa pacharwo.Mari yebasa yakakwira zvakanyanya, kunyanya kana iri nyaya yekudhindwa kwemavara mazhinji.

Kukanganisa kwezvakatipoteredza: Kudhinda sikirini nemaingi ane ruvara rwakajeka hakuna kukanganisa nharaunda, zvisinei maingi anoumbwa nePVC uye formaldehyde ane chepfu chemakemikari makomisheni, uye anoda kudzokororwa oraswa panguva yakakodzera kumisa kusvibiswa kwemvura. .

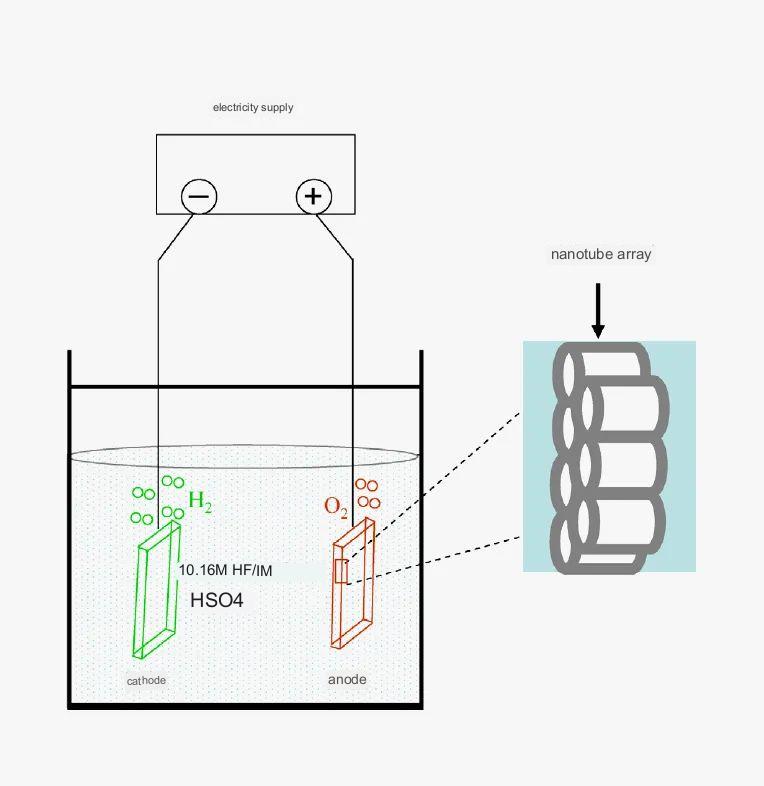

08. Anodizing

—— Anodic Oxidation ——

Iyo anodic oxidation process yealuminium inonyanya kuenderana neelectrochemical concept yekugadzira pasi peiyo yakatetepa layer inoumbwa neAl2O3 (aluminium oxide) firimu paaruminiyamu pamwe nearuminiyamu alloy.Iyo oxide ine zvinhu zvakasiyana sedziviriro kubva mukuora, kushongedzwa, insulation uye kuramba kupfeka.

Zvishandiso zvinoshanda:

Aluminium, aluminium alloy, uye zvimwe zvigadzirwa zvealuminium

Mari yekugadzira: Mukugadzira kushandiswa kwemagetsi nemvura kwakakura, kunyanya panguva yekugadzira oxidation.Simba rinoshandiswa nemuchina pachawo rinoda kugara richitonhodzwa nemvura inoyerera.Simba rinoshandiswa patani rinowanzoita 1000 madhigirii.

Kukanganisa kwezvakatipoteredza: Anodizing haina mutsauko maererano nekushanda kwesimba.Nekudaro, mukugadzira electrolysis yealuminium iyo anode reaction inogadzira magasi ane zvinokuvadza zvinokonzeresa pamhepo yeOzone layer.

