Ulusiwo umagawidwa makamaka mu ulusi wolumikiza ndi ulusi wotumizira

Kwa ulusi wolumikizana waCNC Machining magawondiCNC Kutembenuza magawo, njira zazikulu zogwirira ntchito ndizo: kugwedeza, kupukuta, kutembenuza, kupukuta, kupukuta, ndi zina zotero.

Njira zosiyanasiyana zogwirira ntchito zikufotokozedwa pansipa:

1. Kudula ulusi

Nthawi zambiri amatanthauza njira yopangira ulusi pacnc kutembenuza magawondi zida zopangira kapena zida zopera, makamaka kuphatikiza kutembenuza, mphero, kugogoda, ulusi, kugaya, kugaya ndi kudula kamvuluvulu.Potembenuza, mphero ndi ulusi wopera, chingwe chotumizira chida cha makina chimatsimikizira kuti chida chotembenuza, chodulira mphero kapena gudumu lopukuta chimasuntha chitsogozo molondola komanso molingana ndi axis ya workpiece nthawi iliyonse pamene workpiece imazungulira.Pogogoda kapena ulusi, chida (pampopi kapena kufa) ndi workpiece kupanga wachibale kasinthasintha kayendedwe, ndipo woyamba anapanga ulusi poyambira amatsogolera chida (kapena workpiece) kusuntha axially.

Kutembenuza ulusi pa lathe kutha kugwiritsa ntchito chida chosinthira mawonekedwe kapena chipeso cha ulusi (onani zida zopangira ulusi).Kutembenuza ulusi ndi kupanga zida zotembenuza ndi njira yodziwika yopangira chidutswa chimodzi komanso chochepa chamagulu ang'onoang'ono opangira ulusi chifukwa cha zida zosavuta;kutembenuza ulusi ndi ocheka ulusi kumakhala ndi mphamvu zambiri zopanga, koma mawonekedwe a chida ndi ovuta ndipo ndi oyenerera kutembenuza pakatikati ndi kupanga zazikulu Zogwiritsira ntchito zazifupi zokhala ndi phula labwino.Kulondola kwa phula kwa ulusi wa trapezoidal kutembenukira pa lathes wamba kumangofikira magiredi 8 mpaka 9 (JB2886-81, chimodzimodzi pansipa);kukonza ulusi pazingwe zapadera za ulusi kumatha kupititsa patsogolo zokolola kapena kulondola.

2. Kupera ulusi

Kugaya kumachitika pamakina ophera ulusi ndi chodulira ma disc kapena chodulira zisa.Odulira ma disc mphero amagwiritsidwa ntchito makamaka pogaya ulusi wakunja wa trapezoidal pazinthu zogwirira ntchito monga zomata ndi nyongolotsi.Chodula chofanana ndi chisa chimagwiritsidwa ntchito popera ulusi wamba wamkati ndi kunja ndi ulusi wamba.Popeza amagayidwa ndi chodula chamitundu yambiri, kutalika kwa gawo lake logwirira ntchito ndi lalikulu kuposa kutalika kwa ulusi wokonzedwa, kotero chogwiriracho chimangofunika kutembenuza 1.25 mpaka 1.5 kutembenuka.Zokwanira, zokolola zambiri.Kulondola kwa phula kwa mphero ya ulusi nthawi zambiri kumatha kufika giredi 8-9, ndipo kuuma kwapamtunda ndi R 5-0.63 microns.Njirayi ndi yoyenera pakupanga ma batch a ulusi wopangidwa ndi ulusi wokhazikika kapena wowuma musanayambe kugaya.

3. Kupera ulusi

Amagwiritsidwa ntchito makamaka popanga ulusi wolondola kwambiri wa zida zowumitsidwa pa zopukusira ulusi.Malingana ndi mawonekedwe a gudumu lopera, amatha kugawidwa m'mitundu iwiri: gudumu lopera la mzere umodzi ndi gudumu lopukuta la mizere yambiri.Kulondola kwa phula la gudumu lopukuta la mzere umodzi ndi magiredi 5-6, kuuma kwapamwamba ndi R 1.25-0.08 microns, ndi kuvala kwa gudumu lopera ndikosavuta.Njirayi ndiyoyenerakugaya mwatsatanetsatane zomangira kutsogolo, zoyezera ulusi, nyongolotsi, timagulu ting'onoting'ono tazidutswa tating'onoting'ono ndi zibowo zopukutira bwino.Mipikisano mizere akupera gudumu akupera agawidwa mitundu iwiri: longitudinal akupera njira ndi agwere akupera njira.M’njira yopera motalika, m’lifupi mwa gudumu lopera ndi locheperapo kuposa kutalika kwa ulusi woti ausinthidwe, ndipo ulusiwo ukhoza kupedwa mpaka kufika kukula komalizira mwa kusuntha gudumu lopera motalika kamodzi kapena kangapo.M'njira yopumira, m'lifupi mwake gudumu lopera ndilokulirapo kuposa kutalika kwa ulusi woti utsike, ndipo gudumu lopera limadula pamwamba pa chogwirira ntchito mozungulira, ndipo chogwiriracho chimatha kugwedezeka pambuyo pa kuzungulira kwa 1.25.Zokolola ndizokwera, koma kulondola kumakhala kotsika pang'ono, ndipo kuvala kwa gudumu lopera kumakhala kovuta kwambiri.Njira yoperayo ndi yoyenera popopera mpumulo ndi magulu akuluakulu ndikupera ulusi wina kuti amange.

