Intambo yahlulwe kakhulu ibe yintambo yokudibanisa kunye nentambo yokuhambisa

Yemisonto yokudibanisa yeCNC Machining iinxalenyekwayeCNC Ukuguqula iinxalenye, iindlela eziphambili zokucwangcisa: ukucofa, ukuxubha, ukuguqula, ukugoba, ukugoqa, njl njl. Kwintambo yokuhambisa, iindlela eziphambili zokucubungula zi: ukuguquka kunye nokuguqulwa kakuhle-ukugaya, ukugaya i-whirlwind-rough and fine turning, njl.

Iindlela ezahlukeneyo zokusetyenzwa zichazwe ngezantsi:

1. Ukusika imisonto

Ngokubanzi ibhekisa kwindlela yokusetyenzwa kwemisonto kwicnc ukuguqula iindawongezixhobo zokwenza okanye izixhobo zokusila, ingakumbi ezibandakanya ukujika, ukungqusha, ukucofa, ukuthunga, ukugquma, ukugawula kunye nokusika isaqhwithi.Xa ujika, ukugaya kunye nokugaya imicu, ikhonkco lokuhambisa isixhobo somatshini liqinisekisa ukuba isixhobo sokuguqula, i-milling cutter okanye ivili lokugaya lihambisa isikhokelo ngokuchanekileyo kwaye ngokulinganayo kunye ne-axis ye-workpiece rhoqo xa i-workpiece ijikeleza.Xa ucofa okanye ukuthunga, isixhobo (itephu okanye ufe) kunye nesixhobo sokusebenza senza intshukumo ejikelezayo, kwaye i-groove yokuqala eyenziwe ngentambo ikhokela isixhobo (okanye i-workpiece) ukuhamba nge-axially.

Ukuguqula intambo kwi-lathe kunokusebenzisa isixhobo sokuguqula ifom okanye ikama yentambo (jonga izixhobo zokuthunga).Ukuguqula imicu kunye nokwenza izixhobo zokuguqula kuyindlela eqhelekileyo yecandelo elilodwa kunye ne-batch-batch encinci yemveliso ye-threaded workpieces ngenxa yesakhiwo sesixhobo esilula;ukuguqula imisonto kunye nabasiki bemisonto kunomgangatho ophezulu wemveliso, kodwa isakhiwo sesixhobo sinzima kwaye sifanelekile kuphela ukujika kwimveliso ephakathi kunye nenkulu imveliso emifutshane enemisonto enepitch entle.Ukuchaneka kwe-pitch yentambo ye-trapezoidal evula i-lathes eqhelekileyo inokufikelela kuphela kumabakala 8 ukuya kwi-9 (JB2886-81, efanayo ngezantsi);ukucutshungulwa kwemisonto kwiintambo ezikhethekileyo kunokuphucula kakhulu imveliso okanye ukuchaneka.

2. Ukugaya imisonto

Ukugaya kwenziwa kumatshini wokugaya intambo kunye ne-disc cutter okanye i-comb cutter.Izisiki zokusila iidiskhi zisetyenziswa ikakhulu kwimisonto yokusila yetrapezoidal yangaphandle kwizinto zokusebenza ezifana nezikrufu kunye neentshulube.Umsiki wokusila omile njengekama usetyenziselwa ukugaya imisonto eqhelekileyo yangaphakathi nangaphandle kunye nemisonto ye-taper.Ekubeni ixutywe nge-multi-edged milling cutter, ubude becandelo layo lokusebenza likhulu kunobude bomtya ogqityiweyo, ngoko ke i-workpiece ifuna kuphela ukujikeleza i-1.25 ukuya kwi-1.5 ijika kwi-process.Imveliso epheleleyo, ephezulu.Ukuchaneka kwepitch yokugaya intambo ngokubanzi kunokufikelela kwibanga lesi-8-9, kwaye uburhabaxa bomphezulu yi-R 5-0.63 microns.Le ndlela ifanelekile kwimveliso yebhetshi yee-workpieces ezinemisonto ngokuchaneka ngokubanzi okanye umatshini orhabaxa phambi kokugaya.

3. Ukusila imisonto

Isetyenziselwa ikakhulu ukwenza imisonto echanekileyo yezixhobo zokusebenza eziqinisiweyo kwiigridi zemisonto.Ngokwemilo yecandelo le-cross-section yevili lokusila, linokwahlulwa libe ziindidi ezimbini: ivili lokugaya umgca omnye kunye nevili lokugaya i-multi-line.Ukuchaneka kwe-pitch yevili lokugaya umgca owodwa ngamabakala angama-5-6, ubunzima bomhlaba yi-R 1.25-0.08 microns, kunye nokugqoka isondo lokugaya kukulungele ngakumbi.Le ndlela ifanelekileukucola izikhonkwane zelothe ezichanekileyo, iigeji zentambo, iintshulube, iibhetshi ezincinci zemisonto ephothiweyo kunye nokusila okuchanekileyo.Ukugaya ivili lokusila ngemigca emininzi yohlulwe ibe ziindidi ezimbini: indlela yokugaya i-longitudinal kunye nendlela yokugaya.Kwindlela yokugaya i-longitudinal, ububanzi bevili lokusila buncinane kunobude bomsonto oza kucolwa, kwaye umsonto unokucolwa ukuya kutsho kumlinganiselo wokugqibela ngokuhambisa ivili lokusila ngobude kanye okanye izihlandlo eziliqela.Kwindlela yokugaya i-plunge, ububanzi bevili lokusila bukhulu kunobude bomsonto oza kuculwa, kwaye ivili lokusila lisike kumphezulu we-workpiece radially, kwaye i-workpiece inokucolwa emva kokujikeleza malunga ne-1.25.Imveliso iphezulu, kodwa ukuchaneka kuncinci, kwaye ukugqoka kwevili lokugaya kunzima ngakumbi.Indlela yokugaya i-plunge ilungele iitephu zokusila ngeebhetshi ezinkulu kunye nokusila imisonto ethile ukuze kuqiniswe.