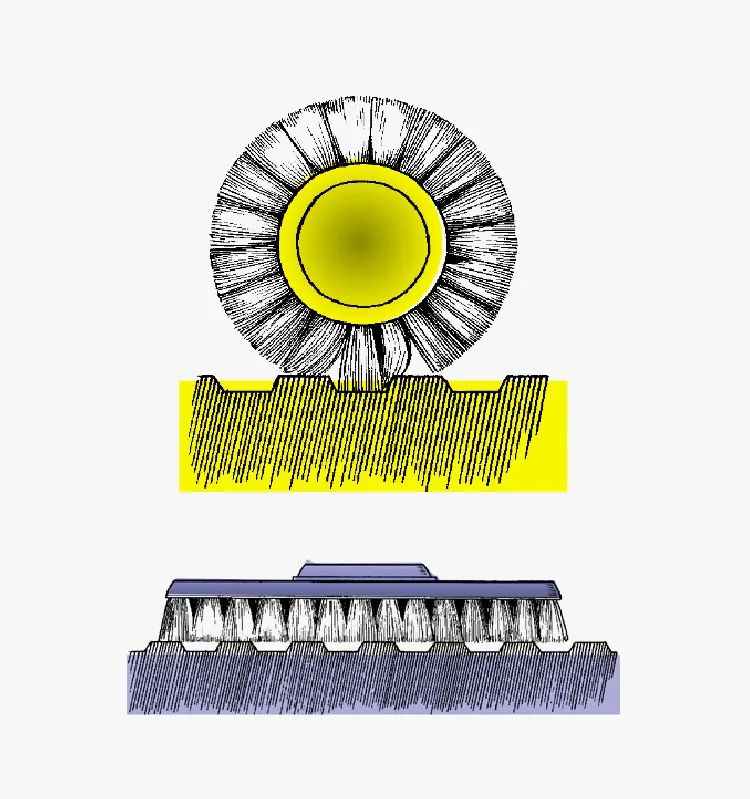

09. Metal wire drawing

—— Metal Wired ——

Iyo nzira yekurapa pamusoro inogadzira mitsetse pamusoro penzvimbo yebasa nekukuya chinhu kuti chiwane chinokwezva.Zvinoenderana neakasiyana zvimiro mushure mekuenzanisira kwetambo, inogona kupatsanurwa kuita: yakatwasuka tambo yekudhirowa, isina kurongeka tambo yekudhirowa, marata, pamwe nekutenderera.

Zvishandiso zvinoenderana: Zvinenge zvese zvigadzirwa zvesimbi zvinogona kushandisa simbi tambo yekudhirowa maitiro.

Mari yekugadzira: Maitiro ekuita ari nyore, michina yacho yakatwasuka, mashandisirwo emidziyo ishoma, mutengo wakadzikiswa zvakaringana, uyezve mukana wemari wakakwira.

Pesvedzero yezvakatipoteredza: zvigadzirwa zvesimbi zvakachena, hapana pendi kana chero rudzi rwemakemikari zvinhu pamusoro, 600 madhigirii yakakwirira tembiricha hainyunguduke, haiburitse magasi ane muchetura, inosangana nekuchengetedza moto pamwe nekuchengetedzwa kwezvakatipoteredza.