4. Kupera ulusi

Chopukusira ulusi wamtundu wa nati kapena phula amapangidwa ndi zinthu zofewa monga chitsulo chonyezimira, ndipo mbali za ulusi wokonzedwa zokhala ndi zolakwika za phula zimayikidwa kutsogolo ndikubwerera kumbuyo kuti mawu ake akhale olondola.Ulusi woumitsa wamkati nthawi zambiri umachotsedwanso pogaya kuti ukhale wolondola.

5. Kugogoda ndi ulusi

Kugogoda ndiko kugwiritsa ntchito torque inayake kukhomera mpopi mu dzenje lobowoledwa kale pachogwirira ntchito kuti mukonze ulusi wamkati.Kuwombera ndikugwiritsa ntchito ma dies kudula ulusi wakunja pa bar (kapena chitoliro) zogwirira ntchito.Kulondola kwa makina pogogoda kapena kulumikiza kumadalira kulondola kwa mpopi kapena kufa.Ngakhale pali njira zambiri zopangira ulusi wamkati ndi kunja, ulusi wamkati waung'ono ukhoza kukonzedwa ndi matepi.Kugogoda ndi ulusi kungathe kuchitidwa pamanja, kapena lathes, makina obowola, makina opopera ndi makina opangira ulusi.

Mfundo ya ulusi wokhotakhota kudula kuchuluka kwa kusankha

Popeza kuti phula (kapena kutsogolera) kwa ulusi kumatchulidwa ndi chitsanzo, chinsinsi chosankha kuchuluka kwa kudula potembenuza ulusi ndikuzindikira liwiro la spindle n ndi kudula kuya ap.

1. Kusankha liwiro la spindle

Malinga ndi makina omwe spindle imazungulira 1 revolution ndipo chida chimadyetsa 1 lead potembenuza ulusi, liwiro la chakudya cha CNC lathe potembenuza ulusi limatsimikiziridwa ndi liwiro losankhidwa.Ulusi wotsogola wolamulidwa mu block processing block (phokoso la ulusi ndi ulusi woyambira kamodzi), womwe ndi wofanana ndi kuchuluka kwa chakudya vf choimiridwa ndi kuchuluka kwa chakudya f (mm/r)

vf = nf (1)

Zitha kuwoneka kuchokera munjira yoti kuchuluka kwa chakudya vf kumayenderana ndi f.Ngati liwiro la spindle la chida cha makina lasankhidwa kwambiri, kuchuluka kwa chakudya chosinthidwa kuyenera kupitilira kuchuluka kwa chakudya cha makina.Chifukwa chake, posankha liwiro la ulusi wokhotakhota, kuyika magawo a dongosolo la chakudya ndi kasinthidwe kamagetsi ka chida cha makina kuyenera kuganiziridwa kuti tipewe zochitika za "mano osokonekera" a ulusi kapena phula pafupi ndi poyambira / kumapeto. osakwaniritsa zofunikira.

Kuphatikiza apo, ndikofunikira kudziwa kuti ulusi ukangoyambika, liwiro la spindle silingasinthidwe, ndipo liwiro la spindle kuphatikiza kumalizitsa makina liyenera kutsatira mtengo womwe wasankhidwa pa chakudya choyamba.Kupanda kutero, dongosolo la CNC lipangitsa ulusi kukhala "wosokoneza" chifukwa cha kuchuluka kwa "kuchuluka" kwa pulse encoder reference pulse sign.

2) Kusankhidwa kwa kuya kwa kudula

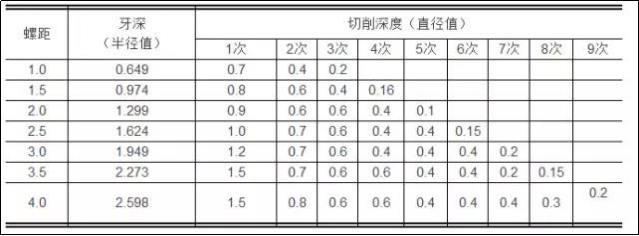

Popeza njira yokhotakhota ulusi ikupanga kutembenuka, mphamvu ya chida ndi yosauka, ndipo chakudya chodulira chimakhala chachikulu, ndipo mphamvu yodulira pachidayo ndi yayikulu.Chifukwa chake, kachulukidwe kakang'ono kazakudya kaŵirikaŵiri kumafunika, ndipo kuzama koyenera kumasankhidwa malinga ndi kucheperachepera.Table 1 imatchula za nthawi ya chakudya komanso kuya kwa kudula kwa ulusi wamba wa metric kuti awerengere owerenga.

Tebulo 1 Kudyetsa nthawi ndi kuya kwa kudula kwa ulusi wamba wa metric

Nthawi yotumiza: Dec-10-2022