4. Ukusila imisonto

I-nut-type okanye i-screw-type thread grinder yenziwe ngezinto ezithambileyo ezifana nentsimbi etyhidiweyo, kwaye iindawo zemisonto ezicutshungulweyo ezineempazamo ze-pitch zigutyungelwa phambili kunye nezalathiso ezibuyela umva ukuphucula ukuchaneka kwe-pitch.Intambo yangaphakathi eqinile idla ngokuchithwa ngokusila ukuphucula ukuchaneka.

5. Ukucofa kunye nokuthunga

Ukucofa kukusebenzisa itorque ethile ukujija impompo kumngxuma osezantsi ogrunjiweyo ngaphambili kwisixhobo sokusebenza ukuqhubekekisa umsonto wangaphakathi.I-threading kukusetyenziswa kweedies ukusika imisonto yangaphandle kwibar (okanye umbhobho) workpieces.Ukuchaneka komatshini wokucofa okanye ukuthunga kuxhomekeke ekuchanekeni kompompo okanye kufa.Nangona kukho iindlela ezininzi zokucutshungulwa kwangaphakathi nangaphandle, iintambo zangaphakathi ezinobubanzi obuncinci zinokucutshungulwa kuphela ngeetephu.Ukucofa kunye nokudibanisa kunokwenziwa ngesandla, okanye iileyile, oomatshini bokwemba, oomatshini bokucofa kunye noomatshini bokuthunga.

Umgaqo wokuguqula intambo yokusika ubuninzi bokukhetha

Ekubeni i-pitch (okanye i-lead) yentambo ichazwe yipatheni, isitshixo ekukhetheni isixa sokusika xa ujika intambo kukugqiba isantya sokusonta kunye nobunzulu bokusika ap.

1. Ukukhethwa kwesantya sokusonta

Ngokwendlela yokuba i-spindle ijikelezisa i-1 revolution kunye nesixhobo sondla i-1 lead xa uguqula intambo, isantya sokutya kwe-CNC lathe xa uguqula intambo imiselwe ngesantya esikhethiweyo sokusonta.Intambo ekhokelayo eyalelwe kwibhloko yokusetyenzwa kwentambo (intambo yomgca ngumsonto omnye-wokuqala), elingana nomlinganiselo wesondlo vf omelwe yimali yokutya f (mm/r)

vf = nf (1)

Inokubonwa kwifomula ukuba isantya sesondlo vf silingana nesantya sesondlo f.Ukuba isantya sokusonta sesixhobo somatshini sikhethwe siphezulu kakhulu, isantya sokutya esiguquliweyo kufuneka sigqithise kakhulu isantya sokutya esilinganiselweyo sesixhobo somatshini.Ke ngoko, xa ukhetha isantya sokujikeleza sokuguqula umsonto, ukusetwa kweparameter yenkqubo yokutya kunye nohlengahlengiso lombane lwesixhobo somatshini kufuneka kuqwalaselwe ukuthintela into “yamazinyo asiphithiphithi” womsonto okanye i-pitch kufutshane nendawo yokuqala/yesiphelo. ukungazifezekisi iimfuno.

Ukongeza, kubalulekile ukuqaphela ukuba xa ukusetyenzwa komsonto kuqalisiwe, ixabiso lesantya sokusonta ngokubanzi alinakutshintshwa, kwaye isantya sokusonta esibandakanya ukugqiba umatshini kufuneka silandele ixabiso elikhethiweyo kwisondlo sokuqala.Ngaphandle koko, inkqubo ye-CNC iya kubangela ukuba intambo ibe "chaotic" ngenxa ye-"overshoot" yexabiso le-pulse encoder reference pulse signal.

2) Ukukhethwa kobunzulu bokusika

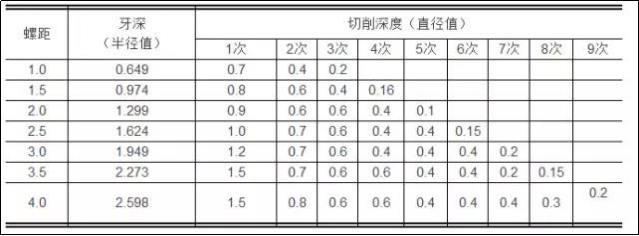

Ekubeni inkqubo yokuguqula intambo yenza ukujika, amandla esixhobo ahluphekile, kwaye ukutya okusika kukhulu, kwaye amandla okusika kwisixhobo nawo mkhulu.Ke ngoko, ukusetyenzwa komxhesho wokutya kuyafuneka ngokubanzi, kwaye ubunzulu bokusika obufanelekileyo bukhethwa ngokwendlela ehlayo.Itheyibhile yoku-1 idwelisa amaxabiso ereferensi yamaxesha okutya kunye nobunzulu bokusikwa kwi-metric thread yokusika ireferensi yabafundi.

Itheyibhile 1 Amaxesha okutya kunye nobunzulu bokusika ukusika i-metric thread eqhelekileyo

Ixesha lokuposa: Dec-10-2022