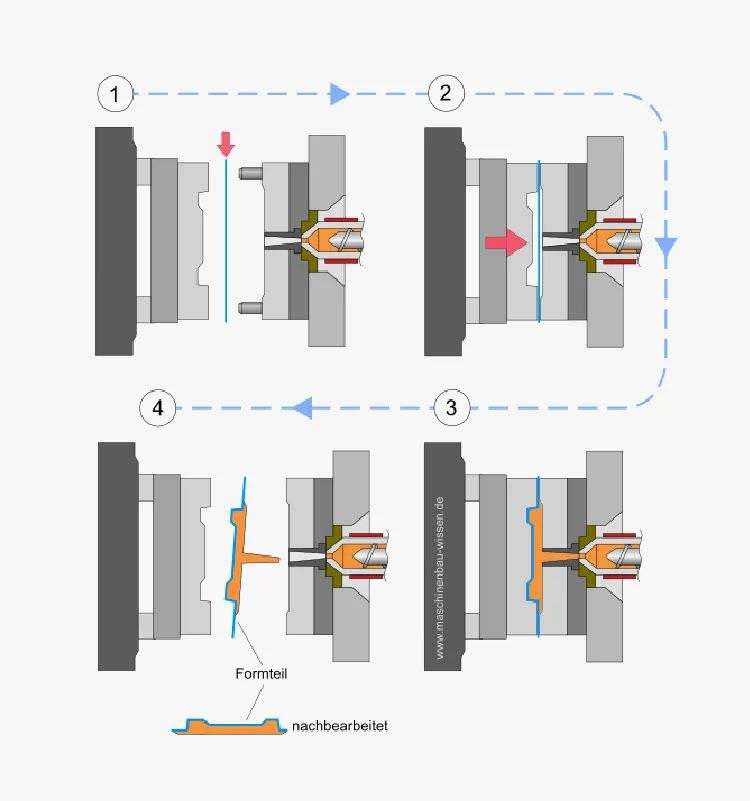

10. In-mold decoration

—— In-Mold Decoration-IMD ——

Iyo inyanzvi yekuumba iyo inoisa iyo pateni-yakadhindwa diaphragm mukati mesimbi mold uye mildew, inopinza resin yekuumbwa mukati mesimbi mold uye mildew pamwe nekujoinha diaphragm, uye inogadzira diaphragm yakadhindwa pateni pamwe neiyo. resin inosanganisirwa pamwe nekuomeswa kuita chigadzirwa chakapedzwa.

Chigadzirwa chakakodzera: nzvimbo yepurasitiki

Gadzirisa mutengo: zvinongoda kuvhura muunganidzwa we mold uye mildew, izvo zvinogona kuderedza mari uye zvakare maawa emunhu, yakakwirira-otomatiki kugadzira, yakapfava nzira yekugadzira, imwe-nguva jekiseni yekuumba nzira, pamwe nekuwana kuumbwa nekushongedza panzvimbo. nguva imwechete.

Kukanganisa kwezvakatipoteredza: Iyi tekinoroji yemazuva ano inoenderana nenharaunda uye ine hushamwari kwezvakatipoteredza, kudzivirira kusvibiswa kunokonzerwa neyakajairwa kupenda pamwe ne electroplating.

Zvakanakira zveAnebon machaji akadzikiswa, timu inotambira mari, nyanzvi QC, mafekitori akasimba, masevhisi emhando yepamusoro ecnc machining aluminium zvikamu zvekugadzira sevhisi uye cnc machining kushandura zvikamu zvekugadzira sevhisi.Anebon yakaisa chinangwa kuInoenderera mberi system innovation, manejimendi innovation, elite innovation uye chikamu hunyanzvi, kupa kutamba kwakazara kune zvakanakira zvakazara, uye kugara uchivandudza kutsigira zvakanakisa.

Anebon Chigadzirwa Chitsva China Lock-Hole Processing Machine uye Aluminium Window Lock Hole Processing Machine, Anebon ine yakakwana yekugadzira zvinhu mutsara, mutsara wekuunganidza, mhando yekudzora system, uye zvakanyanya kukosha, ikozvino Anebon ine akawanda patent tekinoroji uye ine ruzivo rwehunyanzvi & timu yekugadzira, ine ruzivo rwekutengesa sevhisi. team.Nezvakanakira vanhu vese, tanga tichigadzira "inozivikanwa pasi rose mhando yenylon monofilaments", uye tichiparadzira zvinhu zvedu kumakona ese epasi.Isu tanga tichifamba uye tinoedza nepatinogona napo kushandira vatengi veAnebon.

Nguva yekutumira: Jul-29-2023